Shockwave ICE Installation and operating instructions

2

TABLE OF CONTENTS

How To Get Help

Service Tips

Important Safety Information

Mounting Instructions

Fastener Torque

Understanding the Basics

Using Autotune System

Daily Operational Checks

Maintenance Schedule

General Troubleshooting

Troubleshooting –Autotune Overview

Autotune 1 Troubleshooting Electrical Diagram

Autotune 1 Troubleshooting Flow Diagram

Troubleshooting –Autotune

Troubleshooting –Finding an Air Leak

Troubleshooting –Fixing an Air Leak

Troubleshooting –Solenoid Orientation Check

Shock Configuration

Warranty

Warranty Claim Form

Warranty Claim Procedure

Service and Repair Procedure

3

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

TABLE OF CONTENTS

3

HOW TO GET HELP / SERVICE TIPS

ADDRESS

PHONE

FAX

EMAIL

HOURS

WEBSITE

2074 Henry Avenue, Sidney BC Canada, V8L 5Y1

+1.778.426.8544

+1.250.655.4334

8 AM to 5 PM Pacific Standard Time

shockwaveseats.com

SERVICE TIPS

HOW TO GET HELP

We are here to help. Call or email us if you have any problems, questions or concerns.

• Drawings and an Illustrated Parts Breakdown are supplied according to the specific ICE configuration ordered. Addi-

• Tell us what the concern is. Be sure to answer all the Who, What, When, Where and Whys of the situation so we have

a clear understanding and can provide the best advice.

• Please identify the SHOCKWAVE product by supplying the serial number, which is typically located inside the front

hatch on the helm side.

• Tell us who you are and what your relationship is with the product.

• Provide both wide angle and close-up photos of the item or area of concern.

• Let us know where you are located and your contact information.

• Tell us the urgency of the request.

• Refer to the Warranty Claim Procedure section of this document for more information.

4

IMPORTANT SAFETY INFORMATION

DANGER

Your SHOCKWAVE ICE will mitigate the effects of shock and vibration, reducing the potential of injury,

but it will NOT prevent the possibility of injury. The increased level of comfort and control provided by the

SHOCKWAVE ICE will allow for the operation of the craft at higher speeds in sea states which create high

shock loads on the craft and potentially the occupants; SHOCK LOADS THAT COULD POTENTIALLY EXCEED

THE ICE’S CAPABILITIES TO MITIGATE.

Operating marine craft in a high shock load environment is inherently hazardous. Tolerance to the effects of

shock and vibration vary from person to person and it is the responsibility of the craft operator to ensure the

safety of each person onboard. Pain and/or discomfort are indicators of a potential injury. Constantly monitor

the physical state of the craft and the personnel onboard. Hazardous operation of the craft may result in

serious injury, death or damage to the craft.

IMPORTANT

Follow IMPORTANT instructions located throughout the Operations and Service Manual to prolong the

appearance and service life of your SHOCKWAVE ICE Console.

WARNING

• Do not modify the equipment by drilling extra

holes, removing material, or adding extra

equipment. Serious injury can result.

• Do not use the ICE if it is, or appears to be,

damaged. Serious injury can result.

• Do not use seating if the seat to ICE attach-

ments are loose. Serious injury can result.

• Do not use the ICE if the resting height is

lower than normal. This may be an indication

of a damaged or leaking system. Serious injury

and damage can result.

• Do not operate the console with insufficient

air pressure in shocks to prevent bottoming.

Serious injury and damage can result.

CAUTION

• Do not use the ICE for uses other than its

intended purpose. Damage to the equipment

or bodily harm may result.

• Do not use the ICE if fasteners are loose.

Damage to the equipment or bodily harm may

result.

• Do not attempt to open, perform maintenance

or repair the ICE while the craft is underway.

Damage to the equipment or bodily harm may

result.

• Do not place items under or around the ICE

that may interfere with the ICE’s range of

motion. Damage to the equipment or bodily

harm may result.

IMPORTANT SAFETY INFORMATION

5

DANGER

Incorrectly installed ICE consoles can cause damage to the ICE and vessel, as well as cause serious injury or death.

WARNING

Control arms should be kept as short as possible. Do not extend more than 0.25” [6.35mm] per link end from

fully retracted position.

MOUNTING INSTRUCTIONS

• There must be enough deck structure to support the weight of the ICE and occupants within the vessel’s operational

• There must be no flex in the mounts or deck plate when the ICE is loaded.

• The shock brackets, linkage brackets, sway bar brackets and the ICE must not be modified.

• Do not mount the ICE on a curved deck if it was not specifically designed for the curved deck by SHOCKWAVE.

• Do not mount the ICE in the middle of an unsupported deck plate.

• Ensure that the movement of the ICE does not interfere with the vessel structure or equipment.

• Check operation of the ICE after installation by filling and draining the system. It must not bind or stick.

• All the ICE deck mounts must be positioned as per SHOCKWAVE specification. CAD files or a metal drill template for

• Ensure the ICE is true to the deck by using a plumb bob to find the center of the front and rear of the ICE and ensure

the ICE is aligned with the centerline of the mounts. Adjust the ICE by rotating the center shaft of the control arms

to extend or reduce the length.

C L

MOUNTING INSTRUCTIONS

6

RECOMMENDED FASTENER TORQUE

All fasteners are prone to becoming loose from sustained high-performance use. SHOCKWAVE recommends that

all bolts should be visually inspected for signs of being loose. Always use a thread-locker on fasteners to prevent

loosening. Please use the reference table below:

SIZE PITCH TORQUE (STAINLESS)

Dry

#6

M5

#8

M6

M8

M10

M12

5/16”

5/8”

3/8”

3/4”

7/16”

1”

#10

1/4”

1/2”

32

0.8

32

1.0

1.25

1.5

1.75

18

11

16

10

14

8

24

20

13

32

28

20

10 in-lbs

45 in-lbs

21 in-lbs

6 ft-lbs

15 ft-lbs

31 ft-lbs

54 ft-lbs

11 ft-lbs

96 ft-lbs

20 ft-lbs

131 ft-lbs

32 ft-lbs

299 ft-lbs

23 in-lbs

6 ft-lbs

45 ft-lbs

33 in-lbs

8 ft-lbs

47 ft-lbs

9 in-lbs

40 in-lbs

17 in-lbs

6 ft-lbs

14 ft-lbs

27 ft-lbs

48 ft-lbs

9 ft-lbs

82 ft-lbs

17 ft-lbs

111 ft-lbs

27 ft-lbs

254 ft-lbs

20 in-lbs

6 ft-lbs

38 ft-lbs

28 in-lbs

7 ft-lbs

40 ft-lbs

IMPERIAL

METRIC

Lubricated

RECOMMENDED FASTENER TORQUE

7

SHOCKWAVE ICE is designed to mitigate shock and

vibration encountered in high speed vessel operation on

rough seas. Following the suggestions in this section will

ensure that you are getting the most out of the product.

