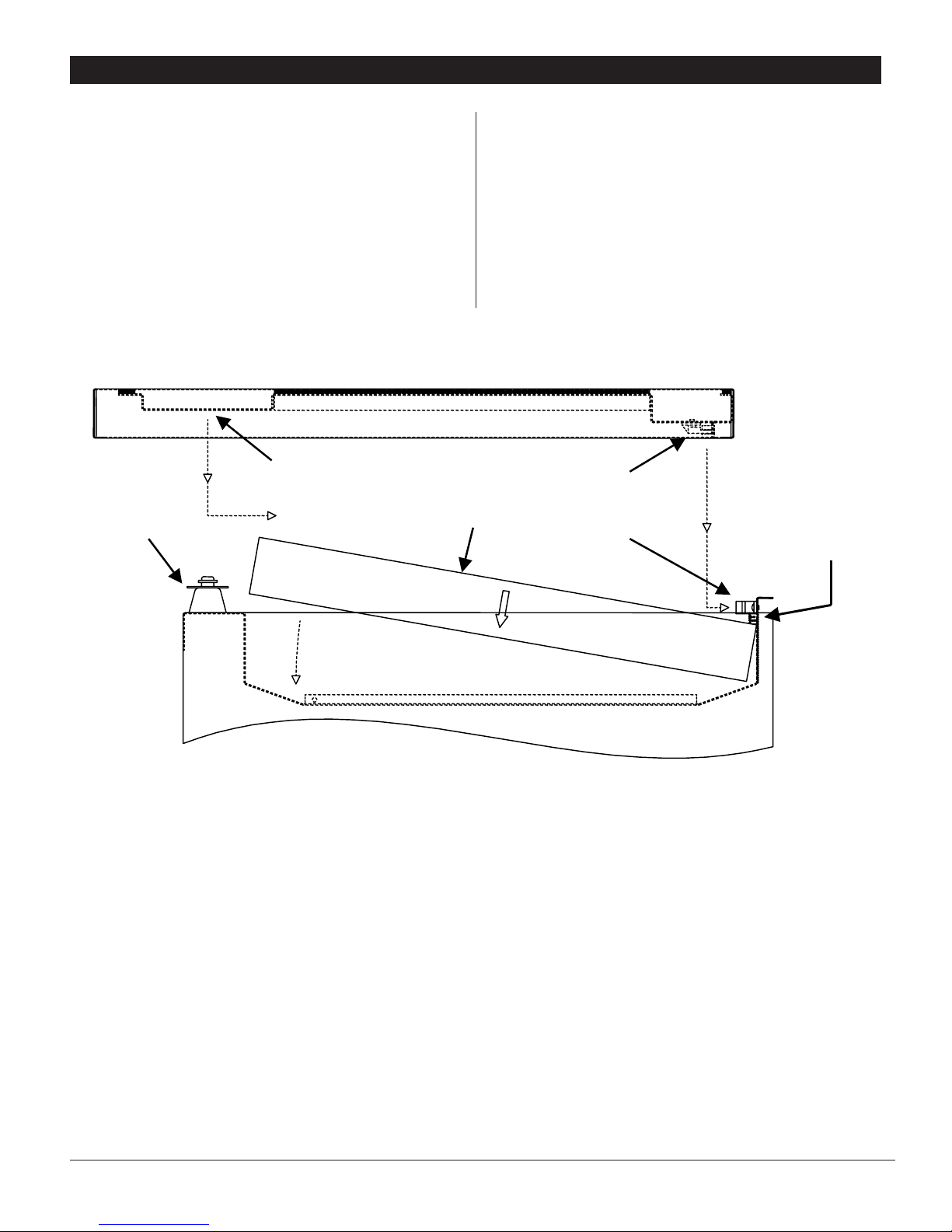

4.1A Filter Options

An optional filter frame is available

that attaches to the back of the

machine and adds 6-1/2" to the units’

depth. It allows the choice of using

either 95% efficient, HEPA grade, or

activated carbon filters in addition to

the standard filter. These filters are

accessible by removing the 4 screws

from the filter frame top cover.

The MERV 14 95% efficient filters

(as rated by ASHRAE 52-76 Dust

Spot Test) capture about 95% of

all particles greater than 1 micron.

