D+H RZN 4304 User manual

99.820.55 1.6/05/05

D+H Mechatronic GmbH • Georg-Sasse-Str. 28-32 • D-22949 Ammersbek • Tel. +4940-60565219 • Fax +4940-60565264

Instruction for use

1234567

1234567

230VAC

power supply

drive group

2x group

3x group

optional

alarm

display

panel

detector

contacts

control

contact

of

external

system

2xgroup

vent

button

2 x lines

smoke or

thermal

detector

2 x lines

smoke vent

button

rain

detector

2 x lines

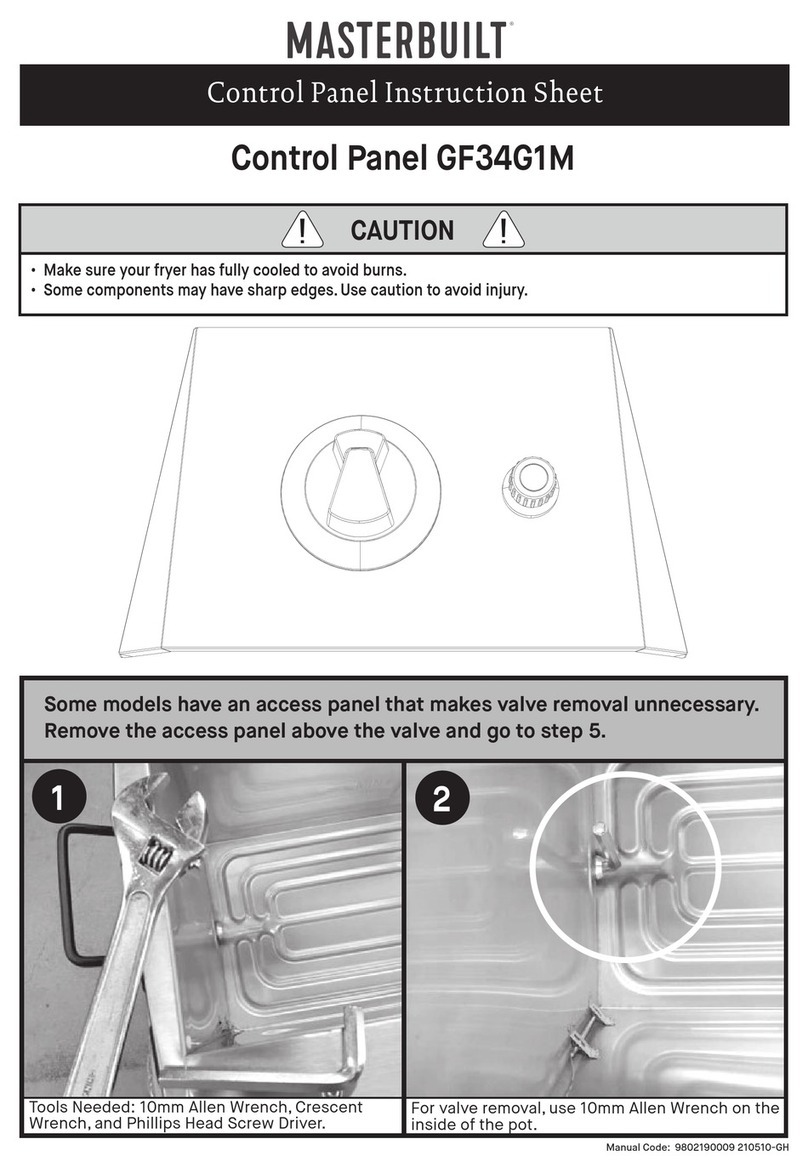

SmokeVent Control Panel RZN 4304/08-M

Installation

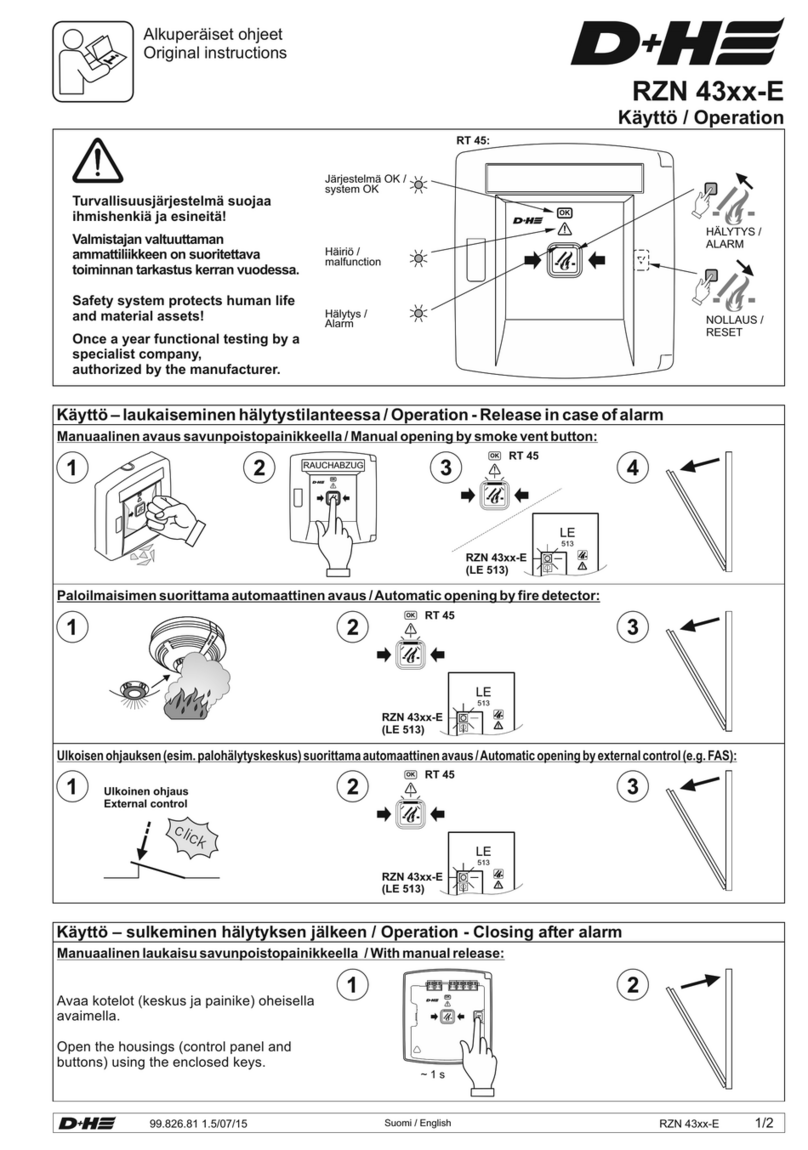

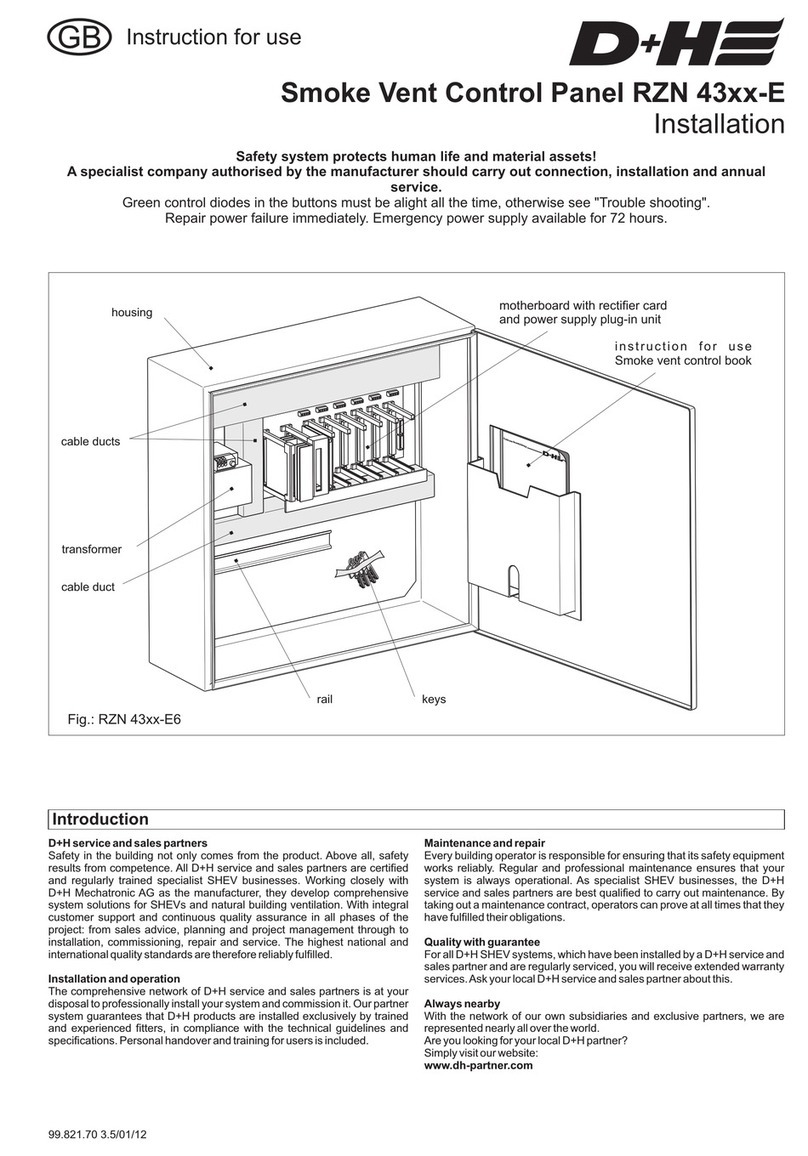

This system is designed to protect lives and safeguard valuable property!

Annual function check by manufacturer or duly authorized specialist.

Wiring, installation and functional testing only by qualified electrician.

The green pilot lights on the vent buttons must be lit up at all times,

otherwise refer to "Troubleshooting".

