6

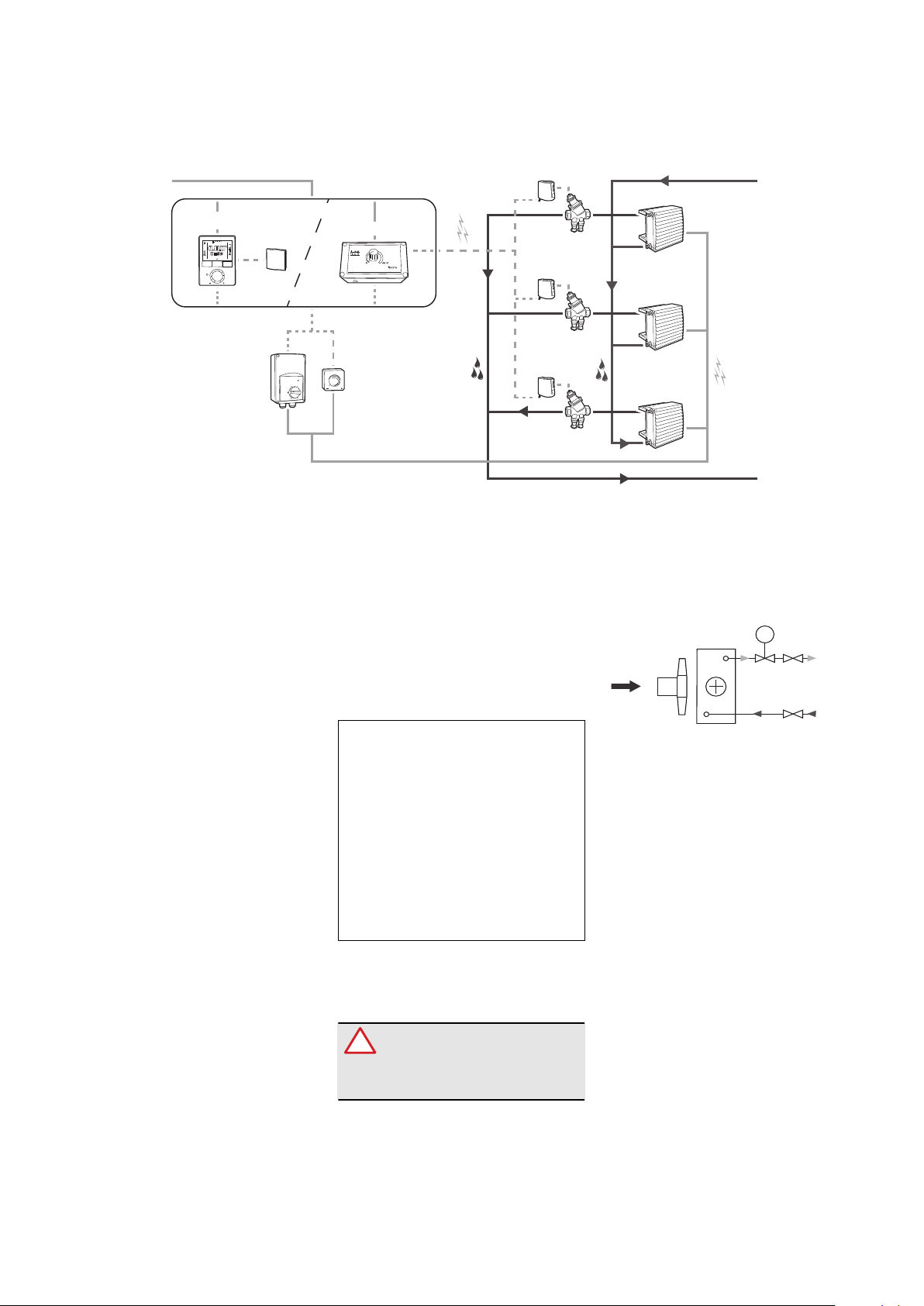

3.5 Electrical connections

The electrical connections

must be made according to

current regulations and by

authorised personnel.

