1

COOLING SYSTEMS Fan Instruction Manual

1. Safety Precautions

・

In order to ensure that this product is used safely, be sure that you read and

understand the following precautions fully and use the product only as directed.

・

Be sure to read these Safety Precautions carefully before installing, connecting,

operating, maintaining, or inspecting this product. Follow all the precautions and

directions given here.

・

This product has been designed and manufactured for use as a device to be

used in general industrial machinery, and may not be used as a standalone

product.

・

The product of our company (hereafter called the product) falls into the

category of the products specified in the Attached List 1, Item 16 (Class 84,

Item 14) of the Export Trade Control Ordinance. To export the product as an

individual part or to export a product into which the product is assembled, the

Information Requirements

and

Objective Requirements

that the Ministry

of Economy, Trade and Industry established based on the

Catchall Controls

must be studied for applicability. Based on information on applicability and

specified requirements, appropriate export formalities must be performed.

In order to prevent any possible bodily injury or damage to property or

equipment, the following precautions for ensuring safety are displayed

according to the following two ranks of importance:

※Note: Items marked

Warning

might also result in serious bodily injury or death in

some circumstances. Always follow the instructions for items marked

Danger

.

Handling or using the product improperly and in disregard of the

instructions with this mark might result in serious bodily injury or death.

Handling or using the product improperly and in disregard of the

instructions with this mark might result in bodily injury or physical

damage.

Dange

Warning

Descriptions of the precautions to be taken to ensure safety are given

below.

Dange

・If the product is used in medical appliances or other types of equipment

that affect people's lives, sufficient safety-related evaluations and

preparations must be made in advance, and the product or the type of

equipment into which the product is assembled must be used on the

user's own responsibility.

・If the product is used in types of equipment that have a strong social

and public impact, sufficient prior evaluations and safety-related

evaluations and preparations must be made, and the product or the type

of equipment into which the product is assembled must be used on the

user's own responsibility.

・If the product is used in an environment where there are vibrations, for

example, in a car or aboard a ship, sufficient prior evaluations and safety-

related evaluations and preparations must be made, and the product or

the piece of equipment into which the product is assembled must be

used on the user's own responsibility.

・Connect all wires properly and securely. Failure to do so might result in

burns, fire, or exposure to electrical shock.

・If there are any grounding taps or wires, attach all grounds securely.

Failure to do so might result in exposure to electrical shock.

・Never use in explosive atmosphere, as doing so might result in fires,

burns, or bodily injury.

・Never operate with any live wires exposed, as doing so might result in

electrical shock.

・Never allow any persons or objects to approach or come into contact

with the rotor while in operation, as doing so might result in damage or

personal injury.

・Turn off the power and stop using the product immediately if you notice

any sparks, smoke, odd odors, sounds, or anything unusual during

operation. Failure to do so might result in fire, burns, or electrical shock.

・Never allow the product to fall, topple over, or otherwise be subjected

to excessive shocks when moving it, as doing so might result in product

breakdown or substandard operation.

・The product should be handled only by personnel with sufficient training

and knowledge and under the responsibility of the end user.

・Never attempt to disassemble, repair, or alter this product in any way, as

doing so might result in fire, burns, or electrical shock.

・Dispose of the product as industrial waste. Please contact your local

government office for further details about disposal.

Warning

Handling

・Installation, placement, connections, wiring, or relocation of the product

should be performed by knowledgeable or correctly licensed personnel.

Never perform such work while the product is live as this might lead to

injury, electrical shock, burns, or fire.

・Do not use the fan if not fixed or stand in hand.

・Never allow yourself to come into contact with the ends of wires or

plugs when measuring the insulation resistance or dielectric strength

voltage. This might result in electrical shock.

・Never attempt to disassemble or alter this product in any way. Doing so

might invalidate any warranties concerning the functions or performance

of the product, and might also result in fire, burns, bodily injury, or

electrical shock.

Instruction

・If the fan stops during operation, give proper consideration to the device

for its protection.

・Never use the product at voltages, temperatures, or any other settings

which exceed those given in the product specifications. This might result

in substandard operation, breakdown, fire, bodily injury, or electrical

shock.

・The fan may fail to operate properly if there is insufficient power

capacity, because the starting current is several times larger than the

rated current will flow at the moment of the voltage is supplied to the

fan. Be sure to inquire about startup current levels for individual models.

・Do not control the speed of the fan by changing power voltage. It may

cause fan failure.

・Start up all fans at the same possible timing if two or more fans which

wind interferes with each other are installed in the device. If the fan is

exposed to wind from other fans at start up, it may cause fan failure or

the fan may not start up correctly.

・Never insert or remove any lead wires or connectors while the power

is turned on. When inserting or removing plugs or connections, always

be sure to first check that the power has been turned off and hold the

housing of the plug or connector when doing so. Failure to do so might

result in damage or exposure to electrical shock.

・Do not remove the lead wire from the frame hook. It may scratch and

damage the surface of the lead wire.

・Never remove the product identification plate or install the product so

that the identification cannot be seen after installation. This could result

in the product being improperly used, and subsequently result in fires.

・Do not push the nameplate of the DC fan with strong force. The

nameplate may break and touch the shaft.

・The product might become damaged if foreign objects or external forces

are allowed to interfere with normal fan operation.

・Do not implement ON-OFF of power supply in negative line. That might

cause damage of the fan.

