Operating, Mounting and Maintenance Instructions

en

TDO--Ge

4/

8Safety and Enviromental Protection Regulation “SV 1” 3 348/98 1099236

Storage

The interior areas of the SCHOTTEL products in

question are preserved, following the trial run on the

test stand. Corrosion protection is sufficient for

approx. 6 months, when stored in dry environments

(no sea climate).

Prior to launching y prior to every intial start--up it is

necessary to top up oil

To this effect it is necessary to observe the different

operating instructions.

If a SCHOTTEL unit is put out of operation or re-

moved due to damage, then the unit must be filled

with fresh oil during the storage period, in order to

prevent damage through corrosion.

When storing in the open and/or with considerable

changes in ambient temperature, pressure relief

must be maintained for oil--filled units, as well as for

empty units (e.g new units).

This means:

In the case of units equipped with a vent valve,

the same be opened.

In case of units equipped with a mushroom--type

vent, pressure compensation is already main-

tained.

In the case of units which are only preas-

sembled, a provisional pressure compensation

device with dust protection must be installed at

a pipe connection.

ATTENTION

The storage of electric components, for instance in-

strument panels, switch cabinets etc. in the open is

prohibited.

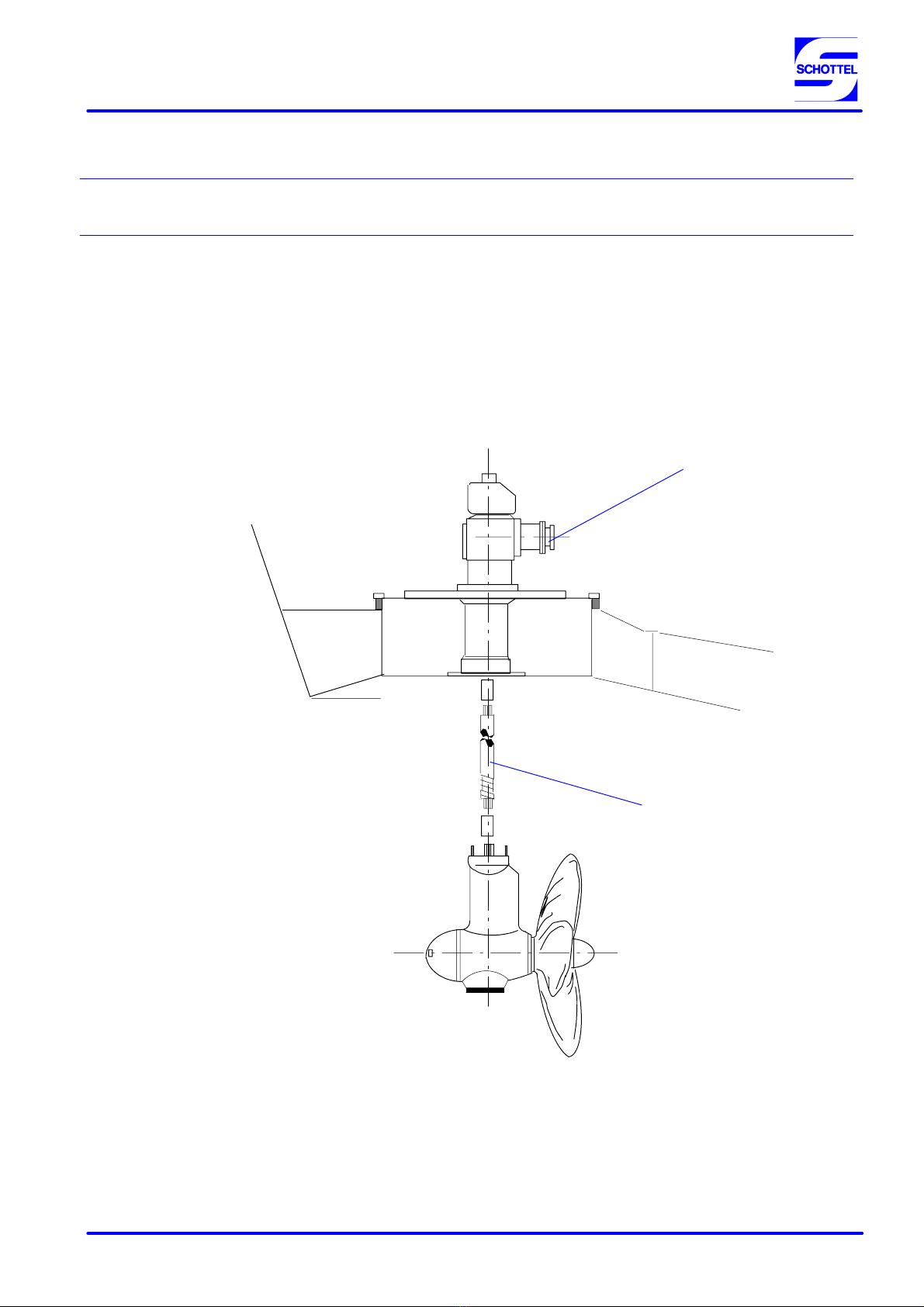

3 Installation, Starting--up and Operation

Installation of SCHOTTEL Products

Before commencing installation, check that the

delivery is complete. All parts must be installed

and/or removed in a competent manner.

The installation of SCHOTTEL products requires

that:

Only those personnel who possess sufficient

technical expertise and the required equipment

shall be employed.

The installation proposals of SCHOTTEL--Werft

shall be observed, and/or requested as necess-

ary.

The relevant technical regulations shall be ob-

served.

Regulations of acceptance authorities under pri-

vate law and/or public law shall be complied

with.

Starting--up and operation (general)

The operating instructions of the relevant provisions

must be observed.

Before putting SCHOTTEL products into operation,

a check must be made for obvious defects and to en-

sure that all protection devices (e.g. cover plates) are

installed soundly. Defective units may not be put into

operation.

Units with defective instruments, pilot lamps and/or

control elements may not be put into operation.

The operator must make absolutely sure that no one

is located within the danger zone of the unit before

putting this into operation.

The indicating instruments must be checked for cor-

rect functioning directly after starting--up, if neces-

sary the unit must be switched off again.