www.larius.com

8

GHIBLI 30:1/40:1

REV.. 01 - 03/2020 - Cod. 150088

F

G

The conditions of guarantee do not apply in the

following situations:

- improper washing and cleaning of components

causing malfunction, wear or damage to the

equipment or any of its parts;

- improper use of the equipment;

- use that does not conform with applicable

national legislation;

- incorrect or faulty installation;

-modifications,interventionsandmaintenancethat

have not been authorised by the manufacturer;

- use of non-original spare parts or parts that do

not correspond to the specific model;

- total or partial non-compliance with the

instructions provided.

CONDITIONS OF GUARANTEE

SAFETY RULES

ALL THOSE RISKS STEMMING FROM ACCIDENTS, ABOUT

THE USE OF SAFETY DEVICES FOR THEIR OWN SAFE-

TY AND ABOUT THE GENERAL RULES FOR ACCIDENT

PREVENTION IN COMPLIANCE WITH INTERNATIONAL

REGULATIONS AND WITH THE LAWS OF THE COUNTRY

WHERE THE PLANT IS USED.

COMPLY WITH THE ACCIDENT PREVENTION AND ALSO

ENVIRONMENTAL REGULATIONS IN FORCE IN THE

COUNTRY WHERE THE PLANT IS INSTALLED AND USED.

WHERE YOU ARE WORKING CREATES A POTENTIAL RISK

OF ACCIDENTS.

STANCE.

DAMAGED PARTS AND THE MACHINE CAN WORK PRO-

PERLY.

AND THE REGULATIONS IN FORCE.

EQUIPMENT OUT OF THE WORK AREA.

NEVER EXCEED THE MAXIMUM WORKING PRESSURE

INDICATED.

NEVER POINT THE SPRAY GUN AT YOURSELVES OR AT

OTHER PEOPLE. THE CONTACT WITH THE CASTING CAN

CAUSE SERIOUS INJURIES.

SEEK IMMEDIATE MEDICAL ADVICE SPECIFYING THE

TYPE OF THE PRODUCT INJECTED. NEVER UNDERVALUE

A WOUND CAUSED BY THE INJECTION OF A FLUID.

PRESSURE IN THE CIRCUIT BEFORE PERFORMING ANY

CHECK OR PART REPLACEMENT OF THE EQUIPMENT.

REGULARLY THE COMPONENTS OF THE SYSTEM.

REPLACE THE PARTS DAMAGED OR WORN.

