– 3 –

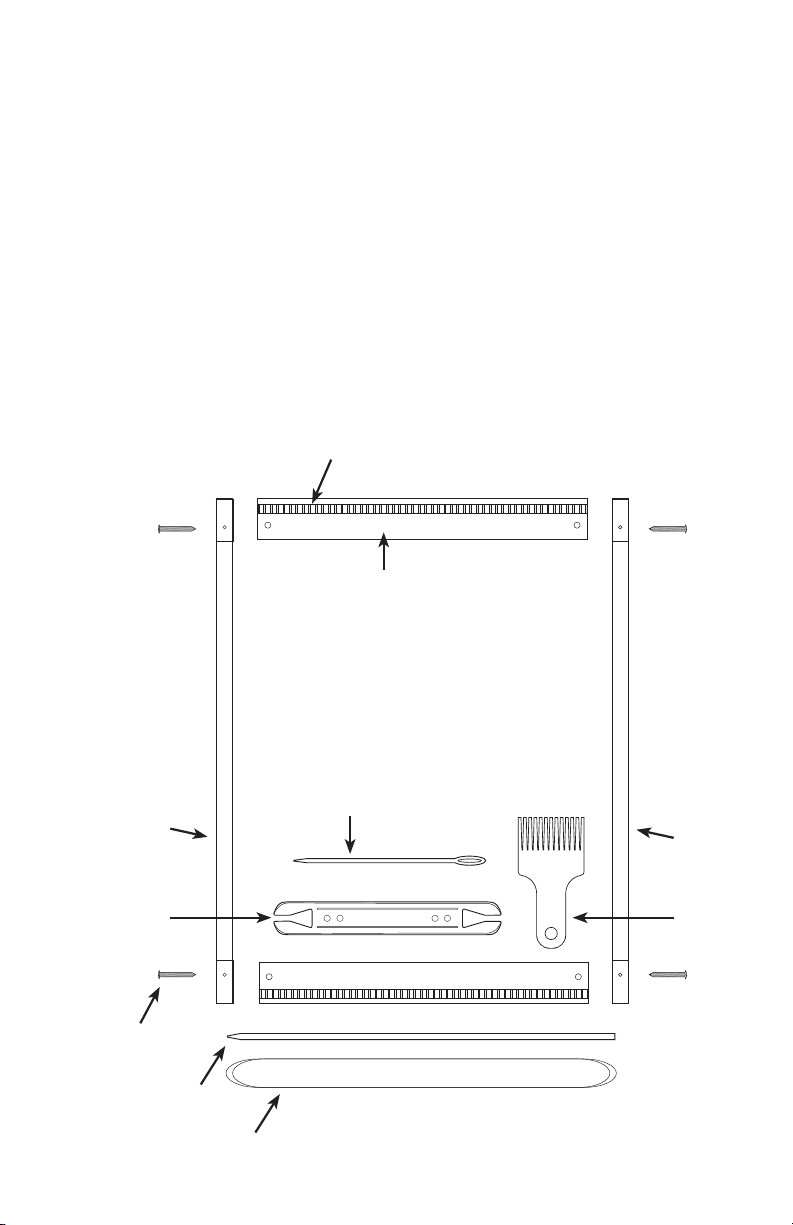

FIGURE 1: ASSEMBLED LILLI LOOM

ASSEMBLE THE LOOM

1. Lay the loom sides parallel to each

other and about 10” apart.

2. Place the top beam into the cut

grooves in the tops of the loom sides

(with the beam teeth facing up and

out). Line up the holes and fasten the

beam to each side with a screw.

3. Place the other beam into the bot-

tom cut grooves of the loom sides

(with the beam teeth facing down and

out). Line up the holes and fasten the

beam to each side with a screw.

