Page ~

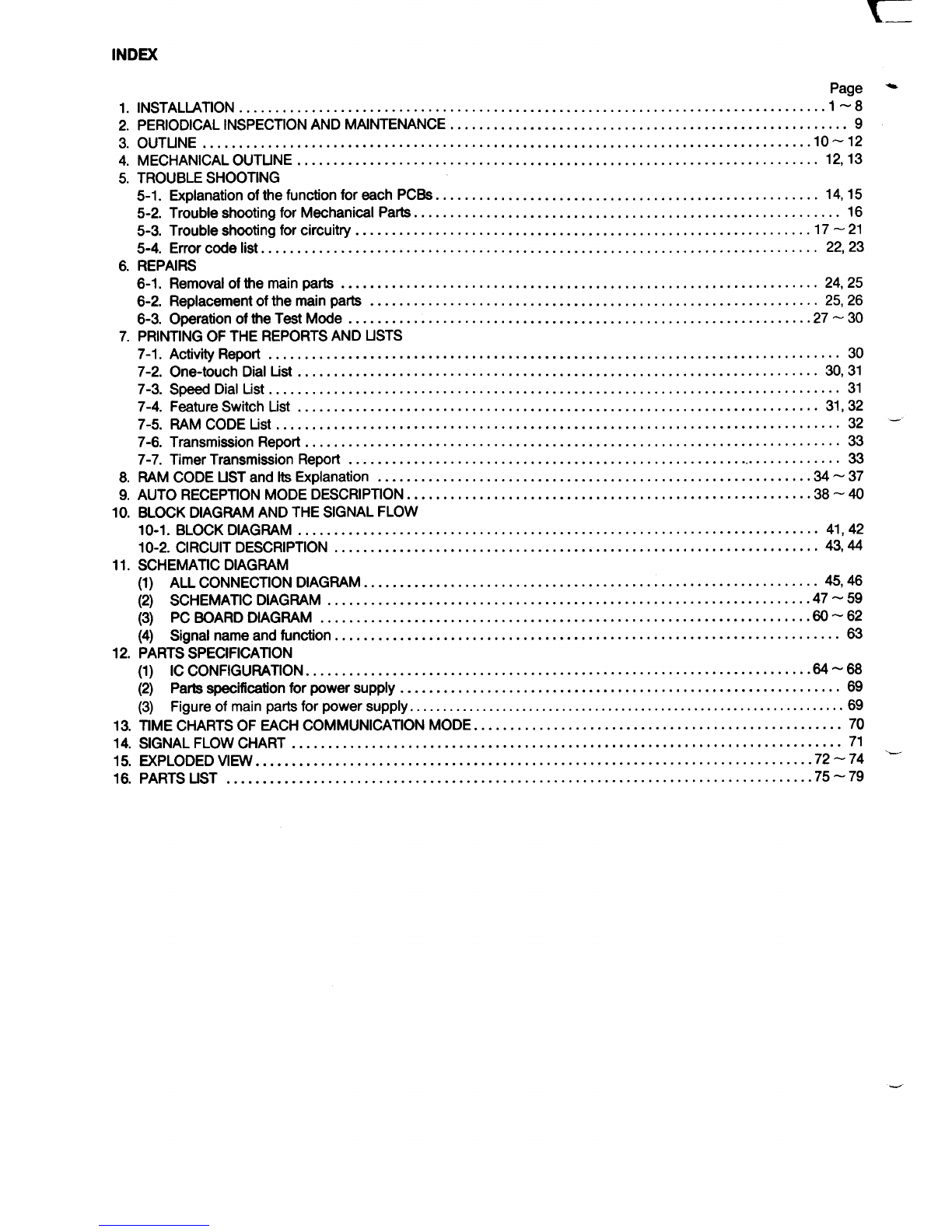

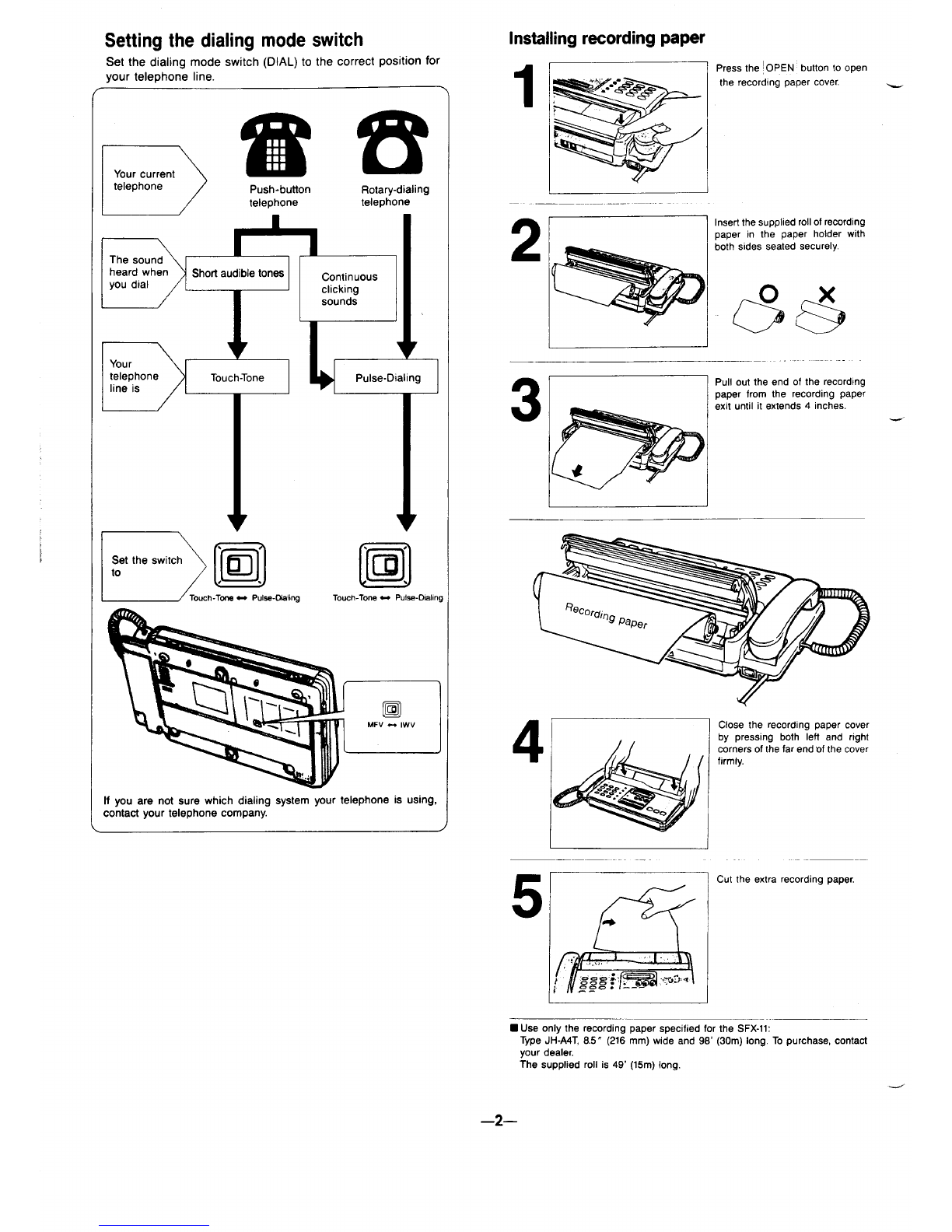

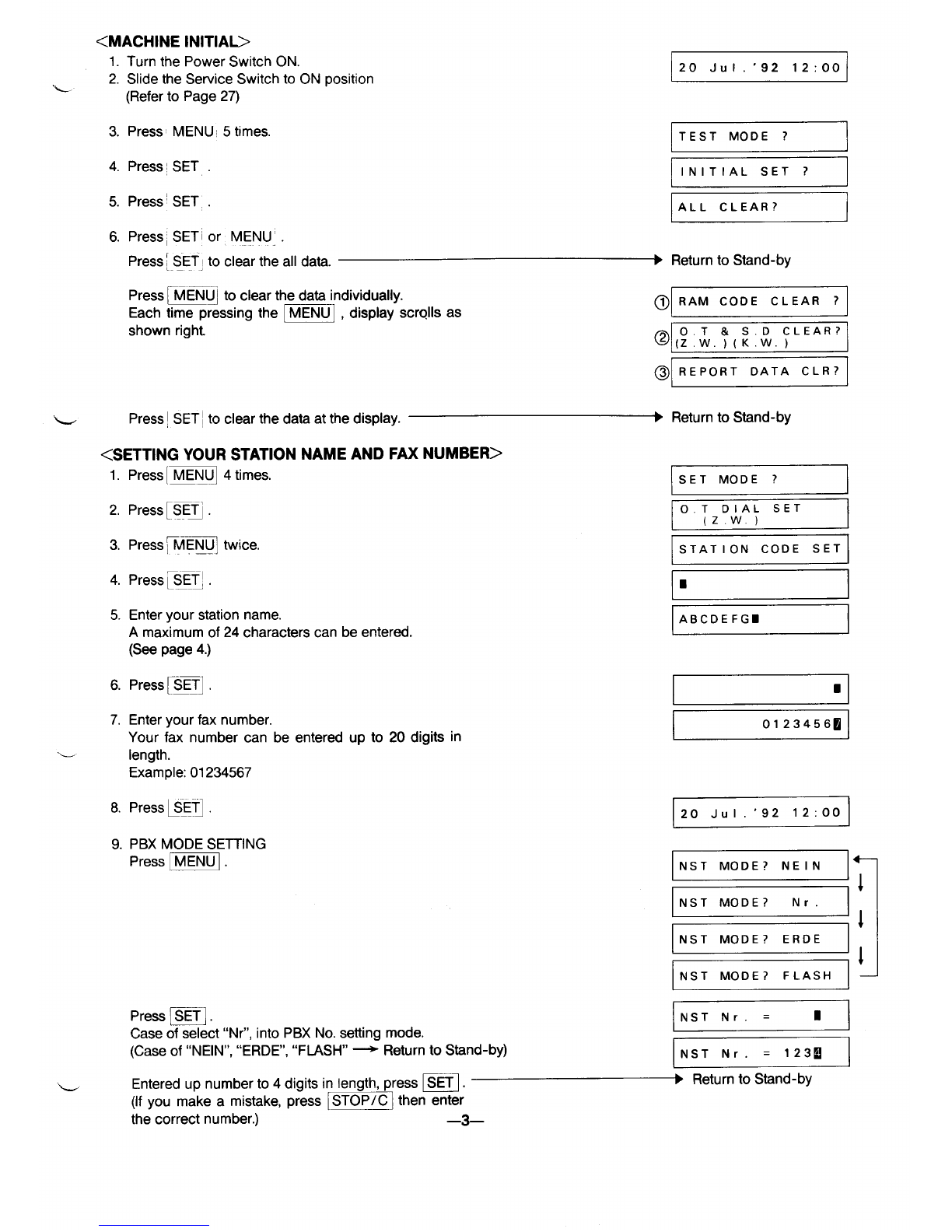

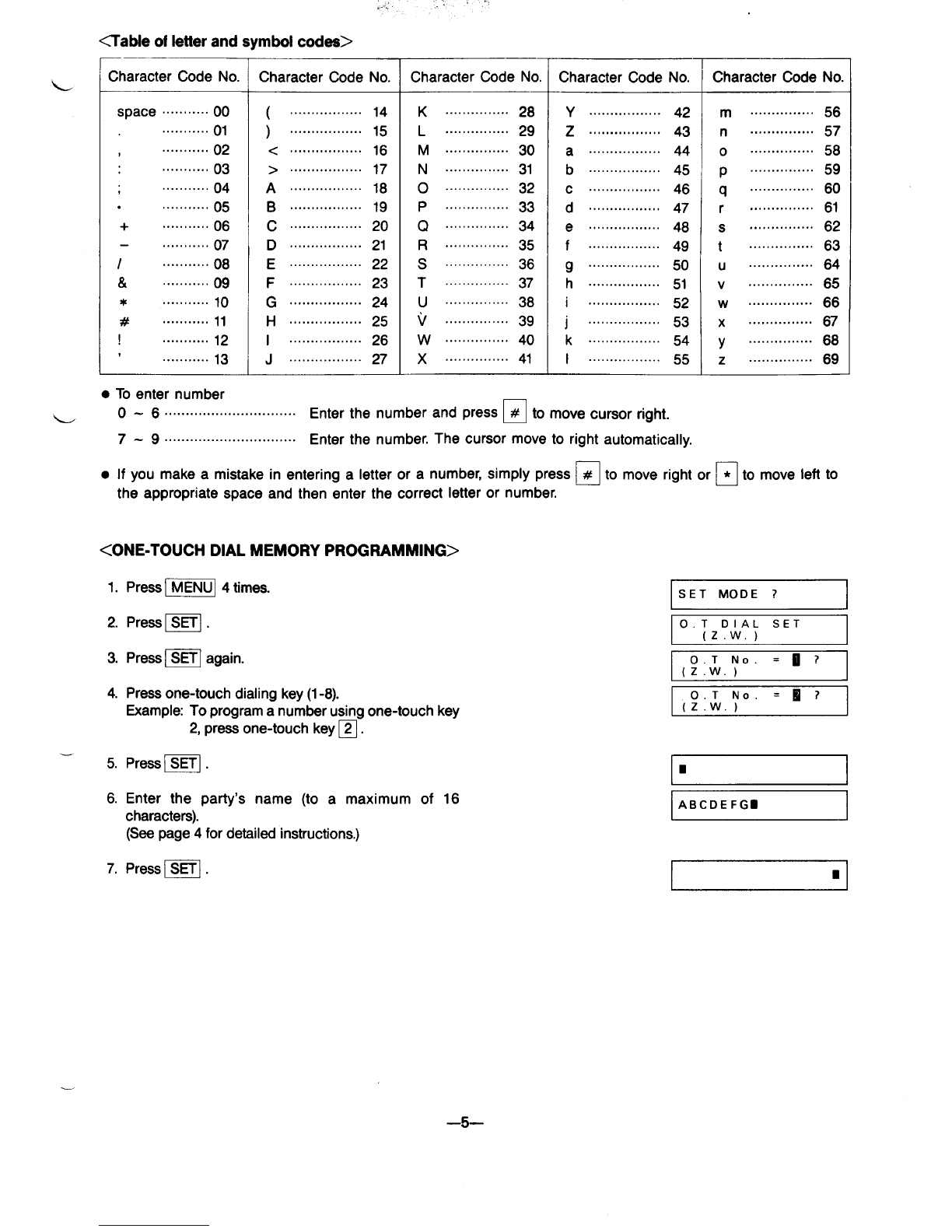

1. INSTALLATION .................................................................................1-8

2. PERIODICAL INSPECTION AND MAINTENANCE ....................................................... 9

3. OUTUNE ....................................................................................10-12

4. MECHANICALOUTUNE ........................................................................ 12,13

5. TROUBLESHOOTING

5-1. Explanation ofthefunctionforeach PCBS .....................................................14.15

5-2. Trouble shooting for Mechanical Patts ........................................................... 16

5-3. Trouble shooting forcircuitry ...............................................................17–21