Rectify power failure without delay. Emergency power supplied for 72 hours.

Guarantee

You will get 2 years guarantee for all D+H products from date of verified handing over of the

system up to maximal 3 years after date of delivery, when mounting and starting has been

carried out by a D+H authorized distributor.

D+H guarantee is expired, with connection of D+H components with external systems or

with mixing of D+H products with parts of other manufacturers.

2/12 RZN430x-M Rev.:1.6

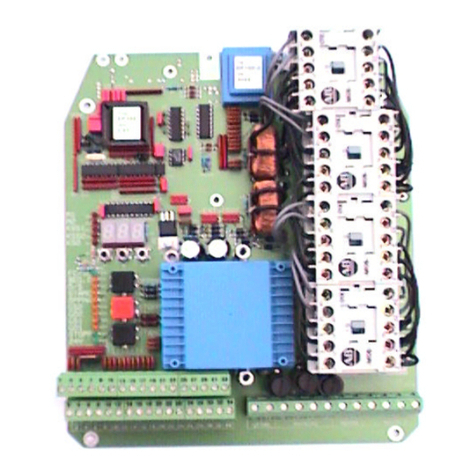

Mainboard - General View

FAULT GROUP 1

LED

DRIVES GROUP 1

fuse

Connection for

thirdgroup or

weatherplug-in

(optional)

Thermaltrip

FAULT GROUP 2

LED

DRIVES GROUP 2

fuse

DIP-switchblock S2

DIP-switchblock S1

ALARM LINIE 2

LED

FAULT LINIE 2

LED

FAULT LINIE 1

LED

ALARM LINIE 1

LED

ALARM - RESET

Line ON/ OFF

Resetdetectors

ALARM - RESET

Line ON/ OFF

Resetdetectors

Pilot light

EXT. DETECTION

fuse

POWER LED POWER fuse BATTERY fuse BATTERY connection

Charging voltage

controlfor BATTERY

BATTERY FAULT

LED

DIP DIP

3/12

RZN430x-M Rev.:1.6

230V power supply:

Separate, nondisconnectible circuit.

Mark fuses for ID.

Power cable NYM-I 3x1.5.

Connected load for

RZN 4304-M =120 VA,

for RZN 4308-M = 240 VA.

24V emergency power supply:

Use only VdS - approved batteries.

RZN 4304-M: 2 x 12 V / 1,9Ah

RZN 4308-M: 2 x 12 V / 6,5Ah

For connection with alarm - objects:

RZN 4304-M: 2 x 12 V / 6,5Ah

RZN 4308-M: 2 x 12 V / 6,5Ah

Attention! For RZN 4304-M in conjunction

with 7,0 Ah Batteries, always use the

housing of RZN 4308-M.

Low-voltage wiring:

Install and insert low-voltage wiring separa-

te from power-supply lines.

Mark wiring and terminal boxes red for

identification.

Control panel:

Mount in sheltered position suitable for

maintenance access in vicinity of drives.

Smoke-vent buttons:

Installations should be 150 cm above floor

level.

Fire detectors:

Max. area of surveillance for smoke- and

heat-vent system 400m².

Min. clearance from walls, beams, etc. 50cm.