SET THE RIDE HEIGHT

The suspension must be allowed to compress and extend

as designed. Ensure the ICE is SET after each time the

payload on the ICE changes. This should allow the ICE to

sit 2” [50mm] less than full shock extension.

OPERATE IN THE VESSEL’S DESIGN ENVELOPE

Driving the boat beyond its limitations can have damaging

effects on the hull, engines and equipment. The SHOCK-

WAVE ICE is designed to provide shock mitigation to the

occupants. It will not protect the occupants from injury

caused from operating the vessel outside of its operational

envelope.

OPERATE THE VESSEL IN YOUR CREWS PHYSICAL

CONDITIONING ENVELOPE

Personal fitness is a limiting factor to the amount of sus-

tained G loads a person can endure without injury. If you

have inexperienced, relatively unfit or overweight per-

sons aboard, extra caution must be exercised to prevent

injury. The helmsman must be keenly aware of the shock

loads being transmitted to passengers not in the ICE or

standing, as serious injury can occur. Installation of the

SHOCKWAVE ICE provides an extra level of protection, but

the ICE will not protect a person from ALL shock loads.

OPERATE IN YOUR OWN ABILITY ENVELOPE

The SHOCKWAVE ICE will increase the confidence of

the helmsman. Overconfidence can lead to loss of boat

control. Generally, the ICE will permit greater control of

the vessel and the helmsman should focus on using the

control advantages of the shock mitigated ICE to better

look after the vessel and crew.

DO NOT TIE THE BOAT UP WITH THE ICE

As tempting as it may be, the SHOCKWAVE ICE is not

designed to tie up the boat.

ENSURE THAT THE ICE IS FUNCTIONING PROPERLY

Refer to the Caution Notes in the preceding sections.

The following is provided as a general checklist.

Do not operate the ICE if:

• The shock ride height is incorrect.

• Any components are loose, broken or missing.

• The ICE makes a strange noise when being operated.

USE SEAT BELTS – IF SUPPLIED

Seat belts prevent occupants from being ejected from the

vessel and the seat. When not in use, the seat belt buckle

clasp should be fastened to prevent damage to the ICE.

SET FORE AND AFT SEAT ADJUST CORRECTLY – IF

SUPPLIED

Correct ergonomics and posture enhance the ability to

operate the vessel safely and reduces the risk of shock

and vibration related injury. Take the time to adjust the

seat so that it is comfortable.

DO NOT SIT IN SEATS WITH HARD OR SHARP

OBJECTS. DO NOT WALK ON SEATS

Ensure that sharp objects and heavy gear are worn so that

they will not tear the upholstery.

RINSE ICE WITH FRESH WATER AFTER EACH USE

Rinse the ICE and the seats with fresh water after each

use, or every week if being stored outside, to prevent a

buildup of salt and debris.

COVER SEATS WHEN NOT IN USE

Seat covers are available from SHOCKWAVE to cover all

the seats.

TIE EVERYTHING DOWN

Pay attention to how you have stowed your gear. Elastic

shock cords and ratchet tie downs should be used to

secure all gear. Plastic containers of oil and other fluids

must be protected from chafing and puncture. Electronic

equipment must be secured to prevent damage from

shock loads.

CHECK ALL EQUIPMENT

Conventional mounting brackets for heavy items such as

fire extinguishers are subject to much more loading than

without shock mitigation. Make sure all your equipment

brackets are tight. Recheck major equipment bolts reg-

ularly. Wiring, cables and fluid hoses should be bundled

tightly and not allowed to flail. Do not allow any objects

under the ICE. The objects will limit the stroke of the ICE

and damage the objects or damage the ICE.

REMOVE OR PAD BODY STRIKE HAZARDS

Hard objects, particularly in the head strike zone, need to

be rounded and padded. When assessing your body strike

hazards consider a generous portion of clearance, as the

body will stretch in a high G situation.

UNDERSTANDING THE BASICS

UNDERSTANDING THE BASICS

8

The ICE is typically equipped with the SHOCKWAVE AUTOTUNE system that allows for simple filling and setting of the

ICE system. To get the most out of your ICE, it is important to always setup the suspension properly when weight is either

added or removed from the ICE.

STEP 1: Ensure the ICE is set up with its full occupants and gear weight in place.

STEP 2: If the red ‘WAIT’ light is illuminated the compressor is running to fill up the air tank. This can take up to 5

minutes. Once the green ‘READY TO FILL’ light is illuminated the air tank is full.

STEP 3: Lift and hold the momentary toggle switch in the ‘FILL’ position to fill all shocks. Hold the switch until the ICE is

at full height.

STEP 4: Set the ICE console to ‘SET’ height by holding the switch in the ‘SET’ position. This generally takes 5-10 seconds.

STEP 1: Ensure the ICE console is set up with its full occupants and gear weight.

STEP 2: Lift the ‘ON/OFF’ toggle switch to the up position. The ‘FILL’ light should be blinking.

STEP 3: Lift the ‘FILL’ toggle switch to the up position and wait until the ‘FILL’ light has stopped blinking.

STEP 4: When the system is ready, the ‘SET’ light will be flashing. At this time hold the ‘SET’ toggle down until the light

stops blinking. At this point the ‘STATUS’ light should be solid green in the “READY” state.

USING AUTOTUNE 1 SYSTEM

USING AUTOTUNE 2 SYSTEM

1LOAD OCCUPANTS AND GEAR INTO ICE

2WAIT UNTIL GREEN LED IS ILLUMINATED

3‘FILL’ UNTIL ICE IS AT FULL HEIGHT

4TOGGLE SWITCH TO ‘SET’ UNTIL ICE SETTLES

5TO LOWER ICE, PRESS AND HOLD ‘DRAIN’

INSTRUCTIONS

WAIT READY TO FILL

DRAIN

SET

FILL

USING AUTOTUNE SYSTEM

9

DAILY OPERATIONAL CHECKS

IMPORTANT

The SHOCKWAVE ICE does not have to be drained after every use. It is acceptable to leave your ICE console

filled for extended periods of time, but it will still need to be set properly before its next use.

