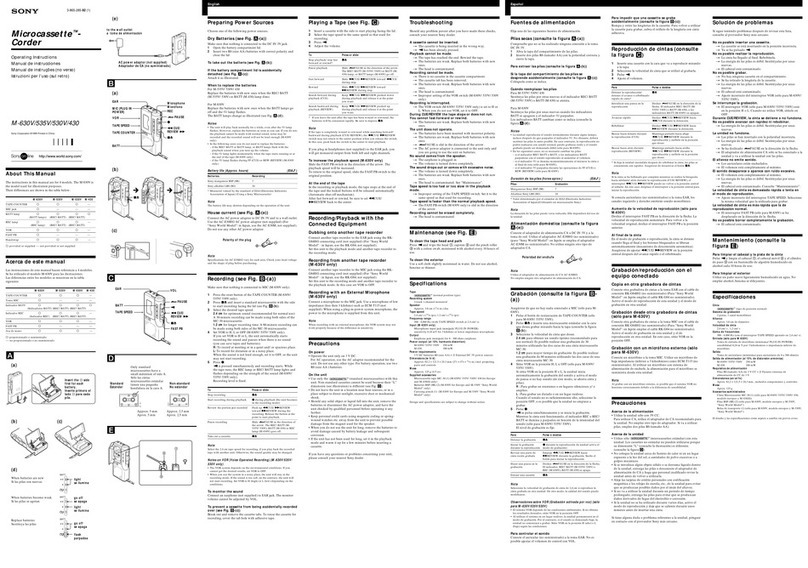

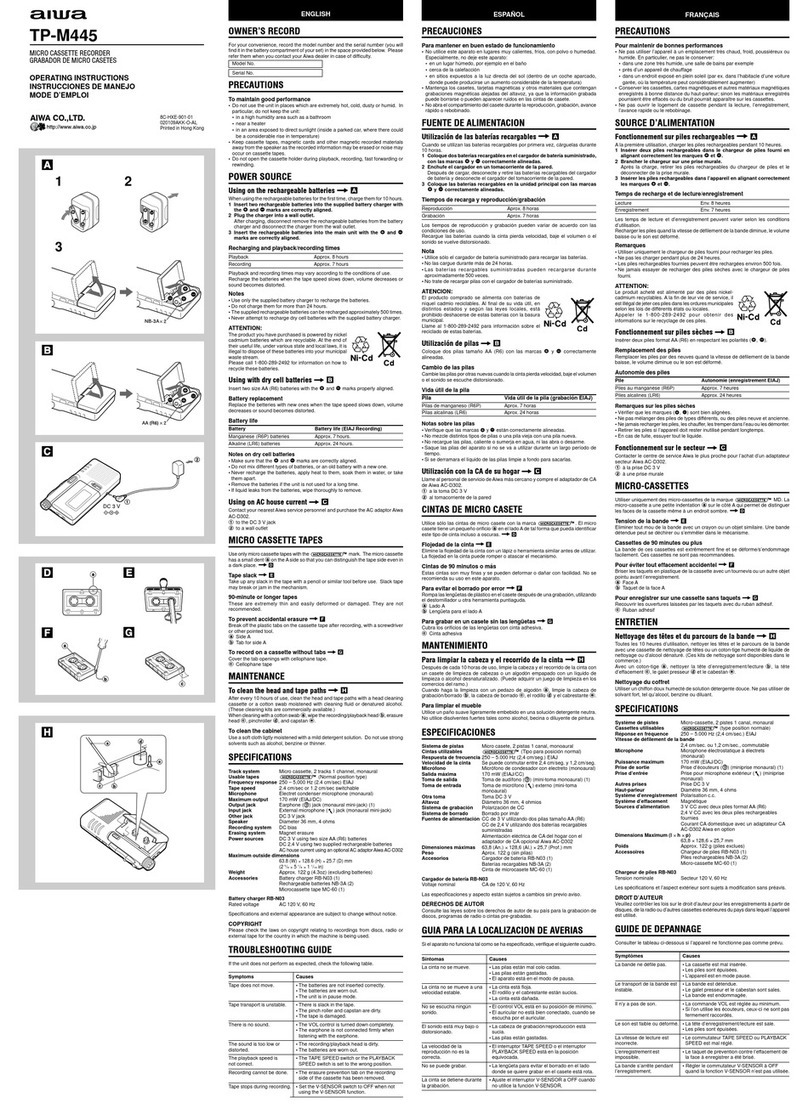

PARTS LIST

MECHA

Ref. No

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

121

122

123

124

125

126

127

128

129

130

131

132

133

L

134

135

136

137

138

139

SM (TM-T5880 MECiSH)

Part No.

