www.larius.com

7

STAR 3001S GUN

ED. 15 - 02/2020 - Cod. 150099

L.c - Remove the locking ring ................................. p.27

L.d - Remove the needle......................................... p.28

L.e - Remove the needle support ............................ p.28

L.f - Remove the locking ring .................................. p.30

L.g - Remove the locking ring nut ........................... p.30

L.h - Remove the adjusting ring nut......................... p.31

L.i - Remove the low pressure air cap ..................... p.31

L.j - Remove the low pressure cone tip ................... p.32

L.k - Remove the mistless-airless cone tip .............. p.32

L.l - Remove the front head .................................... p.33

L.m - Remove the low pressure fan tip .................... p.33

L.n - Remove the mistless fan................................. p.34

L.o - Remove the airless fan tip............................... p.34

L.p - Verify the spring and the gasket ...................... p.35

ASSEMBLY AFTER CLEANING AND MAINTENANCE............

p.36

M.a - Insert the needle support ............................... p.36

M.b - Insert the needle ........................................... p.37

M.c - Insert the nozzle tip ....................................... p.38

M.d - Insert the gasket ........................................... p.38

M.e - Insert the fixing ring and the locking ring nut .. p.38

M.f - Insert the spring ............................................. p.39

M.g - Insert the front barrel ..................................... p.39

M.h - Insert the external ring nut ............................. p.39

M.i - Insert the product inlet hose ........................... p.40

M.k - Position the spring holder .............................. p.40

M.l - Insert the trigger............................................. p.41

M.m - Tighten the screws ....................................... p.41

M.n - Tighten the nozzle tip .................................... p.42

M.o - Insert the low pressure air cap ....................... p.42

M.p - M.u - Insert the ring nuts..............................p.43-44

BARREL FOR STAR 3001S SPRAY GUN ........... p.46

HANDGRIP FOR STAR 3001S SPRAY GUN

.............. p.48

CONE TIP NOZZLE RANGE FOR STAR 3001S GUN

. p.50

FAN TIP NOZZLE RANGE FOR STAR 3001S GUN

........ p.52

TROUBLESHOOTING.......................................... p.54

NOZZLES FOR STAR 3001S SPRAY GUN ......... p.56

NOZZLES KIT FOR STAR 3001S SPRAY GUN .. p.57

HOSES FOR STAR STAR 3001S SPRAY GUN.... p.57

WARNINGS .......................................................... p.8

TRANSPORT AND UNPACKING ......................... p.9

SAFETY RULES ................................................... p.9

CONDITIONS OF GUARANTEE .......................... p.10

STANDARD OUTFIT. ............................................ p.11

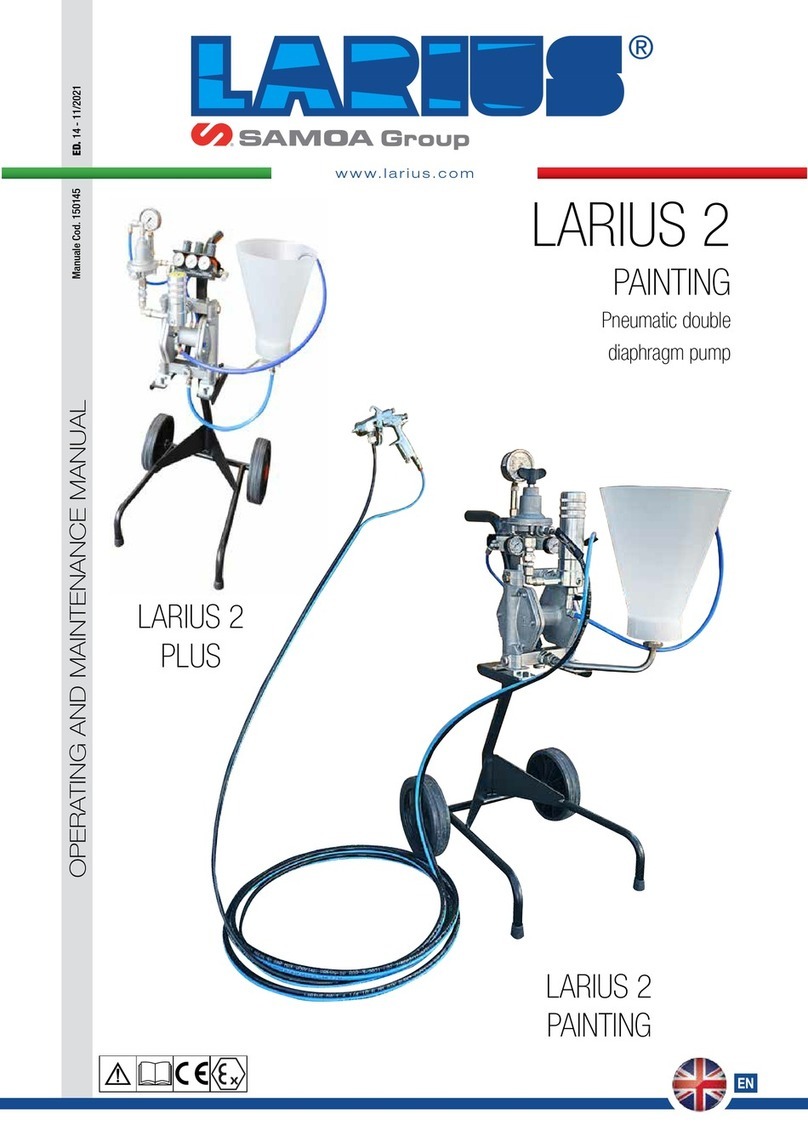

GENERAL DESCRIPTION.................................... p.12

E.a - Working principle ........................................... p.12

E.b - Features and advantages ............................... p.12

TECHNICAL DATA ............................................... p.13

F.b - Dimensions and overall manual gun ................ p.14

F.b - Dimensions and overall automatic gun ............ p.15

DESCRIPTION OF THE MANUAL GUN .............. p.16

DESCRIPTION OF THE ELECT. GENERATOR.... p.17

CONNECTIONS ................................................... p.18

I.a - Rules for an excellent electrostatic effect ......... p.18

I.b - Typical connections of the equipment .............. p.19

GROUNDING ....................................................... p.20

J.a - Grounding of the generator ............................. p.20

J.b - Grounding of the fluid ..................................... p.20

J.c - Grounding of operator’s glove ......................... p.20

J.d - Grounding of the target object ........................ p.21

SETTING UP ........................................................ p.22

K.a - Adjust the trigger ........................................... p.22

K.b - Adjust the handgrip........................................ p.22

K.c - Adjust the safety lock ..................................... p.22

K.d - Product resistivity test.................................... p.23

k.d1 - Low resistivity............................................... p.23

K.d2 - High resistivity ............................................. p.23

K.e - Adjust resistivity level..................................... p.23

K.f - Choose spraying method ................................ p.24

k.g - Choose fan nozzle orientation ......................... p.24

k.h - Adjust air atomization ..................................... p.24

k.i - Adjust fan pattern width................................... p.24

K.l - Store setting parameters ................................. p.25

K.l1 - Store the program ......................................... p.25

K.l2 - Recall stored programs ................................. p.25

DISASSEMBLY AND MAINTENANCE................. p.26

L.a - Remove the barrel .......................................... p.26

L.b - Remove the product inlet hose ....................... p.26

A

B

C

D

E

F

G

H

K

L

J

M

P

N

O

I

Q

R

S

T

U

STAR 3001S ELECTROSTATIC GUN