Do not mount in airflow from ventilation

systems or domelights. Fire extinguishing

systems must not adversely affect the

detectors. In case of sprinkler systems,

please ask for information on special

interactive control! Area of surveillance in

conjunction with acoustic alarm as per BMA

regulations.

Drives:

All connected drives must not have more

than4 ampere altogether, whenusing control

panel type RZN 4304-M, and they must not

have more than 8 ampere altogether, when

using control panel type RZN 4308-M.

Direction of drive rotation:

Reverse poles if running in wrong direction.

Regulations:

The relevant regulations are VDE 0833

covering danger warning equipment, VDE

0100 for electrical systems, DIN 18232 for

smoke- and heat-extraction systems, local

fire-brigade regulations and the EVU for

connection to mains supply.

Pictograph explanation

Smoke / heat alarm

Fault

Control panel O.K.

Fuse

Power supply

Vent button "OPEN"

Vent or smoke/heat vent button "CLOSE"

Battery charging voltage control

Installation Information

4/12 RZN430x-M Rev.:1.6

Standard Connection with RT 42

11

5/12

RZN430x-M Rev.:1.6

* Terminal resistors for line monitoring:

Are connected to terminals in the control panel during transport. Remove and wire

according to diagram. In the absence of fire detectors or external control system, the

terminal resistors remain connected to terminal RM 1,2.

** Max. no. of drives:

RZN 4304-M = 4 drives,

RZN 4308-M = 8 drives, each connected with total of 1A to a control panel.

Twice as many drives when powered with 0.5A.

If alarm devices wired, 1A less!

*** Smoke-vent button RT 42

On smoke-vent buttons with a lower PCB serial no. than DH4642 (see rear of PCB):

Line connection to next smoke-vent button from terminal 2.

Terminal 7 is without significance.

**** Fire detectors

Only use detectors authorized for D+H systems.

Parallel Connection of Smoke Vent Buttons - RT 42

YR

5x 0,8

RT 42RT 42

10k *W

10kW

RT 42

RT 42

RM RT

Smoke-vent button

1stline

Smoke-vent button

2ndline

123456 7

line

line

line

line

line

–

–

–

–

–

+control

+control

+control

+control

+alarm

+alarm

+alarm

+alarm

closed

closed

closed

closed

7

7

72

2

23

3

3

1

1

1

6

6

6

4

4

4

YR

7x 0,8

OKOK

last smoke vent

button each

first to penultimate smoke

vent button each

* Shunt connection

by customer

6/12 RZN430x-M Rev.:1.6

External

excitation

Fire

detector Vent button Drives

Typ** LT 43 (-SD)

2 resistors 47k

or terminal module

W

branch

box

branch

box

operating contact

alarm resistor

10k *W

10k *W

10kW

47kW

47kW

1kW

out

out

in

in

closed

–N

open signal.

open

last

first or

panultimate

LT 43

thermal

detector THE4

ye

bk

bk

closed

open signal (optional)

open

monitored

Mot.a

Mot.b

L

L

P

P

bl

bu

br

bn

control

alarm

closed

general malfunction

Smoke vent button

RT 43-H

RT 43-N

10kW

alarm

control

-

line

line

malfunction

closed

27

83164

alarm

zu

red

green

yellow

malfunction

line

-

control

alarm

closed

23164

7

5

last

first or

panultimate

line

line

–

–

–N

56712341122

< optional >

RM RM RT LT MOT

34567

line

-

S

E1

Standard Connection with RT 43-H/-N

7/12

RZN430x-M Rev.:1.6

1234567

RZN 4304/ 08-M

line

line

–

–

control

alarm

close

RM/RT

Smoke vent button

1st lane

Smoke vent button

2nd lane

RT 43-H RT 43-H

RT 43-N

RT 43-N

10kW

10kW

alarm

alarm

control

control

-

-

line

line

line

line

malfunction

malfunction

close

close

22

77

8833116644

alarm

alarm

zu

zu

red

red

green

green

yellow

yellow

malfunction

malfunction

line

line

-

-

control

control

alarm

alarm

close

close

2233116644

77

55

*

last smoke

vent button

each

first to

penultimate

smoke vent

button each

*

Shunt

connection

by customer

S

general

malfunction

E1

Parallel Connection of

Smoke Vent Buttons - RT 43-H/-N

* Terminal resistors for line monitoring:

Are connected to terminals in the control panel during transport. Remove and wire

according to diagram. In the absence of fire detectors or external control system, the

terminal resistors remain connected to terminal RM 1,2.

