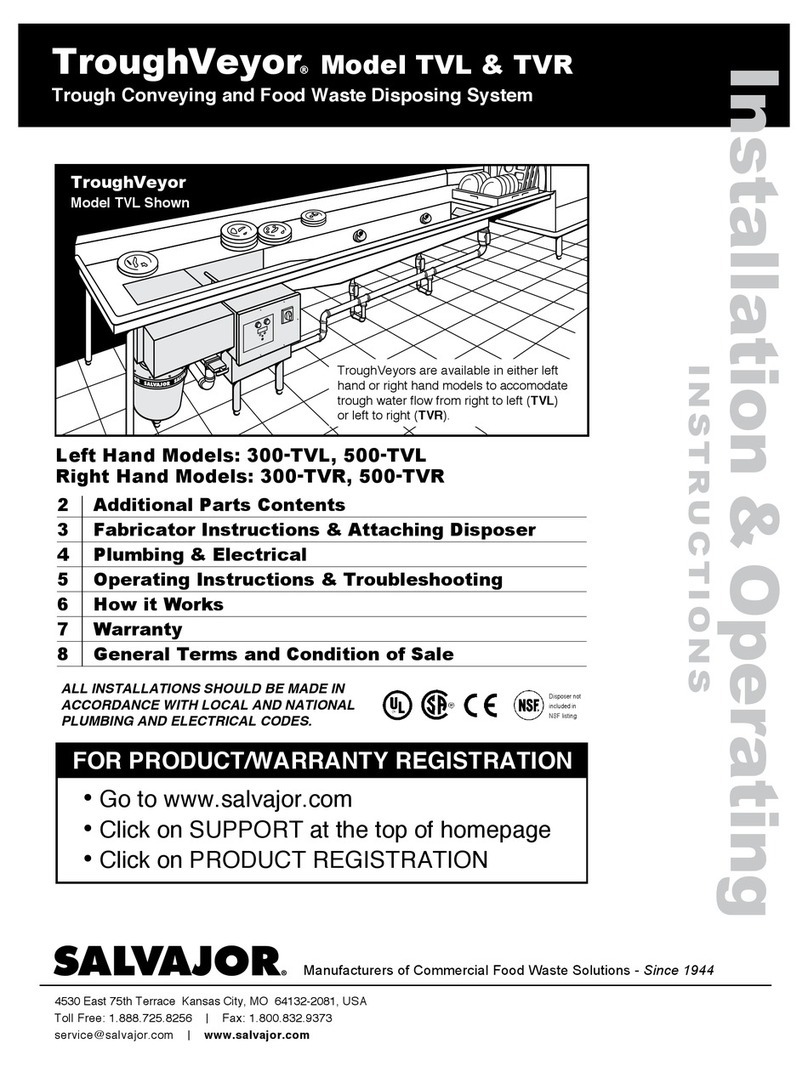

Disposer Disassembly

TOP HOUSING ASSEMBLY

#996045 CENTER GASKET

SHREDDER

#7814RN ROTOR NUT

#997092 LOCKWASHER

FACE PLATE

#996025 ROTOR SHAFT GASKET

#12151 0-RINGS

#123/222

O-RING

KLIXON

(Thermal

Overload)

KLIXON

COVER

GASKET

KLIXON

COVER

#987001

RETAINING

WASHER

#980132 ROTOR BASE

#993001 TOP END BELL

INSERT W/SEAL

#985001 TOP BEARING CUP/CONE

#ANL79X15S TOLERANCE RING

#S67350 BOTTOM VARILIP SEAL

MOTOR HOUSING

RUBBER DRAIN OUTLET

CLAMP

DRAIN INSERT

#11026 O-RING

#997070 KEY

MOTOR ROTOR

#996020 O-RING

BOTTOM END BELL

JUNCTION BOX COVER

#996023 RUBBER ISOLATOR

#6205 BOTTOM BEARING

#987002 DRIVE WASHER

#996024 FRICTION WASHER

#987003 WAVY WASHER

#997050 CASTLE NUT

#997051 COTTER PIN

Step 1

SHUT OFF POWER TO THE DISPOSER CONTROL

and remove disposer from service. Remove the top housing

by removing the eight top housing bolts. Remove the center

gasket located on the top of the cutters.

Note: For easier removal, the top housing can be

left attached to the sink, remove the eight bolts

so that only the disposer bottom comes off. This

eliminates the need to undo the plumbing to the

top housing.

Step 2 Turn the unit upside down so the junction box and

thermal overload covers are facing up and remove both of

these covers. Remove the black rubber gasket over the

thermal overload and pull the thermal overload out of its

seat by pulling on the red button. Remove the o-ring and

push the thermal overload back through the hole so that it is

inside the bottom of the unit.

Step 3 Turn the unit back over and now you are looking

at the cutters. The stationary cutter is the shredder and the

cutter in the middle that spins is the face plate. The piece

under the face plate is the rotor base. Remove the shredder

by inserting a screwdriver in between the face plate and the

shredder and pry it out. Remove the 1-1/4” rotor nut (1-10

hp)or the 3/8” rotor bolt (older style 1 hp). Lift face plate off

the motor shaft, remove the rotor shaft gasket and the rotor

base the same way as the face plate. Next remove the four

screws in the top end bell insert.

Note: Rotor base might come off attached to the

face plate, if so, separate these parts as the rotor

shaft gasket is located between these parts.

Step 4 Lay unit on its side, use a RUBBER mallet to strike

the large threaded end (7/8-14)of the motor shaft, driving it

out the bottom. The motor rotor will come out with the bot-

tom end bell assembly still attached.

Note: Verify that Step 2 is complete before com-

pleting Step 4 or the thermal overload wiring may

be damaged.

Step 5 Turn the motor housing upside down and remove the

top end bell insert by pushing it out from inside the motor bar-

rel. After the insert is out, the tolerance ring and o-rings will also

need to be removed if they did not come out with the insert.

Step 6 Using a long screwdriver, drive out the bottom seal

from the motor barrel side of the unit. It will come out similar

to the top end bell insert.

Step 7 Remove the cotter pin and 1/2” castle nut from the

bottom end bell assembly and remove the four washers. Use

a RUBBER mallet to separate the bottom end bell assem-

bly and the motor rotor. Once separated, remove the bottom

sealed bearing and the orange bottom end bell rubber isolator.

You are now ready to install the seal kit. Items in bold are included in kit.