– 3 –

one of the slots in the shaft frame. Using

very gentle pressure, ex the heddle

bar just enough to t the other end into

the slot on the opposing side of the shaft

frame. Push approximately half of the

heddles to each end of the shaft.

Put the shaft back in the loom and secure

the jack pin with the hex nut. Repeat

for the other shafts. Be sure to keep the

heddles oriented in the same direction for

easier threading.

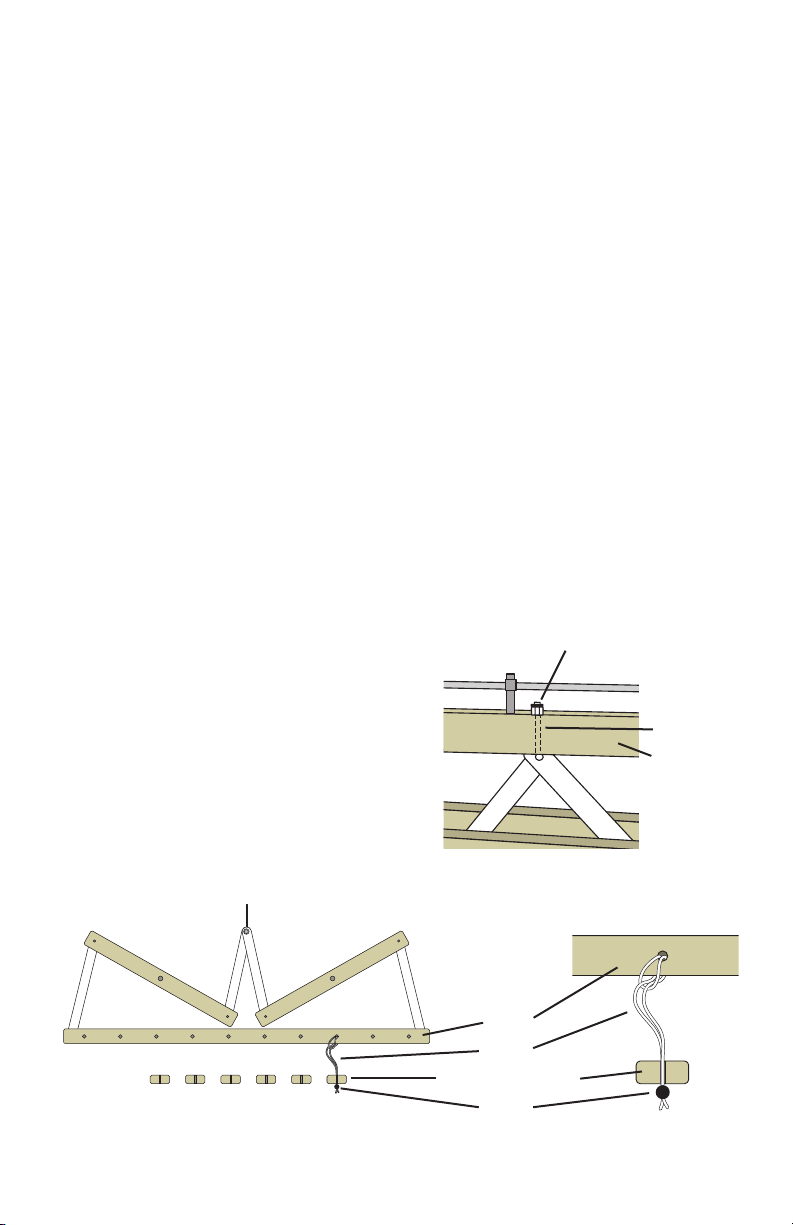

INSTALLING THE TIE-UP CORDS

There is one tie-up cord for every lamm

hole: 24 for 4-shaft looms; 80 for 8-shaft

and 4 Now-4 Later looms. Loop one end

of each tie-up cord through a hole in the

lamm.

Loop one end of each tie-up cord through

a hole in the lamm. Tie shafts to a treadle

by slipping a tie-up cord into the slot in a

treadle (Figure 5). Work from the front

lamm to the rear lamm for each treadle.

pinched cord through the second hole in

the cord. Pull on the pinched cord until

a new loop forms that is large enough

for the apron bar to slip through (Figure

3C). Slide the apron bar through the loop

(Figure 3D) and pull tight. Repeat until all

cords are attached to the apron bar. Attach

the other apron bar to its beam in the

same way.