** Fire detectors

Only use detectors authorized for D+H systems.

*** Max. no. of drives:

RZN 4304-M = 4 drives,

RZN 4308-M = 8 drives, each connected with total of 1A to a control panel.

Twice as many drives when powered with 0.5A.

If alarm devices wired, 1A less!

8/12 RZN430x-M Rev.:1.6

DIP switch 1 from S1 and S2 ON = At alarm on one line the other line will be switched

on automatically, that means all groups will open.

DIP switch 2 ON = In case of a line fault (e.g. break in button wiring or missing terminal

resistor), the control panel switches to alarm status, i.e. the smoke

vent opens.

DIP switch 3 ON = A smoke detector alarm cannot be reset by pressing the button in

the smoke/ heat vent button unit once.

If you require a remote reset facility for the smoke detector using the smoke/heat vent

button, DIP switches 3 must be OFF.

DIP switch 4 ON = The vent closes completely after the vent button has been pressed

once.

If DIP switch 4 is OFF, the vents will only close as long as the vent button is pressed.

After that it is no longer possible to close the vents using the smoke/ heat vent buttons

or weather control!

DIP switch 5 ON = The vent opens completely after the vent button has been pressed

once.

If DIPswitch 5 is OFF, the vents will only open as long.

Coding line and group

The following functions can be coded on the control panel using the DIP switches on the

mainboard.

DIP switchblock S1 codes Line 1 and Group 1

DIP switchblock S2 codes Line 2 and Group 2

9/12

RZN430x-M Rev.:1.6

Maintenance

Onceayearby a specialist company, whois

authorized by the appliance manufacturer.

Renew test badge, keep control book.

Respective current D+H maintenance

instruction is decisive.

D+H authorized expert companies are

specially trained by D+H for carrying out this

maintenance compentently, and therefore

they are automatically provided with relevant

maintenance instructions.

Following tests must be carried out with

maintenance:

- Outside examination/ inspection of system

components

- Measuring of insulation resistances

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation

according to directions

Every 6 months and after specialist or other

qualified personnel has taken the system

into operation.

Eliminate faults without fail. Keep a log book.

Inspection:

Check all devices and cable connections for

visible damage and dirt. Fire detectors, smo-

ke-vent buttons, smoke vents, etc. must not

be impeded in operation by storage goods

or reconstruction measures.

Function:

Continually activate a different smoke-vent

button (smoke detector) per line during each

new test.

Open the smoke-vent button. First all open

the system, then close it again.

Activate fire detectors with D+H smoke-

detector test unit or cigarette smoke. Re-

sponse time-lag approx. 20 sec. The red

LED must light up, and the smoke vent must

open.

Closing after automatic activation by smo-

ke detector:

Wait until the detector no longer contains any

smoke.

Use the button in the control panel to

switch the line on / off.

Press the concealed button marked in

the smoke vent unit. The smoke vent closes,

and the red LEDs in the button and in

the control panel extinguish.

When dip switch 3 is switched on OFF, the

flap can be closed directly by smoke vent

button as well. For this press masked key

in button.

Smoke vent closes, detectors will be reset.

If used, activate external control.

The smoke vent must open.

Closing after automatic activation by

external control:

Opening the contact in the external system,

e.g. by resetting the fire detection system.

Press the concealed button marked in

the smoke vent unit.

The smoke vent closes, and the red LEDs

in the button and in the control panel

extinguish.

Check alarm display and all drives for

smooth operation up to final opening/closing

position.

Emergency power supply:

Cut out the main fuse in the distribution

system. Repeat the function test. The green

pilot light in the smoke-vent buttons must

not light up.

The green LED Power in the control

panel must not light up.

Ventilation is disabled.

Check-Up

10/12 RZN430x-M Rev.:1.6

Troublesshooting

Should the smoke extraction system fail to operate satisfactorily or the green pilot light in

the button fail to light up, check the following points.

Causes

No 230 VAC power

supply.

Batteryfaulty.

Batterie O.K.

Fault in MOT group.

Fault in MOT group.

Fault in MOT group.

Group O.K.

Fault in smoke-vent

button line RT or in

smoke

detector line RM

Line O.K.

Remedy

Call duty electrician at once to

rectify cause of power failure.

Check battery, fuse and

connections.

Check fuse, connections,

cables, terminal resistors on

drives.

Check terminal resistor or

module between terminals 5

and 7.

Check terminal resistor or

module between terminals 5

and 6.