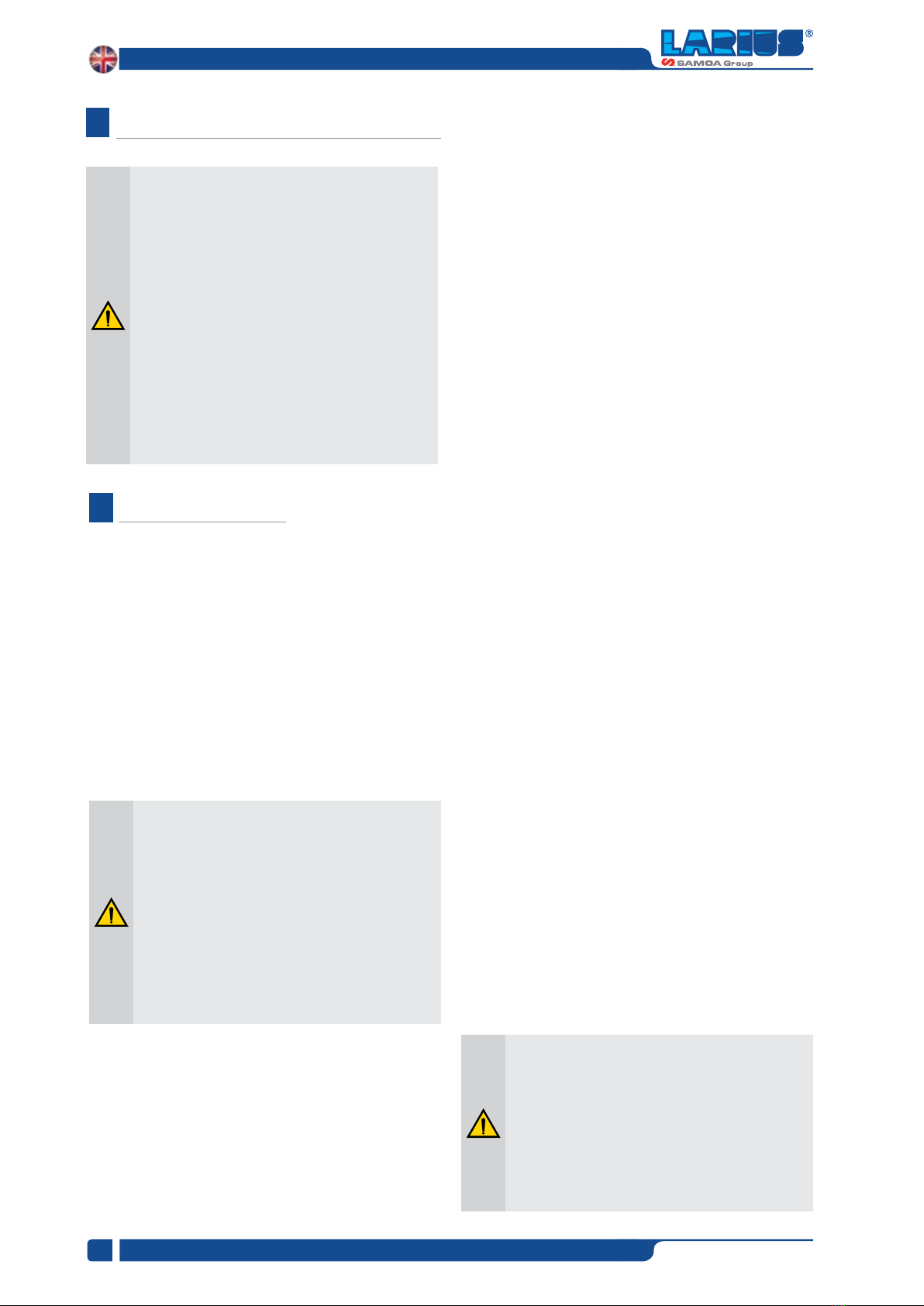

CONNEC-

TION BETWEEN PUMP, FLEXIBLE HOSE AND SPRAY GUN

BEFORE USING THE EQUIPMENT.

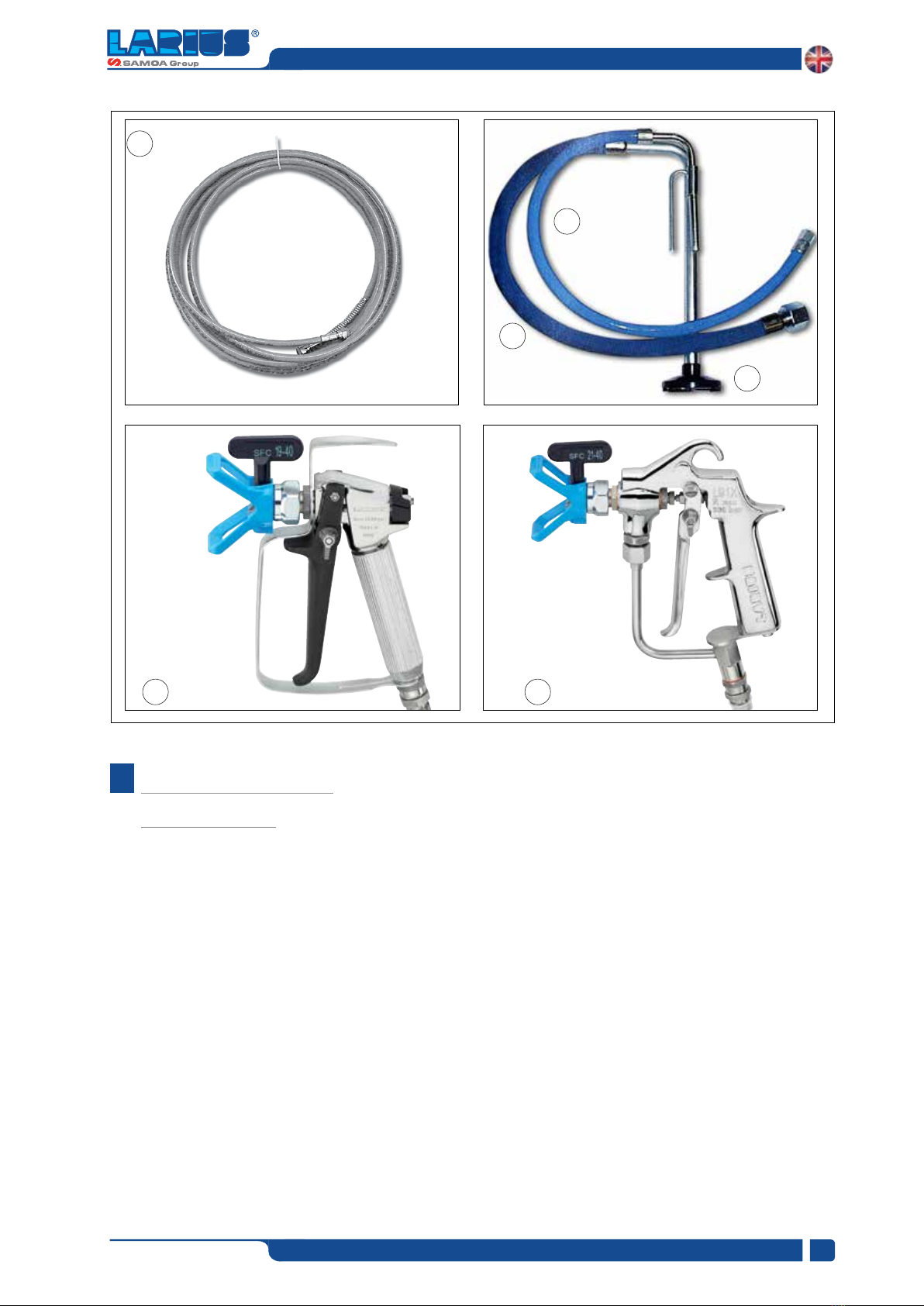

STANDARD KIT.