Before each use, ensure there are no missing, damaged or cracked components on or under the ICE.

Check for equipment that might have been placed under the ICE.

Before sitting in the ICE, raise the zip tie travel indicators up on the exposed shock until they rest against the upper

shock body. Setup the ICE as per instructions on page 8. Once the console is “SET”, check to see if there is a gap

between the shock body and the zip tie. If a gap exists, there is a potential for an air leak in the system which has

caused the ICE to settle since its last operation. Monitor the shock in question and follow the trouble shooting guide

on page 11 if any problems arise.

DAILY OPERATIONAL CHECKS

10

MAINTENANCE SCHEDULE

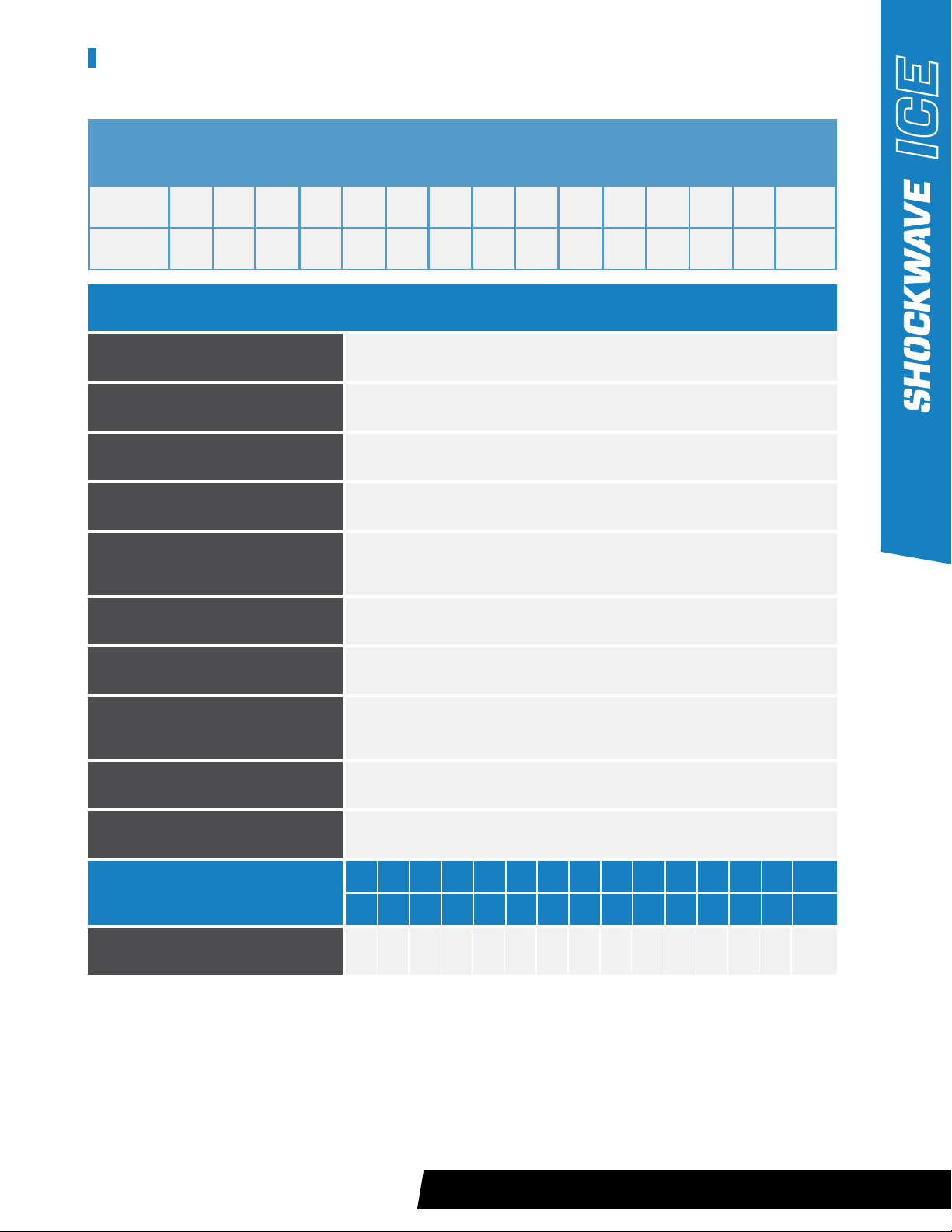

15 YEAR LIFE CYCLE MAINTENANCE PROGRAM - BASED ON 400 HRS./YR.

Service at the indicated hours or months - whichever comes first.

HOURS

MONTHS

400

12

800

24

1200

36

1600

48

2000

60

2400

72

2800

84

3200

96

3600

108

4000

120

4400

132

4800

144

5200

156

5600

168

6000

180

WHEN NOT BEING USED OR IF STORED OUTSIDE

Cover seating with Boat Cover

or Seat Cover

AFTER EVERY EXPOSURE TO SALT WATER SPRAY

Clean ICE - Fresh Water or

Wash with Car or Boat Wash

EVERY 200 HRS OR AFTER EXPOSURE TO EXTREME IMPACTS

Inspect Shock Mounts and Shock

Bolts for damage or bends

WEEKLY

Lubricate Link Ends – LPS 3, triple

guard grease or equivalent

EVERY 40 HOURS (AFTER SEATS HAVE DRIED FROM CLEAN)

Protect Metal Surfaces and

Fasteners – LPS 1® or equivalent

EVERY 125 HOURS

Check Fastener Torques

EVERY 200 HOURS

Use Soapy water to check for

air leaks

AS REQUIRED (REMOVING ANY BUILDUP OF DIRT OR SALT)

Clean Upholstery – Boat or

Automotive Detail Spray Cleaner

AFTER EVERY EXPOSURE TO SALTWATER SPRAY

Clean Console Underside and Deck

Mounts – Fresh Water or Wash with

Car or Boat Wash

WEEKLY

Clean and Lubricate Fox Shock

Absorber Shaft – After cleaning

apply LPS 1®

HOURS

MONTHS

400

12

800

24

1200

36

1600

48

2000

60

2400

72

2800

84

3200

96

3600

108

4000

120

4400

132

4800

144

5200

156

5600

168

6000

180

X X X X X X X

Replace Link End Heim Joints

MAINTENANCE TASK

MAINTENANCE SCHEDULE

11

Squeaks when in use

Zip tie travel indicator below

“Safe Travel Zone Marker”

• Rod end bearings of the ICE

links are dry

• Sway bar links are dry

• Insufficient air pressure

in shocks

• Console overweight

• Lubricate with heavy duty

marine grease.

