2

TABLE OF CONTENTS

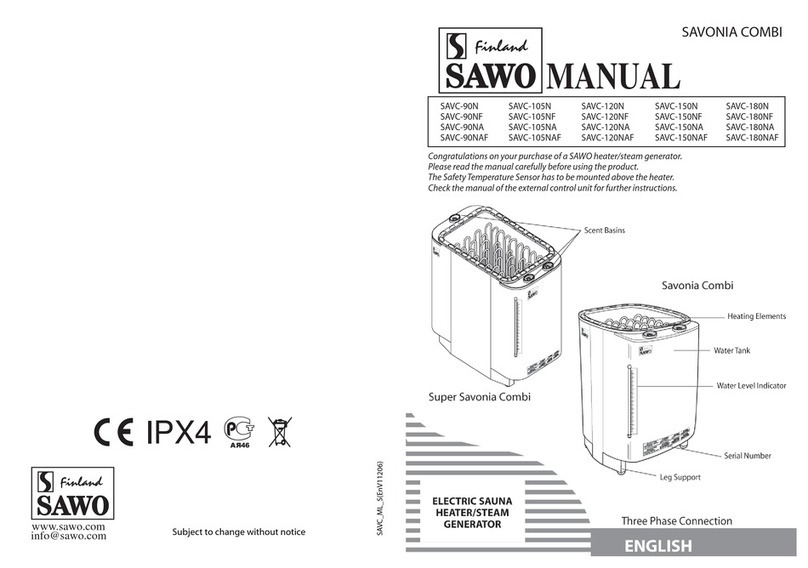

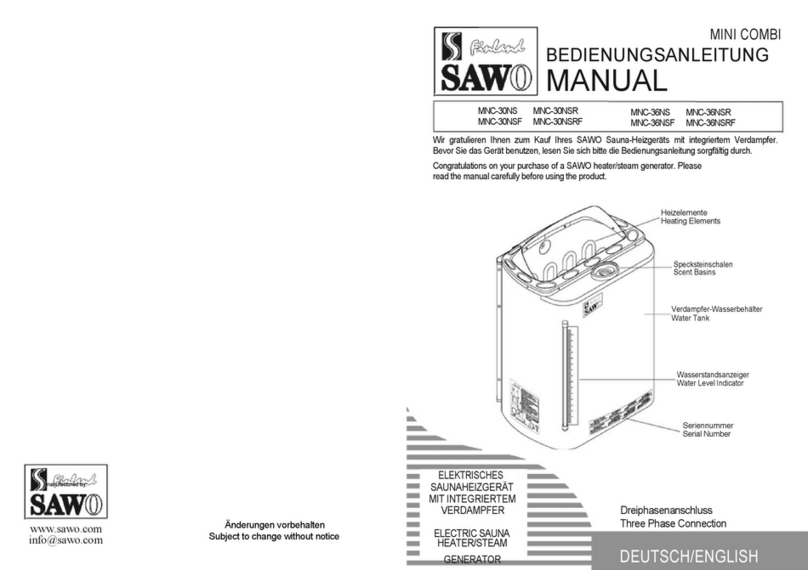

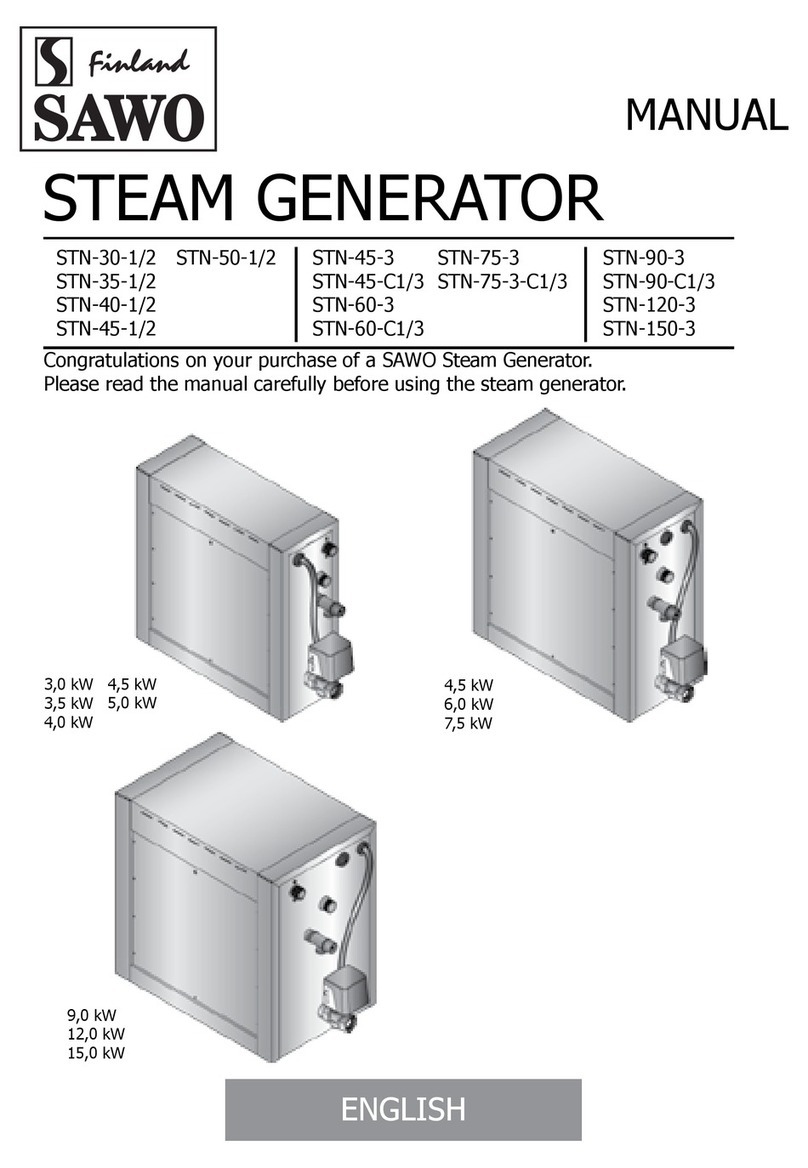

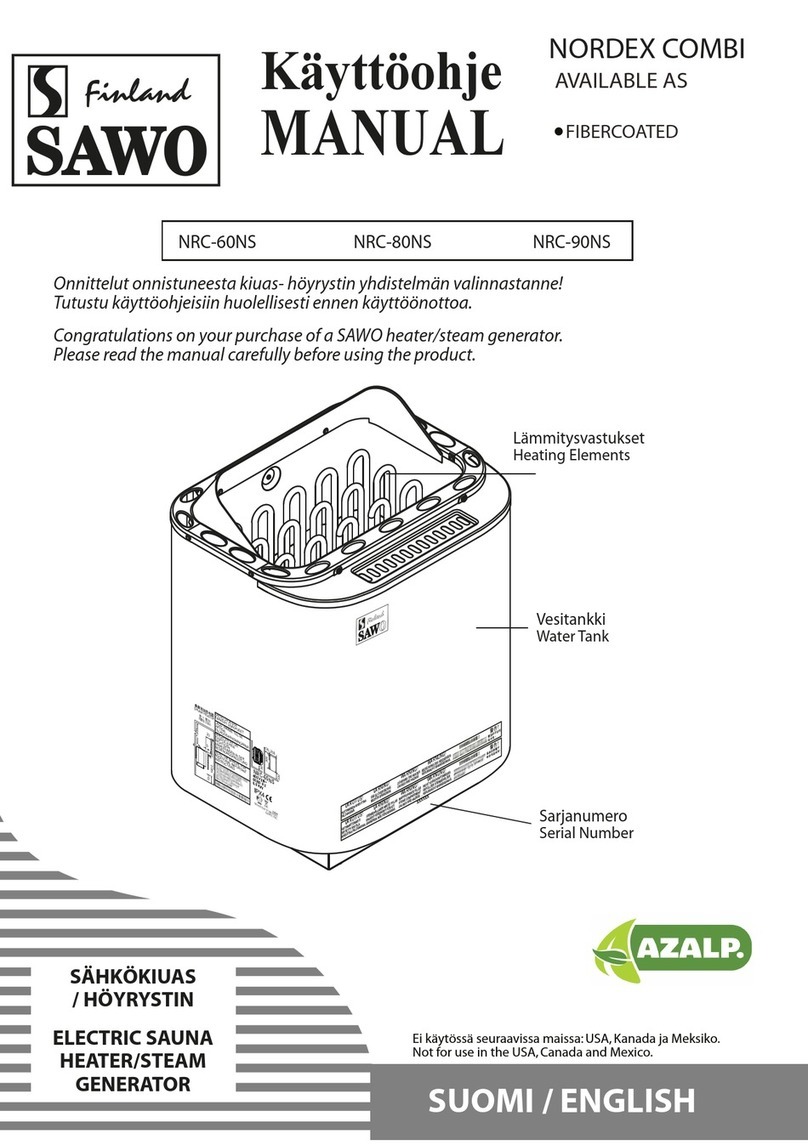

