\

.... LASER BEAM SAFEti PRECAUTIONS (CD)

IDo not look straight at the laser beam from the pickup and do IStructural Safety Interlock

not point the beam at your fingers or any other part of your

body. IThis model has adisc chuck lever and top lid. This disc chuck

‘.

Note: The Iaser beam must never be allowed to enter the eyes lever and top lid prevent to expose the laser beam for users.

Isince this may damage the eyes.

Power must never be supplied to apickup with adamaged laser

output part (objective lens, etc.). I

INVISIBLE LASER RADIATION EXPOSURE TO BEAM IS DANGEROUS CLASS 1- LASER PRODUCT

IOUTPUT POWER :0.6 mW MAX WAVELENGTH :790 nm I

., .,

..

1L-. -l I

m

t2#Wl10N-USEOFCON7ROLSORADJU.Sl’14ENlSORPERFORMANCEOFPROCEDURES01’t+133TNANTNoSESPECIFIEDINlHE

OPERATINGINSRNJC710NSUAYRESULTINNAZ4RDOUSRADLATIONEXPOSURE. --

YHECOMPACTDISCPLAYERSHOULONOTBEAOWSTEDORREPAIREO

❑YANYONEEXCEPTPROPERLYOUAUFIEDPERSONNEL

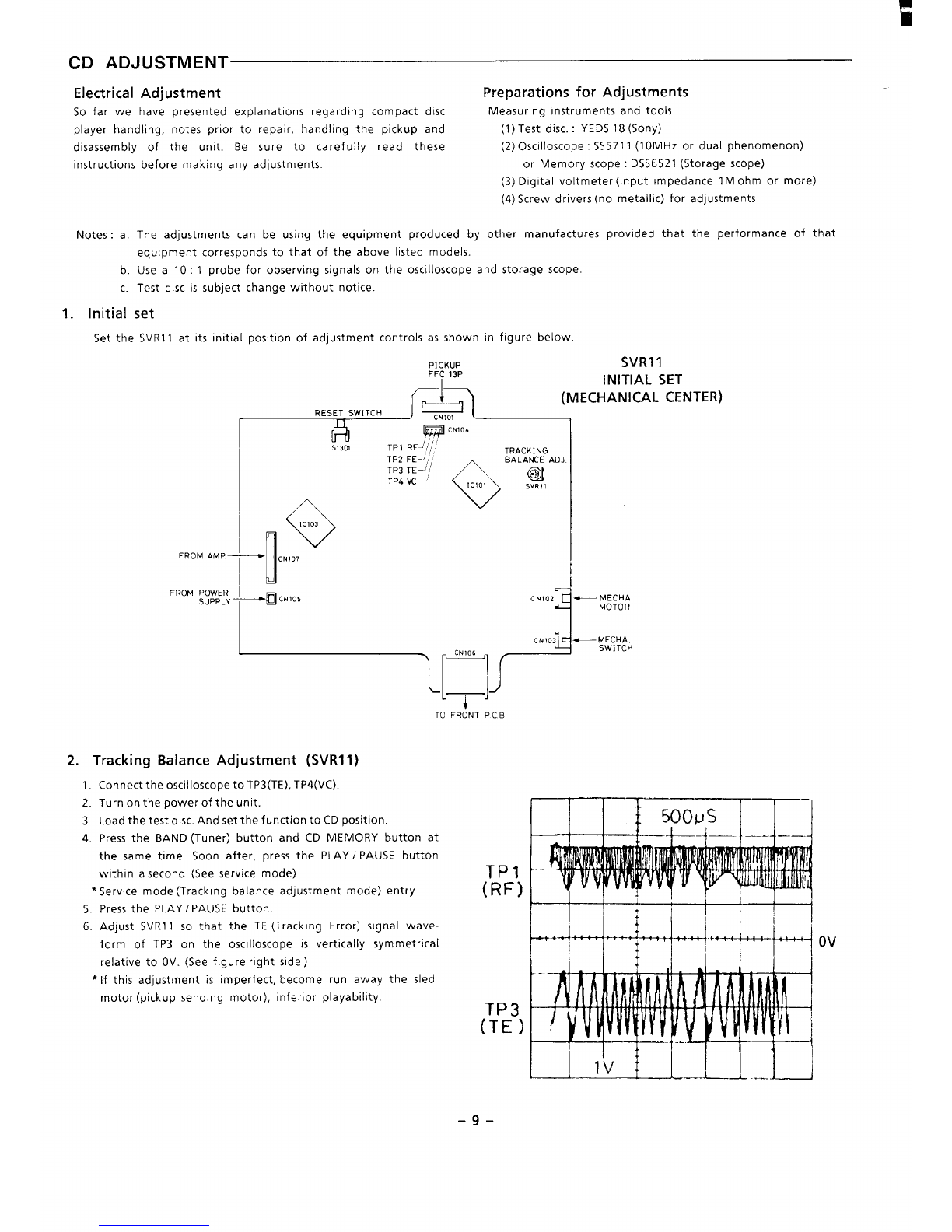

BEFORE REPAIRINGTHE COMPACT DISC PLAYER SECTION

..

Many semiconductors (ICS and transistors) and apickup (with abui!t-in laser diode) for reading the music signals on compact discs b

means of alaser beam are used as the parts in the compact disc player section.

1) Precautions for handling the pickup and semiconductors

(particularly the ICS)

~The pickup and semiconductors (particularly the ICS) may be da-

maged if they come into contact with asource of high voltage

static electricity. Do not bring them; therefore, into contact with

or into the vicinity of anything which has been charged with high

voltage static.

@The pickup consists of alarge number of optical and precision

parts. Do not store or repair it, therefore, in any location with a

high temperature, high humidity, high magnetic fields or higtr

dust concentration. (Since the pickup contains apowerful magnet.

.. it must not be brought near any magnetized objects.)

... -@Do not apply strong external pressure to the pickup or subject it to

impact. Actions like these can cause the printed circuit board to

crackor malfunctioning to occur.

@Do not use apickup which has been subjected to strong external

pressure or to an impact. The performance of such apickup may

deteriorate gradually and cause malfunctioning.

@The pickup isa single integrated partwhich has been very precisely