• Remove sway bar arm and

lubricate bearing area with

heavy duty marine grease.

• Follow: Finding an air leak on

the subsequent pages.

• Remove excess weight from

the console.

Clunking Noise During Operation • Loose bolts or cracked

components

• Check bolt torques and

inspect for loose, cracked or

bent parts. Start by checking

the upper shock bolts and

work your way down to the

deck, checking all fasteners

and brackets.

CONDITION CAUSE REMEDY

GENERAL TROUBLESHOOTING

GENERAL TROUBLESHOOTING

12

TROUBLESHOOTING – AUTOTUNE OVERVIEW

The AUTOTUNE systems contain valves, hoses, compressors and shocks which work together to manipulate the

SHOCKWAVE ICE with simple toggle switches. While the ICE configurations vary slightly due to body shape and space

availability the general layout is consistent throughout the SHOCKWAVE ICE product line.

• Each shock has two air connections. The fill port is used to add/remove air from the shock. The set port

is used to automatically drain a certain amount of air from the shock to provide the correct ride height.

• The compressor, tank, and water separator are typically located in the rear lower section of the ICE.

• The fill and set solenoid valves are typically located just inside the body of the ICE near the shock mounts.

Each shock has its own ‘FILL’ and ‘SET’ solenoid valve.

• The main fill solenoid valve is typically located near the air/water separator and the main drain solenoid is

typically located near the distribution manifold.

SET PORT

(USED TO OPTIMIZE PERFORMANCE)

FILL PORT

(USED TO ADD/REMOVE AIR)

TROUBLESHOOTING – AUTOTUNE OVERVIEW

13

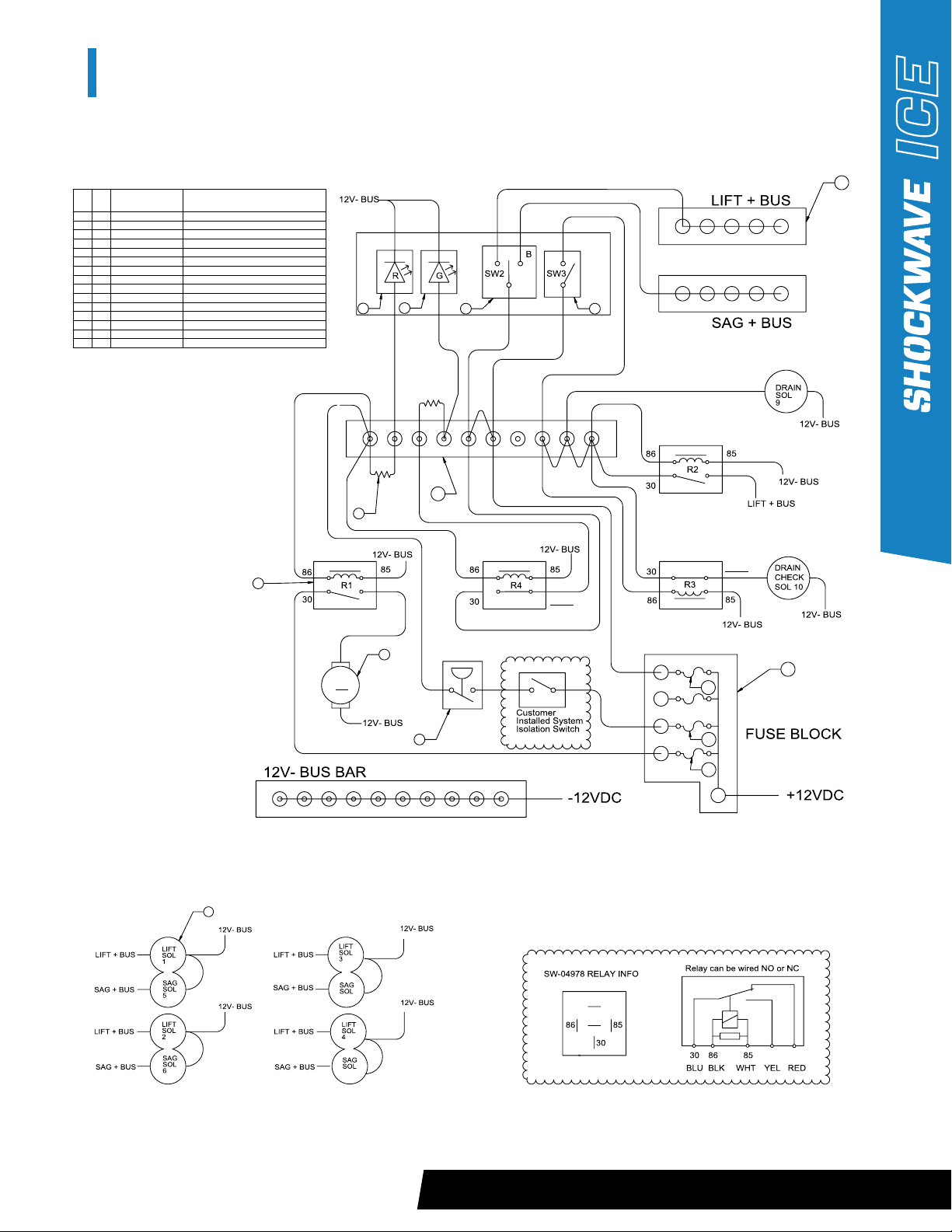

AUTOTUNE 1 TROUBLESHOOTING

ELECTRICAL DIAGRAM

M

A

87

87A**

87A**

87

8

2

3

4

567

9

10

11

12

13

14

15

ITEM

QTY.

PART NO.

