Modula 6100

4/61

Content

Safety measures........................................................................................................................................... 3

1

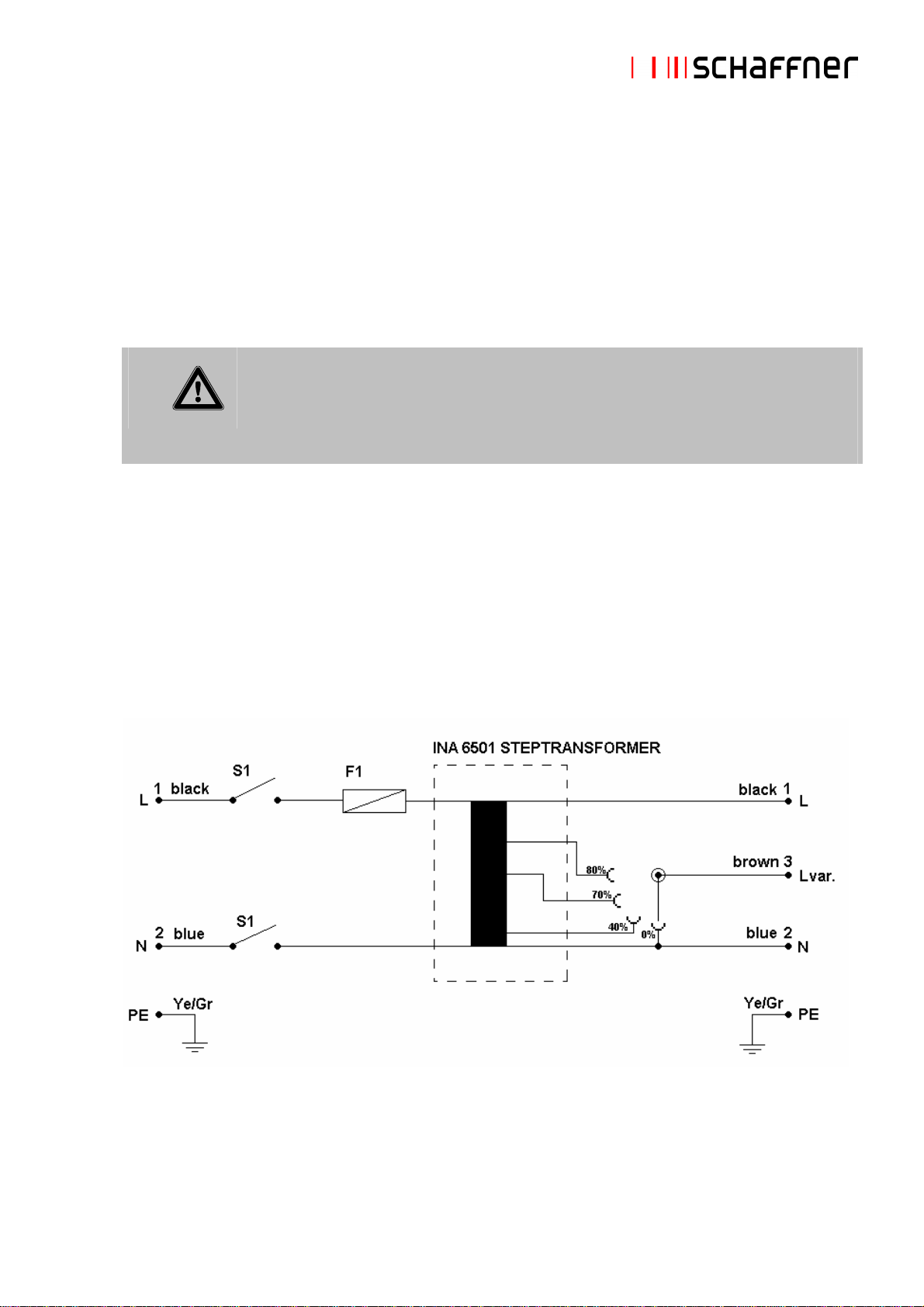

Manual step transformer INA 6501............................................................................................ 7

1.1

Circuit diagram INA 6501.............................................................................................................. 7

