Operator's manual

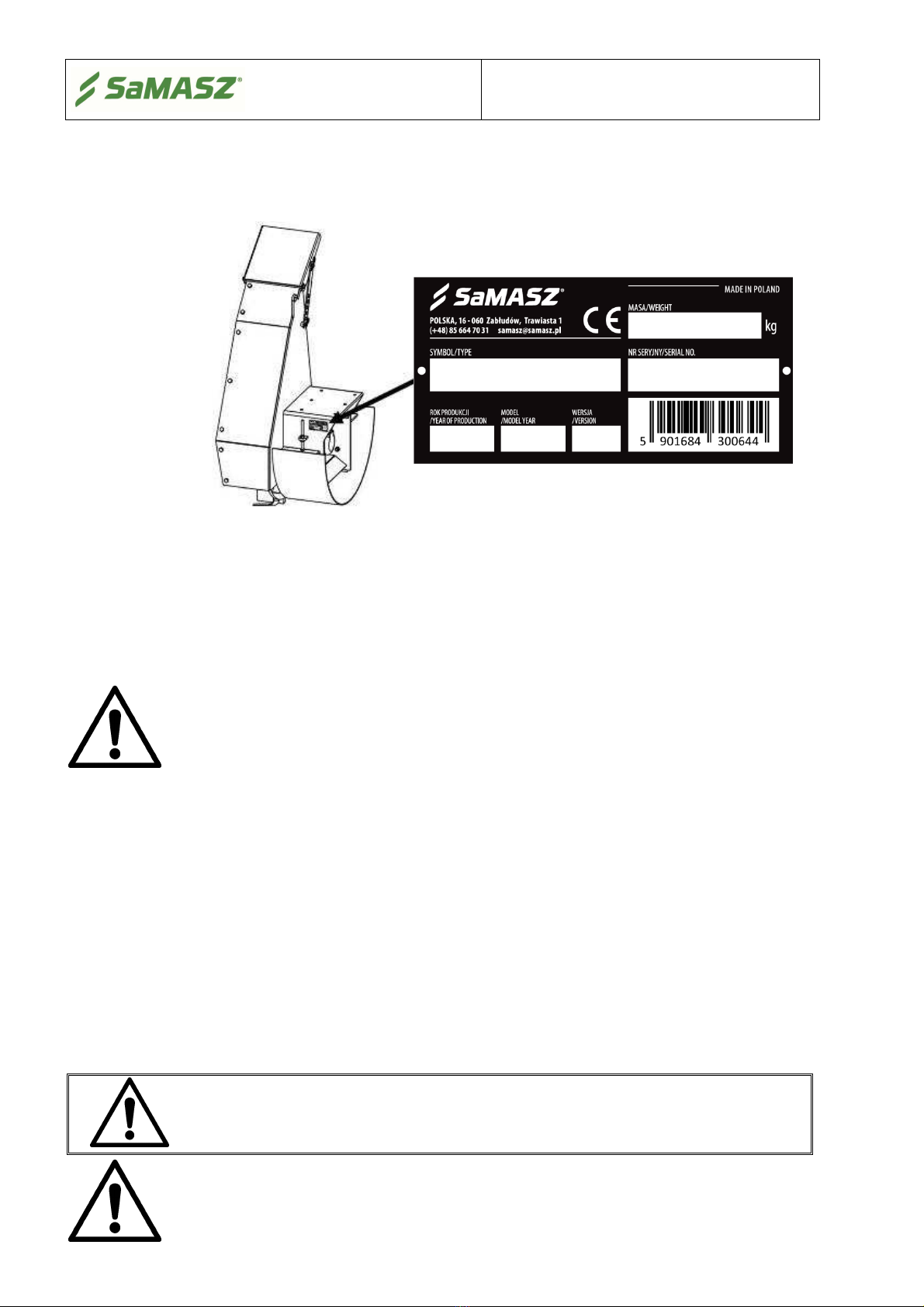

DITCH CLEANER

OR 080 (L)

- 6-

4.1.2 Mounting

Mount and dismount cleaner on extension arm with the latter mounted on a tractor, and when

the whole aggregation is arrested by the tractor’s engaged parking brake.

When connecting hydraulic hoses to ditch cleaner’s nozzles wear protective eyewear, protective

gloves and protective wear.

Mount and dismount ditch cleaner from extension arm on even and paved surface while keeping

particular attention.

Tractor's 3-point linkage should be adjusted with tensioning chains, so that stiff connection

between a tractor and extension arm, onto which ditch cleaner is mounted is provided.

Tractor with the mounted aggregation of extension arm and ditch cleaner should be balanced in

the manner, which allows stability of the whole aggregation of tractor and extension arm.

Mount ditch cleaner on extension arm only with use of genuine fittings and safety devices.

When connecting hydraulic hoses to tractor hydraulic connectors make sure, that both the

tractor’s and the arm’s hydraulics are pressure free.

Prior to connecting hydraulics reduce pressure in hoses.

4.1.3 Operation

When operating on public roads always respect the local traffic regulations.

Admissible slope, on which the machine is able to operate, is provided by the Manufacturer.

Angular value for safe operation on slope is 8º.

Unauthorized personnel and animals should be present in safe distance, which is at least 15 m

from the machine. Keep particular attention when operating near roads and lanes, where

presence of unauthorized personnel is likely.

When operating the aggregation, the tractor should always be equipped with operator's cabin.

Prior to operating, the machine should undergo a technical inspection paying particular attention

to condition of basic connections of machine’s assemblies as well as proper mounting of the

machine to a tractor.

Prior to commencing operation, condition of cutting knives along with cutting disk MUST be

examined, and if need be, handed for recovery or replaced with new ones.

Prior to starting tractor make sure that each drive is disconnected while control levers for

hydraulics are in neutral position.

Prior to moving make sure whether there are no unauthorized personnel directly nearby the

machine, give an acoustic signal.

The tractor’s engine must never be left running without supervision. Before leaving the tractor,

turn the engine off, set the aggregation of tractor and extension arm in standstill position and

take the ignition key out.

In the event of any break in the machine’s operation, the drive should be disconnected.

Road ditch cleaner should be operated at PTO shaft rpm value of 800÷1000 (applies to

SaMASZ extension arm).

Perform any ditch cleaner maneuvering only from the operator’s seat. DO NOT control from

outside the tractor’s cabin.

The operator is not allowed to leave the tractor while driving.

For any break in the machine operation, disconnect the drive.

Never leave the tractor’s engine running without any supervision. Before leaving the tractor,

turn the drive off, set the aggregation of tractor and extension arm and the ditch cleaner in a

standstill position and remove the ignition key.

Operating speed of the aggregation of extension arm and ditch cleaner should be adjusted to

operating conditions such as: density of cleaned material, depth of the cleaner’s immersion,

range of surface's unevenness.

DO NOT operate ditch cleaner after dusk.

DO NOT leave the aggregation on slopes without any additional protection.

DO NOT operate with damaged or missing guards.