Actual filter size is 19.38" wide

x 15.38" high x 3.75" deep. Two

filters are stacked to form a 32" high

filter bank. These filters can be tested for replacement using the

optional filter test listed in Section 4.1B.

The HEPA media filter captures 99.97% of all particles 0.3

microns or larger that pass through it. Actual filter size is 19.38"

wide x 30.75" high x 3.75" deep. These filters can be tested for

replacement using the optional filter test listed in Section 4.1B.

Optional Carbon filter/Pleated filter combination: The carbon

filter is actually a blend of activated carbon and potassium

permanganate. This blend removes the vast majority of gaseous

contaminants encountered in most filtering applications. The

activated carbon removes the heavier volatile organics while the

potassium permanganate removes the lower molecular weight

contaminates. The life of this disposable filter depends upon both

the hours used and the contamination level. The filter contains 8.7

pounds of active media (17.4 pounds with two filters).

Another advantage of this blend versus an all carbon filter is that it

changes color as it loads up with contaminates. It starts out black,

then turns pink, then brown, and finally white. It is best changed

when it passes the brown stage and begins to turn white, as it

has lost most of its effectiveness at that point. Actual filter size of

the carbon filter is 19.38" wide x 15.38" high x 2.88" deep. The

.88" deep pleated filter is the same nominal size and is installed

downstream of the carbon dust. The two filter combos are stacked

to form a 32" high filter bank.

4.1B Optional Filter Test

The optional 95% efficiency and HEPA filters have long lives

when prefiltered by the standard MERV 11 65% efficient pleated

inlet filter; they can last many years in certain conditions. How

long they last can, however, vary widely depending upon the

following: unit run time, air contamination level and standard inlet

filter cleanliness. Given the expense of the optional filter, it can

be costly to change them prematurely. The following test helps

determine when they should be changed.

Air exiting the bottom rear of the unit enters the filter frame, then

passes through the optional filter and into the room. If the filter

is dirty, air pressure builds up before the filter. To check this

pressure, remove the plastic plug from the filter frame top; you

will feel air coming out of the hole with the unit running. Place

the ping pong ball that came with the filter frame on the hole and

let go (any marked, regulation sized ping pong ball will work). If

the ball does not move or only bounces slightly and does not spin

continuously, the filter is clean enough for continued use. If the

ball floats above the hole and starts to spin and perhaps wobble

within 30 seconds, the filter needs to be changed.

5. Service

CAUTION! Servicing the Santa Fe Rx with

its high pressure refrigerant system and high voltage circuitry

presents a health hazard which could result in death,

serious bodily injury, and/or property damage. Only

qualified service people should service this unit.

5.1 Warranty

A warranty certificate has been enclosed with this unit. Read

it before any repair is initiated. If a warranty repair is required,

call the factory first at 1-800-533-7533 for warranty claim

authorization and technical assistance.

5.2 Technical Description

The Santa Fe Rx uses a refrigeration system similar to an air

conditioner’s to remove heat and moisture from incoming air, and

add heat to the air that is discharged (see figure 1).

Hot, high pressure refrigerant gas is routed from the

compressor to the condenser coil. The refrigerant is cooled and

condensed by giving up its heat to the air that is about to be

discharged from the unit.The refrigerant liquid then passes through

a filter/drier and capillary tubing which cause the refrigerant

pressure and temperature to drop. It next enters the evaporator coil

where it absorbs heat from the incoming air and evaporates.

The evaporator operates in a flooded condition, which means that

all the evaporator tubes contain liquid refrigerant during normal

operation. A flooded evaporator should maintain constant pressure

and temperature across the entire coil, from inlet to outlet.

The mixture of gas and liquid refrigerant enter the accumulator after

leaving the evaporator coil. The accumulator prevents any liquid

refrigerant from reaching the compressor. The compressor evacuates

the cool refrigerant gas from the accumulator and compresses it to a

high pressure and temperature gas to repeat the process.

FOR HVAC INSTALLER ONLY

4Santa Fe Rx Installer’s & Owner’s Manual

Santa Fe Rx with

Optional Filter Frame

Attached to Back