Connect the motors to the electrical

supply.

The fans can be connected to

different types of speed regulators.

See the wiring diagrams on pages 10

to 13.

After connecting the motor, check

the direction of rotation from the fan

inlet side.

Directions of rotation

• VM-4 and –5: Counter-

clockwise

• VM-6, -7 and –8: Clockwise

Access to the fan motor on units with

mixing housings is typically done by

removing a side plate opposite the

damper shaft.

The damper motor has a terminal

box for direct cable connection.

4. Maintenance

The air heaters are designed to give

long and reliable operation and to

require little service.

The electric system must be

switched off and locked to

avoid unintentionally starts

when the air heaters are

undergoing maintenance.

The air heaters must be kept clean at

all times for optimum performance

and best level of comfort. Inspect

and clean the units as needed. Units

installed indust-filled environments

require more frequent maintenance.

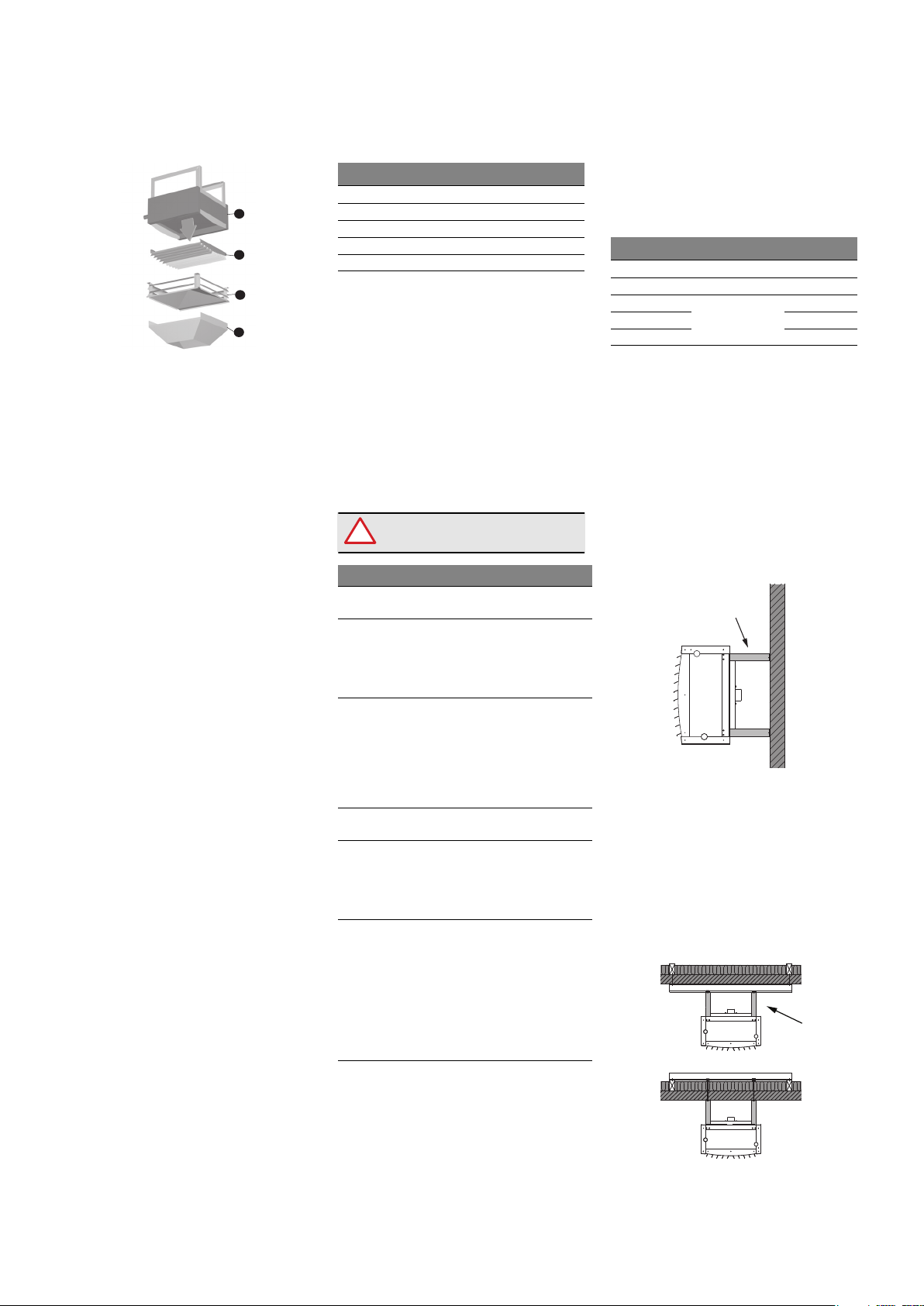

Refer to figure 1. Basic unit in the

following sections.

4.1 Inspection

Air heaters without accessories on

the inlet side can be checked directly.

Inspection of the inlet on units with

mixing housings is typically done by

removing a vertical side plate of the

mixing housing opposite to the

damper shaft.

4.2 Cleaning

Dust builds up inside the unit

cabinets and reduce the

performance if not removed.

Build-ups on fan suspensions, wire

guards, heating coils and dampers

can usually be removed by vacuum

cleaning. Cleaning the inlet of the

heating coil can be done after

removing the fan unit with

suspension. See section “4.4 Motor”.

On the outlet side it is possible to

remove the front grille.

Wall grilles for fresh air and wire

guards for return air ducts must also

be kept free from dust and foreign

particles.

4.3 Impeller

Prior to delivery, the fan unit has

been carefully balanced. If

vibrations occur during operation, it

is normally due to dust on the fan

blades. If vibrations persist after

cleaning; stop the unit and call for

