MISCELLANEOUS ADJUSTMENTS SET 4737 PSET 4737 P

SET 4737 PSET 4737 P

SET 4737 Paa

aa

agg

gg

ge 1e 1

e 1e 1

e 1

B+ CHECKB+ CHECK

B+ CHECKB+ CHECK

B+ CHECK

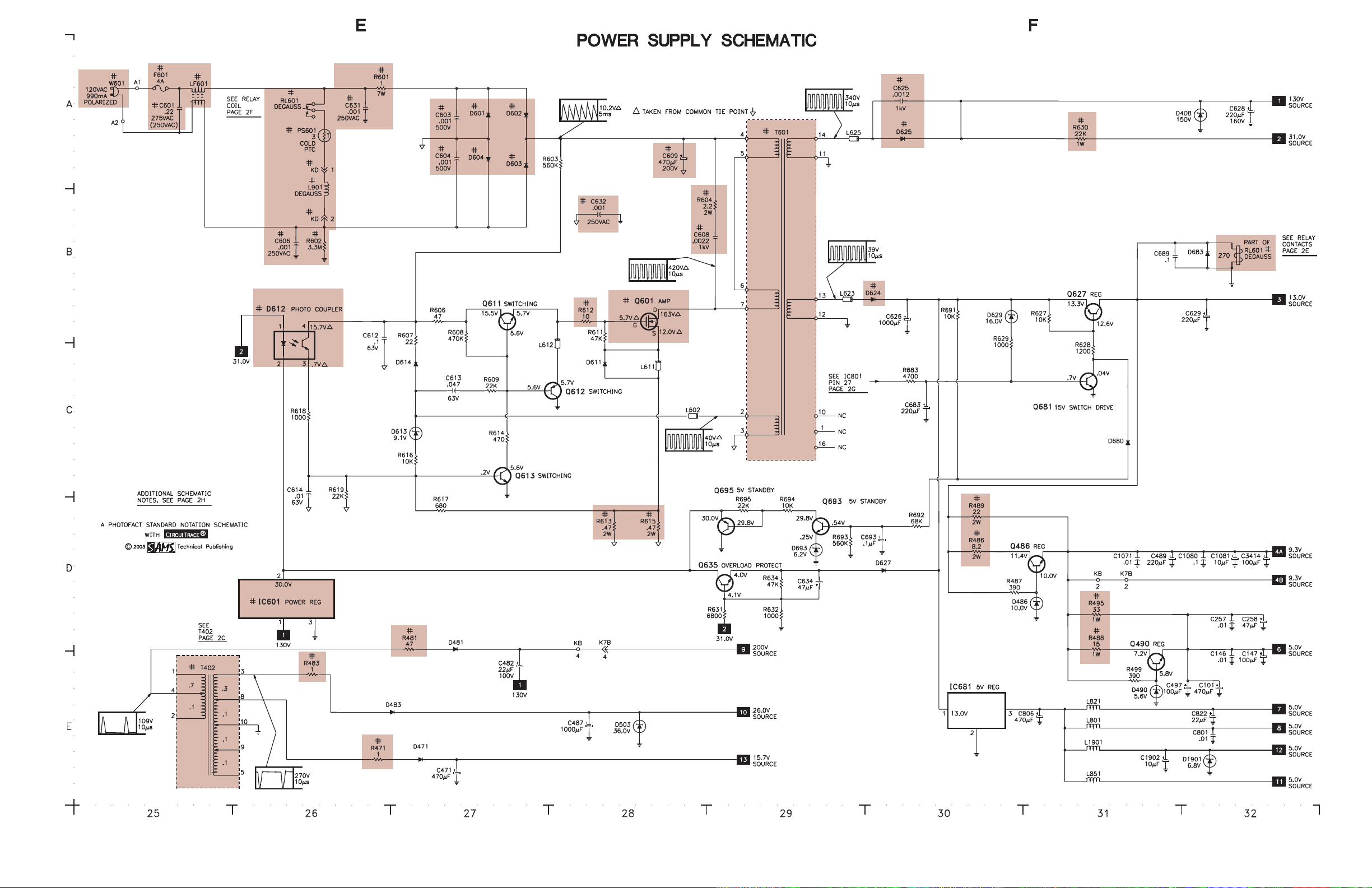

Connect a digital DC voltmeter to the cathode of D625. Set brightness and picture

to minimum. With AC line set to 120VAC, B+ should read 130V ±2.0V.