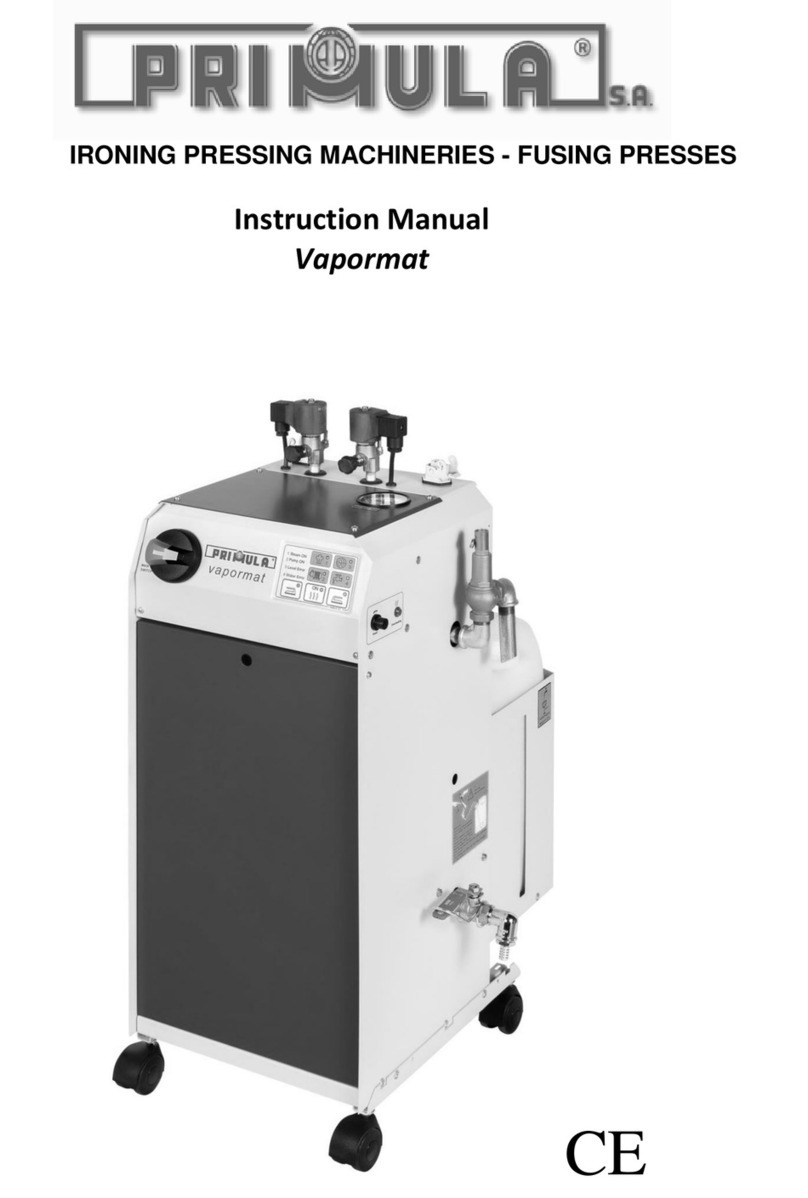

Steambath Generator Systems

Installation, Operation & Maintenance Manual

This highlights information

that is especially relevant

to a problem-free

installation.

IMPORTANT NOTE:

signals a situation where

minor injury or product

damage may occur if you

do not follow instructions.

!

