INDEX Page

1. INSTALLATION

(1) Unpacking. .......................................................................1

(2) Telephonelineand ACconnections. .....................................................1

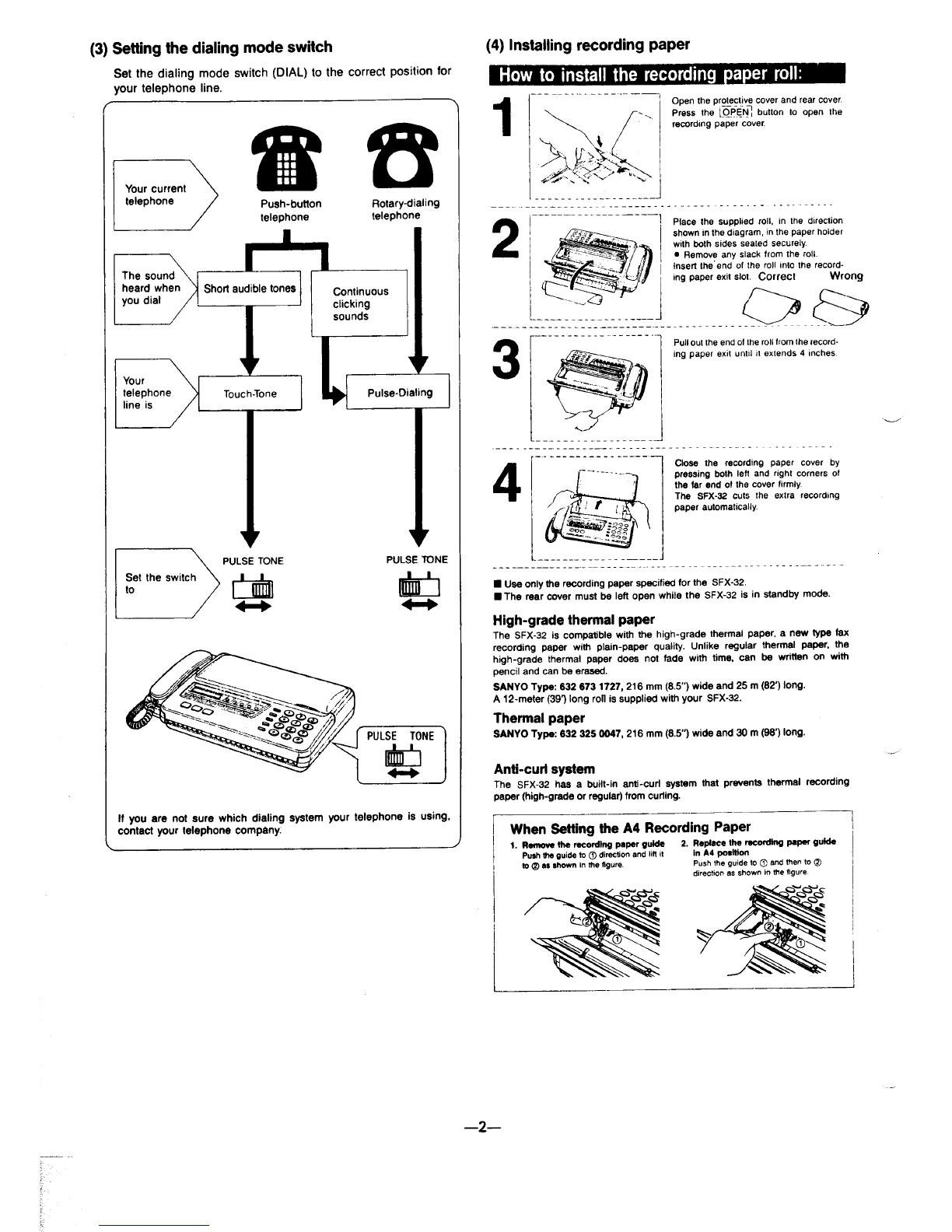

(3) Settingthedialing modeswitch .........................................................2

(4) installing recording paper .............................................................2

