Sanyo M1011 User manual

Other Sanyo Microcassette Recorder manuals

Sanyo

Sanyo TRC-6300 User manual

Sanyo

Sanyo MCD-X75L User manual

Sanyo

Sanyo M1112 User manual

Sanyo

Sanyo MEMO-SCRIBER TRC-6030 User manual

Sanyo

Sanyo TRC 8080 - Cassette Transcriber User manual

Sanyo

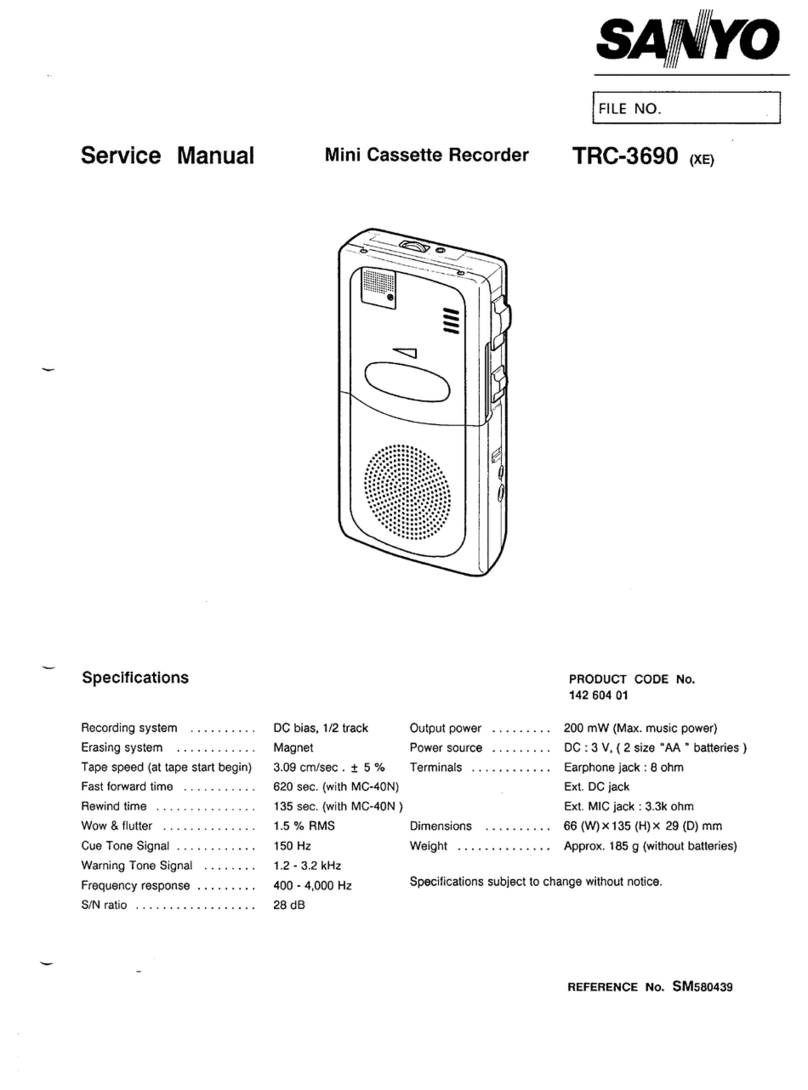

Sanyo TRC-3690 XE User manual

Sanyo

Sanyo M1110 User manual

Sanyo

Sanyo TRC-5880 User manual

Sanyo

Sanyo TRC540M - Auto Stop Microcassette Recorder User manual

Sanyo

Sanyo MCD-S730F User manual