HIGHHIGH

HIGHHIGH

HIGHVV

VV

VOLOL

OLOL

OLTT

TT

TAA

AA

AGE CHECKGE CHECK

GE CHECKGE CHECK

GE CHECK

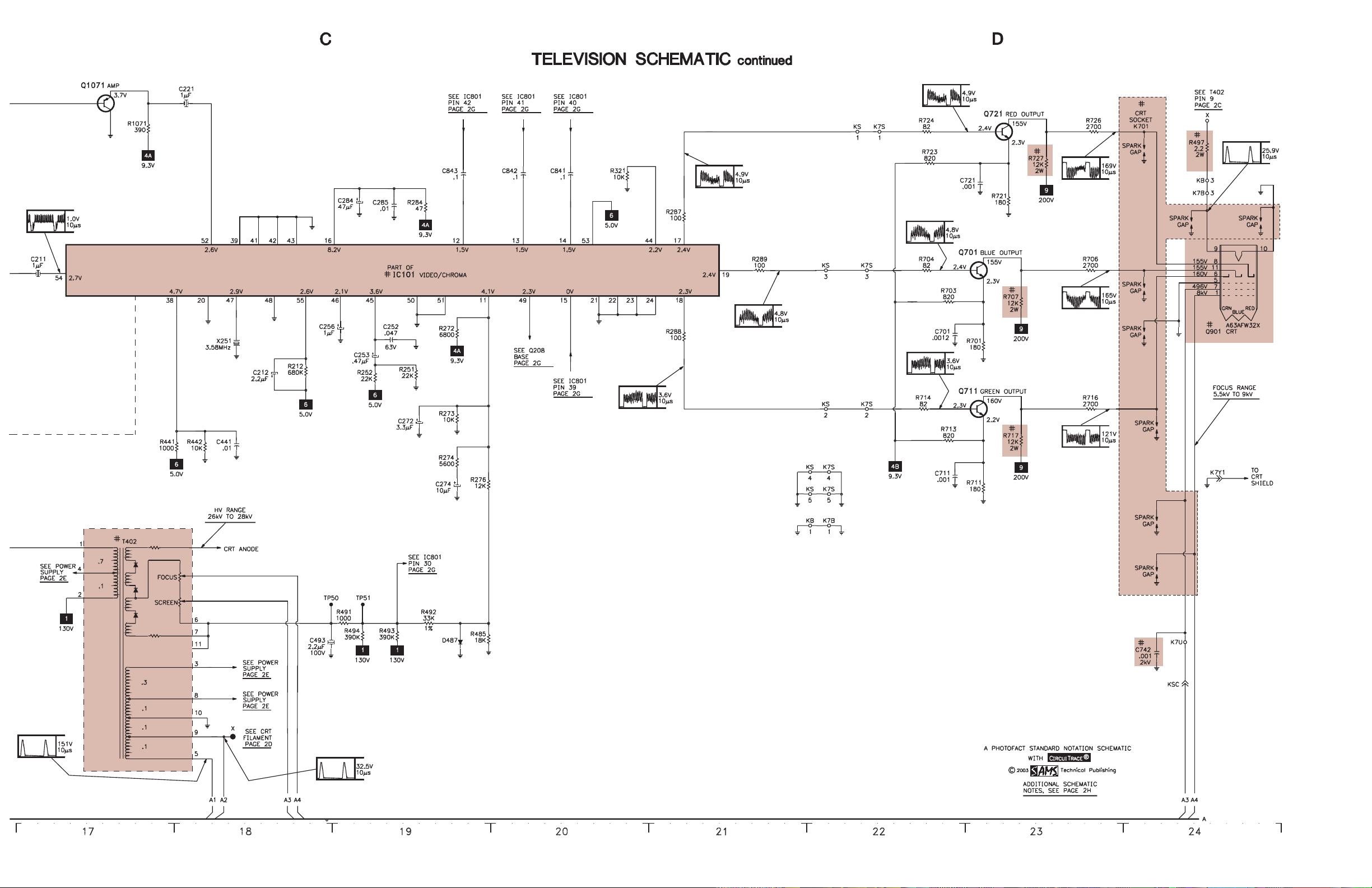

Tune in a picture. Set customer controls to minimum. Connect a high voltage probe

to CRT anode. High voltage should measure 26kV to 28kV.