DESCRIPTION

110

SW-04968

12V Solenoid Valve - 1/4" NPT Female

21

SW-04973

12V Pressure Switch - 200PSI NC

34

SW-04978

12V 30A Relay With Pigtail

41

SW-04979

12V 4MM Panel Mount LED - Green

51

SW-04980

12V 4MM Panel Mount LED - Red

61

SW-04982

SPDT Harsh Environment Toggle Switch

71

SW-04985

Seadog 30A Push Button Switch

81

SW-05071

VIAIR 480C Air Compressor

92

SW-05098

Resistor 680 Ohm 1 Watt

10 1

NOT SUPPLIED

4 Position ATD/ATC Fuse Block

11 2

NOT SUPPLIED

4 Position - Common Bus Bar

12 1

NOT SUPPLIED

8 Position Terminal Block - No Common

13 1

NOT SUPPLIED

ATD/ATC Fuse - 5A

14 1

NOT SUPPLIED

ATD/ATC Fuse - 20A

15 1

NOT SUPPLIED

ATD/ATC Fuse - 40A

8

7

1

87A**

87

87A**

87

AUTOTUNE 1 TROUBLESHOOTING ELECTRICAL DIAGRAM

14

AUTOTUNE 1 TROUBLESHOOTING

FLOW DIAGRAM

SW-MB005 – MAINTENANCE INSPECTION ON S1, S2 AND S3 CARRIAGE ROLLERS / FEBRUARY, 2016

Y

Y

N

N

Y

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

PROBLEM

FIXED?

CONFIRM TANK IS

PRESSURIZED USING

PRESSURE GUAGE

TANK

PRESSURIZED?

CONTACT SHOCKWAVE

SUPPORT CODE #1

(TANK NOT PRESSURIZING)

JUMP TERMINALS OF

PRESSURE SWITCH TO

TEST COMPRESSOR

DOES

COMPRESSOR

RUN?

CHECK SYSTEM FOR LEAKS

AND LOOSE HOSES

PROBLEM

FIXED?

CHECK CONNECTIONS AND

CONFIRM 12VDC AT

COMPRESSOR RELAY

CONNECTIONS

OK?

CONTACT SHOCKWAVE

SUPPORT CODE#3

(COMPRESSOR)

REPAIR AS

REQUIRED

FINISH

TOGGLE / PUSH SWITCH

TO ‘DRAIN’

START

DOES ICE CONSOLE

LIFT UNTIL AT FULL

HEIGHT?

TOGGLE SWITCH TO ‘SET’

DOES ICE

DROP TO

SAG HEIGHT?

TOGGLE SWITCH

TO ‘FILL’

CHECK CONNECTIONS AND

12VDC AT SWITCH #2

PROBLEM

FIXED?

CONFIRM OPERATION OF

SOLENOIDS #5-8 AND

CONNECTIONS TO GROUND

DOES ICE

CONSOLE LOWER

TO THE GROUND?

CONFIRM OPERATION OF

SOLENOID #9 AND

CONNECTIONS TO GROUND

CHECK CONNECTIONS

AND 12VDC AT SWITCH #3

PROBLEM

FIXED?

NOTE: ALWAYS CONFIRM POWER

SOURCE IS SWITCHED ON AND

FUNCTIONING CORRECTLY

PROBLEM

FIXED?

PROBLEM

FIXED?

CONTACT SHOCKWAVE

SUPPORT CODE#4

(SOLENOID)

CONTACT SHOCKWAVE

SUPPORT CODE#2 (POSSIBLE LEAK)

CONFIRM OPERATION OF

SOLENOIDS #1-4, 10 AND

CONNECTIONS TO GROUND

See Electrical Diagram on page page 13 for reference.

AUTOTUNE 1 TROUBLESHOOTING FLOW DIAGRAM

15

AUTOTUNE 1 TROUBLESHOOTING

AUTOTUNE 2 TROUBLESHOOTING

System will not fill • Loss of power to the system • Check Autotune fuse

• Ensure wiring is not damaged,

pinched or corroded.

CONDITION CAUSE REMEDY

ON/OFF light won’t illuminate

FILL light will not stop blinking

SET light does not stop blinking

Status lights not illuminating but

system still functioning

• No power to the system

• System cannot reach maximum

operating pressure (MIN 190 PSI)