Check fuse, connections,

cables, terminal resistors,

terminals, smoke-vent buttons,

smoke detectors an external

control system.

Symptoms

Power

LED fails to light up.

Battery

LED lights up.

LED fails to light up.

Group 1 or 2

LED lights up.

Pilot light extinguishes

during closing operation; red

LED lights up; vent cannot

close.

Pilot light extinguishes

during closing operation after

approx. 20 sec.; red LED

lights up.

LED fails to light up.

Line 1 or 2

LED lights up.

LED fails to light up.

11/12

RZN430x-M Rev.:1.6

* Table applies to 1A drives. For 0,5A drives, twice the line length applies.

** 2 conductors per drive line wire -MOT- in parallel!

*** Applies only to drives with 1A motor current.

Use “160“ for drives with 0,5A motor current.

Detector Cables (Line):

The detector cables are monitored for short

circuit and for break.

The opening device is automatically

triggered and opens up in case of fault, when

DIP-switch 2 is on ON.

Smoke vent button cable and cable of

automatic detectors:

- weak current sheathed flexible cable YR

6 x 0.8

or

- house wiring cable IY(ST)Y 4 x 2 x 0.6

Cables through areas not monitored:

An increased time of functioning of the cable

can be required, when drive lines are

installed through building parts, which are

not monitored.

- Safety line with functional conservation

... E90, according to DIN 4102* or standard

guidelines for line systems MLAR.

(see supplementary sheet 1 to DIN VDE

0108)

* Notice: No type designation is given

for these cables, because of a large

variety on the market. Please consult

your D+H distributor about these.

The smoke vent control panel is designed

for opening smoke vent devices, which

operate by thermal ascending force and by

automatic fire recognition devices (thermal

detector, smoke detector), and they release

either self-acting or manual by smoke

detectors at an early stage of a fire, and

remain in opened position without further

power consumption. In these cases,

functioning preservation of the electrical line

system is required only at an early stage of

fire. Protected wiring is required with

protection against mechanical damages

according to DIN 18232 section 2.5.5

paragraph 4.

Control Cable (Group):

Cable from the smoke vent control panel to

connection of drive (drive lines have a

monitoring wire, in which fire recognition

devices (thermal maximal detector e.g. THE)

can be looped-in):

- Safety line, with functional conservation

... E30, according to DIN 4102* or standard

guidelines for line systems MLAR.

Cable for D+H Smoke and Heat Vent Systems

Line lengths and Cross sections:

Number of wires and cross-sections indicated, refer to required lines only. In case of

using a line with earthed conductor (green/ yellow), this one will not be counted in and

must not be wired.

12345678

Cable 4x 1,5mm² 100 50 30 25 20 16 14 12 m

Cable 4x 2,5mm² 200 100 75 50 40 32 28 25 m

Cable** 7x 2,5mm² 400 200 150 100 80 64 56 50 m

Actuators*

Single length of cable (m) x no. of actuators

80***

Cross-section

(mm²) =

Drives*

drives

12/12 RZN430x-M Rev.:1.6 All sizes in millimetre • Rights to technical modifications reserved. • Reprintingandphototechnical

reproduction also in extracts has to be expressively authorized by D+H Mechatronic GmbH.

Mounting Arrangements

Connection in case of line branch:

- supply wires

Mot. a and Mot. b branch in parallel

-Monitoring is looped through through all

the cables up to group end.

Example 1:

1 Lane

Simple wiring, however unfavourable for

voltage drop:

All drives on one line.

Example 2:

2 lanes

Control panel in the centre, one side wired as

branch, the other one as terminal line.

Remember 4 wires for branch!

Example 3:

2 lanes on one side

Branch and terminal line in same direction.

Numberofdrives varyaccordingto lengthsof

lines.

Remember 4 wires for branch!

Example 4:

3 lanes

Due to extremely long distances 3 lines are

provided:

2 lines with 3 drives each over 75 m line as

branch and 1 line with 2 drives over 200 m

line.

Remember 4 wires for branch!

This manual suits for next models

1

Table of contents

Other D+H Control Panel manuals

Popular Control Panel manuals by other brands

EDM

EDM Solution 4+4 installation manual

Elko

Elko iNELS EST-2 Series Manual instructions

DeDietrich

DeDietrich Diematic iSystem Installation, user and service manual

Alde

Alde 3010 413 Instructions for use and assembly

Geovent

Geovent MULTIBOX III instruction manual

Siemens

Siemens MJ-4A Installation and operation manual