CAUTION

IMPORTANT NOTE: As you follow these instructions, you will notice warning and caution symbols. This

blocked information is important for the safe and efficient installation and operation of this generator.

These are types of potential hazards that may occur during this installation and operation:

states a hazard may

cause serious injury

or death if precautions

are not followed.

!

WARNING

Before Installing..............................................................................

Locating the Steam Generator....................................................

Installation.......................................................................................

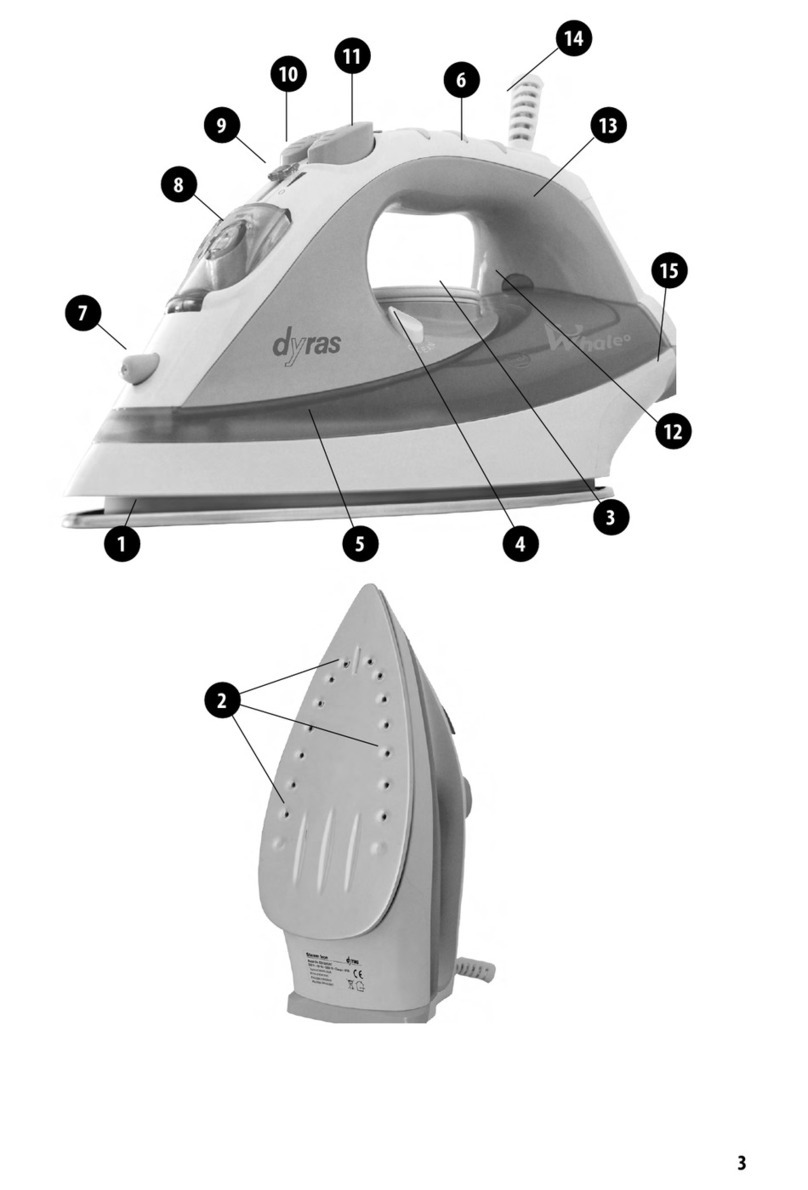

Generator Diagram.......................................................................

Electrical............................................................................................

Field Power Wiring..........................................................................

Wiring Diagrams............................................................................

Optional Tandem Cable................................................................

for connecting 2-5 steam generators in tandem

Optional Automatic Drain System.............................................

Technical Data................................................................................

Steam Generator Parts..................................................................

Installing the Remote Temperature Probe................................

SAWO Control..................................................................................

Connection of SAWO Control and Temperature............

Preventive Maintenance......................................................

3

IMPORTANT: The following general information should be used in conjunction with

consultations with your architect, designer and contractor in determining all factors necessary

in providing a suitable and safe steam room.

