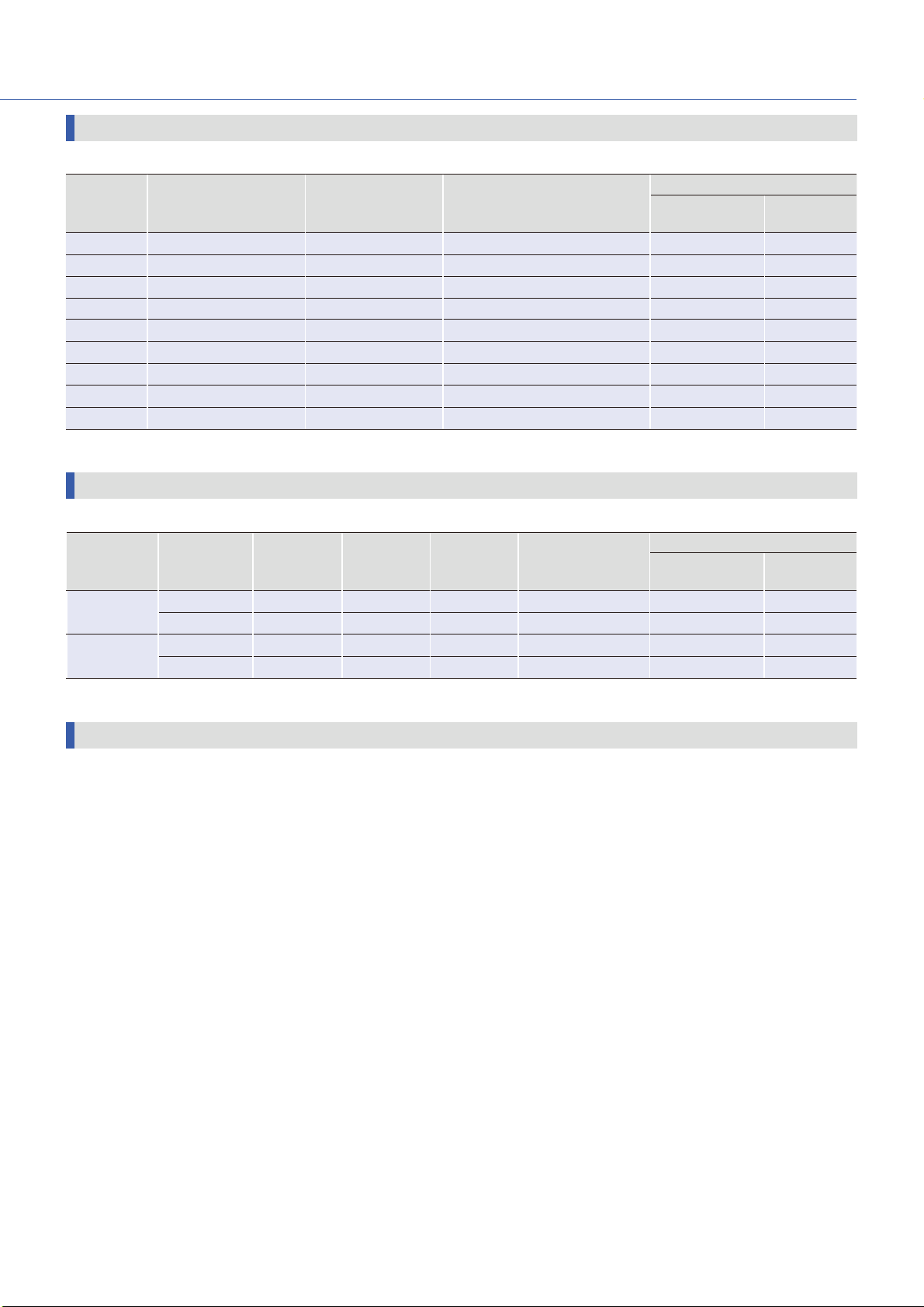

10

AC input Set model

Micro step

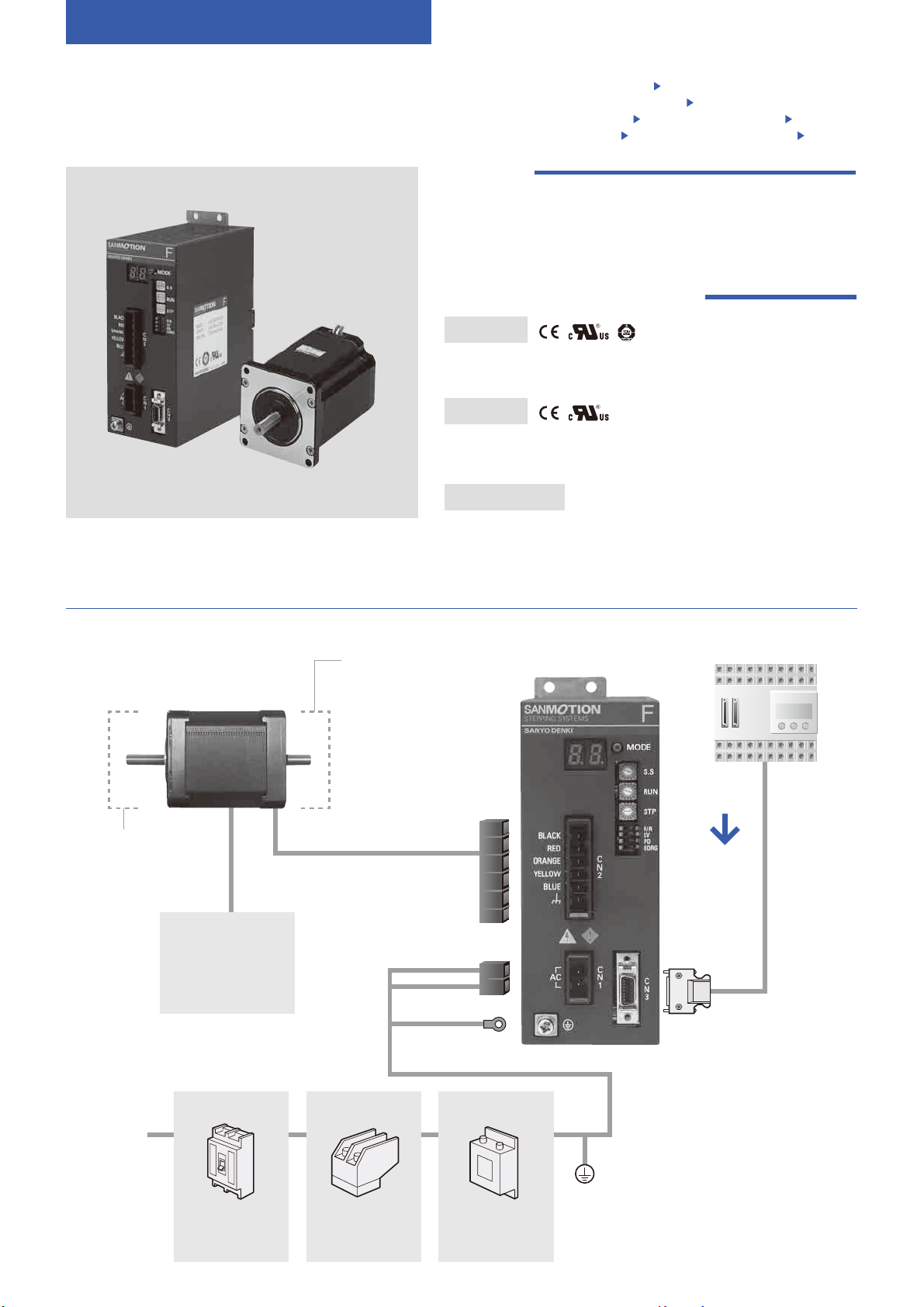

Set Model Conguration This is a set comprising a driver, motor and connectors.

AC Input Driver Model No.:FS1W075P00 Basic step angle:0.72° Rated current:0.75A/phase

Model Motor

size

Single shaft Double shaft Page

Set model

number

Set model conguration items Set model

number

Set model conguration items

Motor model

number

Connector

number

(note)

Motor model

number

Connector

number

(note)

Speci-

cations

Dimen-

sions

Standard model

42mm sq.

(1.65inch sq.)

FSF551S 103F5505-7041 PM-AP-065 FSF551D 10 3 F5 50 5 -7 011 PM -A P- 0 6 5 P.12 P. 97

FSF552S 103F5508-7041 PM-AP-065 FSF552D 10 3F 5 50 8 -7 011 P M- A P- 0 6 5 P.12 P. 97

FSF554S 103F5510-7041 PM-AP-065 FSF554D 103F5510-7011 PM-AP-065 P.12 P.97

60mm sq.

(2.36inch sq.)

