2

TECHNICAL FEATURES

1. Flame detection

The following types of flame detector can be employed:

– Ionisation electrode, where the mains supply provides a

neutral earth connection. Suitable for gas burners (signal

current from flame cannot be influenced by interference

from ignition spark).

– UV sensor type UVZ 780 red, suitable for gas and combi

burners.

– Infra-red flicker detector type IRD 1020.1 for all types of

burner.

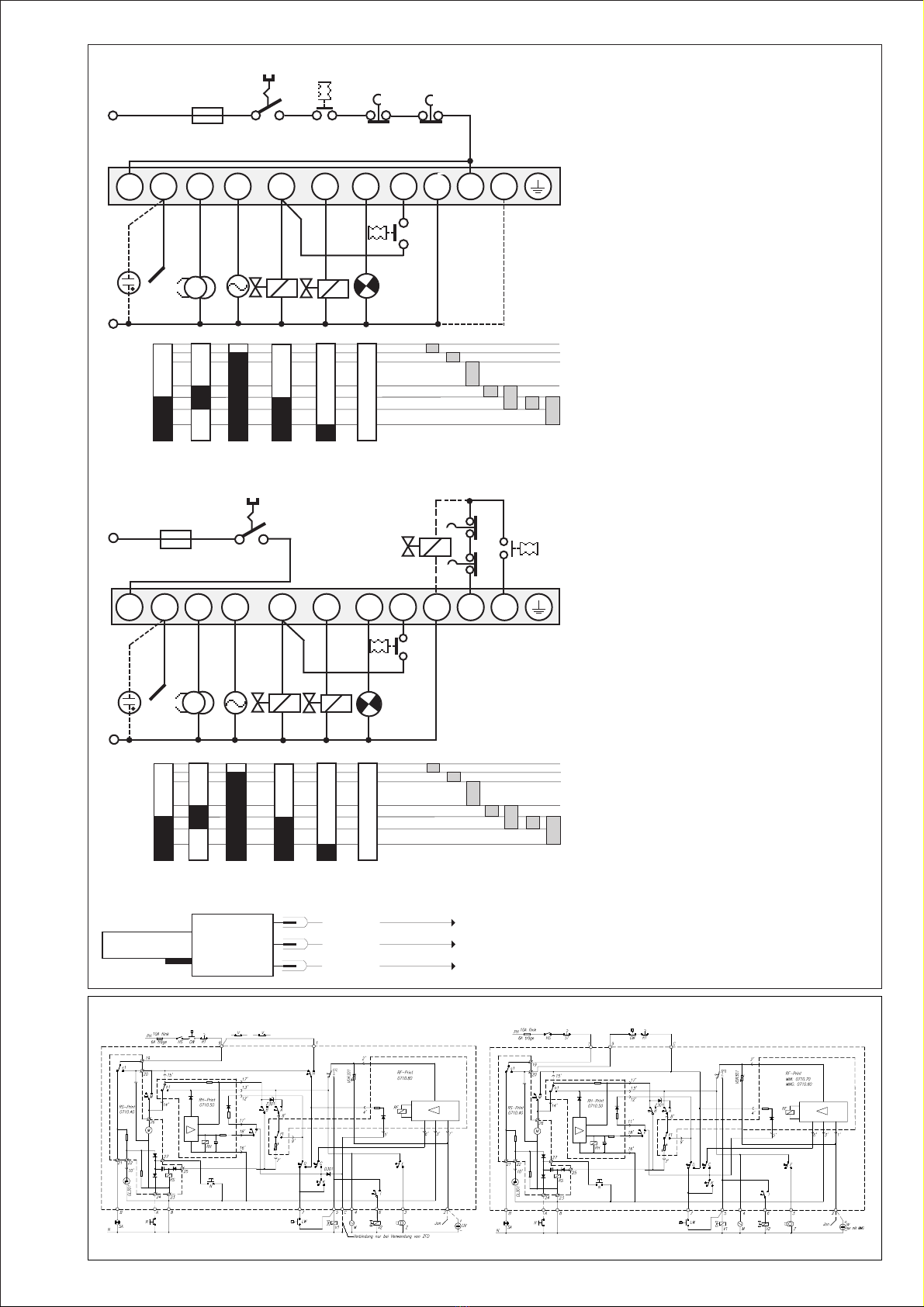

2. Burner Control

– The burner controls features a low-voltage protection. If

the supply voltage dropps below 160 V during operation,

the burner switches-off. When the supply voltage raises

above 180 V, the burner performs a restart independently.