ENTERING SERENTERING SER

ENTERING SERENTERING SER

ENTERING SERVICE MODEVICE MODE

VICE MODEVICE MODE

VICE MODE

Disconnect the AC power cord. While pressing the menu button on the front of the

set, connect the AC power cord. Use the channel up and down buttons to select the

service number. Use volume up and down buttons to change the value. Press the

menu button to exit the service mode.

HORIZONTHORIZONT

HORIZONTHORIZONT

HORIZONTALAL

ALAL

ALWIDTHWIDTH

WIDTHWIDTH

WIDTH

Tune in a crosshatch pattern. Enter the service mode and select service item number

47 EWD. Adjust for the proper horizontal width.

HORIZONTHORIZONT

HORIZONTHORIZONT

HORIZONTAL POSITIONAL POSITION

AL POSITIONAL POSITION

AL POSITION

Tune in a crosshatch pattern. Enter the service mode and select service item number

03 HP. Adjust for the best horizontal centering.

RF ARF A

RF ARF A

RF AGC DELAGC DELA

GC DELAGC DELA

GC DELAYY

YY

Y

Tune in a picture. Enter the service mode and select service number 42 RAD.

Adjust where no snow (noise) appears in picture.

VERVER

VERVER

VERTICAL SIZETICAL SIZE

TICAL SIZETICAL SIZE

TICAL SIZE

Tune in a crosshatch pattern. Enter the service mode and select service item number

04 VS. Adjust for proper vertical size and best vertical linearity.

VERVER

VERVER

VERTICAL CENTERINGTICAL CENTERING

TICAL CENTERINGTICAL CENTERING

TICAL CENTERING

Tune in a crosshatch pattern. Check that the pattern is centered. If too low, replace

resistor R513 1000 ohms 1/2W with a 470 ohms 1W. If too high, remove resistor

R513 1000 ohms 1/2W.

VCOVCO

VCOVCO

VCO

VCO must be adjusted after IC101, IC802, or T151 is replaced. Tune in a picture.

Connect positive lead of a digital voltmeter to pin 58 of IC101 and the negative lead

to TE7. Adjust T151 to obtain a reading of 3.6V ± 0.2V.

VIDEO LEVELVIDEO LEVEL

VIDEO LEVELVIDEO LEVEL

VIDEO LEVEL

Tune in a color bar pattern. Set picture and brightness to normal. Connect an

oscilloscope to the emitter of Q202, and the negative lead to ground. Enter the

service mode and select service number 46 VL. Adjust for 1.0Vp-p ±0.1Vp-p

waveform on the oscilloscope.

GRAGRA

GRAGRA

GRAY SCALEY SCALE

Y SCALEY SCALE

Y SCALE

Tune in an active channel. Enter the service mode. Set the value of service numbers

15 RB, 16 GB, and 17 BB to 0. Set the value of service numbers 18 RD and 20 BD

to 55. Set screen control, color, brightness, and picture to minimum. Adjust screen

control, if necessary, to obtain a barely visible horizontal line. Select service

number 73. Adjust the bias levels for a white line. Select service number 72 DRV

and adjust the drive values for normal black and white picture at all brightness

levels.

SUB BRIGHTNESSSUB BRIGHTNESS

SUB BRIGHTNESSSUB BRIGHTNESS

SUB BRIGHTNESS

Tune in a color bar pattern. Set picture and brightness to normal. Connect positive

lead of a digital voltmeter to TP51 and the negative lead to TP50. Enter the service

mode and select service number 53 SB. Adjust for 820mV ±10mV.

SUB COLOR,SUB COLOR,

SUB COLOR,SUB COLOR,

SUB COLOR, SUBSUB

SUBSUB

SUBTINTTINT

TINTTINT

TINT,,,,

,SUB SHARPNESSSUB SHARPNESS

SUB SHARPNESSSUB SHARPNESS

SUB SHARPNESS

Tune in a picture. Enter the service mode. Select service number 54 SCO. Adjust for

normal color level. Select service number 55 STI. Adjust for normal flesh tones.

Select service number 56 SSH. Adjust for contrast range.

OSD HORIZONTOSD HORIZONT

OSD HORIZONTOSD HORIZONT

OSD HORIZONTAL POSITIONAL POSITION

AL POSITIONAL POSITION

AL POSITION

Tune in a local channel. Enter the service mode and select service item number 59

HR. Adjust for centered on screen menu.