• System has not detected signifi-

cant air flow during SET process

• Console was not able to get

above the SET point

• Status light shave burnt out

• Dimmer switch turned down

• Check Autotune fuse

• Ensure wiring is not damaged,

pinched or corroded

• Check for air leaks around the

tank, compressor and shocks

• Re-calibrate the system

• Reduce weight in the ICE

• Re-calibrate the system

• Adjust dimmer switch to

maximum brightness

• Remove panel and check for

voltage at LED’s Replace if

necessary

CONDITION CAUSE REMEDY

AUTOTUNE TROUBLESHOOTING

16

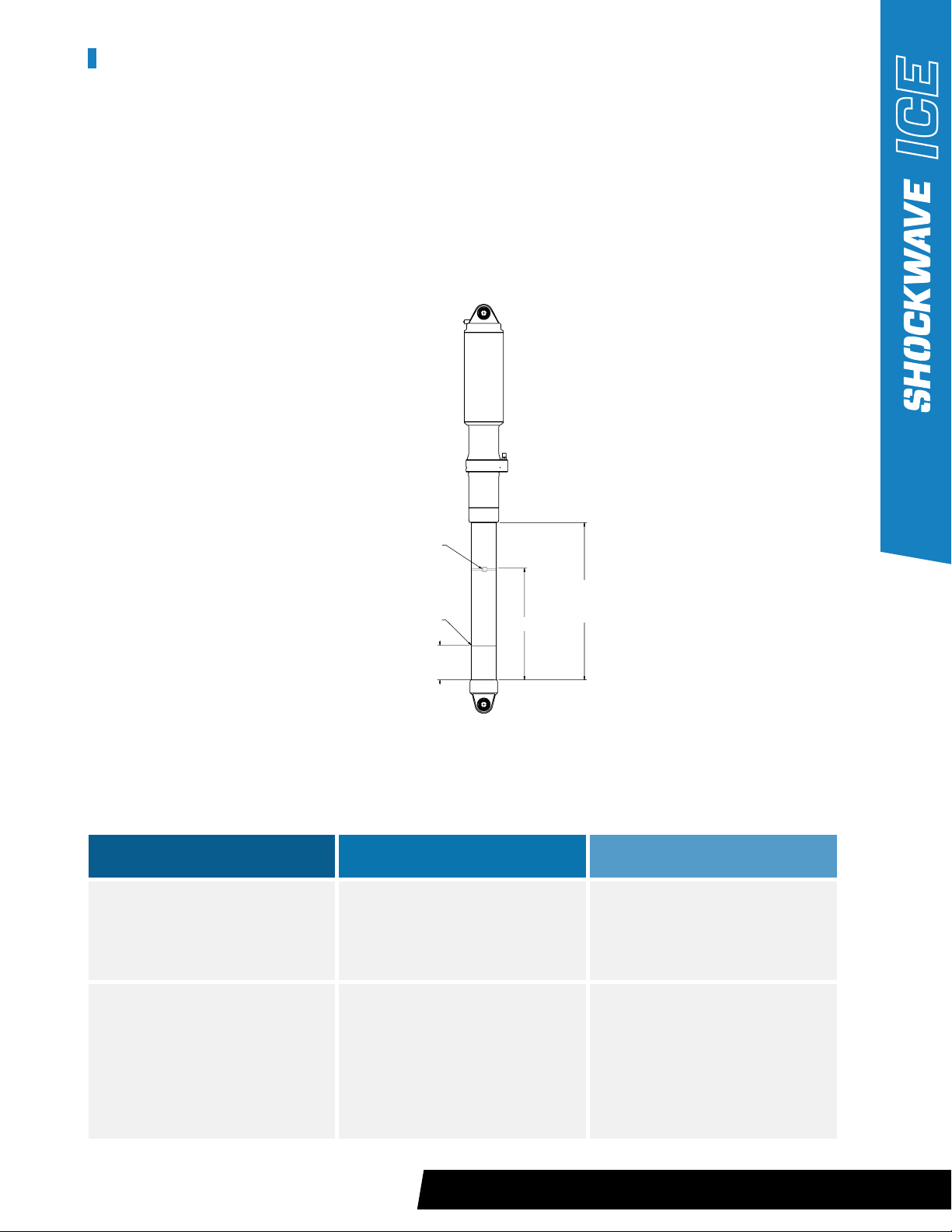

TROUBLESHOOTING – FINDING AN AIR LEAK

If there are operational problems with the console bottoming out or not holding air, the procedure below can

help to narrow down the problem.

STEP 1: Fill the system to max pressure using the fill toggle switch on the AUTOTUNE system. Allow the shocks to fully

extend by allowing the compressor to reach maximum pressure (around 200psi on the tank gauge) and record

the tank pressure.

STEP 2: If the red ‘WAIT’ light is illuminated the compressor is running to fill up the air tank. This can take up to 5 minutes.

Once the green ‘READY TO FILL’ light is illuminated the air tank is full.

STEP 3: Allow the console to sit for 3-4hrs or overnight if possible. Do not allow anyone to enter or add gear to the ICE

during this time.

STEP 4: Measure all the shocks on the ICE and record the extended length as well as the tank pressure.

Tank pressure has dropped but

shocks are still measuring the

same extended length.

Tank is still at max pressure but

extended length of one or more

shocks has dropped.

• Potential air leak between

compressor and “FILL” solenoid

• Potential leak of shock or fitting

between “FILL” Solenoid and

“SET” solenoid.

• Check all fittings with soapy

water, replace or tighten any

loose fittings.

• Check the shock body fittings

with soapy water, replace or

tighten any loose fittings. If the

shock is leaking through its main

seal it will need to be removed

and repaired or replaced.

CONDITION CAUSE REMEDY

ZIP TIE

SAVE TRAVEL ZONE MARKER

[73mm]

2 7/8”

DIM #1

EXTENDED LENGTH

[354mm]

13-15/16”