FSF781S 103F7851-7041 PM-AP-064 FSF781D 10 3 F 78 51-70 11 P M- A P- 0 6 4 P.12 P. 9 8

FSF782S 103F7852-7041 PM-AP-064 FSF782D 10 3F 7 8 52-7 011 P M -A P- 0 6 4 P.13 P. 9 8

FSF783S 103F7853-7041 PM-AP-064 FSF783D 10 3 F 7 85 3 -7 011 PM - A P- 0 6 4 P.13 P. 9 8

φ86mm

(φ3.39inch)

FSF851S 103F8581-7041 PM-AP-064 FSF851D 10 3 F8 5 81-7011 PM - AP - 0 6 4 P.13 P. 99

FSF852S 103F8582-7041 PM-AP-064 FSF852D 10 3F 8 5 82-70 11 P M -A P - 0 6 4 P.13 P. 99

FSF853S 103F8583-7041 PM-AP-064 FSF853D 1 03 F8 5 8 3 -7 011 P M -A P - 0 6 4 P.14 P. 99

φ106mm

(φ4.17inch)

FSF892S 103F89582-7041 PM-AP-063 FSF892D 10 3 F8 9 5 8 2-7 011 P M -A P- 0 6 3 P.14 P.10 0

FSF893S 103F89583-7041 PM-AP-063 FSF893D 10 3 F8 9 5 8 3 -7 011 P M -A P- 0 6 3 P.14 P.10 0

CE / UL model

42mm sq.

(1.65inch sq.)

FSM551S 103M5505-7041 PM-AP-065 FSM551D 10 3M 55 0 5 -7011 P M- AP - 0 65 P.15 P.9 7

FSM552S 103M5508-7041 PM-AP-065 FSM552D 1 03 M5 5 0 8 -7011 P M- A P- 0 6 5 P.15 P. 97

FSM554S 103M5510-7041 PM-AP-065 FSM554D 103M5510-7011 PM-AP-065 P.15 P.97

60mm sq.

(2.36inch sq.)

FSM781S 103M7851-7041 PM-AP-064 FSM781D 10 3 M78 51-7 011 P M- A P- 0 6 4 P.15 P. 9 8

FSM782S 103M7852-7041 PM-AP-064 FSM782D 10 3 M7 85 2-7 011 P M- A P- 0 6 4 P.16 P. 9 8

FSM783S 103M7853-7041 PM-AP-064 FSM783D 10 3 M7 8 53 -70 11 P M -A P- 0 6 4 P.16 P.9 8

φ86mm

(φ3.39inch)

FSM851S 103M8581-7041 PM-AP-064 FSM851D 10 3M 8 5 81-70 11 P M -A P- 0 6 4 P.16 P. 9 9

FSM852S 103M8582-7041 PM-AP-064 FSM852D 10 3 M8 5 8 2-70 11 PM - AP - 0 6 4 P.16 P. 99

FSM853S 103M8583-7041 PM-AP-064 FSM853D 10 3 M 85 8 3 -7 011 P M- A P- 0 6 4 P.17 P. 9 9

φ

106mm

(φ4.17inch)

FSM892S 103M89582-7041 PM-AP-063 FSM892D 103M89582-7011 PM-AP-063 P.17 P.100

FSM893S 103M89583-7041 PM-AP-063 FSM893D 103M89583-7011 PM-AP-063 P.17 P.100

Low-backlash gear model

42mm sq.

(1.65inch sq.)

FSF551S-CX3.6 103F5505-70CXA4 PM-AP-065 FSF551D-CX3.6 10 3 F5 50 5 -7 0C X A1 P M- AP - 0 65 P.18 P.101

FSF551S-CX7.2 103F5505-70CXB4 PM-AP-065 FSF551D-CX7.2 10 3F 55 0 5 -70 CX B1 P M- AP - 0 65 P.18 P.101

FSF551S-CX10 103F5505-70CXE4 PM-AP-065 FSF551D-CX10 10 3F 5 50 5 -7 0C XE1 P M -A P- 0 6 5 P.18 P.10 1

FSF551S-CX20 103F5505-70CXG4 PM-AP-065 FSF551D-CX20 10 3F 55 0 5 -70 CXG1 PM - AP - 0 65 P.18 P.101

FSF551S-CX30 103F5505-70CXJ4 PM-AP-065 FSF551D-CX30 10 3F 5 50 5 -70 CX J1 PM - AP - 06 5 P.19 P.101

FSF551S-CX36 103F5505-70CXK4 PM-AP-065 FSF551D-CX36 10 3F 55 0 5 -70 CX K1 PM - AP - 06 5 P.19 P.101

60mm sq.

(2.36inch sq.)

FSF781S-CX3.6 103F7851-70CXA4 PM-AP-064 FSF781D-CX3.6 10 3 F 78 51-70 CX A1 P M- A P- 0 6 4 P.19 P.10 1

FSF781S-CX7.2 103F7851-70CXB4 PM-AP-064 FSF781D-CX7.2 10 3 F 78 51-7 0C XB1 P M- A P- 0 6 4 P.19 P.10 1

FSF781S-CX10 103F7851-70CXE4 PM-AP-064 FSF781D-CX10 10 3 F 78 51 -70 CX E1 P M -A P- 0 6 4 P. 2 0 P.10 1

FSF781S-CX20 103F7851-70CXG4 PM-AP-064 FSF781D-CX20 10 3 F 78 51-70 CXG1 P M -A P - 0 6 4 P. 20 P.101

FSF781S-CX30 103F7851-70CXJ4 PM-AP-064 FSF781D-CX30 10 3 F 78 51 -70 CX J1 P M - AP - 0 6 4 P. 2 0 P.10 1

FSF781S-CX36 103F7851-70CXK4 PM-AP-064 FSF781D-CX36 10 3F 7 8 51-7 0 CX K1 P M- A P- 0 6 4 P. 2 0 P.10 1

φ86mm

(φ3.39inch)

