Heterence

Information

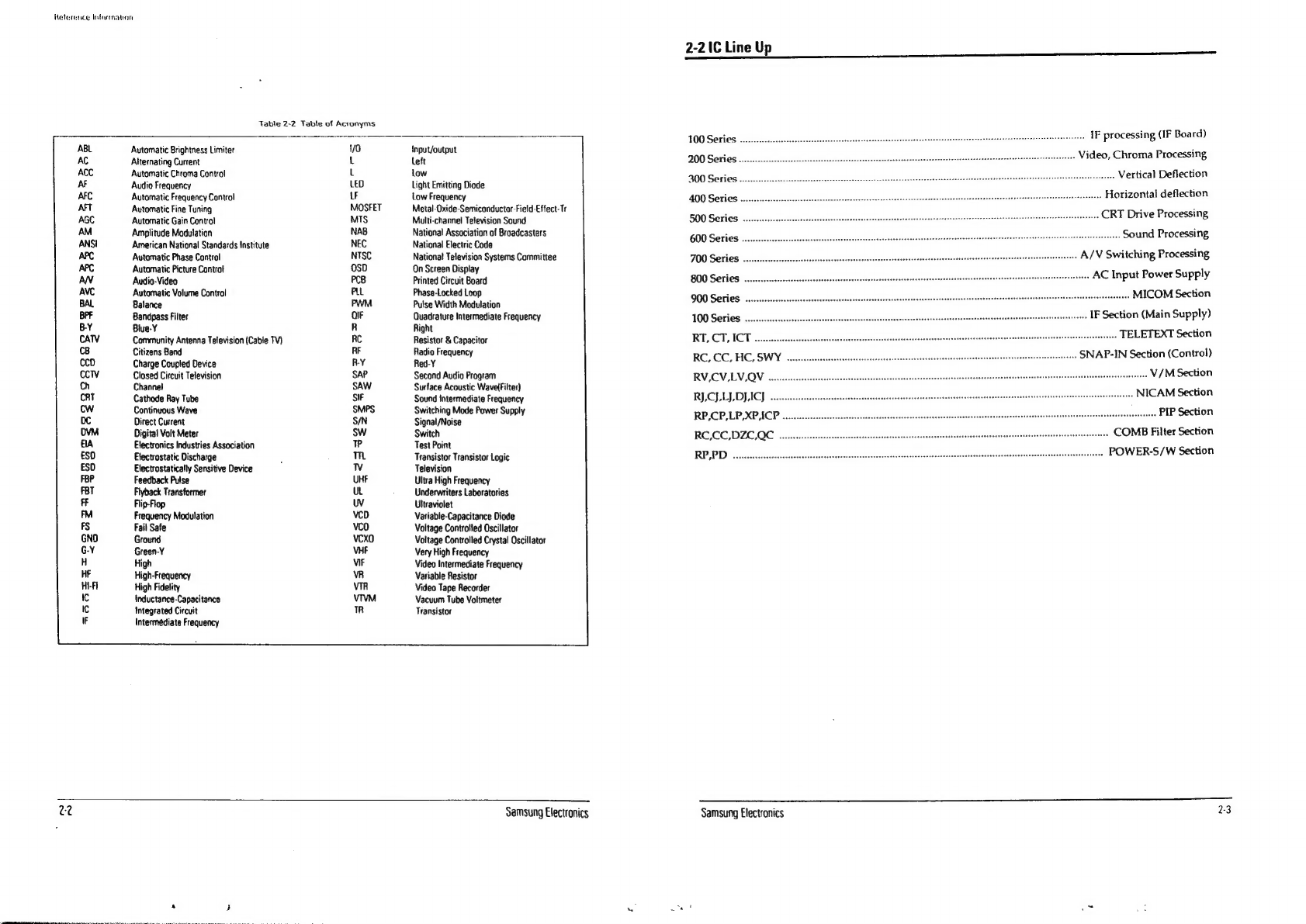

Table

2-2

Table

of

Acronyms

Automatic

Brightness

Limiter

70

Alternating

Current

L

Automatic

Chroma

Control

L

Audio

Frequency

LED

Automatic

Frequency

Control

LF

Automatic

Fine

Tuning

MOSFET

Automatic

Gain

Control

MIS

Amplitude

Modulation

NAB

American

National

Standards

Institute

NEC

Automatic

Phase

Control

NTSC

Automatic

Picture

Control

OsD

Audio-Video

PCB

Automatic

Volume

Control

PLL

Balance

PWM

Bandpass

Filter

OIF

Blue-Y

R

Community

Antenna

Television

(Cable

TV)

RC

Citizens

Band

RF

Charge

Coupted

Device

R-Y

Closed

Circuit

Television

Channet

Cathode

Ray

Tube

Continuous

Wave

Direct

Current

Digital

Volt

Meter

Electronics

Industries

Association

Etectrostatic

Discharge

Electrostatically

Sensitive

Device

Feedback

Pulse

Flyback

Transformer

Flip-Flop

Frequency

Modulation

Fail

Safe

Ground

Green-Y

High

High-Frequency

High

Fidelity

Inductance-Capacitance

Integrated

Circuit

Intermediate

Frequency

22

{input/output

left

Low

Light

Emitting

Diode

Low

Frequency

Metal-Oxide-Semiconductor-Field-Effect-Tr

Multi-channel

Tetevision

Sound

National

Association

of

Broadcasters

National

Electric

Code

Nationa!