WEAVING ON THE LILLI LOOM

Weaving is the process of interlacing two sets of threads to make a fabric. One

set, the warp, is held taut by the loom; the other set, the weft, is woven across

the warp threads. There is no limit to the possibilities that can be explored by

changing colors, sizes, and textures of the weaving materials.

WEAVING TERMS

Beam teeth—the plastic “combs” or

“teeth” attached to the top and

bottom beams.

Beams—the top and bottom cross

pieces of the loom frame.

EPI—the number of warps in an inch.

This loom can be set up with either

6 or 12 ends per inch.

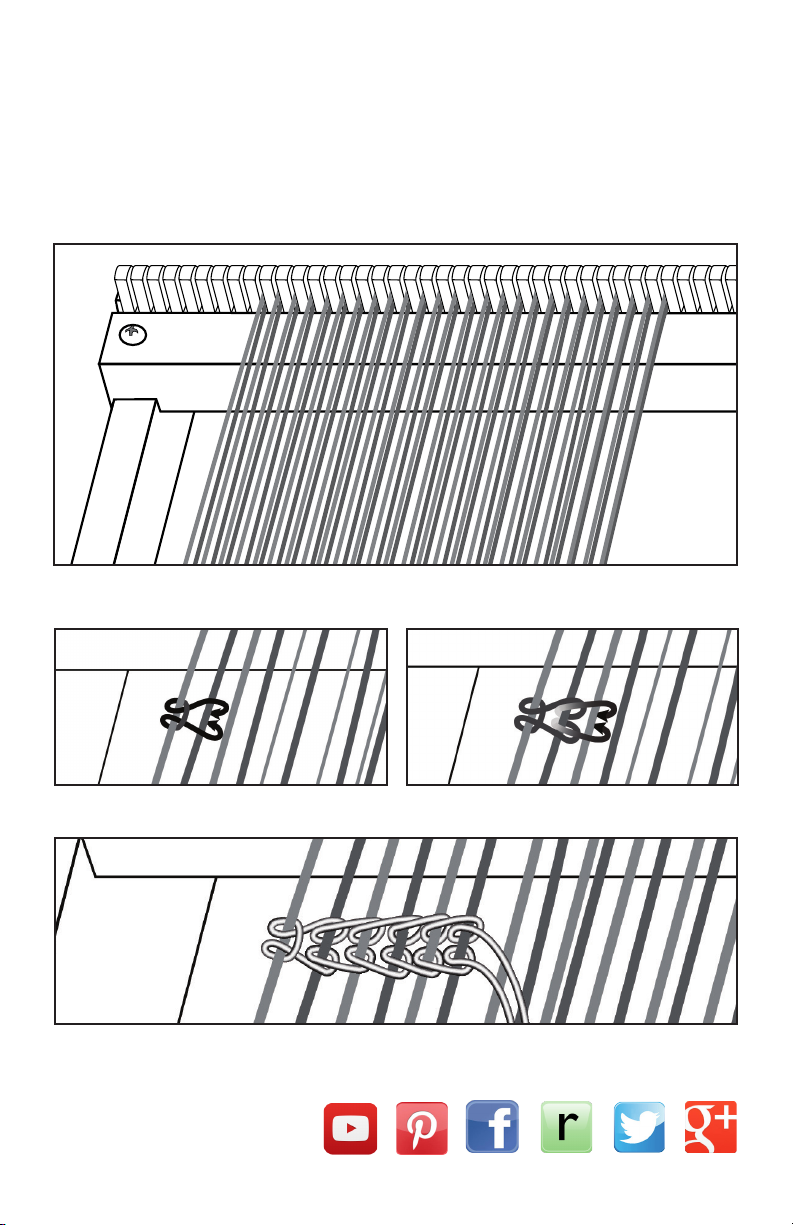

Pick-up stick—on the Lilli Loom the

pick-up stick is inserted in the

opposite row as the shed stick. It is

turned on edge to make the shed.

Plain weave—the most basic weave,

in which the threads interlace

alternating over and under.