FSF851S-CX3.6 103F8581-70CXA4 PM-AP-064 FSF851D-CX3.6 10 3 F8 5 81-7 0 CX A1 PM - A P- 0 6 4 P. 21 P.10 1

FSF851S-CX7.2 103F8581-70CXB4 PM-AP-064 FSF851D-CX7.2 10 3F 8 5 81-70 CX B1 P M -A P- 0 6 4 P. 21 P.101

FSF851S-CX10 103F8581-70CXE4 PM-AP-064 FSF851D-CX10 10 3 F8 5 81-7 0C XE1 P M- A P- 0 6 4 P. 21 P.101

FSF851S-CX20 103F8581-70CXG4 PM-AP-064 FSF851D-CX20 10 3F 8 5 81-70 CXG1 P M- A P- 0 6 4 P. 21 P.101

FSF851S-CX30 103F8581-70CXJ4 PM-AP-064 FSF851D-CX30 10 3 F8 5 81-70 CX J1 P M- A P- 0 6 4 P. 2 2 P.10 1

FSF851S-CX36 103F8581-70CXK4 PM-AP-064 FSF851D-CX36 10 3F 8 5 81-70 CX K1 P M -A P- 0 6 4 P. 2 2 P.1 01

Harmonic gear

model

42mm sq.

(1.65inch sq.)

FSF551S-HX30 103F5505-70HXJ5 PM-AP-065 FSF551D-HX30 10 3 F5 50 5 -7 0H XJ 2 PM -A P- 0 6 5 P. 23 P.102

FSF551S-HX50 103F5505-70HXL5 PM-AP-065 FSF551D-HX50 10 3F 55 0 5 -70 H XL 2 P M- AP - 0 65 P. 2 3 P.10 2

FSF551S-HX100 103F5505-70HXM5 PM-AP-065 FSF551D-HX100 10 3F 55 0 5 -70 H XM 2 P M- AP - 0 65 P. 2 3 P.10 2

60mm sq.

(2.36inch sq.)

FSF781S-HX50 103F7851-70HXL4 PM-AP-064 FSF781D-HX50 10 3F 7 8 51-7 0 HX L1 P M- A P- 0 6 4 P. 2 3 P.10 3

FSF781S-HX100 103F7851-70HXM4 PM-AP-064 FSF781D-HX100 10 3 F 78 51 -70 H XM1 P M- A P- 0 6 4 P. 24 P.10 3

φ86mm

(φ3.39inch)

FSF851S-HX50 103F8581-70HXL4 PM-AP-064 FSF851D-HX50 10 3 F8 5 81-7 0 HX L1 P M -A P- 0 6 4 P. 24 P.10 3

FSF851S-HX100 103F8581-70HXM4 PM-AP-064 FSF851D-HX100 10 3 F8 5 81-7 0H X M1 PM - A P- 0 6 4 P. 2 4 P.10 3

Electromagnetic brake

model

42mm sq.

(1.65inch sq.)

FSF551S-XB 103F5505-70XB41 PM-AP-065 −− −P.25 P.10 4

FSF552S-XB 103F5508-70XB41 PM-AP-065 −− −P.25 P.104

FSF554S-XB 103F5510-70XB41 PM-AP-065 −− −P. 25 P.10 4

60mm sq.

(2.36inch sq.)

FSF781S-XB 103F7851-70XB41 PM-AP-064 −− −P. 25 P.104

FSF782S-XB 103F7852-70XB41 PM-AP-064 −− −P.26 P.10 4

FSF783S-XB 103F7853-70XB41 PM-AP-064 −− −P.2 6 P.10 4

φ86mm

(φ3.39inch)

FSF851S-XB 103F8581-70XB41 PM-AP-064 −− −P.26 P.104

FSF852S-XB 103F8582-70XB41 PM-AP-064 −− −P.26 P.104

FSF853S-XB 103F8583-70XB41 PM-AP-064 −− −P.27 P.10 4

(Note) : A set of connectors (for power, and input/output signals) for the driver and motor are included in each set conguration.

Connector

number

Driver connector set model

number

Motor connector

model number

PM-AP-065

PM-AP-078

4835758-1

PM-AP-064 4837994-1

PM-AP-063 4838971-1