User guide OC 2010 (UK 07/2011 CE) page 6 of 16

2.0. Installation

2.1. Control at delivery

Afterunpacking,pleaseconrmthatthedelivereditemsareinaccordancewiththepackinglist.

Possible inconsistencies should be reported to the supplier immediately. If some parts are dam-

aged please contact the shipping company.

2.2. Instrument identication

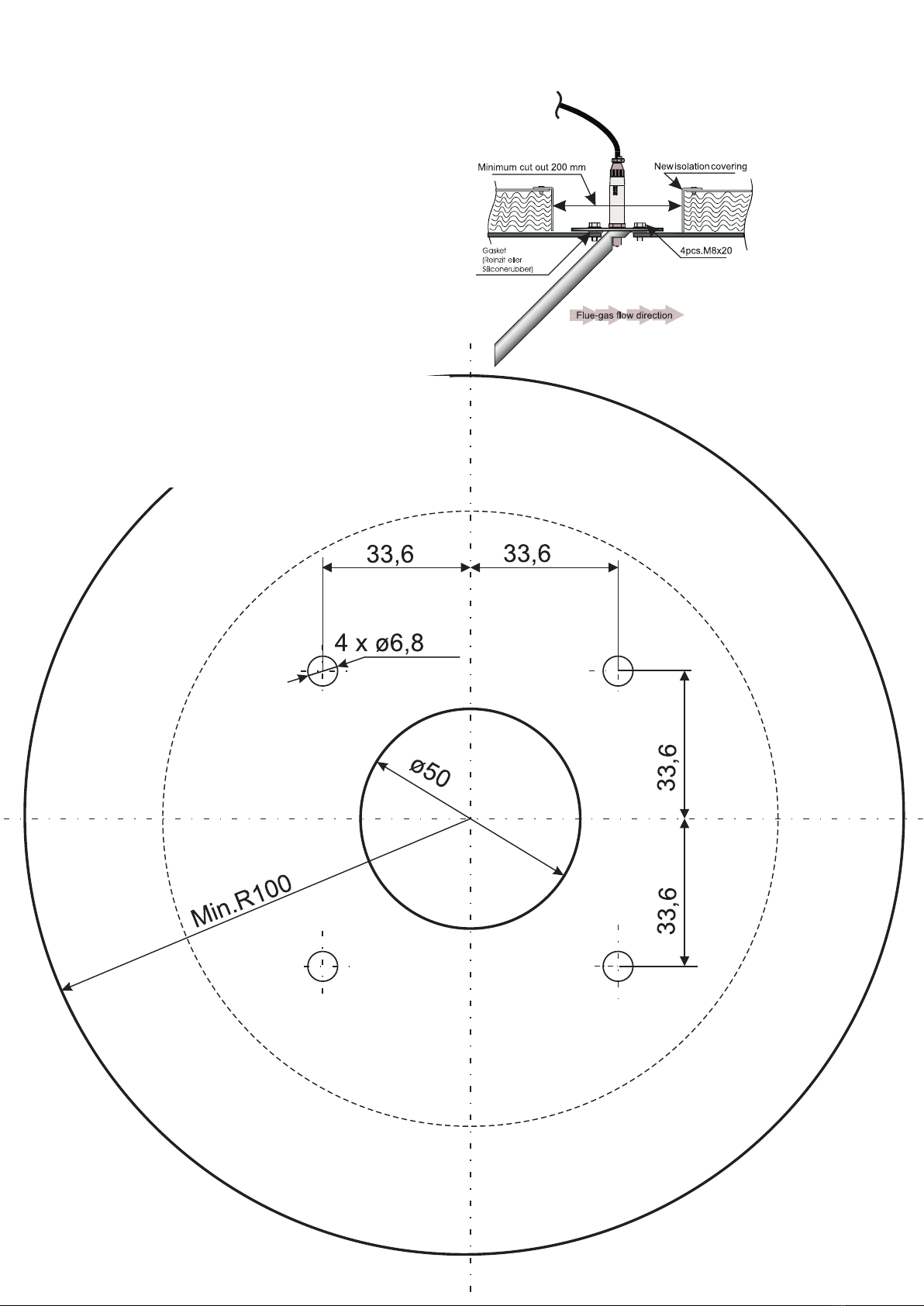