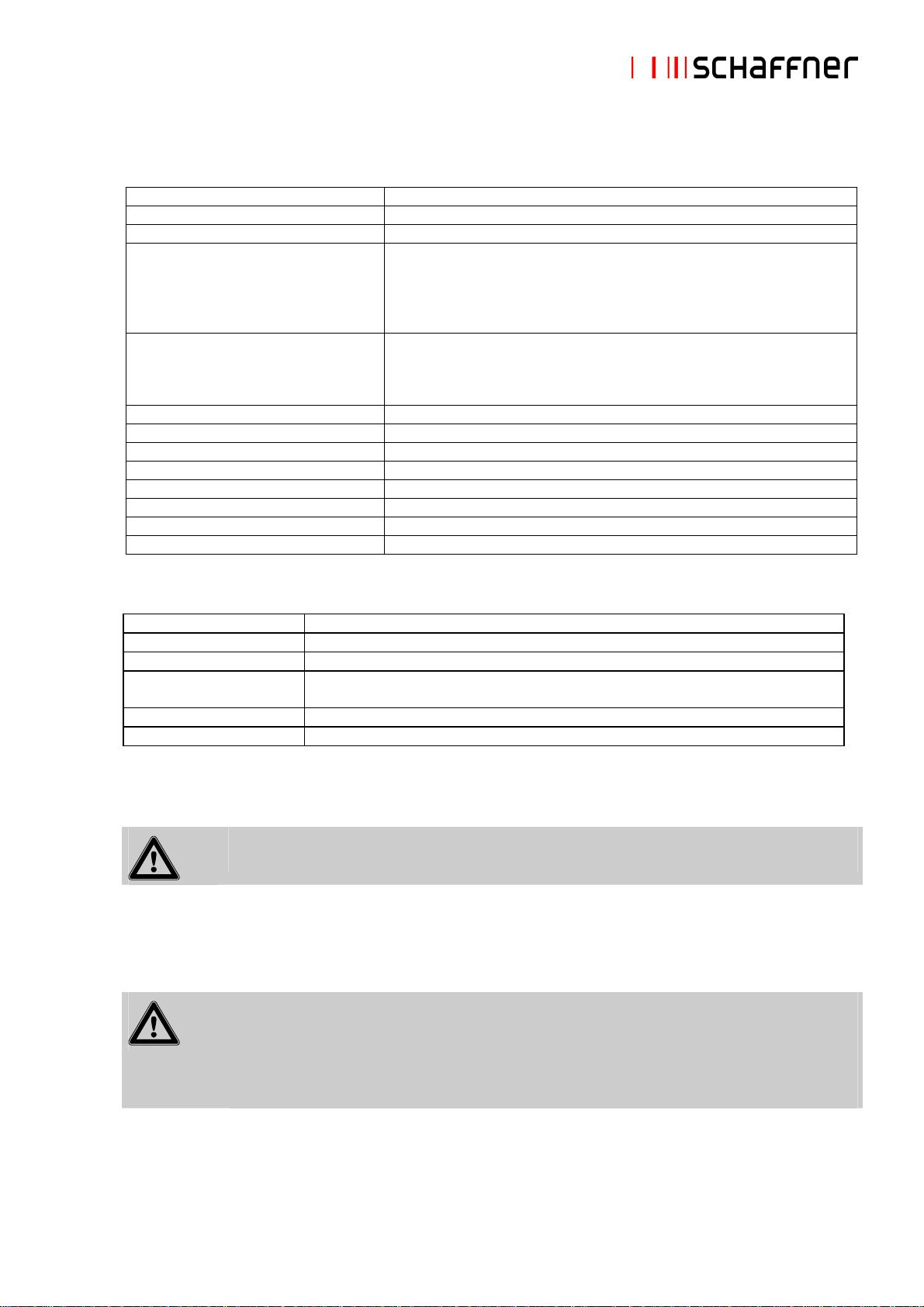

1.2

Technical specifications INA 6501................................................................................................ 8

1.2.1

Parts description ........................................................................................................................... 8

1.3

Installation - connection to Modula ............................................................................................... 8

2

Automatic step transformer INA 6502 .................................................................................... 10

2.1

Circuit diagram INA 6502............................................................................................................ 10

2.2

Technical specifications INA 6502.............................................................................................. 11

2.2.1

Parts description ......................................................................................................................... 11

2.2.2

Compatibility ............................................................................................................................... 12

2.3

Installation - connection to Modula ............................................................................................. 13

2.4

HW Detection.............................................................................................................................. 14

2.4.1

Operation .................................................................................................................................... 14

3

Automatic variable transformer VAR 6501............................................................................. 16

3.1

Circuit diagram VAR 6501 .......................................................................................................... 16

3.2

Technical specifications VAR 6501 ............................................................................................ 17

3.2.1

Parts description ......................................................................................................................... 17

3.2.2

Compatibility ............................................................................................................................... 18

3.3

Installation - connection to Modula ............................................................................................. 18

3.4

Using WinModula standard variation test................................................................................... 19

3.5

Specials using Winmodula and variation test............................................................................. 20

3.5.1

Operation .................................................................................................................................... 20

4

Automatic variable transformer VAR 6502............................................................................. 22

4.1

Circuit diagram VAR 6502 .......................................................................................................... 22

4.2

Technical specifications VAR 6502 ............................................................................................ 23

4.3

Variable transformer VAR 6502.................................................................................................. 23

4.3.1

Parts description ......................................................................................................................... 24

4.4

Compatibility ............................................................................................................................... 24

4.4.1

Installation - connection to Modula ............................................................................................. 25

4.4.2

Operation .................................................................................................................................... 25

5

Manual variable transformer VAR 6503.................................................................................. 27

5.1

Circuit diagram VAR 6503 .......................................................................................................... 27

5.2

Technical specifications VAR 6503 ............................................................................................ 28

5.2.1

Parts description ......................................................................................................................... 28

5.3

Installation - connection to Modula ............................................................................................. 28

6

Magnetic fields options MFO 650X ......................................................................................... 30

6.1

Magnetic field loops INA 701 and INA 702................................................................................. 30

6.2

Manual magnetic field option MFO 6501.................................................................................... 32

6.2.1

Circuit diagram MFO 6501.......................................................................................................... 33

6.2.2

Technical specifications MFO 6501............................................................................................ 33

6.2.3

Parts description ......................................................................................................................... 34

6.2.4

Installation................................................................................................................................... 34

6.2.5

Operation – adjustments............................................................................................................. 35

6.3

Automatic magnetic field option MFO 6502................................................................................ 36

6.3.1

Circuit diagram MFO 6502.......................................................................................................... 37

6.3.2

Technical specifications MFO 6502............................................................................................ 37

6.3.3

Parts description ......................................................................................................................... 38

6.3.4

Compatibility ............................................................................................................................... 38

6.3.5

Installation - connection to Modula ............................................................................................. 38

6.3.6

Operation .................................................................................................................................... 39