2 • Schlage • PIM400-485 user guide

Contents

Overview...........................................................................................................................3

Getting started ..................................................................................................................3

Features............................................................................................................................4

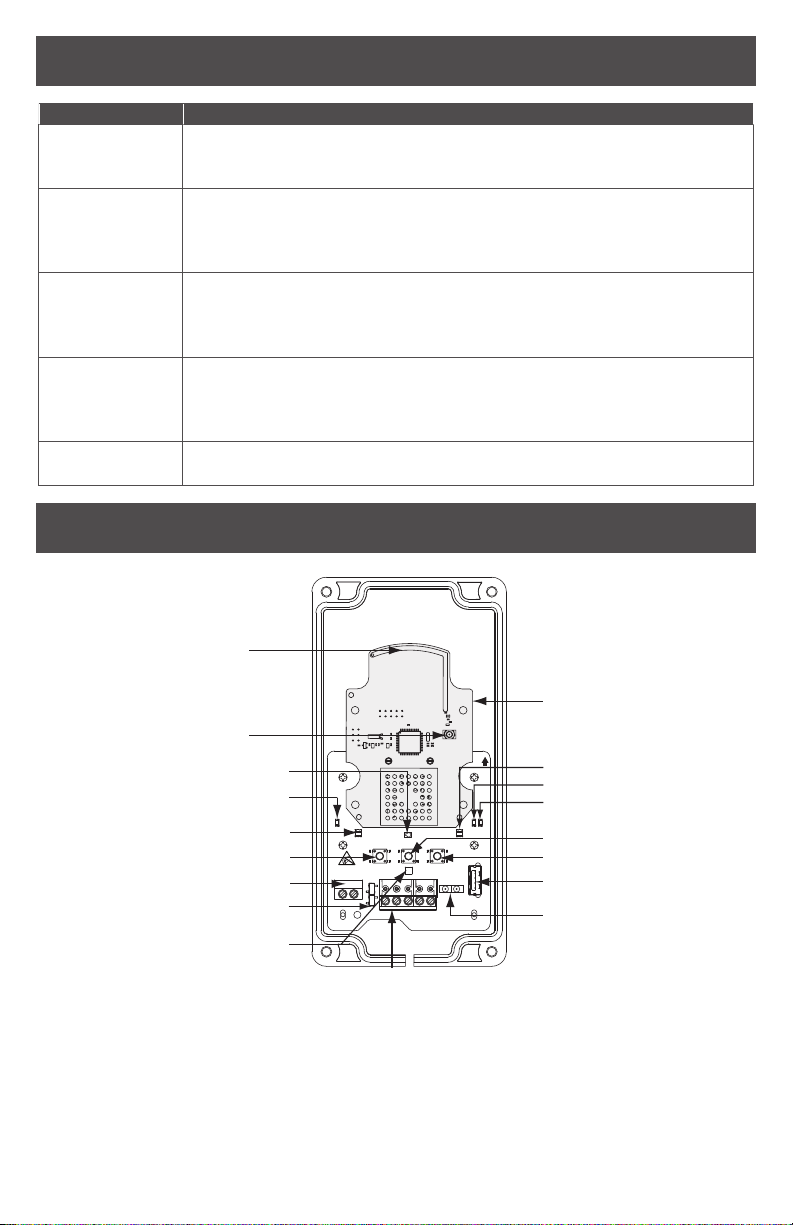

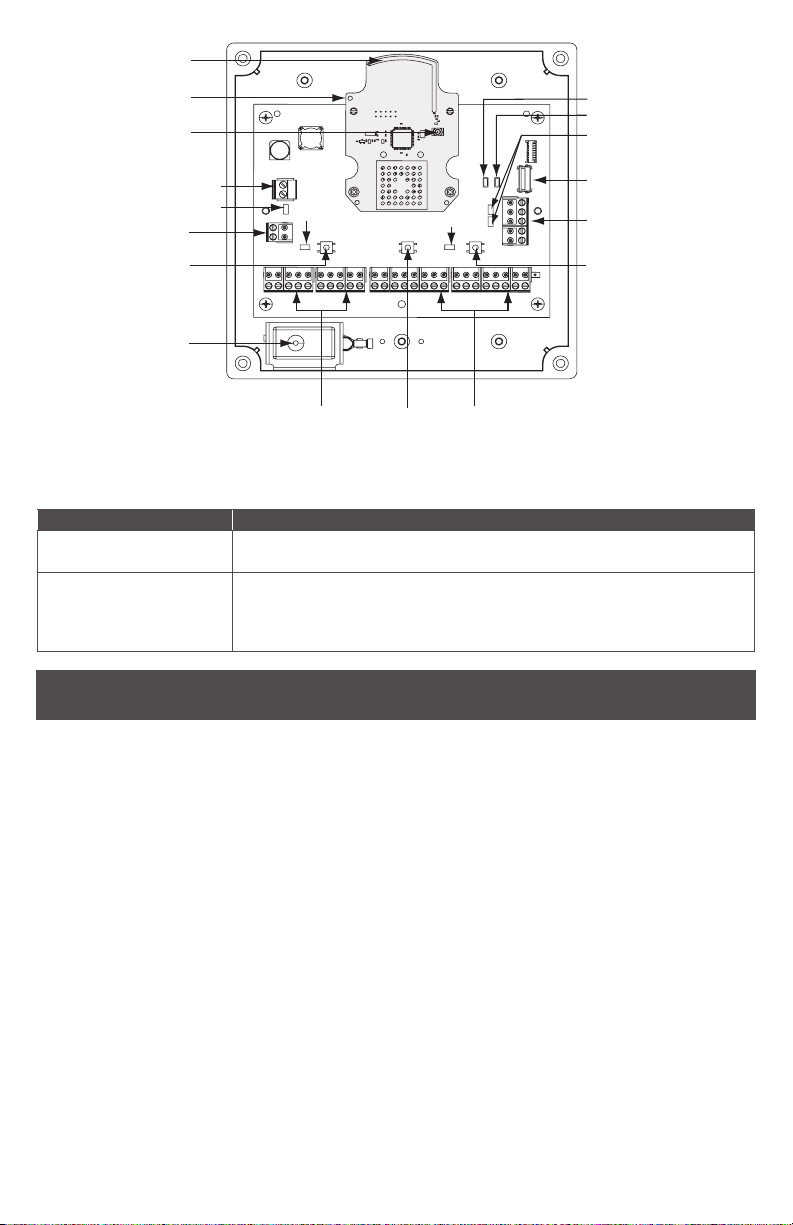

Components .....................................................................................................................4

Installation.........................................................................................................................5

Determine the location ..................................................................................................5

Pre-installation test........................................................................................................6

Drill holes for wiring.......................................................................................................6

