Sanyo FVM3982 User manual

Other Sanyo TV manuals

Sanyo

Sanyo DS19310 User manual

Sanyo

Sanyo C28ER57 User manual

Sanyo

Sanyo CP21AF1VA User manual

Sanyo

Sanyo TS4421S User manual

Sanyo

Sanyo CPP2930TX User manual

Sanyo

Sanyo 21DN2F User manual

Sanyo

Sanyo AVM-32F4, AVM32F9 User manual

Sanyo

Sanyo CE32FWH1F-C User manual

Sanyo

Sanyo C29LF37 User manual

Sanyo

Sanyo DP26649 - 26" LCD TV User manual

Sanyo

Sanyo C21LB29S User manual

Sanyo

Sanyo DS27930, DS32424 User manual

Sanyo

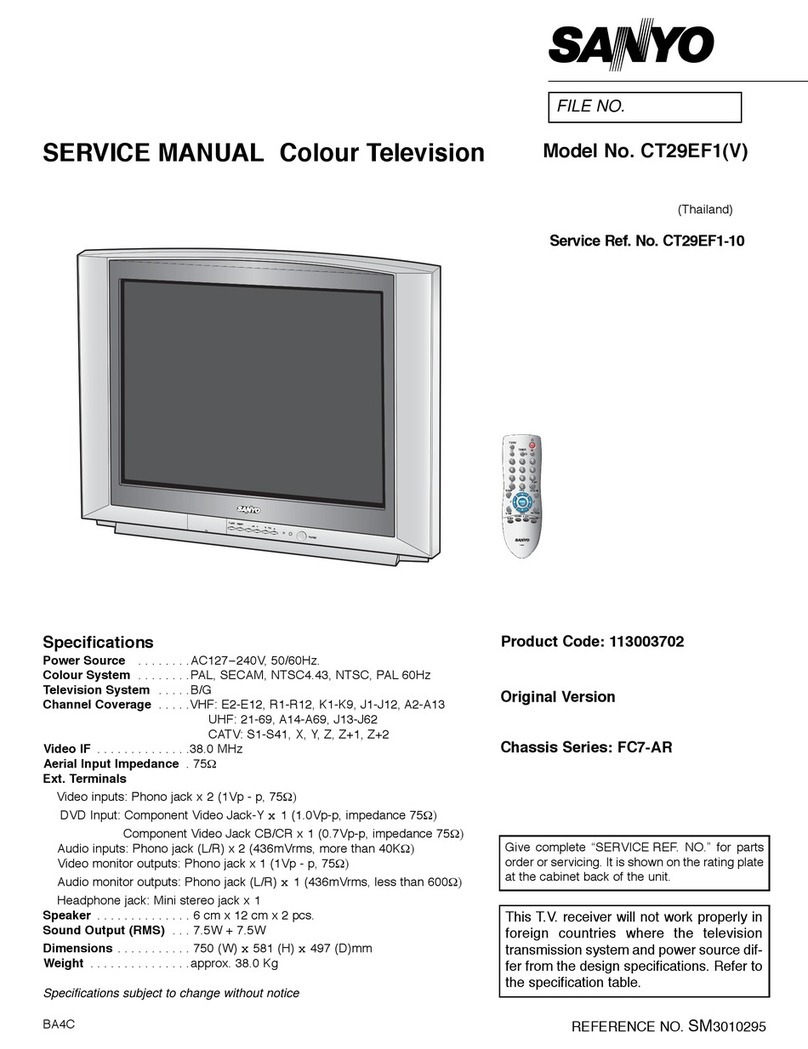

Sanyo CT29EF1 User manual

Sanyo

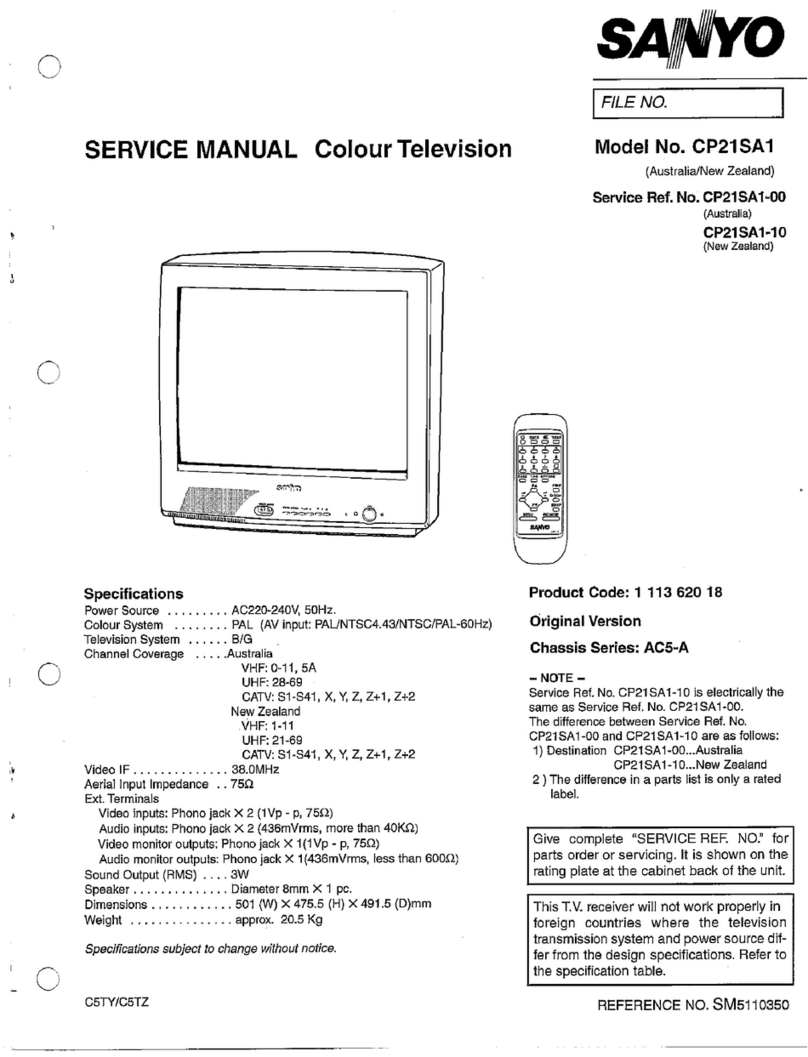

Sanyo CP21SA1 User manual

Sanyo

Sanyo DP26746 - 26" LCD TV Product information sheet

Sanyo

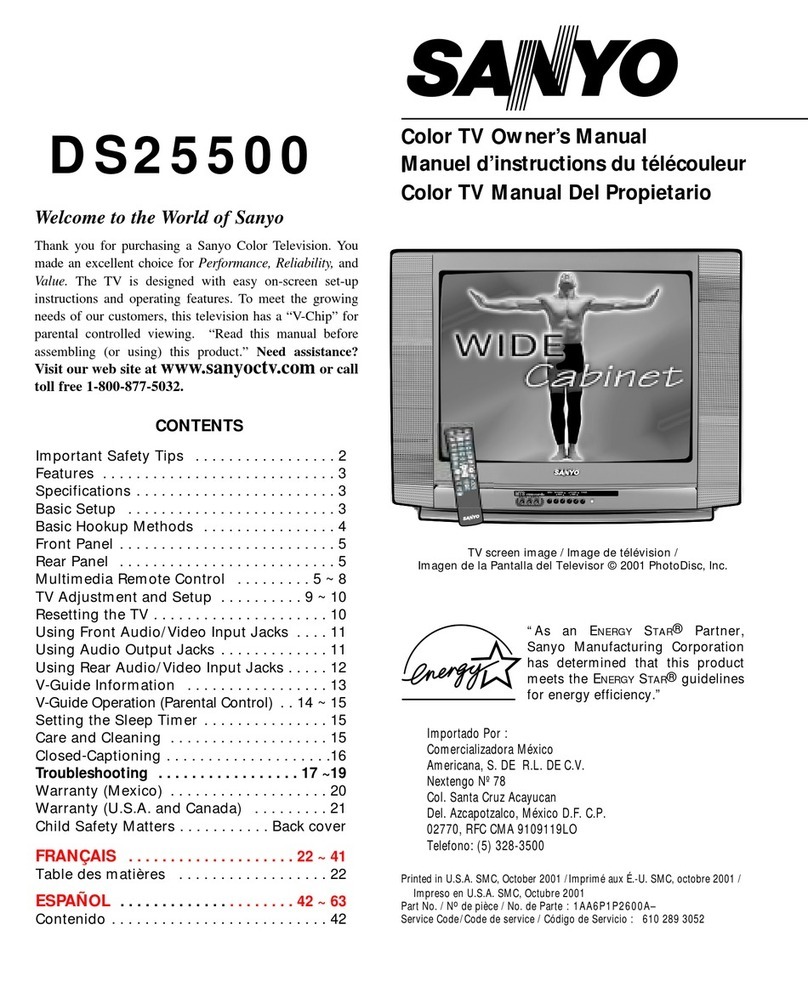

Sanyo DS25500 User manual

Sanyo

Sanyo CE28WN4J-B User manual

Sanyo

Sanyo D32830H User manual

Sanyo

Sanyo AVM-2550S, AVM-2759S Installation guide

Sanyo

Sanyo DS32224 Operation and maintenance manual