TROUBLESHOOTING – FINDING AN AIR LEAK

17

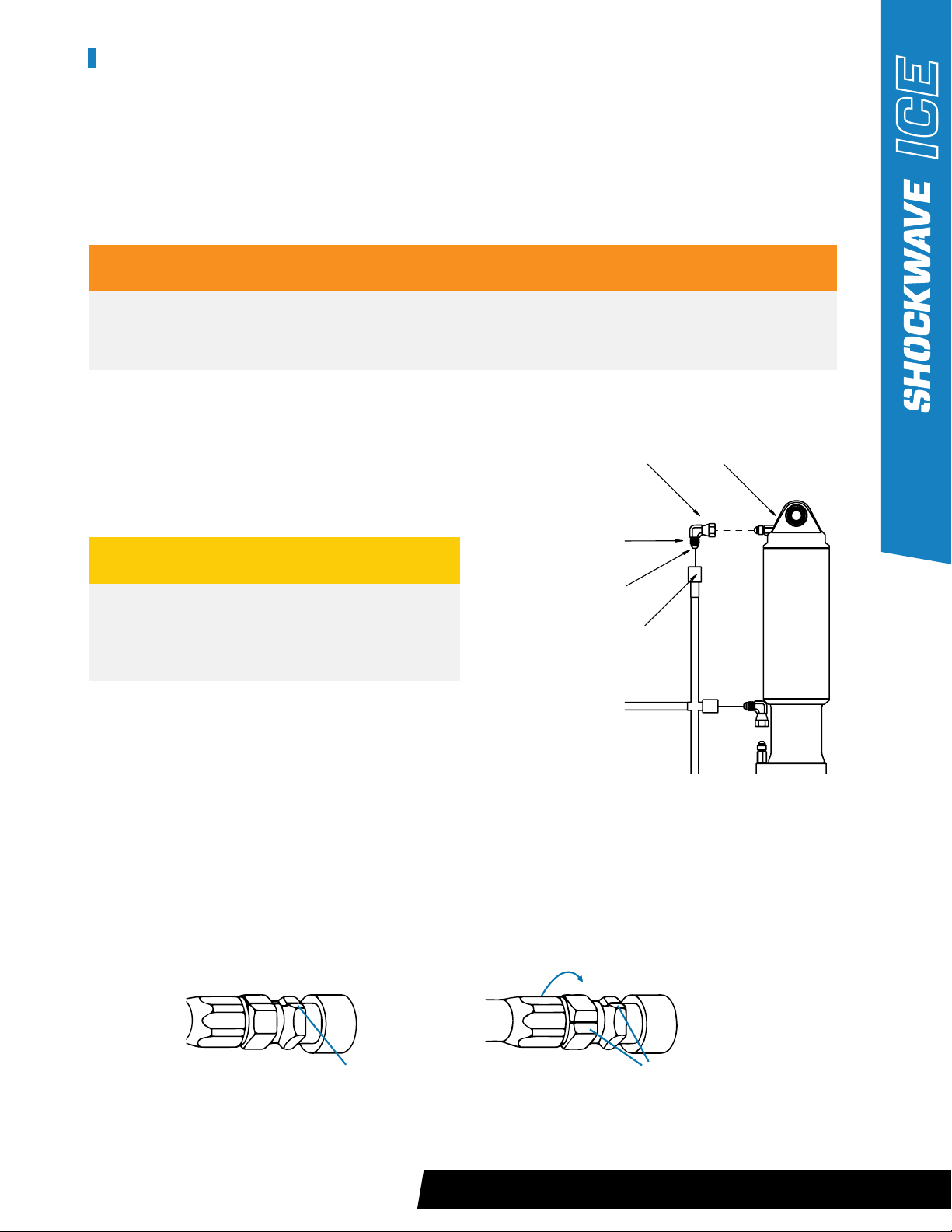

TROUBLESHOOTING – FIXING AN AIR LEAK

STEP 1: Drain the system ensuring the ICE is securely resting on the deck and all the air has been released from the shocks.

STEP 2: If there is obvious damage to the fitting such as a crack or a hole, replace the fitting with a new one sourced

from a hydraulic supply shop or purchase directly from SHOCKWAVE.

STEP 3: Ensure the compressor does not turn on by turning off either the boat power or the auxiliary power switch for

the compressor if supplied.

STEP 4: Remove the leaking fittings, in some instances there are multiple fittings connected to generate the proper

hose routing.

STEP 7: Reinstall all fittings and tighten using the method of flats.

a) Tighten the fitting until it bottoms against the seat.

b) Using a marker, draw a line lengthwise on the fitting and extend it onto the adapter

c) Using a wrench, rotate the fitting to tighten by turning the fitting the 1-1/2 to 1-3/4 hex flat rotations.

STEP 8: If the leak continues, replace the fittings or hoses and repeat steps 6-8.

WARNING

When removing combined fittings, always hold both fittings so you only loosen the required fitting.

I.e. Removing Fitting 2 from 1, hold Fitting 1with a wrench and loosen fitting 2 (See drawing below).

THREADS

FITTING 2

FITTING 3

FITTING 1

SEALING FACE

MARK A LINE ON THE FITTING AND

ADAPTER BEFORE TIGHTENING.

MISALIGNMENT OF THE MARK SHOWS

AMOUNT WHICH THE FITTING WAS TIGHTENED.

TROUBLESHOOTING – FIXING AN AIR LEAK

CAUTION

Do not remove Fitting 1 unless there are clear signs

of leakage. If removed, the O-ring on this fitting

needs to be replaced.

STEP 5: Clean the inside and outside of all fittings using a green Scotch-Brite pad or equivalent.

Ensure all contamination is removed from the sealing flanges and threads.

STEP 6: Apply Loctite 5452 to the sealing face (taper) of the fitting and on the threads.

18

TROUBLESHOOTING – SOLENOID

ORIENTATION CHECK

Ensuring that the solenoids are installed correctly is critical to the safety and operational performance of the ICE. To

diagnose the solenoid orientation correctly, the rest of the system must be airtight. Ensure the troubleshooting step

“Finding an Air Leak” (page 16) is completed before proceeding.

STEP 1: Fill the system to max pressure, ensure the tank pressure reads over 190 psi.

STEP 2: Measure and record the extended length of the shock.

STEP 3: Turn off the compressor, this might require the vessel power to be turned off depending on how the system

is powered.

STEP 4: Pull the pressure relief valve on the tank.

Extended shock length has been

reduced.

• Potential incorrect orientation

of the FILL or SET solenoids.

• Install solenoid in the correct

orientation; see AUTOTUNE

Installation Instructions at the

back of this manual.

CONDITION CAUSE REMEDY

TROUBLESHOOTING – SOLENOID ORIENTATION CHECK

CAUTION

Do not put your hands near the pressure relief valve and wear ear and eye protection as the release of air will be

very loud and can potentially cause injury.

STEP 5: Allow the ICE to sit for 3-4 hrs.

STEP 6: Measure the extended length of the shock.