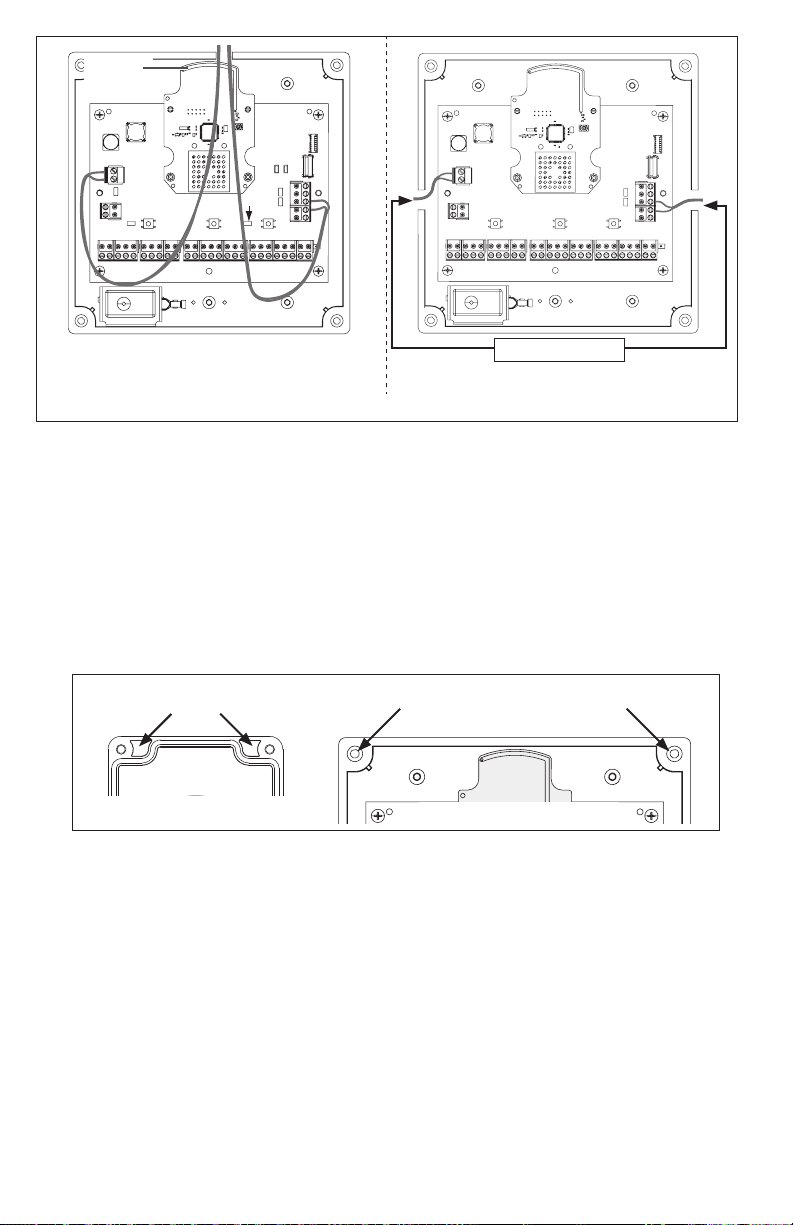

Mount the PIM400-485 .................................................................................................7

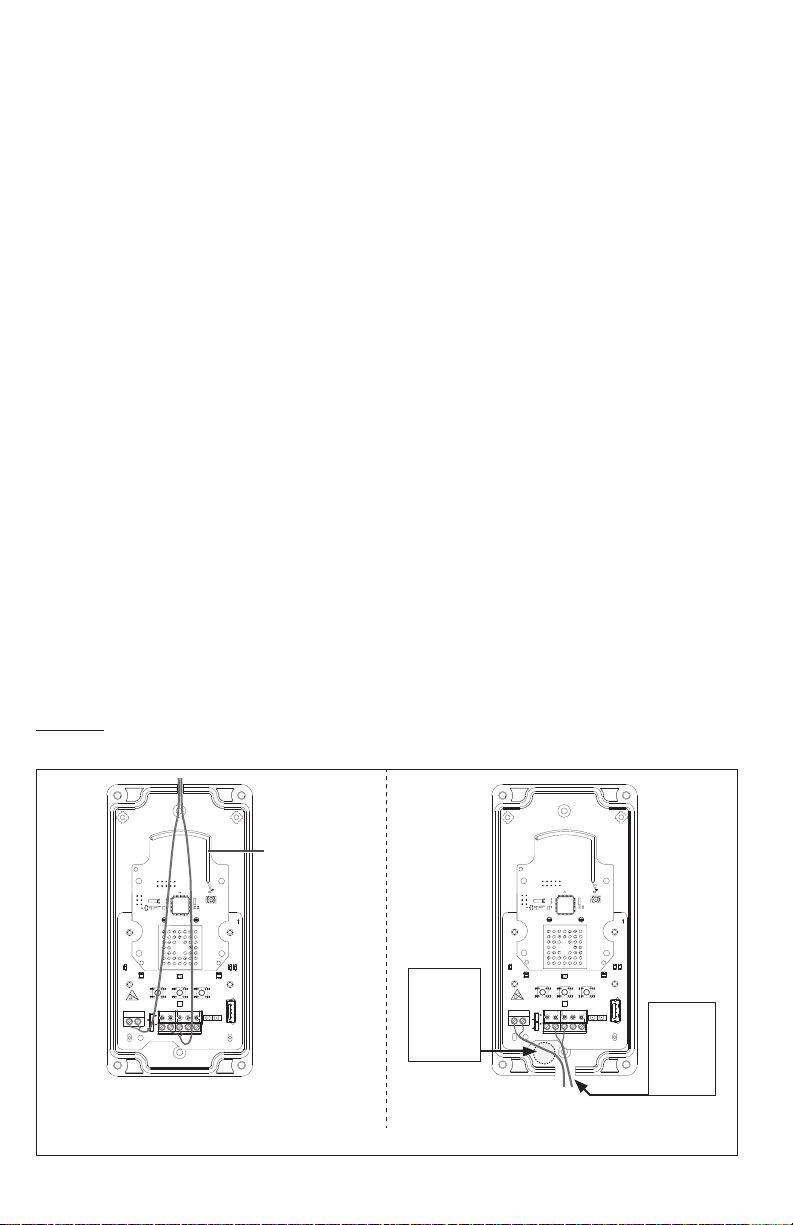

Wire routing...................................................................................................................8

Cable/wire specications ..............................................................................................8

Retrot...........................................................................................................................8