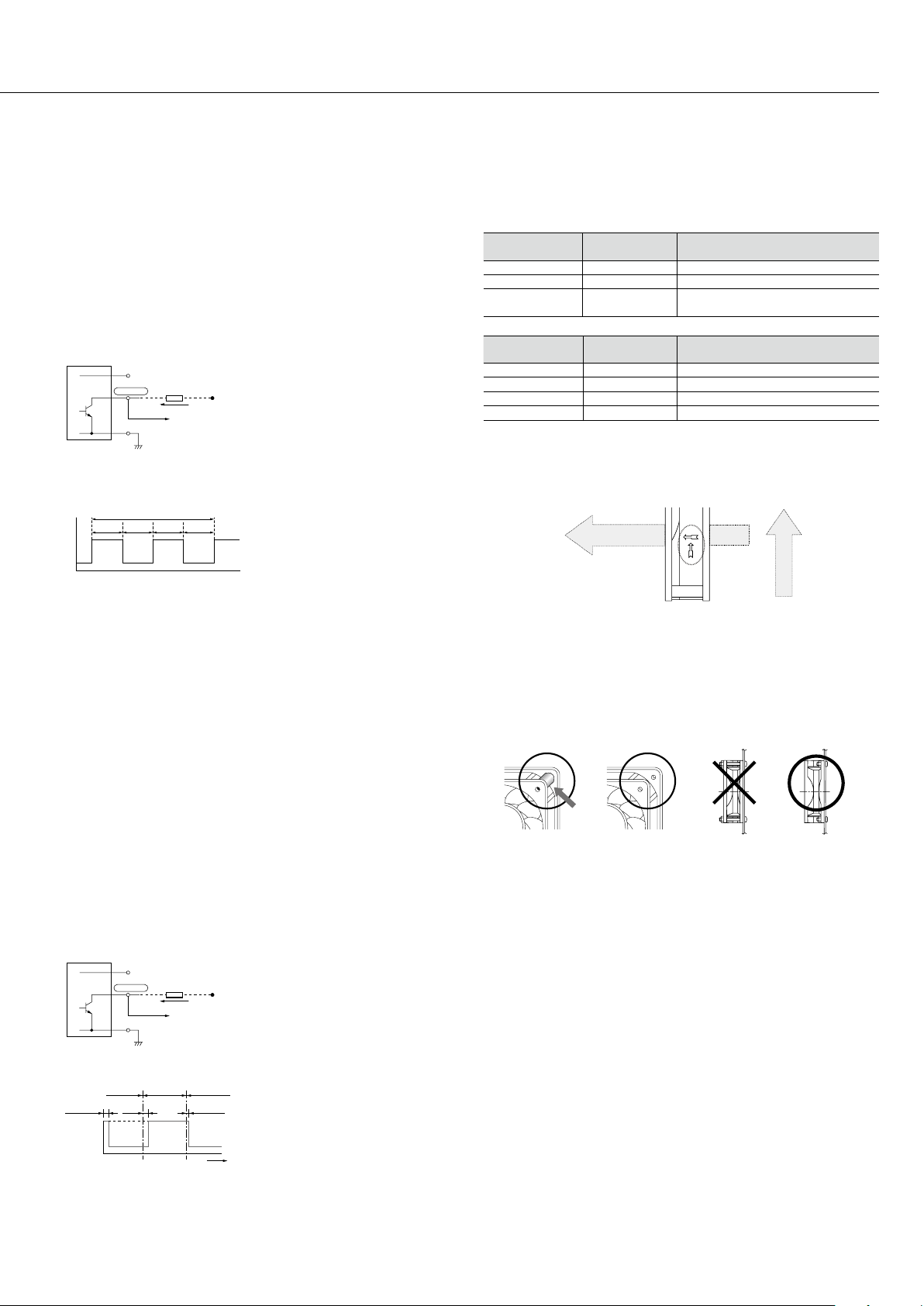

Installation

・When fixing this product into place, be sure to take into consideration

the product's weight, the vibrations generated during operation, and all

other relevant factors. Failure to do so might cause the product or parts

of it to fall out of position, resulting in bodily injury or malfunction of the

product.

・Be sure to check the direction of installation (i.e., the fan), as failing to

do so might result in bodily injury or mechanical breakdown.

・In order to ensure that the product operates properly, allow spaces for

ventilation and take whatever steps necessary to prevent the entry

of foreign objects. Failure to do so might result in bodily injury or

mechanical breakdown.

・When fixing the fan with screws, make sure the screw and sheet metal

do not deform the frame of the fan before operation. If the frame of

the fan is deformed, mechanical failure may be occurred or specified

performance may not be generated.

・When fixing the fan with screws, ensure the screwing torque. If the

screwing torque is over the recommended screw torque, fan frame

may be deformed or damaged. Use a ribbed frame when using screw

for piercing. In order to prevent from loosing screw, please use plain

washer and spring lock washer. For screwing torque of each fan type,

contact SANYO DENKI or SANYO DENKI distributor.

・When fixing the fan with self-tapping screws, fan frame may be

damaged.

・When excessive shock is attacked to fan, impeller may be protruded

from the surface of fan frame. Make sure that impeller does not touch

cover such as finger guard and mounting plate. Do not give excessive

shock to fan to avoid fan failure and deteriorate of fan performance.

・Pulling or pinching the lead wires could result in damage to the wire,

and you should avoid placing excessive stresses on these wires. The

device should also be installed so that the lead wires are not allowed to

come into contact with the rotor or blades. Failure to do so might result

in damage or exposure to electrical shock.

・Take proper precautions against static electricity when making electrical

M0011876