THAN THOSE RECOMMENDED IN THIS MANUAL, MAY

CAUSE DAMAGE OR INJURE THE OPERATOR.

VERY DANGEROUS. HANDLE THE FLEXIBLE HOSE CARE-

FULLY. DO NOT PULL THE FLEXIBLE HOSE TO MOVE THE

EQUIPMENT. NEVER USE A DAMAGED OR A REPAIRED

FLEXIBLE HOSE.

Readcarefullyand entirelythefollowing instructions

before using the product. Please save these

instructions in a safe place.

The unauthorised tampering/replacement of one

or more parts composing the machine, the use of

accessories,tools, expendablematerials otherthan

those recommended by the manufacturer can be a

danger of accident.

The manufacturer will be relieved from tort and

criminal liability.

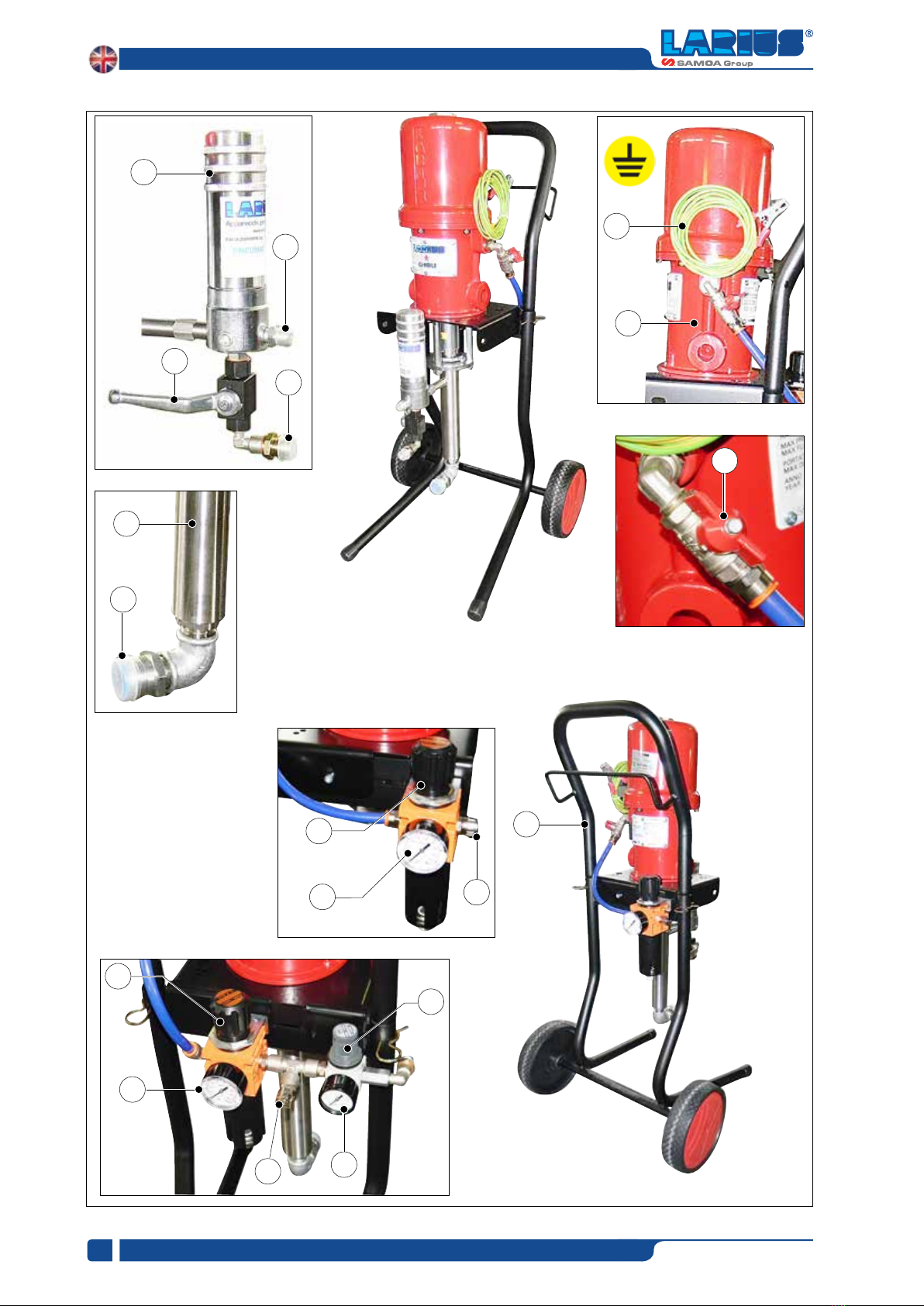

The high speed of travel of the product in the hose

can create static electricity through discharges

and sparks. It is suggested to earth the equipment.

The pump is earthed through the earth cable of

the supply.

The gun is earthed through the high pressure

flexible hose.

All the conductors near the work area must be

earthed.