CONTENTS

1Safety Instructions.................................................................................................... 1-4

Important symbols........................................................................................................................1-4

General safety instructions...........................................................................................................1-4

Intended use................................................................................................................................1-5

Installation and operation .............................................................................................................1-6

2Product Overview...................................................................................................... 2-7

General description of functions...................................................................................................2-7

Vacuum generation (picking up the workpiece).............................................................................2-7

Blow-off (depositing the workpiece) ..............................................................................................2-7

Vacuum/pressure display.............................................................................................................2-8

Versions.........................................................................................................................................2-8

Ejector version PNP or NPN.........................................................................................................2-8

Electrical connection ....................................................................................................................2-8

Ejector design................................................................................................................................2-9

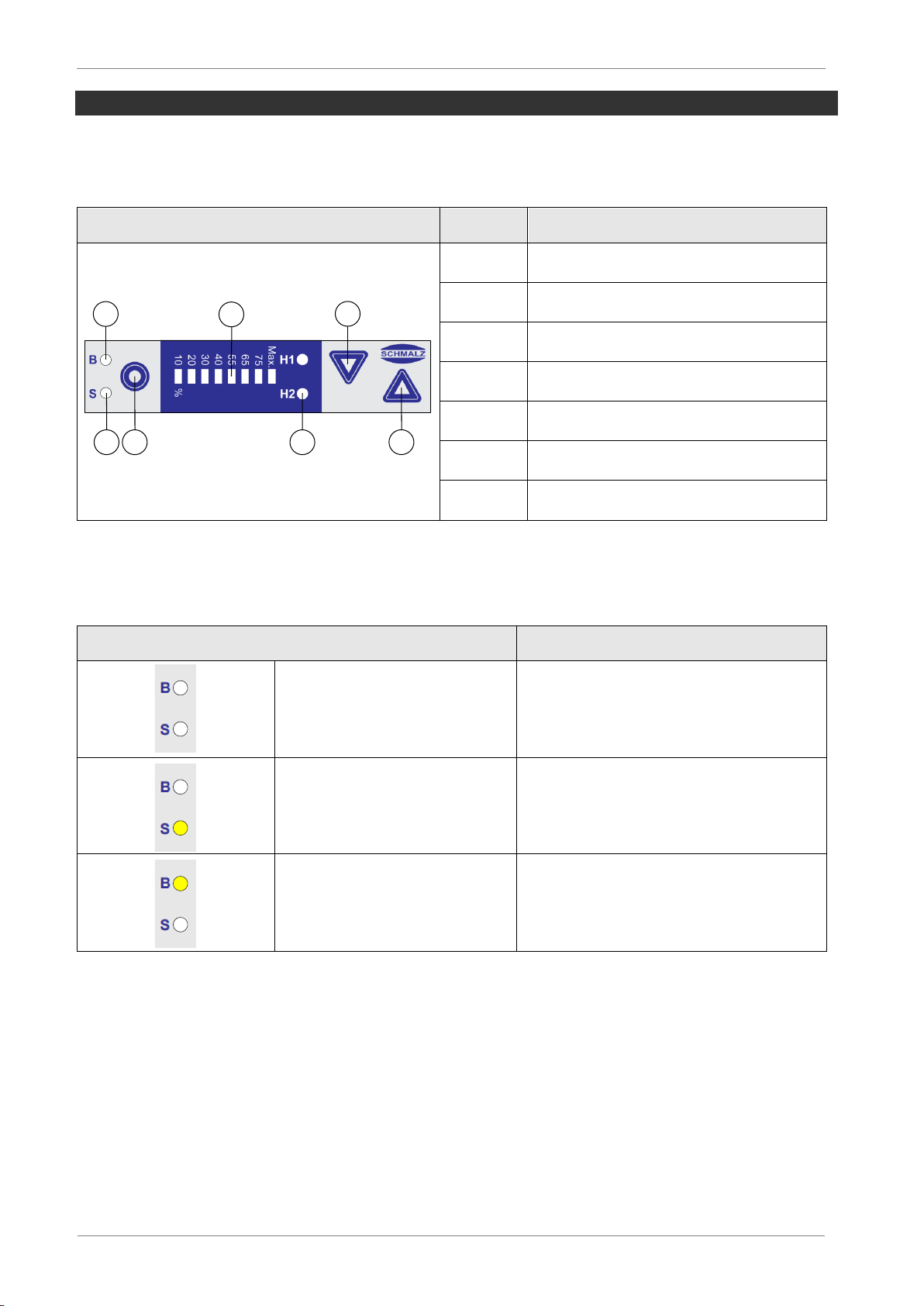

Operating and display elements .................................................................................................2-10

3Description of Functions........................................................................................ 3-12

Operating modes..........................................................................................................................3-12

Ansteuerung Ejektorvariante NO................................................................................................3-14

Ansteuerung Ejektorvariante NC ................................................................................................3-14

General functions.........................................................................................................................3-15

Manual mode.............................................................................................................................3-15

Monitoring the system vacuum...................................................................................................3-16

Control function..........................................................................................................................3-16

Blow-off modes ..........................................................................................................................3-16

Signal output..............................................................................................................................3-16

Vacuum unit...............................................................................................................................3-17

Operating voltage display...........................................................................................................3-17

Locking the keypad....................................................................................................................3-17

Setting the blow-off volume flow.................................................................................................3-17

4Operation and Settings........................................................................................... 4-18

Viewing and setting parameters..................................................................................................4-18

Overview of the operating structure ...........................................................................................4-19

5Operation.................................................................................................................. 5-20

Overview....................................................................................................................................5-20

Mounting....................................................................................................................................5-20

Pneumatic connection................................................................................................................5-21

Electrical connection ..................................................................................................................5-22

Pin assignment of the connection plug........................................................................................5-23

Projektieren................................................................................................................................5-23

Start of operations......................................................................................................................5-24