Schlagsahne-Automaten

Operating instruction SANOMAT - technical changes are subject to modifications and amendments - liability- and

warranty claims due to improper use are basically excluded - The design of the machine and several parts may vary from

pictures - the function stays the same

4

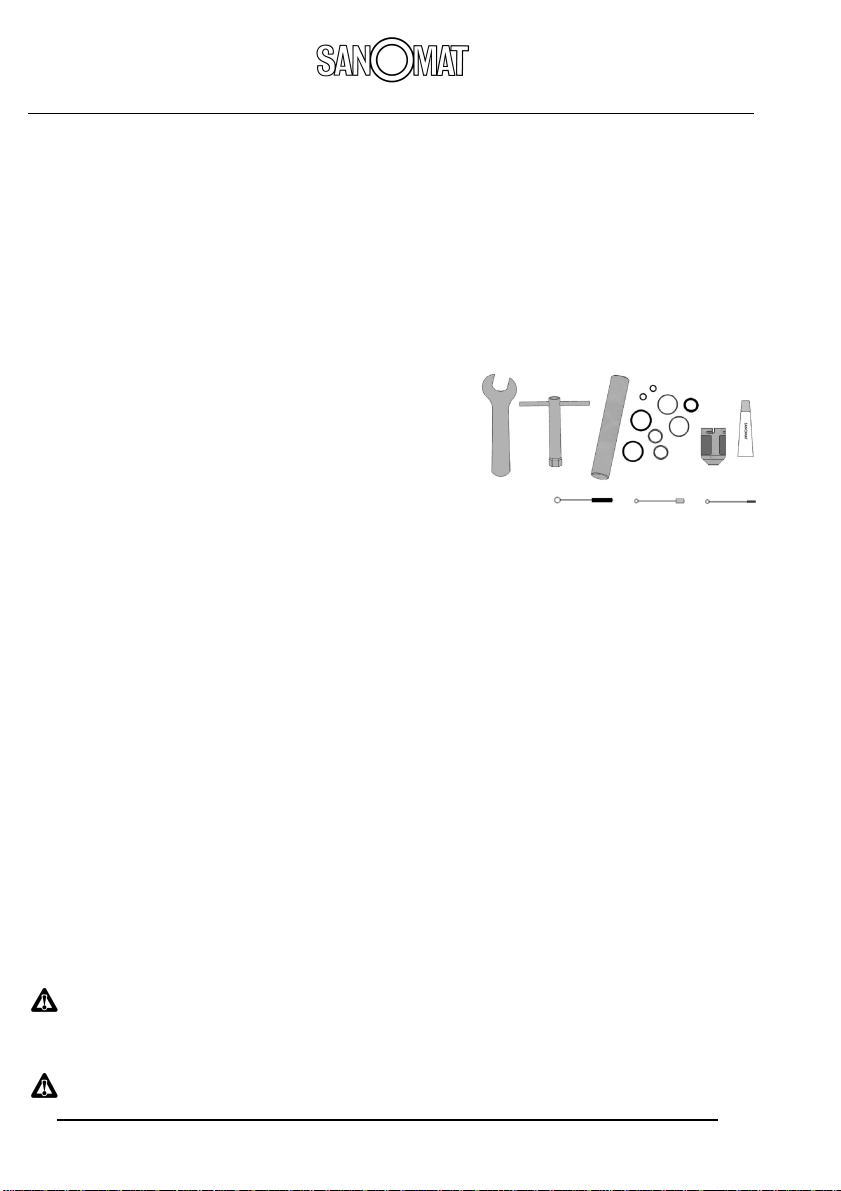

example for tool kit

Unpacking and checking

•Cut the straps with a pair of scissors and lift the carton straight-up.

•Carefully lift the SANOMAT out of the Styrofoam base and check the

SANOMAT for shipping damage. If applicable submit a claim to the transport

company.

•Check that you have received all of the following:

Operating instructions and shipping

documents

A small bottle of disinfection cleaner

SANO-DESINFEKT-Plus

Pouch with tools (per machine

different)(not supplied with every

machine)

cleaning bucket (only at machines

from 5 litre on/for the daily disinfection cleaning you may also use the

cream container)

Intended use of your SANOMAT

•The SANOMAT has to be operated at an environmental temperature up to

max. 40°C

•The SANOMAT is a technical means of work. Its bringing into circulation

serves exclusively for the use in commercial business.

•Do not run the SANOMAT in rooms with explosive atmosphere. The use of

the SANOMAT according to determination is restricted to persons older than

14 years.

Mostly annoying but always important: the safety regulations.

They ensure safety and ongoing satisfaction with your SANOMAT - so

please keep this in mind:

Do not shut SANOMAT off during the night!

This gives additional hygienic protection. Unit should only be turned off when

not in use for several days!

Do not use SANOMAT for other purposes!