04/02 AirSep®Corporation

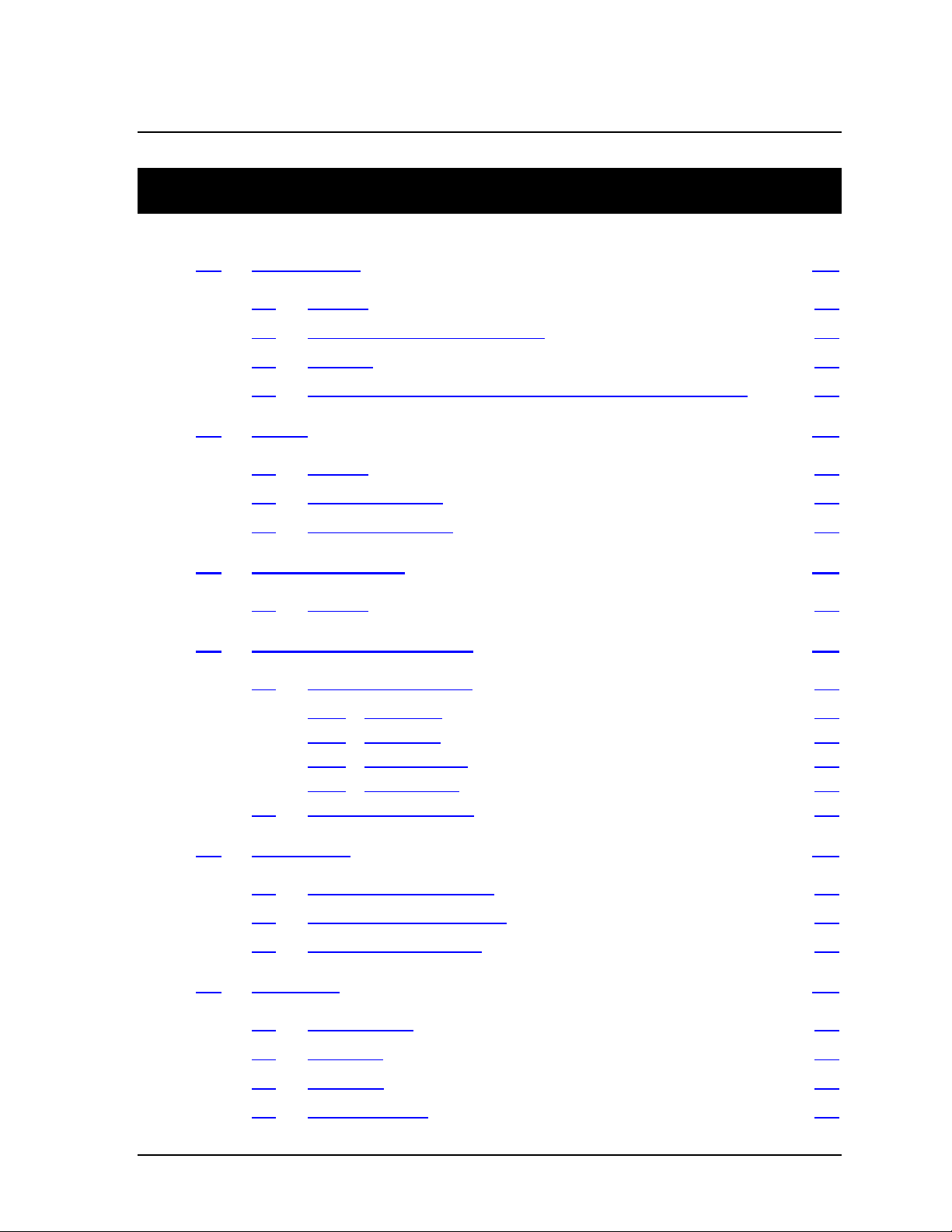

table of contents - ii AS-20—1000 Instruction Manual

6.5 Extended Shutdown..........................................................................6-4

6.6 Start-up after an Extended Shutdown...............................................6-4

7.0 Maintenance..................................................................................... 7-1

7.1 Daily Monitoring ................................................................................7-1

7.2 Monthly Monitoring ...........................................................................7-1

7.3 Removing the Front Cover of the Enclosure (Not available on AS-450

— AS-1000 models) .....................................................................................7-2

7.4 Depressurizing the Filters .................................................................7-3

7.5 Changing Filter Elements .................................................................7-4

7.6 Depressurizing the Oxygen Generator .............................................7-5

7.7 Adjusting the Feed Air Regulator......................................................7-6

7.8 Adjusting the Pressure Switch ..........................................................7-6

8.0 Troubleshooting .............................................................................. 8-1

AAppendix Technical Data............................................................... A-1

Specifications .............................................................................................. A-1

Operating Data ............................................................................................ A-9

Drawings.................................................................................................... A-10

BAppendix Warranty/Returns .......................................................... B-1

Product Warranty......................................................................................... B-1

Limits of Liability .......................................................................................... B-2

Returning the Oxygen Generator or a Component for Service ................... B-2

CAppendix Parts List........................................................................ C-1

AS-20 Parts ................................................................................................. C-2

AS-45 Parts ................................................................................................. C-3

AS-80 Parts ................................................................................................. C-4

AS-160 Parts ............................................................................................... C-5

AS-250 Parts ............................................................................................... C-6

AS-450 Parts ............................................................................................... C-7

AS-750 Parts ............................................................................................... C-8

AS-1000 Parts ............................................................................................. C-9