2

Operating instructions

Magnetic reed switches EX-BN 20

EN

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

EX-BN 20-➀Z-3G/D

No. Insert Description

➀

01 1 NC

02 2 NC

10 1 NO

20 2 NO

11 1 NC / 1 NO

R 1 bistable contact

2R 2 bistable contact

11R 2 bistable contact NC / NO

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Purpose

The magnetic reed switch can be used for monitoring the position of

movable guards and flaps in explosion-endangered areas of Zone 2

and 22 category 3GD. Installation and maintenance requirements to the

standard series EN 60079 must be met.

Actuation of the magnetic reed switch is only possible with the actuators

listed (see list in catalogue "Explosion Protection"). Faultless operation

and repeat accuracy is only assured with these actuators.

The user must evaluate and design the safety chain in

accordance with the relevant standards and the required

safety level.

Conditions for safe operation

Due to the specific impact energy, the components must be fitted

with a protection against mechanical stresses. The specific ambient

temperature range must be observed. The user must provide for a

protection against the permanent influence of UV rays.

2.4 Technical data

Equipment category:

L

II 3GD

Ex protection: Ex nC IIC T5 Gc X, Ex tc IIIC T90°C Dc X

Standards: EN 60079-0, EN 60079-15, EN 60079-31

Enclosure: AlSi 12 die-casting, painted

Max. impact energy: 4 J

Protection class: IP67 to IEC 60529

Connection: screw terminals

Cable section: max. 1.5 mm² (incl. conductor ferrules)

Cable entry: 2x M16

Operating principle: magnetic

Switching voltage: max. 250 VAC/DC

Switching current: max. 3 A

Switching capacity: max. 120 VA/W

Dielectric strength: > 600 VAC (50 Hz)

Actuating speed: max. 18 m/s

Switching frequency: max. 300/s

Switching time “Close”: 0.3 ms … 1.5 ms

Switching time “Open”: max. 0.5 ms

Bounce duration: 0.3 ms … 0.6 ms

Ambient temperature: – 15 °C … + 70 ºC

Storage temperature: – 25 °C … + 70 °C

Mechanical life: 108operations

Electrical life: 1 million … 1 billion operations, depending on load

Resistance to vibration: 50 g on sine wave oscillation

Switching point accuracy: ± 0.25 mm, T = constant

Resistance to shock: 30 g / 11 ms

Resistance to vibration: 10 … 55 Hz, amplitude 1 mm

Tightening force:

‒Cover screws: min. 0.6 Nm

‒Cable gland: min. 1.2 Nm

‒Blocking screws: min. 1.2 Nm

Cable glands:

L

II 2GD

Cable cross-section of the cable glands: min. Ø 6 mm;

max. Ø 10 mm

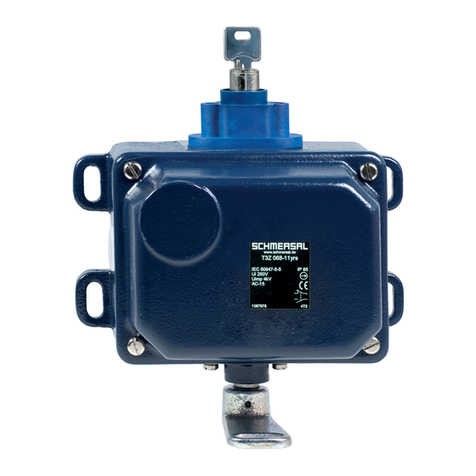

3. Mounting

3.1 General mounting instructions

Fitting is only authorised in a de-energised condition

• Any mounting position, provided that the active surfaces are opposite.

• Do not use the magnetic reed switch as limit stop.

• Two elongated holes are available for fastening the enclosure.

• Ensure the magnetic reed switch is mounted on a flat surface to avoid

tensile stresses that could damage the sensor or lead to varying

switching distances.

• Do not install magnetic reed switches and actuators in strong

magnetic fields.

• If possible do not install the magnetic reed switch and actuator on

ferromagnetic material.

• Do not expose the magnetic reed switch and actuator to strong

vibrations or heavy shocks.

• Inseparably fix the magnetic reed switch and actuator to the safety

guard.

• The use of a protective ground wire is imperative.

• Keep away from metal chips.

Please observe the recommendations regarding maximum

impact energy, actuating speed and tightening torque in the

technical data.

Any changes and alterations that limit the explosion

protection are not allowed.

Please observe the relevant requirements of the standards

ISO 12100, EN 953 and ISO 14119.

3.2 Dimensions

All measurements in mm.

6,5

60

75

30

22 104

M 16x1,5

M 16x1,5

7,5

6,5

10

9,5

25

11,5

47

52