2

Operating instructions

Solenoid interlock EX-AZM 170

EN

1.6 Warning about misuse

In case of inadequate or improper use or manipulations of the

safety switchgear, personal hazards or damage to machin-

ery or plant components cannot be excluded. The relevant

requirements of the standard EN 1088 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages result-

ing from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary re-

pairs, conversions and modifications to the device are strictly forbidden;

the manufacturer shall accept no liability for damages resulting from

such invasive work, arbitrary repairs, conversions and/or modifications

to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

EX-AZM 170-➀Z➁K➂-24VAC/DC-➃-3G/D

No. Option Description

➀

11 1 NO contact / 1 NC contact

02 2 NC contacts

➁

Latching force 5 N

R Latching force 30 N

➂

Power to unlock

A Power to lock

➃

Manual release

2197 Manual release from side

1637 Gold-plated contacts

Only if the information described in this operating instruc-

tions manual are realised correctly, the safety function and

therefore the compliance with the Machinery Directive and

the Explosion Protection Directive is maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Destination and use

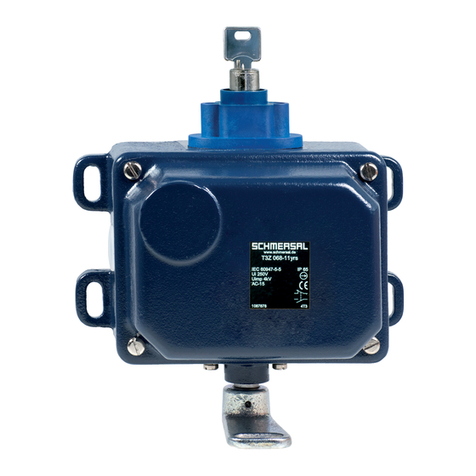

The solenoid interlock has been designed to prevent in conjunction

with the control part of a machine, movable safety guards from being

opened before hazardous conditions have been eliminated. The com-

ponents can be used in explosion-endangered areas of Zone 2 and 22

equipment category 3 GD. The installation and maintenance require-

ments to the standard series EN 60079 must be met.

Conditions for safe operation

Due to the specific impact energy, the components must be fitted with a

protection against mechanical stresses. The specific ambient tempera-

ture range must be observed. The user must provide for a protection

against the permanent influence of UV rays.

Solenoid interlocks with power to lock principle may only be

used in special cases after a thorough evaluation of the risk

of accident, since the safety guard can be opened immedi-

ately on failure of the power supply or upon activation of the

main switch.

Manual release

The locking bolt is pulled into the unlocking position by turning the

triangular key. The normal locking function is only restored after the

triangular key has been returned to its original position. After being put

into operation, the manual release must be secured by installing the

plastic cover, which is included in delivery.

Manual release Manual release from side

Ordering suffix -2197

The user must evaluate and design the safety chain in ac-

cordance with the relevant standards and the required safety

level.

2.4 Technical data

Equipment category:

L

II 3GD

Ex protection: Ex t IIIC T80°C Dc X, Ex nC IIB T5 Gc X

Standards: EN 60947-5-1, EN 60079-0, EN 60079-15, EN

60079-31, BG-GS-ET-19

Enclosure: glass-fibre reinforced thermoplastic,

self-extinguishing

Max. impact energy: 1 J

Actuating speed: max. 1 ms

Actuator and locking bolt: stainless steel 1.4301

Protection class: IP67 to EN 60529

Contact material: Silver

Contact type: change-over with double break Zb,

or 2 NC contacts, galvanically

separated contact bridges

Switching system:

A

EN 60947-5-1, slow action,

NC contact with positive break

Connection: cut clamp terminals

Cable section: 0.75 – 1.0 mm², flexible

Rated impulse withstand voltage Uimp:4 kV

Rated insulation voltage Ui:250 V

Thermal test current Ithe:2 A

Utilisation category: AC-15 / DC-13

Operating current Ie: 2 A / 230 VAC

Rated operating voltage Ue:2 A / 24 VDC

Max. fuse rating: 2 A gG D-fuse

Required short-circuit current: 1000 A

Positive break travel: 11 mm

Positive break force: 6 N for each NC contact fitted

Rated control voltage Us:24 VAC / DC

Magnet: 100% ED

Power consumption: max. 10 W

Ambient temperature:

Mechanical life: max. 1 million operations

Clamping force Fmax:1000 N

Latching force: 30 N for ordering suffix R

Tightening torque

- Cover screws: 0.4 - 0.5 Nm (cylinder-head screw M3 x 20)

- Tightening torque cable gland: 4.5 Nm

Cable glands:

L

II 2GD

Cable cross-section: min. Ø 6.5 mm; max. Ø 12 mm