. ... ... .. ... ... .

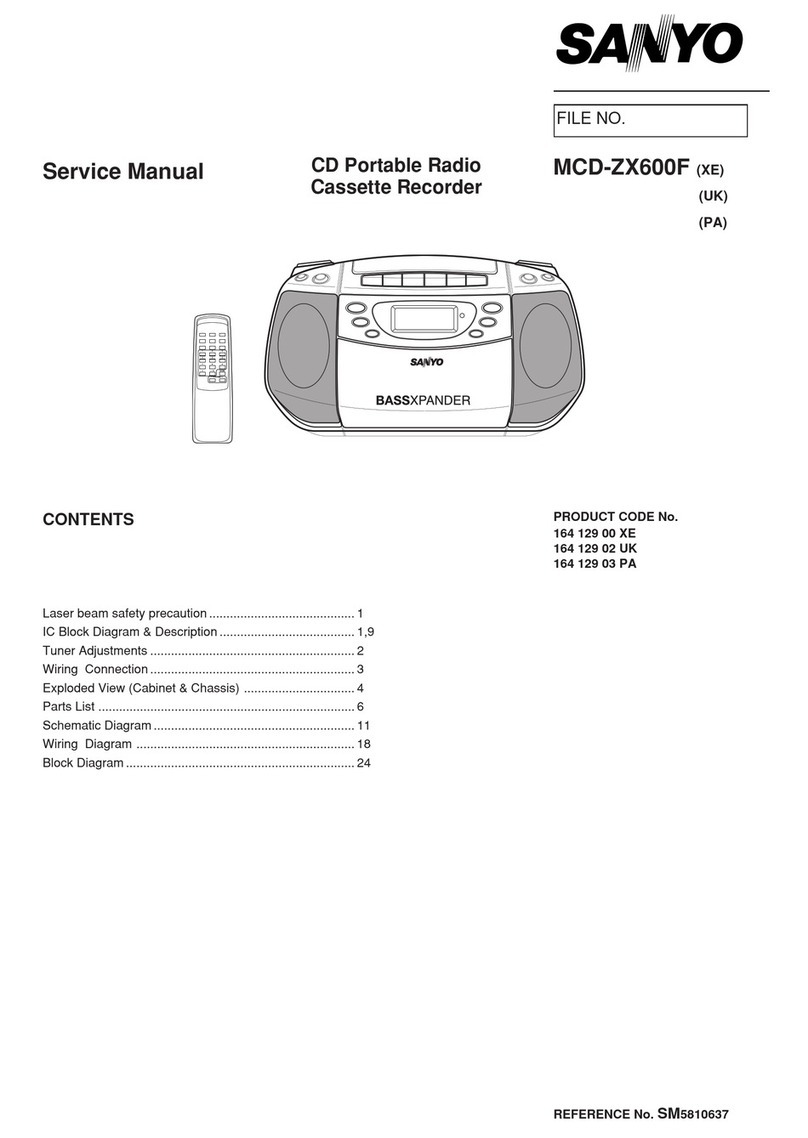

CONTENTS

.,.. .. . . . ... i

.