skilled assistance. Continued

operation may damage the motor

bearings.

4.4 Motor

The motor and impeller is a one

piece assembly. The motor bearings

are greased for life, i.e. approx.

30.000 working hours and cannot be

greased anew. When the service life

of the bearings has run out, they

should be replaced. Replacement of

the bearings should be carried out by

a specialist. During replacement,

remove the entire unit comprising

fan suspension and fan. Afterwards,

remove the suspension from the fan.

When re-mounting, the fan must be

centred carefully with equal blade

clearance around the circumference.

4.5 Heating coil

The heating coil has copper tubes

with aluminium fins and is sensitive

to frost. If there is a risk of hard frost,

it might be necessary – besides the

established frost protection at the

fresh air inlet – to empty the heating

coilofwater.Inexposedinstallations

it is recommended to supply the

plant with antifreeze.

4.6 Damper

The damper function should be

checked on occasion.

4.7 Filters

Filters from Novenco are made of

synthetic material and must be

cleaned occasionally to maintain fan

performance. Cleaning is done

either by vacuum cleaning the dirty

side of the filter mat, rinsing from the

clean side or by washing in

lukewarm soap water at max. 40 °C.

The filter mat can be washed four

times, before it must be replaced.

During cleaning or replacement of

the filter, draw out the filter cassette

and insert a new filter after cleaning

the mat retainers. The filter cassette

is fitted with a handle. The retainers

are of Velcro and reusable.

When ordering a new filter mat,

observe the type and size of fan, e.g.

VMA-62.

The filter condition must be checked

2 weeks after start-up of the fan and

then once every month.

Recommended rise in differential

pressure above the filter mat is

100 Pa.

4.8 Other components

Components for regulation,

ventilation, water outlet and other

accessories essential for the correct

operation of the fan, need regular

inspection and maintenance

according to the manufacturer’s

instructions.