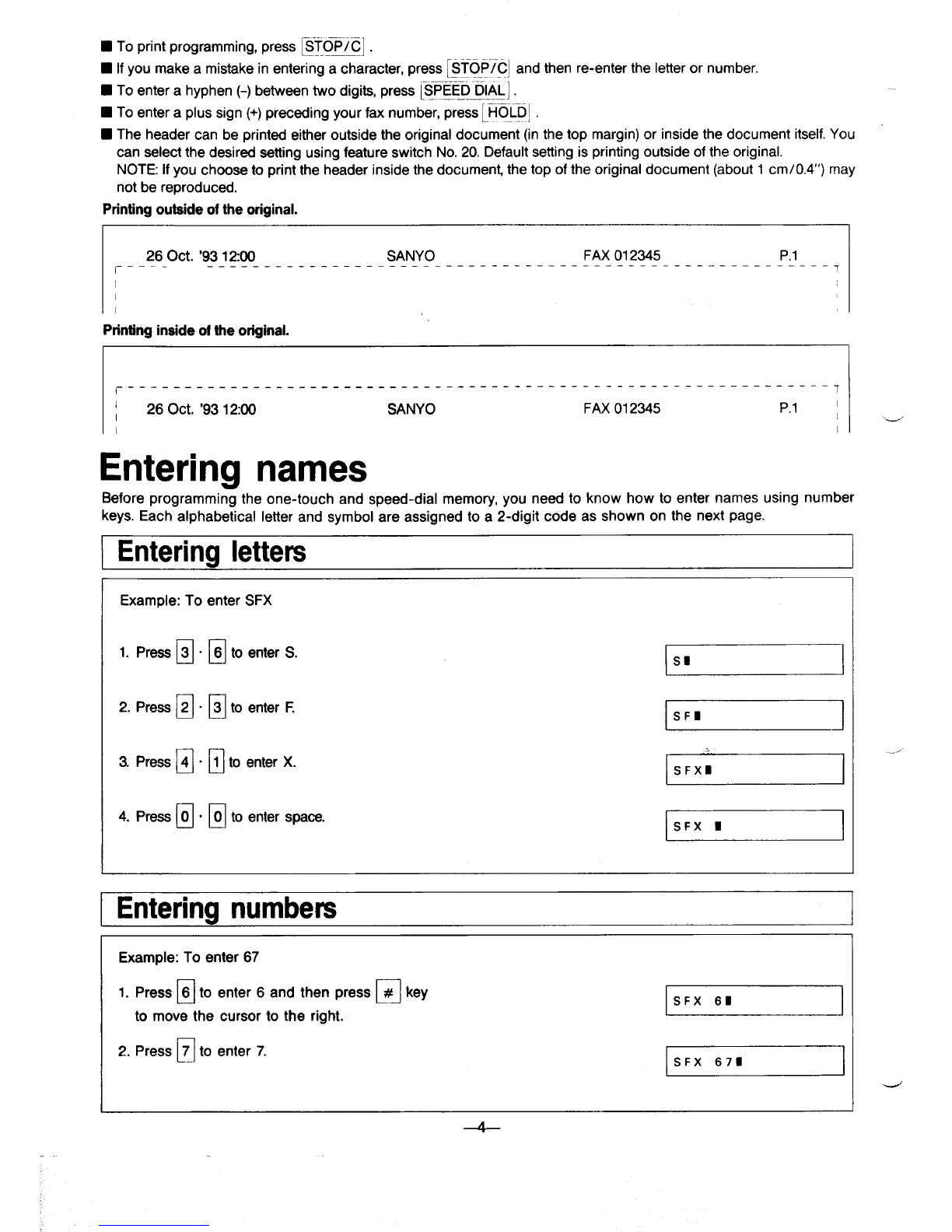

(5) Machine initial .....................................................................3

(6) Machine programming .............................................................3-7