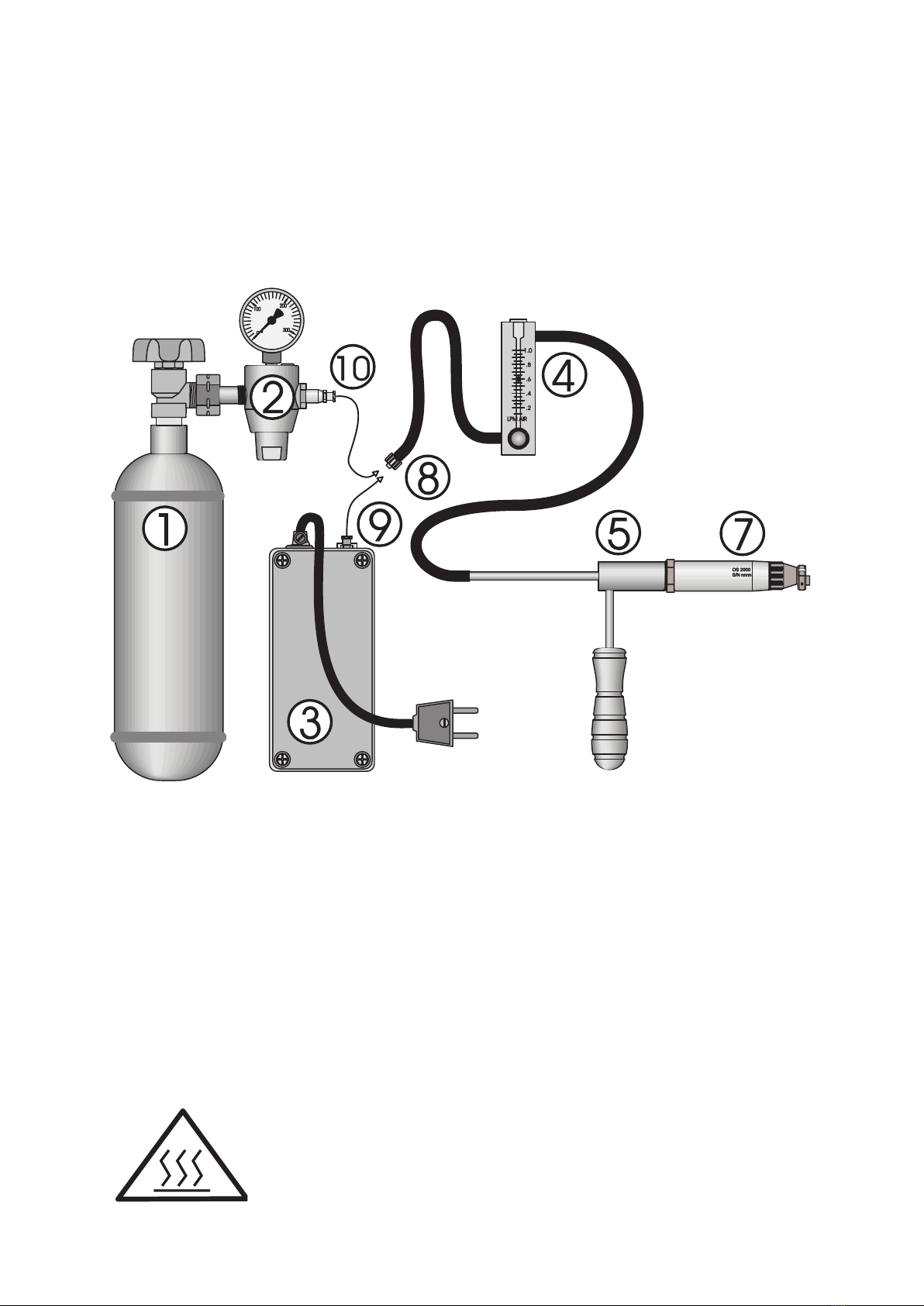

The oxygen control system OC 2010-LSU, as standard, consists of a measuring probe OS 2014,

andsignalamplierOC2010-LSU,aguidetubeincludingagasketand4mountingscrewsare

optional.

Measuring probe

The measuring probe contains a measuring cell,

a heating element and a connection cable with

a multipole connector.