SOUNDSOUND

SOUNDSOUND

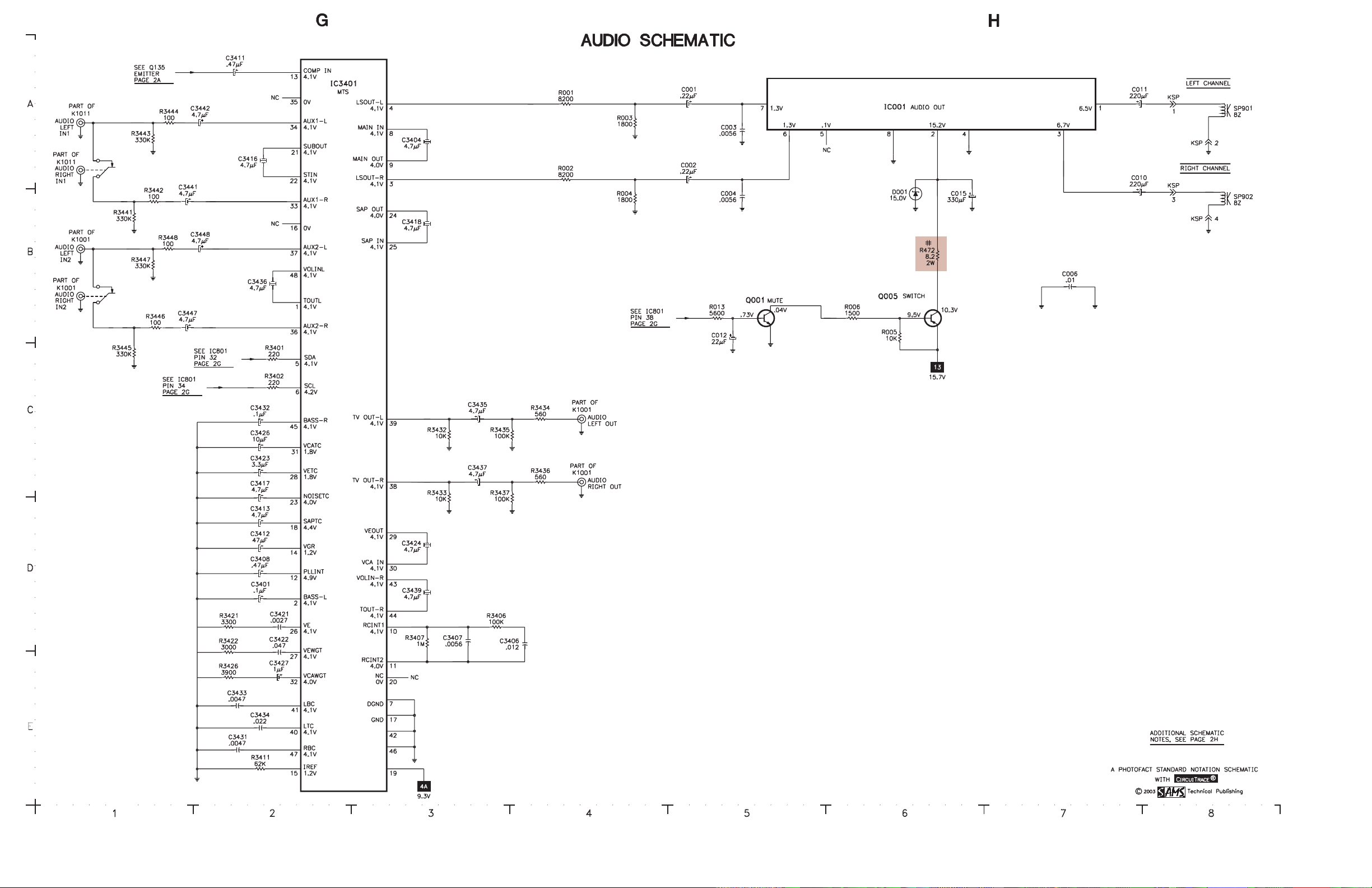

SOUND

Tune in a local channel. Connect an oscilloscope to the base of Q135, and the

negative lead to ground. Enter the service mode and select service number 45 FL.

Adjust for 0.693Vp-p ± 0.07Vp-p waveform on the oscilloscope

INPUT LEVELINPUT LEVEL

INPUT LEVELINPUT LEVEL

INPUT LEVEL

Set generator to 1kHz audio frequency and L-R modulating signal. Connect an

oscilloscope to pin 38 of IC3401. Enter service mode and select the service item

number 60 ATT. Adjust for 0.7Vp-p waveform.