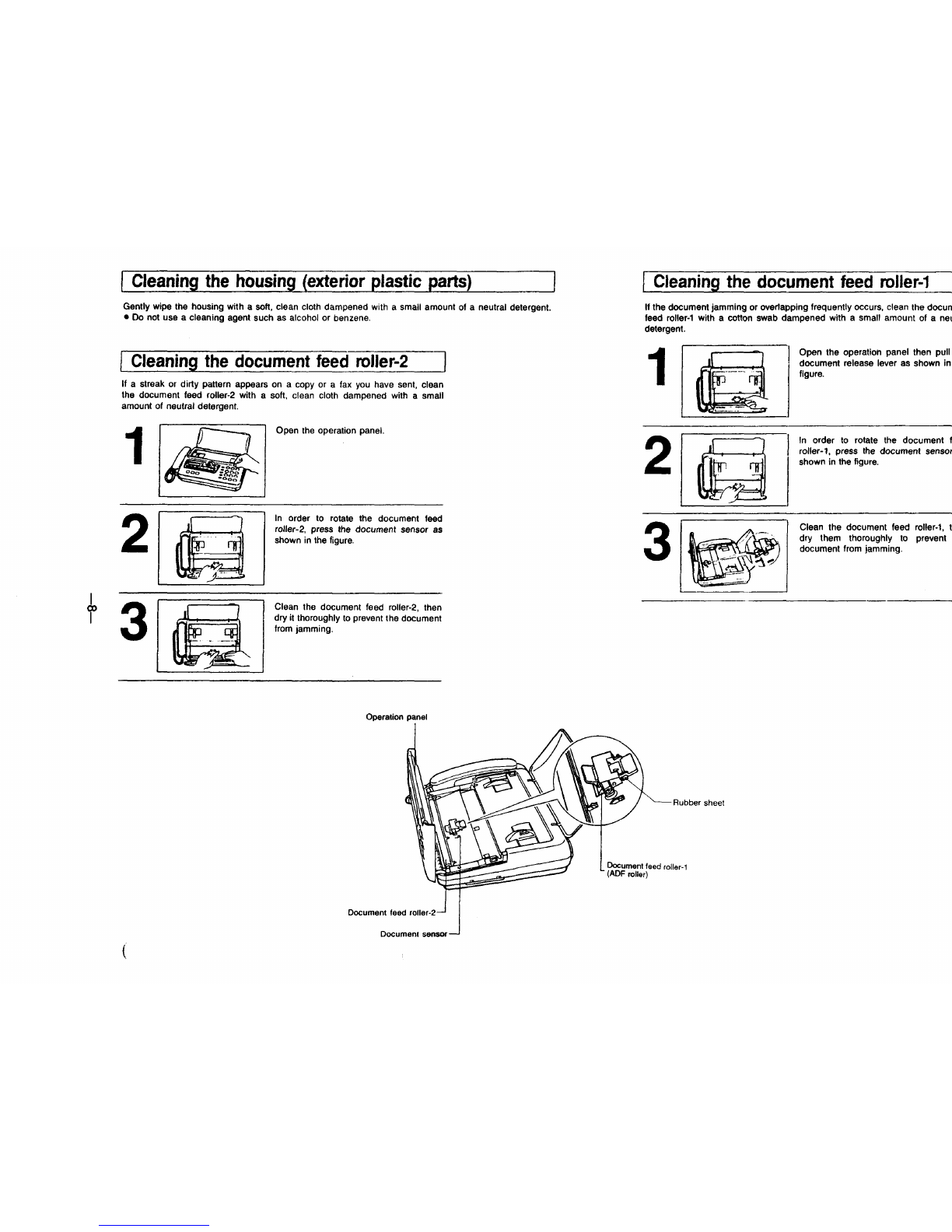

2. PERIODICALINSPECTION AND MAINTENANCE ..............................................8

3.OUTLINE

(l) Partnamesandfunctions .............................................................9

(2) Operation panel ...................................................................10

(3) Original documentsprecautions. ......................................................11

4. MECHANICALOUTLINE ...............................................................12

5.TROUBLESHOOTING

5-1. Function description ofeach PCB ..................................................13-15

5-2. Trouble shooting for Mechanical Parts ..................................................15

5-3. Trouble shooting forcircuitry. .....................................................16–20

5-4. Error code list .................................................................20,21

6.REPAIRS

6-l. Removal ofthemainpatts ........................................................22}23

6-2. Replacementofthe main parts .....................................................23,24

6-3. Test Mode .................................................................. 25-30

6-4. RAM CODE LISTand ltsExplanation ...............................................31-34

7.PRINTINGOFTHE REPORTSANDUSTS

7-1. Activity Report ...................................................................35

7-2. One-touch Dial List ...............................................................35

7-3. Speed Dial List ...................................................................36

7-4. FeatureSwitch List ................................................................36

7-5. RAM CODE List ..................................................................37

7-6. Transmission Report ...............................................................38

7-7. TimerTransmission Report ..........................................................38

8.FLOWCHARTOF AUTO RECEPTION MODE

(l) Autoreceptionwith FAX/TELswitchover function isON ......................................39

(2)Auto reception with FAX/TELswitchover function isOFF ......................................40

(3) Answerreception mode .............................................................41 -

9.BLOCKDIAGRAM ANDTHESIGNALFLOW

9-1. Block Diagram .................................................................. 42

9-2. Signal flow ...................................................................43,44

10. SCHEMATIC DIAGRAM

(l) All Connection Diagram ...........................................................45,46

(2) Each Circuit Diagram ............................................................47-61

(3) PWB Wiring Diagram ............................................................62-64

(4)Abbreviatedsignal explanation ........................................................65

ll. PARTSSPECIFICATION

(l) lCconfiguration ................................................................66-71

(2) Parts specification for power supply .....................................................72

(3) Figure of main parts for power supply ....................................................72

12.TfMECHARTS OF EACH COMMUNICATION MODE ..........................................73

13.SIGNALFLOW CHART ...............................................................74

14.EXPLODEDVIEW ................................................................75-n

15.PARTSUST ....................................................................78-83 ~