Read these instructions before installation or service. Although this steambath generator

has been fully qualified for shipment by SAWO, the following must be reviewed for proper,

safe and enjoyable steam bathing.

Verify that the model and accessories are correct, including incoming line voltage.

Insure steambath generator has been correctly sized for the steambath room. Pay particular

attention to room volume and construction. If any questions, please refer to SAWO sizing

guide enclosed (see page 13).

Marble or glass walls or ceilings, or exterior walls "ENLARGE" the room's size, requiring a

generator larger than one based only on the room's (L x H x W) volume.

The physical size of the unit, clearance for plumbing servicing, and its distance from the steam

room must all be considered before final installation.

IMPORTANT: SAWO units are designed to function using only SAWO controls. Both should be

installed in strict accordance with the specific instructions contained in the manuals provided.

A separate manual is provided for the installation of the SAWO controls as well.

Electrical shock hazard. SAWO AS steam generators are connected to 220-240V

(One Phase models only: STS45-1,STS60-1, STS75-1and STS90-1), or 380-430V (Three Phase

models only: STS45-3, STS60-3, STS75-3, STS90-3, STS120-3and STS150-3) line voltage and

contain live electrical components. All installation and service to be performed by qualified

and licensed electricians and plumbers only. Installation or service by unqualified persons may

void the warranty.

The Steam Room must be fully enclosed, complete with walls, door, flooring and ceiling.

We recommend rubber linings (e.g. gaskets) for the door to effectively seal the heat and

contain the steam inside the Steam Room.

If tiles are used for the flooring or some other smooth surface material, provide suitable

anti-skid strips or rubberized mats to prevent slipping resulting to injury.

Materials used for the walls and ceiling should have water-resistant, non-corrosive surfaces

such as tiles, marbles, molded acrylic, or other non-porous materials.The ceiling should be

dome-shaped to prevent the dripping of condensate. If using an acrylic, a fiberglass or other

non-heat resistant materials are to be used as part of the Steam Room enclosure.

A drain must be provided in the flooring.

Heating, venting or air conditioning devices should not be installed inside the Steam Room.

Steam Room windows should be double paned.

Limit the Steam Room ceiling to a height of 2.5 meters. Exceeding 2.5m will require a

higher-rated steam generator.

SAWO strongly recommends for the“WARNING”(when to or not to use the Steam Room) to be

posted in a conspicuous place near the Steam Room.

Steam Room Guidelines

Before Installing

•

•

•

•

•

1.

2.

3.

4.

5.

6.

7.

8.

9.

!

WARNING

1.

2.

3.

4.

5.

Children, 16 years old and under, should not be allowed to use the Steam Room.

Consult a doctor before using the Steam Room especially for pregnant women or those who have

a heart condition or undergoing medical treatment.

Immediately stop using the Steam Room if you feel faint, dizzy,and drowsy or experience extreme discomfort.

Do not use the Steam Room if you have been recently drinking alcohol.

Installation of non-skid floor materials or the use of proper footwear is a must at all times when inside the

Steam Room to prevent slipping that may result to injury.The Steam Room floor and other surfaces could

become slippery as a result of condensation and moisture.

IMPORTANT! Read the manual provided for use and safety information.

SAWO

SAWO, Inc. SAWO Building Mactan Export Processing Zone 2 Cebu, Philippines 6015 www.sawo.com

!

W A R N I N G

TABLE OF CONTENTS

STS75-3

STS90-1

STS90-3

STS120-3

STS150-3Z

MODELS:

STS45-1

STS45-3

STS60-1

STS60-3

STS75-1

Steambath Generator Systems

Installation, Operation & Maintenance Manual

This highlights information

that is especially relevant

to a problem-free

installation.

IMPORTANT NOTE:

signals a situation where

minor injury or product

damage may occur if you

do not follow instructions.

!

CAUTION

IMPORTANT NOTE: As you follow these instructions, you will notice warning and caution symbols. This

blocked information is important for the safe and efficient installation and operation of this generator.

These are types of potential hazards that may occur during this installation and operation:

states a hazard may

cause serious injury

or death if precautions

are not followed.

!

WARNING

3

4

5

6

7

8

9

10

12

13

14

15

17

20

21