2001-05:1 © Scania Industrial & Marine Engines 3

CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ENVIRONMENTAL RESPONSIBILITY . . . . . .4

CERTIFIED ENGINES . . . . . . . . . . . . . . . . . . . .5

SAFETY DETAILS . . . . . . . . . . . . . . . . . . . . . . .6

Safety precautions for operation . . . . . . . . . . . .7

Safety precautions for handling materials . . . . .8

Safety precautions for care and maintenance . .8

TYPE DESIGNATIONS . . . . . . . . . . . . . . . 10

DEC2 CONTROL SYSTEM . . . . . . . . . . . . 12

STARTING AND RUNNING . . . . . . . . . . . 18

AT FIRST START . . . . . . . . . . . . . . . . . . . . . . .18

CHECKS BEFORE RUNNING . . . . . . . . . . . . .19

STARTING THE ENGINE . . . . . . . . . . . . . . . .19

At temperatures below 0 °C: . . . . . . . . . . . . . .20

RUNNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Engine speed . . . . . . . . . . . . . . . . . . . . . . . . . .21

Coolant temperature . . . . . . . . . . . . . . . . . . . .21

Oil pressure . . . . . . . . . . . . . . . . . . . . . . . . . . .22

STOPPING THE ENGINE . . . . . . . . . . . . . . . . .22

Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

CHECKS AFTER RUNNING . . . . . . . . . . . . . .23

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 24

ENGINES WITH FEW HOURS

OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . .24

MAINTENANCE SCHEDULE . . . . . . . . . . . . .25

LUBRICATING OIL SYSTEM . . . . . . . . . 26

OIL GRADE . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Oil analysis . . . . . . . . . . . . . . . . . . . . . . . . . . .26

CHECKING THE OIL LEVEL . . . . . . . . . . . . .27

OIL CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . .27

Maximum angles of inclination during

operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

CLEANING THE OIL CLEANER . . . . . . . . . .28

CHANGING THE OIL FILTER . . . . . . . . . . . .30

COOLING SYSTEM . . . . . . . . . . . . . . . . . . 30

CHECKING COOLANT LEVEL . . . . . . . . . . .30

CHECKING CORROSION BARS . . . . . . . . . . .31

CHECKING THE SEA WATER PUMP

IMPELLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

CHECKING THE COOLANT . . . . . . . . . . . . . .32

Changing the coolant . . . . . . . . . . . . . . . . . . .34

CLEANING THE COOLING SYSTEM . . . . . .35

Internal cleaning . . . . . . . . . . . . . . . . . . . . . . .37

AIR CLEANER . . . . . . . . . . . . . . . . . . . . . . . 38

READING THE VACUUM INDICATOR . . . .38

CLEANING THE AIR CLEANER

COARSE CLEANER . . . . . . . . . . . . . . . . . . . . .38

CLEANING OR CHANGING THE

FILTER ELEMENT . . . . . . . . . . . . . . . . . . . . . .38

CHANGING SAFETY CARTRIDGE . . . . . . . .40

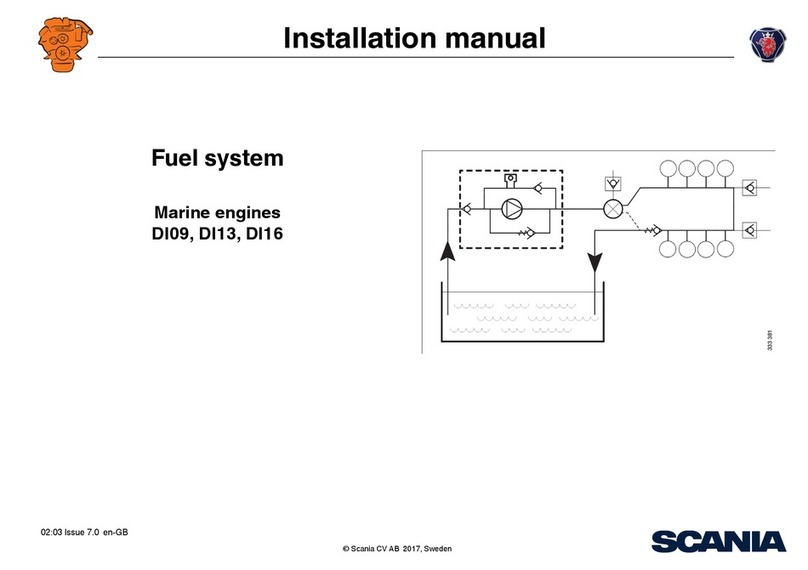

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . 41

CHECKING FUEL LEVEL . . . . . . . . . . . . . . . .41

CHANGING THE FUEL FILTER . . . . . . . . . . .41

CHECKING INJECTORS . . . . . . . . . . . . . . . . .42

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . 43

CHECKING THE

ELECTROLYTE LEVEL IN BATTERIES . . . .43

CHECKING THE STATE OF CHARGE

IN BATTERIES . . . . . . . . . . . . . . . . . . . . . . . . .43

CLEANING BATTERIES . . . . . . . . . . . . . . . . .43

CHECKING THE COOLANT LEVEL

MONITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

CHECKING THE

TEMPERATURE MONITOR . . . . . . . . . . . . . .45

CHECKING THE TEMPERATURE SENSOR .45

CHECKING THE OIL PRESSURE SEN-

SOR/MONITOR . . . . . . . . . . . . . . . . . . . . . . . . .46

CHECKING THE OIL PRESSURE MONITOR

FOR DEC 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

CHANGING THE BATTERY . . . . . . . . . . 47

MISCELLANEOUS . . . . . . . . . . . . . . . . . . . 47

CHECKING THE DRIVE BELT . . . . . . . . . . . .47

CHECKING FOR LEAKAGE, RECTIFY

AS NECESSARY . . . . . . . . . . . . . . . . . . . . . . . .48

CHECKING/ADJUSTING VALVE

CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . .49

CHANGING (OR CLEANING) THE CLOSED

CRANKCASE VENTILATION VALVE . . . . .50

LONG-TERM STORAGE . . . . . . . . . . . . . . 51

Preservative fuel . . . . . . . . . . . . . . . . . . . . . . .51

Preservative oil . . . . . . . . . . . . . . . . . . . . . . . .52

Preparations for storage . . . . . . . . . . . . . . . . .52

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Taking out of storage . . . . . . . . . . . . . . . . . . .53

TECHNICAL DATA . . . . . . . . . . . . . . . . . . 54

FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ALPHABETIC INDEX . . . . . . . . . . . . . . . . 58

https://www.boat-manuals.com/scania/