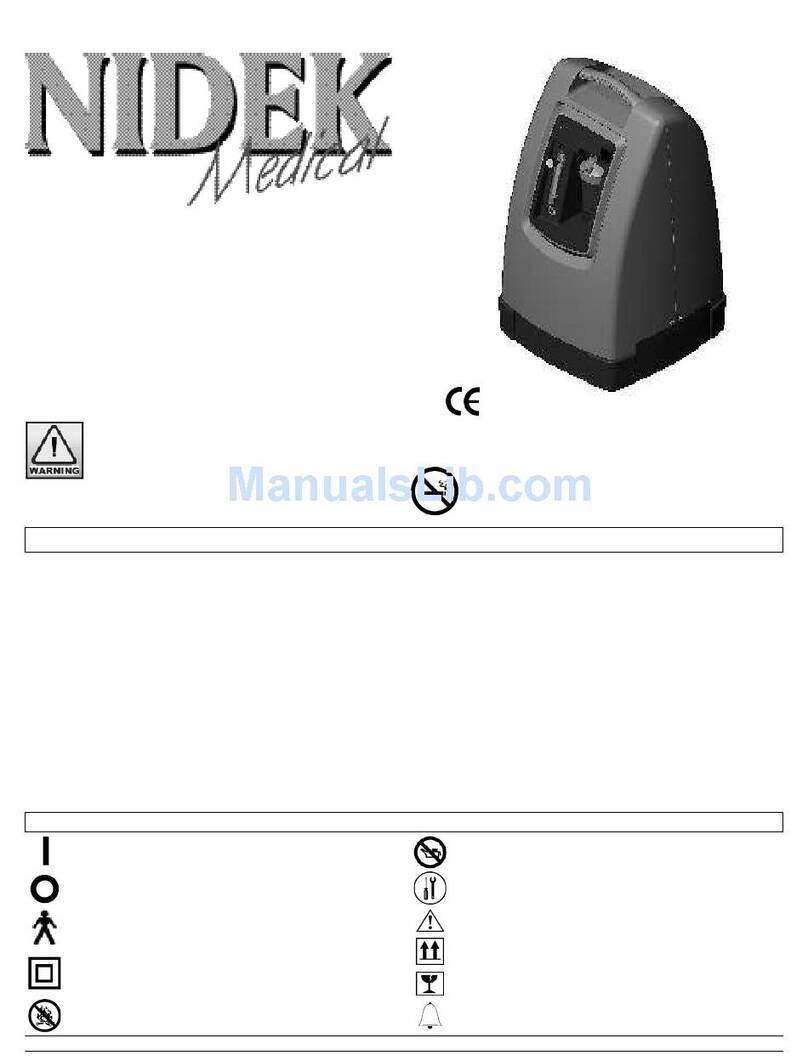

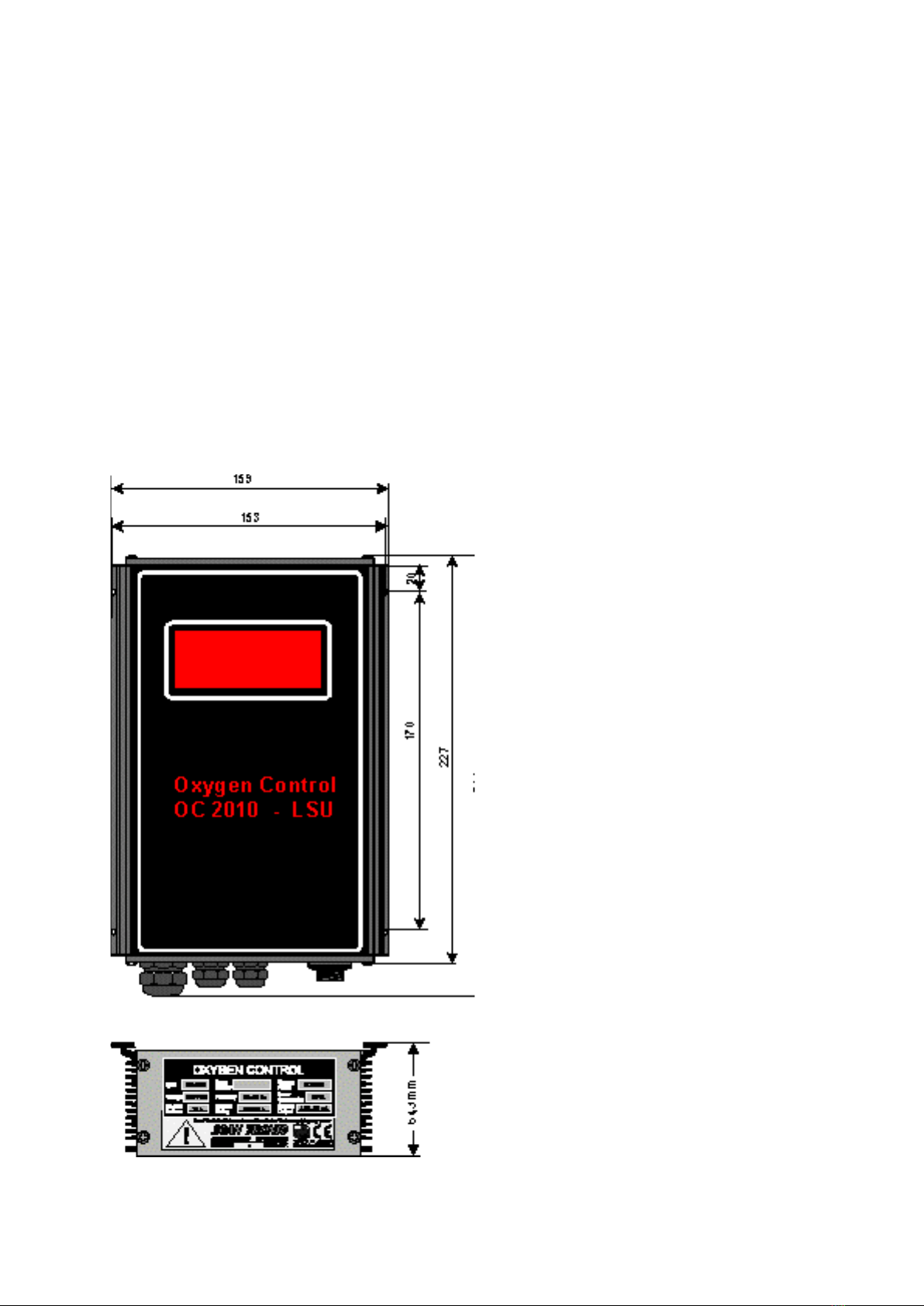

Signal amplier

Themeasuringamplierisbuiltintoanalu-

minium cabinet, and contains a power-supply,

ameasuringamplier,alinearizationunit,an

alarm circuit and a current loop output circuit.

2.3. Place of installation

Satisfactory operation, faultless function and

minimal maintenance is achieved by paying

attention to the following notes:

1)The tting place for the probe should

be chosen in a way that protects the probe

againstmechanical damage.Theuegas-

temperature has to lie within the given

limits of the probe at the measuring point.

2) The gas, which passes the probe, must

be representative.At large crosssections it is

recommended to use the guide-tube (which

leads the gas to the probe).

3)The ue-gas channel must be controlled

forholesandleakages.Oozingofsurroun-

ding air into the channel, before and

after the probe, inuences the accuracy

af to the oxygen measurement in an

unwanted direction.

4) The zirkoniumdioxide measuring cell re-

acts on changes in the concentration

of oxygen (e.g. the partial pressure of the

oxygen), and on changes in the negative

pressure at the measuring point.

To keep this effect at a minimum, the

probe must not be installed between id-

fans and their regulation valves or in the

immedate vicinity of these. The pressure

difference must be kept under 100 mm

water column (H2O).

5) The installation place of the signal

ampliermustbechosensothattheambient

temperature at any time lies over 0 o C,

and below 60 o C.

6) The distance between measuring probe

andsignalampliercannotexceed2,0m.

7) At high gas-temperatures a special guide

tube to be welded into the ue channel

wall can be delivered.

Attention

Mounting of the probe itself should not take

place before the completion of all pipe- and

ue-worksattheboiler,andtheburnerisready

to start.

Care should be taken to assure that the system

is constantly powered and the probe is heated

also when the boiler is out of service.