– The MMG control boxes only operate when a load is

connected to terminal 5. If the fuel valve is isolated during

the pre-purge by way of an external switch contact, a

resistor with a value of max. 22 kΩ/4 watts, must be

connected between terminals 5 and 8.

– Functional check of the air proving switch before the

start, and monitoring of the air pressure during pre-purge

as well as during normal operation. In normal use, switch

contacts with a rating of 4 A / 220 V are sufficient.

– On the MMG 810.1, switch contacts (e.g. valve end

contact) can be wired between terminals 1 and 9. These

contacts are checked for proper closure during the

burner start phase. The connection between terminals 1

and 9 must be complete during the start phase.

– The MMG 810.1 control box monitors the ignition spark

if the UVZ 780 (red) is used for flame detection, and

terminals C and 9 are wired together.

3. Safety

The design/construction and programme sequence of the

control boxes in the MMG series conform to the present

applicable European standards and regulations.

4. Installation

At the base:

– 3 earth terminals with additional terminal for burner

earthing

– 3 neutral terminals with internal permanent connection to

neutral terminal 8

– 2 independant spare terminals (S1 and S2)

– extra terminals A, B and C are standard

– 2 slide-in plates and 2 easy knock out holes plus 2 knock

out holes in the base bottom faciliate the base wiring

Please note

To assist trouble-free operation the main neutral connection

terminal 8 in the wiring base must be fully tightened. The

terminal screws are already in the undone position. To

connect a wire to the terminal, the screw only needs to be

fastened.

General:

– Can be mounted in any position, insulated as per IP 44

standard (unaffected by water spray). The control box

and detector probes should however not be subjected to

excessive vibration.

– The applicable installation regulations must be observed

during installation.

COMMISSIONING AND MAINTENANCE

1. Important

– The wiring must be checked exactly when commissioning

the installation. Incorrect wiring could damage the control

box, putting the safety of the burner system at risk.

– The chosen fuse rating must not, on any account, be

higher than the value given in the technical data. Failure

to observe this instruction could, in the case of a short

circuit, have serious consequences for the control box or

burner system.

– For safety reasons, it must be ensured that the control

box performs at least one normal shut-down during every

24 hour period.

– Switch off or disconnect the power before plugging in or

unplugging the unit.

– Control boxes are safety devices and should not to be

interfered with.

2. Functional Check

During commissioning and after an overhaul of the burner,

the following checks have to be carried out:

a) Starting test with closed manual valve and bridged gas

monitor contact:

–The device must go into a fault condition after the

safety period has elapsed.

b) Close the manual valve in operating position with the gas

monitor contact bridged.

–The device must go into a fault condition after a flame

failure.

c) Air pressure monitor contact interrupted:

–Device goes into a fault condition.

d) Bridge air pressure monitor contact before starting:

–Device must not start.

3. Trouble Shooting

Burner does not go into operation, programme indication

remains:

–Electrical connection defective.

–Thermostat or gas monitor "OFF".

Burner does not go into operation, programme indication

rotates continuously:

–Air pressure monitor defective, respectively, not in starting

position. (Working contact must be open).

– Connection term. 1 - term. 9 interrupted

– mains voltage < 180V

The automatic control switches to fault condition shortly

after the start of the pre-purge time (line within the blue

zone):

–Air pressure monitor contact does not close.

–No load on terminal 5.

–Flame signal.

Automatic control switches to fault condition during the pre-

purging (blue zone):

–No flame formation (ignition missing, valve does not

open, etc.)

–No flame signal or too weak flame signal (flame does not

adhere, poor insulation of the flame detector, burner not

properly connected to the earth conductor).

Automatic control switches to fault condition during the

operating position (red, resp. green zone):

–Flame lift-off

–Air pressure monitor contact opens

–Flame signal too weak.

MMG 810.1 / 811.1