USING THE BEATER PIN

The small metal pin attached to the inside

right leg holds the beater upright during

warping. Push the pin through the hole

in the leg and then through the slot in the

beater side. Pull out the beater pin and

replace it in its holder before weaving or

before folding the loom.

INSTALLING THE HEDDLES

There are 800 heddles for 4-shaft looms

and 1000 for 8-shaft and 4 Now-4 Later

looms.

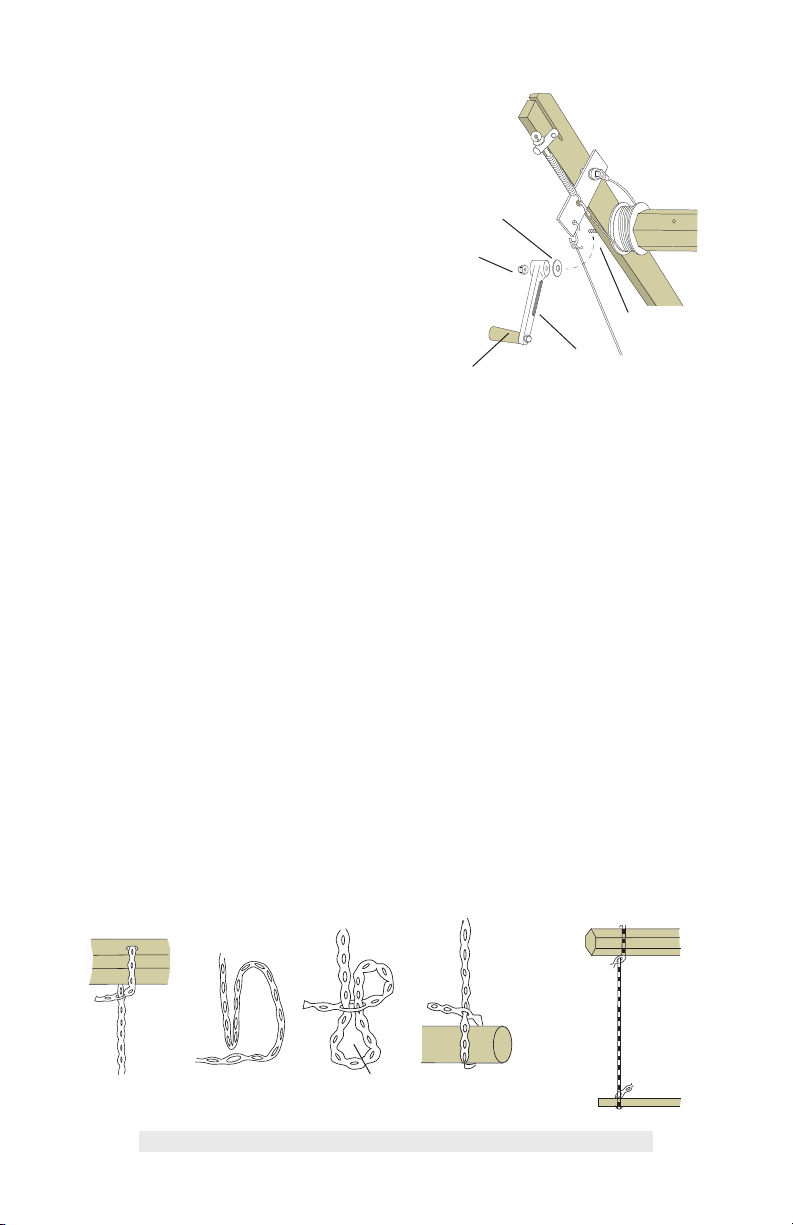

Remove the shafts from the loom

by removing the rubber rings and

unscrewing the small hex nuts from the

jack pins (Figure 4). Pull the shaft straight

up and out of the loom. When you put the

shaft back in the loom, be sure to insert

the jack pin back into the hole and secure

it with the hex nut. Replacing the rubber

ring is optional.

Lay the shaft on a at surface. Lay two

heddle bars next to the heddles. Carefully

slide a group of heddles onto the heddle

bars. Fit one end of each heddle bar into

FIGURE 5: INSTALLING TIE-UP CORDS

FIGURE 4: JACK PIN ATTACHMENT

shaft

frame

hex nut

jack pin

lamm

tie-up

end of treadle (rear)

button