PPI—picks or the number of weft

rows per inch.

Shed—the space between raised and

lowered warp threads through

which the shuttle passes.

Shed stick—narrow stick for marking

the shed. It stays in place, while

the alternate shed is created with

a pick-up stick, taken out after the

row is woven.

Shuttle—a tool for holding and

carrying weft.

Warp—the weaving threads which are

held taut on the loom.

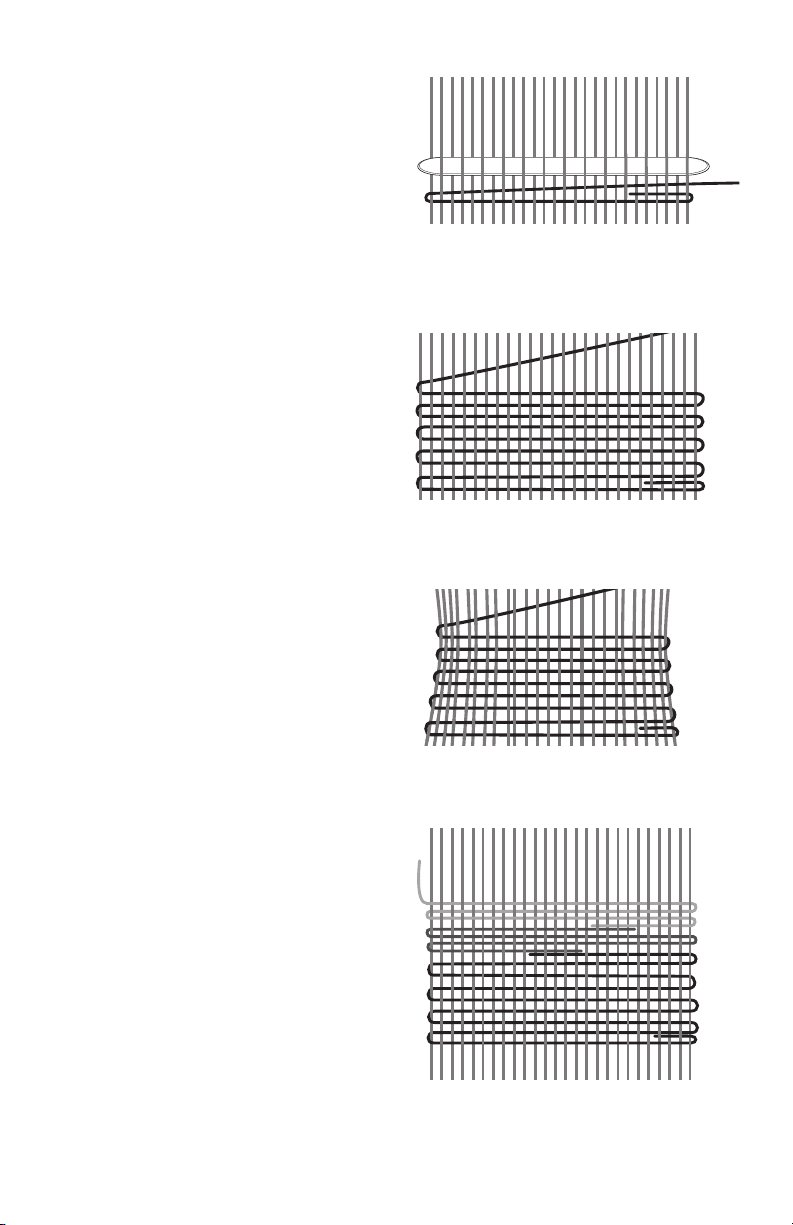

Warping the loom—Putting the warp

threads on the loom.

Weaving needle—the large eyed

needle can be used for weaving. It

is especially useful for short rows

and for weaving at the very top of

the weaving when space is limited.

Weft—the weaving threads which are

woven crosswise through the warp

threads.