2 • Schlage • PIM400-1501 user guide

Contents

Overview...........................................................................................................................3

Getting started ..................................................................................................................5

Schlage Utility Software (SUS) .........................................................................................5

Link mode .........................................................................................................................5

Put the PIM400-1501 into link mode.............................................................................5

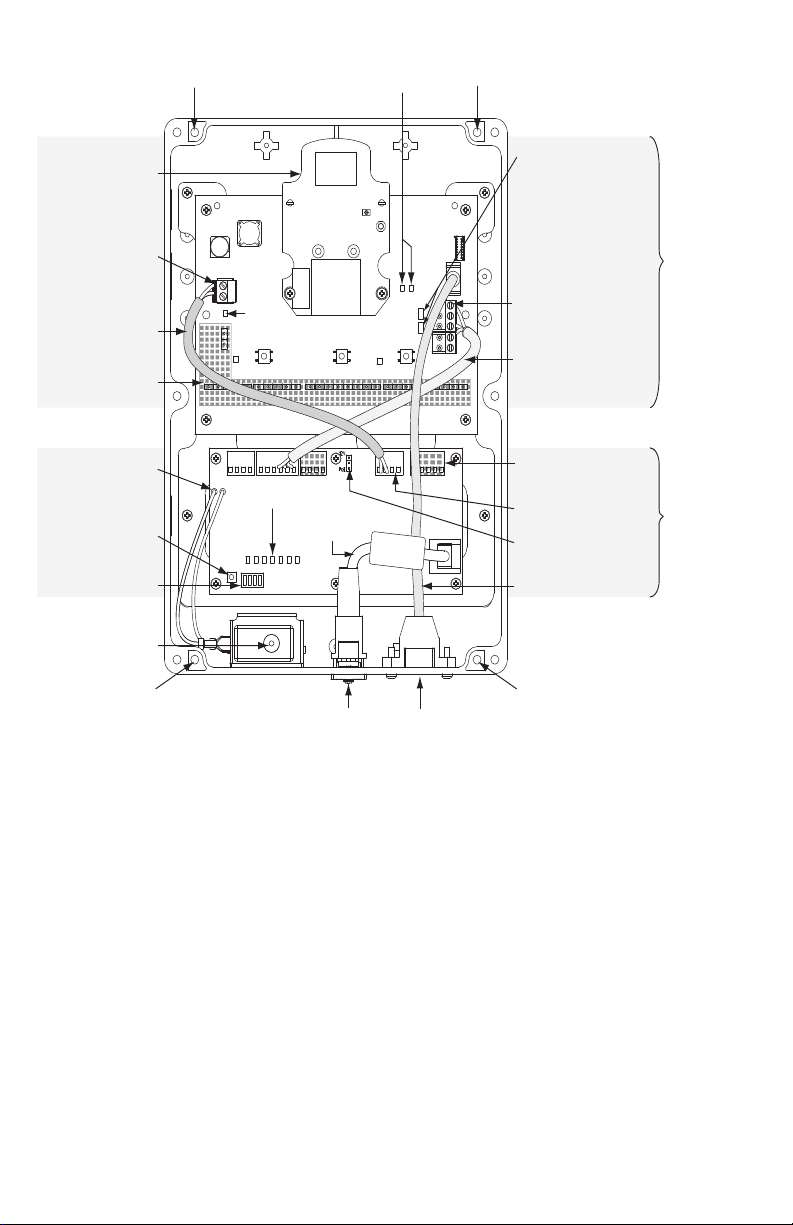

Install the PIM400-1501....................................................................................................6

Determine the location ..................................................................................................6

Pre-installation test........................................................................................................6

Installation.....................................................................................................................7

Permanently mount the PIM400-1501 .......................................................................... 7

Wiring connections ...........................................................................................................8

12 VDC input power......................................................................................................8

PoE Input Power ...........................................................................................................8

Cable recommendations ...............................................................................................8

Network connection ..........................................................................................................9

Ethernet connection ......................................................................................................9

DIP switches .................................................................................................................9

Remote antenna (if applicable)....................................................................................... 10

Antenna location and safety........................................................................................10

Antenna grounding......................................................................................................10

Terminate the coax whip at the PIM400-1501............................................................. 11

Reset to factory defaults .................................................................................................12

Reset the PIM400-485 to factory defaults...................................................................12

Reset the EP-1501 to factory defaults - bulk erase.....................................................12

Memory backup battery ..................................................................................................12

PIM400-1501 LED reference ..........................................................................................13

FCC/IC statements.........................................................................................................14

To comply with FCC and Industry Canada RF radiation exposure limits for general

population, the antenna(s) used for this transmitter must be installed such that a minimum

separation distance of 20 cm is maintained between the radiator (antenna) and all persons

at all times and must not be co-located or operating in conjunction with any other antenna or

transmitter.

This product is a UL-294 & ULC-S319 Listed Class 1 equipment. This product’s UL & ULC

compliance would be invalidated through the use of any add-on, expansion, memory or

other module that has not yet been evaluated for compatibility for use with this product, in

accordance with the requirements of the Standards set forth in UL-294 & ULC-S319.

UL294 Access Control Levels tested to: Destructive Attack - Level 1; Line Security - Level 1;

Endurance - Level 4; Standby Power - Level 1.