5-4. Error code list.............................................................................22,23

6. REPAIRS

6-1. Removal of themain parts .................................................................. 24,25

6-2. Replacementofthe main parts .....,........................................................ 25,26

6-3. OperationoftheTestMode ................................................................27.3O

7. PRINTING OF THE REPORTS AND USTS

7-1. Activity Report ...............................................................................30

7-2. One-touch Dial List ........................................................................30.31

7-3. Speed Dial List ...............................................................................31

7-4. Feature Switch List ........................................................................31,32

7-5. RAM CODE List ..............................................................................32 ‘-

7-6. Transmission Report ..........................................................................33

7-7. TimerTransmission Report ..................................................................... 33

8. RAM CODE USTandlts Explanation ............................................................34-37

9. AUTO RECEPTION MODEDESCRIPTION ........................................................38-40

10. BLOCK DIAGRAM ANDTHESIGNAL FLOW

10-1. BLOCK DIAGRAM ........................................................................ 41,42

10-2. CIRCUIT DESCRIPTION ...................................................................43.44

11. SCHEMATIC DIAGRAM

(1) ALL Connection DIAGWM ............................................................... 45,46

(2) scHEMAnc DIAGMM .......! ...........................................................47.59

(3) PcWARDDIAGMM ....................................................................m.62

(4) Signal nameandfunction ...........................,........................,................. 63

12. PARTSSPECIFICATION

(1) IC CONFIGURATION .,..............,...........................................,.........64-68

(2) Pa~s~ifimtion for~wer supply ............................................................. 69

(3) Figure of main parts for power supply ..................................................................69

13. TIME CHARTS OF EACH COMMUNICATION MODE ...................................................70

14, SIGNAL FLOWCHART ....................................................,....................... 71

15. EXPLODED VIEW .............................................................................72-74 ‘-

16. PARTSUST .................................................................................75-79