PIM400-485 to ACP connection........................................................................................9

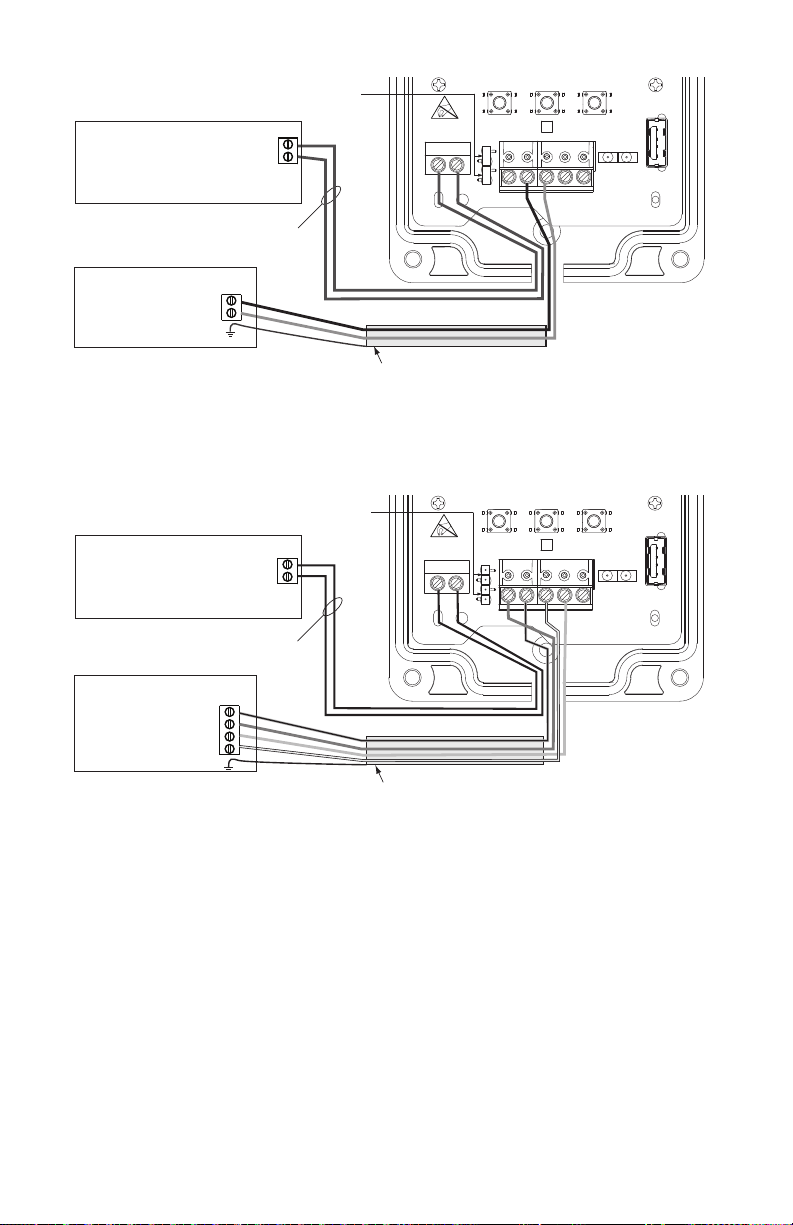

Typical PIM400-485 to ACP wiring diagrams.............................................................. 10

Optional remote antenna ................................................................................................12

Link mode .......................................................................................................................12

Schlage Utility Software (SUS) .......................................................................................12

Reset to factory defaults .................................................................................................12

DC power........................................................................................................................13

Complete the installation ................................................................................................13

Troubleshooting ..............................................................................................................13

FCC/IC statements.........................................................................................................15

To comply with FCC and Industry Canada RF radiation exposure limits for general

population, the antenna(s) used for this transmitter must be installed such that a minimum

separation distance of 20 cm is maintained between the radiator (antenna) and all persons

at all times and must not be collocated or operating in conjunction with any other antenna or

transmitter.

This product is compliant of UL 294 and ULC S319 standard. This product’s compliance

would be invalidated through the use of any add-on, expansion, memory or other module

that has not yet been evaluated for compatibility for use with this UL Listed product, in

accordance with the requirements of the Standards UL 294 and ULC S319. This product has

been evaluated for ULC-S319 Class I.

UL294 Access Control Levels tested to: Destructive Attack - Level 1; Line Security - Level 1;

Endurance - Level 4; Standby Power - Level 1.