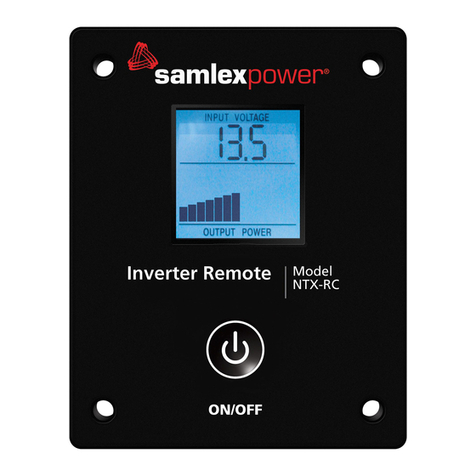

3.1 NAVIGATING THE REMOTE

The EVO-RC provides menu items and adjustable settings to congure your EVO™Inverter/Charger to your specic

parameters. Please refer to the layout at Fig 1.1.

•LCD Display (1) – The 2-line (16 characters each) LCD display with programmable backlight level shows status

and information for the EVO™Inverter/Charger. All Setup Menus and faults also appear on the LCD display.

The level of brightness / dimming of the LCD backlight can be programmed to suit user preference. (See Section

4.9 for details)

•ON/OFF Key (2) – The ON/OFF Key is used for switching ON/switching OFF the EVO™Inverter/Charger.

•Navigation Keys (5, 6, 7, 8) – These four Keys allow simple access to menu items that assists conguring,

monitoring, and troubleshooting the EVO™Inverter/Charger.

oNavigation Key Functions:

•Back – Return to previous selection

•Up – Scroll to higher Screen Nos. / Parameter Group Nos. in various Menu Maps

•Down – Scroll to lower Screen Nos. / Parameter Group Nos. in various Menu Maps

•Enter – Enter the selected option

• Status – Green LED indicator for indicating operating status (See details at Section 6, Table 6.1)

•Alarm (Fault) – Red LED indicator for indicating fault conditions (See details at Section 6, Table 6.1)

•SD Card socket – This slot supports SD memory card (up to 32GB; FAT 16/32). The SD Card is used for (i) Data

logging of EVO™Inverter/Charger's operational statistics and events and (ii) Saving and uploading of programmed

parameters (See Section 5: SD Card)

3.2 POWER ON / POWER OFF

INFO

a) Minimum battery voltage required for initiating manual switching ON of the unit is as follows:

•12V units ----- Higher than 9V

•24V units ---- Higher than 18V

b) Please note that this unit is designed to POWER ON AUTOMATICALLY if (i) AC voltage of 70V ± 5 VAC is

available at the AC Input Terminals and (ii) DC input voltage is > 12V for 12V versions of EVO™ and >24V

for 24V versions of EVO™. If the AC input voltage and frequency are within the programmed limits, the

unit will automatically operate in “Charging Mode”. If the AC input voltage and frequency are not within

the programmed limits, the unit will operate in “Inverting" Mode. Further, as long as AC input voltage >

70 ± 5 VAC is present, the unit CANNOT BE POWERED OFF using the ON / OFF Button on the front panel

of the unit or on the Remote Control EVO-RC. Switch OFF the AC input rst if the unit is required to be

powered off. However, if the unit is in “Fault Mode”, it will be possible to power OFF the unit with the

help of the ON/OFF Push Button on the front panel of the EVOTM unit (11, Fig 2.1 in the EVOTM Owner's

Manual) or, with the On/Off Key on the EVO-RC Remote Control (2, Fig 1.1)

c) Before proceeding, conrm that the unit is NOT in "Standby" Mode. If it is in "Standby Mode", the

"Status" LED (3, Fig 1.1) will ash once every 5 sec and the LED screen will display one of the "Standby

Mode" Screens show in Figs 3.2 (Column 2, GROUP 1). Press the On/Off Push Botton (2, Fig 1.1) on the

EVO-RC to exit the "Standby Mode" to the current operating mode. Refer to Section 3.4 for more details

on "Standby Mode".

SECTION 3 | Operation