412 047 6905

614 253 5325

<614 251 0827

x614 251 0834

614 253 5622

614 250 9623

614 253 7046

614 253 5479

412 047 1009

614 253 5486

614 253 5585

412 047 5700

614 253 5660

614 253 5578

614 253 5653

614 253 5387

412 047 6004

614 253 5677

614 250 9357

412 047 5809

614 250 9371

614 250 9319

614 253 5400

412 047 6400

%614 253 5448

614 253 7077

614 253 6728

412 047 1009

614 250 9388

412 047 5809

410 247 6103

614 253 5417

Q614 253 5431

614 253 5370

614 253 5363

412 047 6301

Description

SPECIAL SCREW, 1.4X1.6MM

ESCUTCHEON,MECHANISM COVER

ASSY,REEL,TAKE-UP

ASSY,REEL,SUPPLY

SPRING,COMP,BACK TENTION

SPRING,PLATE,CASSETTE

ASSY,CHASSIS,MAIN

LEVER,RECORD SAFETY

SPECIAL SCREW

LEVER,RECORD ARM

SPRING,TENSION,REC SAFETY

SPECIAL WASHER,

“E” RING,2.5MM

SPRING WIRE,REC ARM

ROLLER,LOCK

SPRING,PLATE,LEVER

HOLDER,SPRING

SPECIAL SCREW, 1.4X2MM

SPRING WIRE,FR PLATE SPRING

GEAR,CENTER

SPECIAL WASHER, 1.6X3X0.25MM

POLY CUT WASHER

GEAR,REW

BOSS,STUD REW GEAR SCREW

GEAR,COUNTER

SPECIAL WASHER, 1.6X3X0.25MM

POLY CUT WASHER

BELT,SQUARE,COUNTER

ASSY,LEVER,FWD ARM

SPRING,COMP,FWD ARM

SPECIAL SCREW

GEAR,FWD

SPECIAL WASHER,

1.6X3X0.25MM,

POLY CUT WASHER

SPECIAL WASHER,

1.6X3X0.3MM,

POLY WASHER

FLYWHEEL

3ELT,SQUARE,MAIN

SUPPORT,FLYWHEEL

SUPPORT, FLYWHEEL,HOLDER

SPECIAL SCREW,1.4X1.5MM

Ref. No. Part No. Description

141 412 047 5908 SPECIAL WASHER,

“E” RING, l.5MM

142 614 253 5561 SLIOE,LEVER

RECORD/STOP/PLAY/REVIEW

143 614 253 5554 SLIDE,F.FWD/EJECT LEVER

151 614 253 5608 SPRING,TENSION,EJECT LEVER

152 614 253 5592 SPRING,TENSION,SWITCH LEVEI

153 614 253 7060 ASSY,LEVER,SWITCH

154 614 253 5493 LEVER,F.FWD ARM

155 614 253 5516 LEVER,EJECT ARM

156 412 047 6806 SPECIAL SCREW,MOTOR

157 614 250 9333 CUSHION, RUBBER,MOTOR

161 412 047 6202 SPECIAL WASHER,

1.48X2. 1X0. 13MM,

POLY WASHER,FLYWHEEL

162 &614 253 6971 ASSY,MOTOR

163 614 253 5462 COUNTER,TAPE

164 614 255 7723 SPRING PLATE,TAPE COUNTER

165 614 253 5530 LEVER,ERASE HEAD BASE

166 x614 250 9906 HEAD,ERASE

167 412 047 0903 SPECIAL SCREW,HEAO BASE

168 614 253 5684 SPRING WIRE,ERASE HEAO

169 614 253 5547 LEVER,HEAD,BASE

170 614 253 5646 SPRING,COMP,

HEAD BASE SPRING “A”

171 412 047 6707 SPECIAL WASHER, 1.2X3X0.5MM,

LUMINER CUT WASHER

172 614 253 5615 SPRING,TENSION,

HEAD BASE SPRING “B”

173 ~614 253 7053 ASSy,pINCH RoLLER ARM

174 412 047 7407 SPECIAL WASHER,

1.2X3X0.25MM,POLY CUT

175 614 253 5691 SPRING WIRE,PINCH ARM SPRIN

176 412 047 6608 SPECIAL SCREW,l.4X1.5MM

177 412 047 6509 SPECIAL SCREW,l.4X6MM

~78 %614 250 9661 HEAD,RECORO/PLAY

179 614 253 5639 SPRING,COMP,AZIMUTH SPRING

180 614 253 5394 HOLDER,HEAD AZIMUTH SPACER

——

-7-