Television

Systems

Committee

On

Screen

Display

Printed

Circuit

Board

Phase-Locked

Loop

Putse

Width

Modulation

Quadrature

Intermediate

Frequency

Right

Resistor

&

Capacitor

Radio

Frequency

Red-Y

Second

Audio

Program

Surface

Acoustic

Wavelfilter)

Sound

intermediate

Frequency

Switching

Mode

Power

Supply

Signal/Noise

Switch

Test

Point

Transistor Transistor

Logic

Television

Ultra

High

Frequency

Underwriters

Laboratories

Ultraviolet

Variable-Capacitance

Diode

Voltage

Controfied

Oscillator

Voltage

Controlled

Crystal

Oscillator

Very

High

Frequency

Video

Intermediate

Frequency

Variable

Resistor

Video

Tape

Recorder

Vacuum

Tube

Voltmeter

Transistor

Samsung

Electronics

2-2

1C

Line

Up

SS

JOO

Series

coecccecceccssescsscsecscseesesesecseecesecnsacenssesesesanseesessseeneneqecneterevsrsisenensrsstisesemeeretennrarearastes

IF

processing

(IF

Board)

200

Series

.....scccescscsssscsessssesessnssesesecerescsesseseeaesesssaesacseaeseesassecessasscescaeaveseeravennansacersessnsereeses

Video,

Chroma

Processing

BOO

Series

o.ccccecccseceessesesecsesesesscseseeseenescesceceueeeensaesieitenenersimsseaceecseanseesans

addarrseestetieeehie

ss

Vertical

Deflection

400

Series

oo.

cccecessecsssecsscesseesssececeveneescnsevesecseseanenssesnensacnnacsucssneensacanenanenncaaes

...

Horizontal

deflection

SOO

Series

ooececsssccesesseecsesesssessesseconseseneesesscensssesacssssnersanececnessersessesnesseesssesesseesstassnenavenaesctaneaeeess

CRT

Drive

Processing

600

Series

o..ceeccccsccsssesssessessecneestcnveneensssesstsaneseesessssaeanssesesonsevenaesneersaucaensaneancqneesanecnisancareeratesestecaeesstss

Sound

Processing

JOO

Series

..cscecssssesseessecseeeeeeesessrsneescsscsacsseesesseanensessenscssenssenssscaresnseacaneneenseneenecgtenagerensnents

A/V

Switching

Processing

BOO

Series

oovceeccescsesssssssccsecesecceeesuceneecsscsnsscsessesesecneesecsnessseussasecanecaesaveesecssessseasseneeanensenareastenes

AC

Input

Power

Supply

QOO

Series

coeccsssscsscsesseessecssessncesncsessescccssceveeneesessessessassnsssssnecsscssuecueesucsnrasecesosessasssnecananseeseennennesseeasennes

MICOM

Section

WOO

Series

...ceccsecccsssscseesssecsseesssessnscsssssssuessanecnssessessacesnsessesansecunessansessosessnnecsaseesnserensgnanstensy

IF

Section

(Main

Supply)

RT,

CT,

ICT

eessecsessssesssesescoucssssconesuceveeseesstssscasvecncsussnseneeaccnsecanecuseanecuessnesosesneanecanesssenecsanseaseaeeansnnees

TELETEXT

Section

RC,

CO,

HC,

SWY

cesesssssssscssessesceresseesessnssscesssvseseasensesaneenecanetaeccnceunssuecsscanssavanseenscoassens

SNAP-IN

Section

(Control)

RV,

CV,

LV

OV.

eecssesssesssscsnessecsssesneessccasssseenuessssuesscanscarsneessessneenscanecananussncsneasenssscavecnnensscevenveenseaenaarasnne

tine

V/M

Section

RY

CI

LJ

DY

ACI

oesseseessssessssssccsessesesnscsessssenesnsecssnsccsnscssnsesnasscsssusesssersenssceenncassncereeneetensansnrcssicasiansaseses

NICAM

Section

RP,CP,LP,XPACP

...ceessesssscseeecsessesessscuscsesssvcsscsecersceusencescssucsusenscanscascenensccassssensecsnecnscesesassensransnsenecnoganens

ness

PIP

Section

RCE,CO,DZC,QC

creeccsecssssssscsesnnessessnessesssensnsesesssecsscaneseensssnessncansssnsnsanvecersencenscanacanerncsaveqnesancnnets

COMB

Filter

Section

RP,PD

oocccsseccsssescsseessesensesesseccsscsscssssssssessssessvecsnecescceseeasesnanersnsssavonevecencesnensnasaressansennenonsetnrteaee

POWER-S/W

Section

i

Samsung

Electronics

2:3