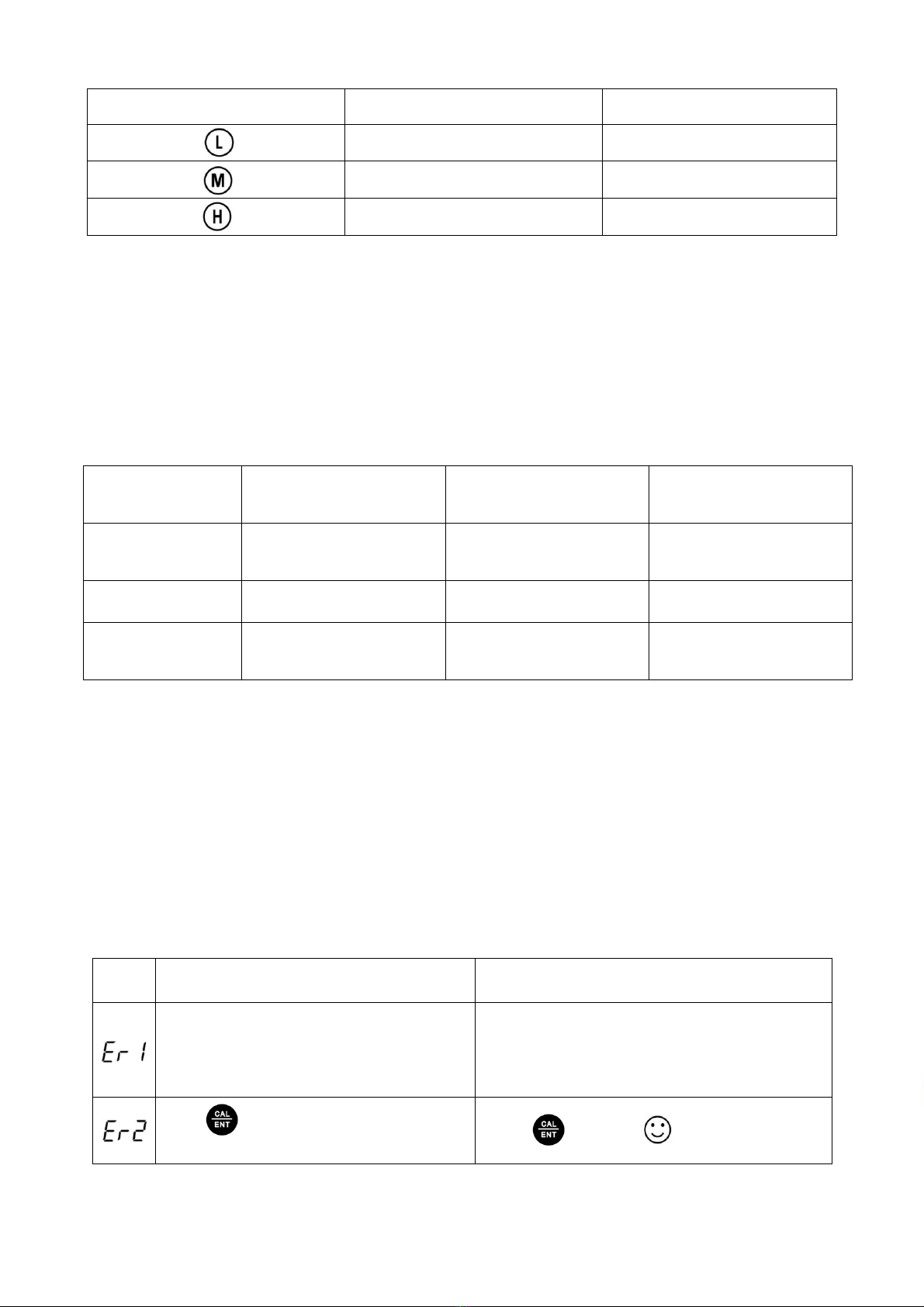

5.2. The tester has self-diagnostic function, information as following chart:

Self-diagnostic information

Wrong pH buffer solution or the recognition

range of calibration solution exceeds standard.

1. Check whether pH buffer solution is correct.

2. Check whether the probe is damaged.

Press key when measuring value is not

stable during measurement.

Press key when icon appears.

6. Conductivity Calibration

6.1. Press key to switch to conductivity measurement mode. Rinse the probe in pure water

and dry it.

6.2. Fill certain amount (about half volume of the calibration bottle) of 1413μS and 12.88mS

conductivity standard solution in separate calibration bottles.

6.3. Long press key to enter calibration mode, short press to exit.

6.4. Dip the probe in 1413μS conductivity standard solution and stir gently, leave to

Stabilize (LCD display as shown in the picture on the right), Short press key

to complete 1-point calibration, The tester then returns to measurement mode and

indication icon will appears on the LCD.

6.5. For multi-point calibration (either 2 or 3 point), rinse the probe in clean water and repeat step

6.4 using 84uS standard solution and / or 12.88mS standard solution. After completion of each

point, the calibration icons (for 84uS) and (for 12.88mS) will appear on the LCD near

the .

7. Conductivity Measurement

7.1. Press key to turn on the tester. Rinse the probe in pure water and dry it. Dip the probe in

sample solution, stir gently, leave to Stabilize, Get reading after LCD displays .

7.2. Press key to switch between →→→

8. Notes

8.1. The tester uses 84μS, 1413μS and 12.88mS conductivity standard solution. User can conduct 2

or 3point calibration. Refer to the chart as following. Generally, calibrating the tester with 1413μS

conductivity standard solution alone will meet the testing requirement.