..,,-

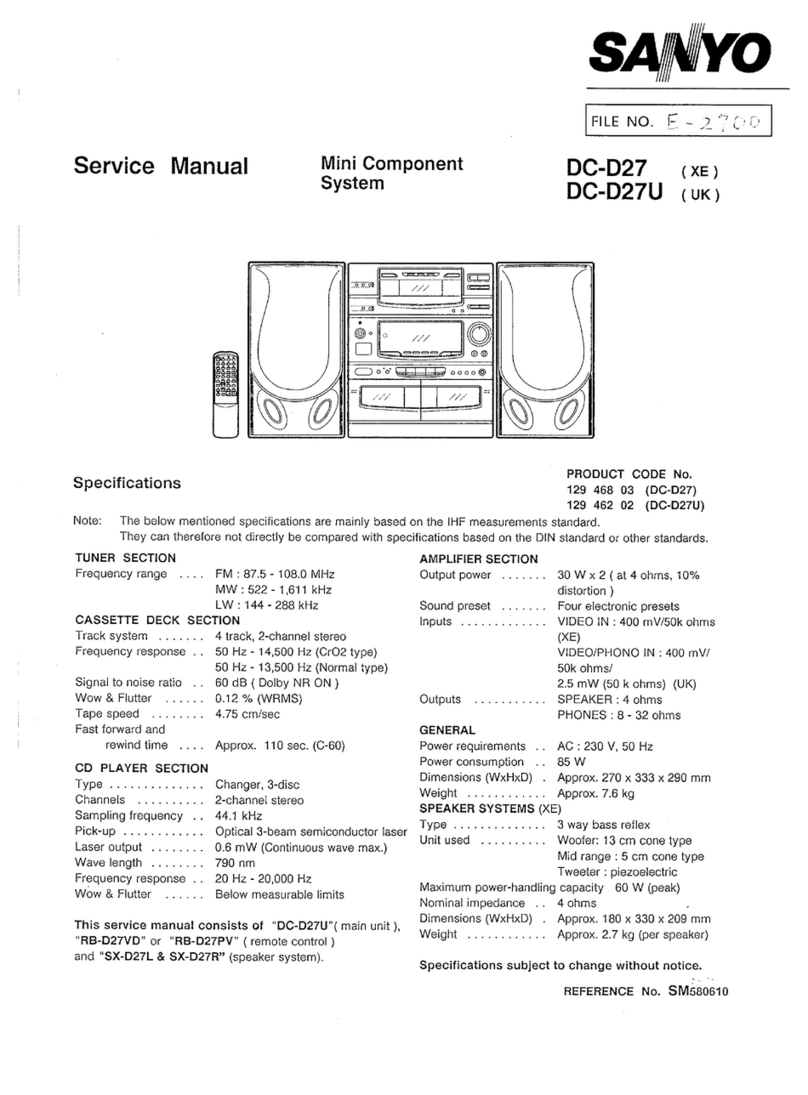

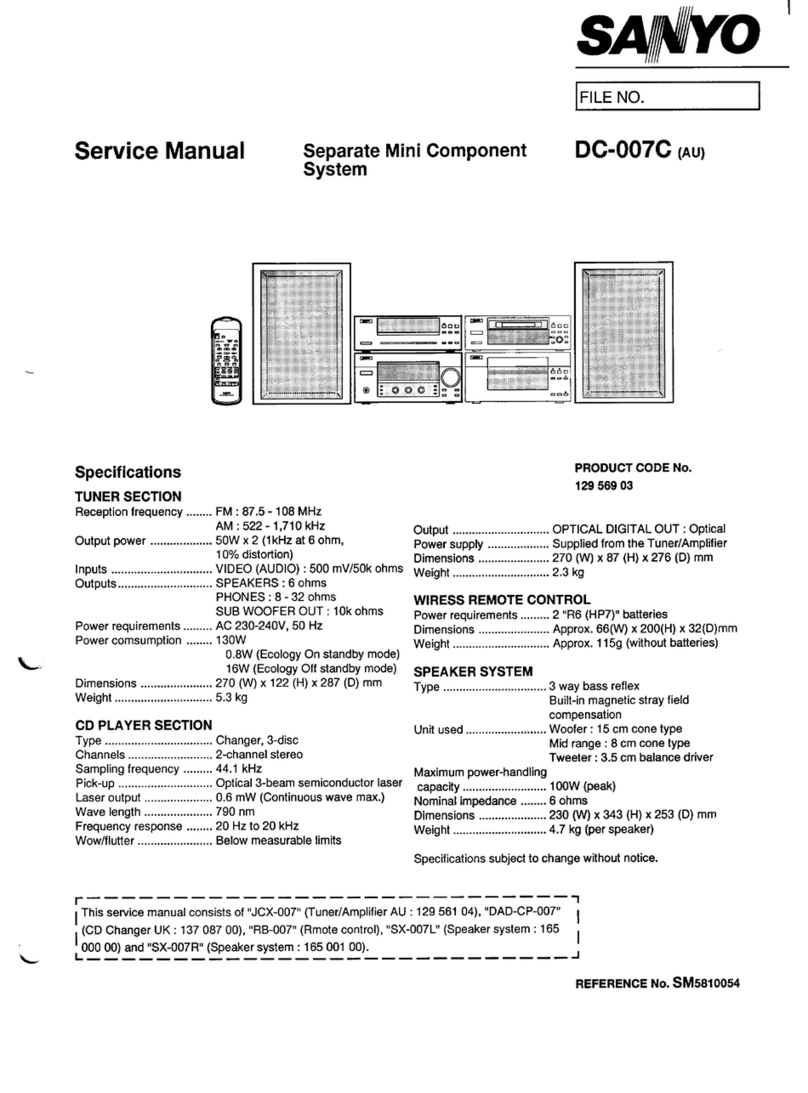

SPECIFICATIONS . . . . . . . . . . . . . . TOP

LASER BEAM SAFETY PRECAUTIONS .1

BEFORE USE OR TRANSPORTATION .2

WHAT TO DO IF . . . . . . . . . . . . . . . . . . 3

REMOVAL AND INSTALLATION ...... 3

TUNER ADJUSTMENTS . . . . . . . . . . . . 5

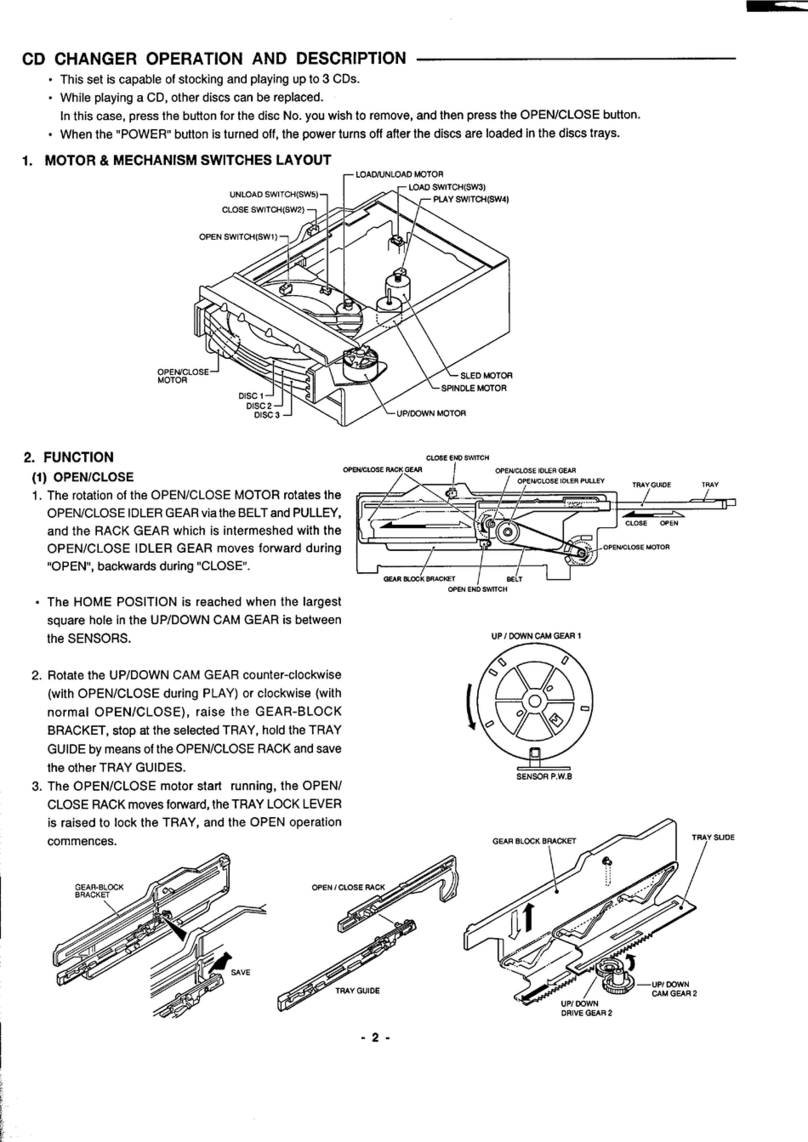

CD CHANGER OPERATION

DESCRIPTION . . . . . . . . . . . . . . . . . . . 6

CD MECHANISM REPLACEMENT .... 10

CD MECHANISM ADJUSTMENTS .... 15

CD PMYER ADJUSTMENTS ....... 17 _, #

TAPE DECK ADJUSTMENTS ....... 19

EXPLODED VIEW . . . . . . . . . . . . . . . . 21

PARTS LIST . . . . . . . . . . . . . . . . . . . 22

IC BLOCK DIAGRAM &

DESCRIPTION . . . . . . . . . . . . . . . . . . 27

SCHEMATIC DIAGRAM ............ 36

WIRING DIAGRAM ............... 38

IC &TRANSISTOR VOLTAGES . . . . . . 56

LASER BEAM SAFEN PRECAUTIONS

.Pick-up that emits alaser beam is used in this CD player. ..

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED

HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE 1“

LASER OUTPUT ..... 0.6 mW Max. (CW)

WAVELENGTH . . . . . . 790 nm .

. ..

!

ICAUTION-INVISIBLELASERRADIATIONWHENOPENAND I

INTERLOCKSDEFEATED.AVOIDEXPOSURETOBEAM.

ADVARSEL-USYNLIGLASER STR~LING VED ~BNING, NiiR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGAUDS HTELSE

FOR STRALING.

VARNIN6- OSYNLIG LASER STRALNING NAR OENNADEL AR OPPNAD

OCHSPiiFtR ~R URKOPPLAO. STR~LEN AR FARLIG.

VORSICltT -UNSICHTBARE LASERSTRAHLUNG TRITT AUS. WENN

]IDECKEL 6EOFFNET UNOWENN SICHERHEITSVERRIEGELUNG I

IIUBERBRiiCKT lsT. NICHT, oErdsTRAHL AUSSETZEN.

VARO! Avattaessaiasuoialukitusohilettaessaoletalttiina

nakymtitliimalle la;era~t~ilylle. Ala katso ateeseen.

-1-

A