SEPSEP

SEPSEP

SEPARAARA

ARAARA

ARATIONTION

TIONTION

TION

Set generator to pilot, 300Hz audio frequency, and left modulating signal. Connect

an oscilloscope to pin 38 of IC3401 and ground. Enter the service mode and select

service number 61 WDB. Adjust for minimum amplitude of the waveform. Set

generator to 8kHz audio frequency. Select service number 62 SPC and adjust for

minimum amplitude of the waveform.

PURITYPURITY

PURITYPURITY

PURITY

NOTE: Operate the receiver for 15 minutes to allow warm-up of CRT.

Use a degaussing coil to demagnetize the CRT. Tune in a green raster. Loosen the

clamp screw. Slide deflection yoke back as far as possible. Adjust purity tabs to

center the vertical green band. Slide the deflection yoke forward to produce a

uniform green screen. Tighten the clamp screw.

CONVERGENCECONVERGENCE

CONVERGENCECONVERGENCE

CONVERGENCE

Tune in a dot pattern. Loosen the clamp screw. Adjust the 4 pole magnets to

converge the red and blue dots at the center of the screen. Adjust the 6 pole magnets

to converge the red/blue dots over the green dots at the center of the screen.

NOTE: Rotate the two tabs of each set of magnets equally and opposite to converge

vertically and rotate both tabs in the same direction to converge horizontally. The 4

and 6 pole magnets interact, repeat adjustment until center convergence is correct.

Tune in a crosshatch pattern. Remove the tilt adjustment wedges between deflection

yoke and the CRT. Loosen the clamp screw. Tilt the deflection yoke up or down to

converge the vertical lines at the top and bottom of the screen and the horizontal

lines at the right and left sides of the screen. Tilt the deflection yoke to the right or

left to converge the horizontal line at the top and bottom of the screen and the

vertical line at the right and left sides of the screen. Repeat convergence procedure

if necessary to obtain best overall convergence. Replace the tilt adjustment wedges.

Tighten the clamp screw.

CRCR

CRCR

CRT NECK ASSEMBLT NECK ASSEMBL

T NECK ASSEMBLT NECK ASSEMBL

T NECK ASSEMBLYY

YY

Y

IC802 REPLAIC802 REPLA

IC802 REPLAIC802 REPLA

IC802 REPLACEMENTCEMENT

CEMENTCEMENT

CEMENT

Perform the following adjustments after replacing IC802. Enter the service mode,

select service number 03 HP and set value to 14. Select service number 07 VLN and

set value to 13. Select service number 28 PRE and set value to 3. Select service

number 37 AF and set value to 1. Select service number 57 OPT and set value to

100. Select service number 58 OP2 and set value to 32. Press the menu button to

exit service mode.

SerSer

SerSer

Servicevice

vicevice

vice VV

VV

Valuealue

aluealue

alue Initial RefInitial Ref

Initial RefInitial Ref

Initial Ref Initial SetInitial Set

Initial SetInitial Set

Initial Set On-SetOn-Set

On-SetOn-Set

On-Set

No.No.

No.No.