adjusted. Therefore, its adjustment points and set screws must not

betouched.

2) How to prevent static during handling

@When replacing any of the parts, disconnect the power plug from

the unit being repaired.

@All measuring instruments, tools and repair equipment must be

grounded. Cover the work bench where the repair work will be

done with agrounded electrically conductive sheet.

@Ground the metal part of the soldering iron in order to safeguard

against leakage of electricity from the heater.

@Repair personnel must wear grounding bands around their wrists

to discharge static picked up by their bodies. These bands are

grounded through aresistor (with a1Mohms resistance).

-2-

Note: Under no circumstances must be the grounding bands be

grounded wit%out aresistor (with a1Mohms resistance) since do-

ing so involves the risk of electric shocks.

Since static in the clothes of the repair personnel will not be dis-

charged by wearing grounding bands, every care must be taken

not to allow the clothes to touch the pickup and semiconductors

(particularly the ICS). ,.,

@The pickup, which is asingle integrated part, is kept in aconduc-

tive bag. Use this bag to convey the pickup from one placeto an-

other. In order to avoid damage resulting from static which may

occur when the pickup is removed from the bag, make sure that it

is not placed on top of the bag.

3) Precautions with laser beam

~DOnot look straight at the laser beam from the pickup and do not

point the beam at your fingers or any other part of your body.

Note: The laser beam must never be allowed to enter the eyes

since this may damage the eyes.

@Power must never be supplied to apickup with adamaged laser

output part (objective lens, etc.).

4) Cleaning the lens surface

~Blow off dust on the lens using the kind of air brush which is used

for cameras.

@Remove stubborn dirt with acotton swab dipped in isopropyl alto.

hoi. Do not use any other type of cleaning fluid since it may mark

the plastic lens.

Notes:

~Do not use too much isopropyl alcohol: the excessmay seep in

side the pickup.

@The lens is held in place by avery feeble support spring. There

fore, when cleaning the lens, avoid applying any more force b)

the cotton swab than is necessary since this may bend the sup

port spring out of shape.