No. AdjustmentAdjustment

AdjustmentAdjustment

Adjustment RangRang

RangRang

Rangee

ee

eVV

VV

Valuealue

aluealue

alue UpUp

UpUp

Up VV

VV

Valuealue

aluealue

alue VV

VV

Valuealue

aluealue

alue NotesNotes

NotesNotes

Notes

01 HFR 0 - 63 29 29 29 Horizontal Frequency

02 AFC 0, 1 0 0 0 AFC Gain

03 HP 0 - 31 15 14 14 H-Position (H-Centering)

04 VS 0 - 127 64 64 51 Vertical Size

05 VPO 0 - 63 5 5 5 Vertical Position

06 VSP 0, 1 0 0 0 Vertical Set Up

07 VLN 0 - 31 18 13 13 Vertical Linearity

08 CRS 0 - 3 0 0 0 Cross B/W

09 GRY 0, 1 1 1 1 Gray Mode

10 VSC 0 - 31 8 8 8 Vertical S Correction

11 HBR 0 - 7 3 3 3 H BLK R

12 HBL 0 - 7 4 4 4 H BLK L

13 CDM 0, 1 0 0 0 CD Mode

14 VC 0 - 7 7 7 7 Vertical Compression

15 RB 0 - 255 0 0 0 Red Bias

16 GB 0 - 255 0 0 0 Green Bias

17 BB 0 - 255 0 0 7 Blue Bias

18 RD 0 - 127 64 64 85 Red Drive

19 GD 0 - 15 8 8 8 Green Drive

20 BD 0 - 127 64 64 62 Blue Drive

21 SBI 0 - 127 48 48 48 Sub Bias

22 OSD 0 - 3 3 3 3 OSD Contrast

23 POS 0, 1 0 0 0 Pre/Over/SW

24 FLS 0 - 7 1 1 1 Filter System

25 CKO 0 - 7 3 3 3 Color Killer Operation

26 GYA 0, 1 0 0 0 G-Y Angle

27 CRG 0 - 3 2 2 2 Coring Gain

28 PRE 0 - 3 1 3 3 Pre Shoot Adjust

29 WP 0, 1 0 1 1 White Peak Limiter, 0 = On, 1 = Off

30 FSW 0, 1 0 0 0 FBP Blanking Switch

31 VBL 0, 1 0 0 0 Vertical Blanking Switch

32 BSG 0 - 3 2 2 2 Black Stretch Gain

33 BSS 0 - 3 1 1 1 Black Stretch Start

34 DCR 0 - 3 1 1 1 DC Reset

35 YGM 0 - 3 1 1 1 Y Gamma

36 CBP 0, 1 0 0 0 C Bypass

37 AF 0, 1 0 1 1 Auto Flesh, 0 = Off, 1 = On

38 BAT 0 - 7 4 4 4 Bright ABL Threshold

39 MSD 0, 1 0 0 0 Mid Stop Def

40 ABL 0, 1 0 0 0 ABL Defeat, 0 = On, 1 = Off

41 RYA 0 - 15 2 2 2 R-Y/B-Y Angle

42 RAD 0 - 63 15 15 37 RF AGC Delay

43 IAS 0, 1 0 0 0 IF AGC Switch, 0 = TV (Normal), 1 = AV (IF Gain Minimum)

44 FMM 0, 1 0 0 0 FM Mute

45 FL 0 - 31 15 15 10 FM Level

46 VL 0 - 7 4 4 5 Video Level

47 EWD 0 - 63 39 39 39 EW DC

48 EWA 0 - 63 30 30 30 EW Amp

49 EWT 0 - 63 34 34 34 EW Tilt

50 EWP 0 - 7 7 7 7 EW Corner Top

51 EWB - 8 8 8 EW Corner Bottom

52 HSC - 7 7 7 Horiz Size Comp

53 SB 0 - 63 32 32 31 Sub Brightness

54 SCO 0 - 31 7 7 7 Sub Color

55 STI 0 - 31 20 20 20 Sub Tint

56 SSH 0 - 15 12 12 12 Sub Sharpness

57 OPT 0 - 255 0 100 100 Option, data 1 should be set to 100, in binary 8 bit 01100100

58 OP2 0 - 255 0 32 32 Option, data 2 should be set to 32, in binary 8 bit 0 0100000

59 HR 0 - 63 27 27 27 OSD Horizontal Position

60 ATT 0 - 15 10 7 8 Attenuation

61 WDB 0 - 63 32 32 34 Wide Band

62 SPC 0 - 63 32 32 11 Spectral

63 SBO 0 - 255 5 5 5 Sub Bright Offset

64 PCO 0 - 63 40 40 40 PIP Color

65 PTI 0 - 63 40 40 40 PIP Tint

66 PUV 0 - 63 24 24 24 PIP Top Position

67 PDV 0 - 255 147 147 147 PIP Bottom Position

68 PLH 0 - 63 10 10 10 PIP Left Position

69 PRH 0 - 255 101 101 101 PIP Right Position

70 PCN 0 - 63 42 42 52 PIP Y Level

71 PBS 0 - 63 15 15 15 PIP BGP Phase

72 DRV 0 - 127 64 64 R 85 Red Drive, press 1 to decrease value and 3 to increase value.

DRV 0 - 127 64 64 B 62 Blue Drive, press 7 to decrease value and 9 to increase value.

73 - 0 - 255 0 0 0 Red Bias, press 1 to decrease value and 3 to increase value.

- 0 - 255 0 0 0 Green Bias, press 4 to decrease value and 6 to increase value.

- 0 - 255 0 0 0 Blue Bias, press 7 to decrease value and 9 to increase value.

74 R00

Thru Thru

146 R72 0 - 255 - 0 0 -

SERVICE MODE ADJUSTMENT CHART