19

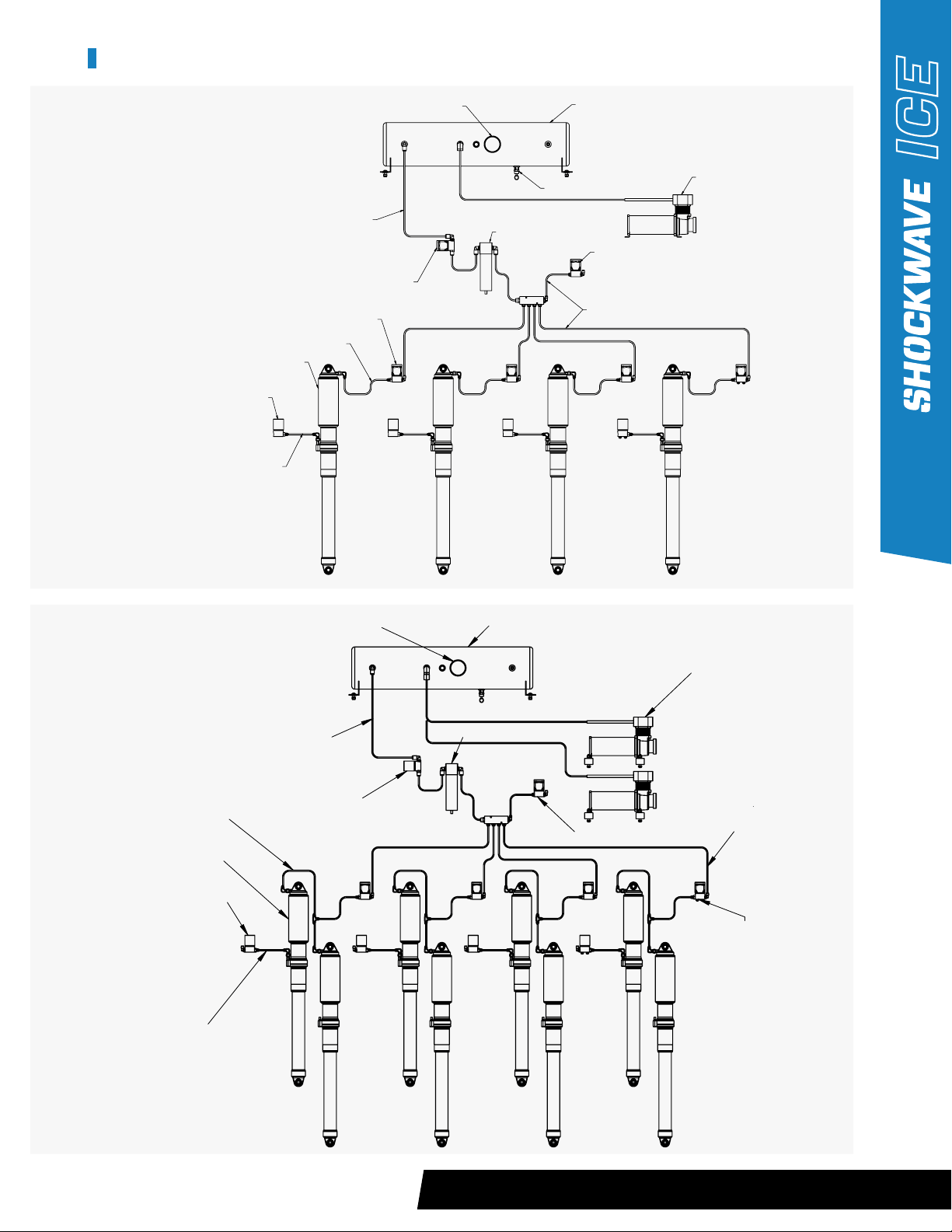

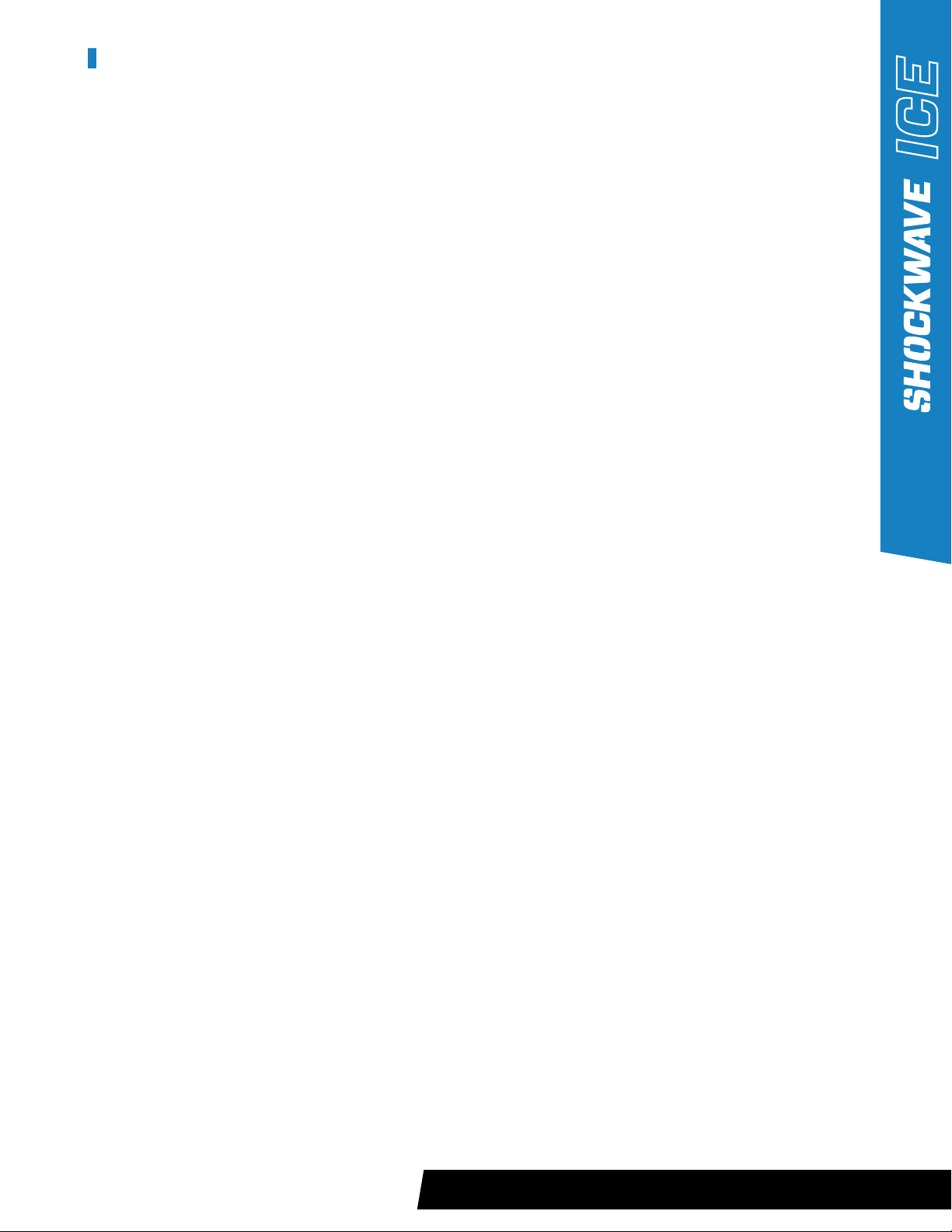

SHOCK CONFIGURATION

‘SET’ SOLENOID (TYPICALLY LOCATED

INSIDE CONSOLE NEAR THE SHOCK)

‘FILL’ SOLENOID (TYPICALLY

LOCATED INSIDE CONSOLE

NEAR THE SHOCK)

LOW PRESSURE PUSH TO CONNECT HOSE AIR/WATER SEPERATOR

AIR COMPRESSOR

MAIN DRAIN SOLENOID

LOW PRESSURE PUSH

TO CONNECT HOSES

PRESSURE GAUGE TANK

MAIN FILL SOLENOID

HIGH PRESSURE

JIC (FLARE) HOSE

MEGAFLOAT SHOCK

HIGH PRESSURE JIC (FLARE) HOSE

SHOCK CONFIGURATION

‘SET’ SOLENOID (TYPICALLY LOCATED

INSIDE CONSOLE NEAR THE SHOCK)

‘FILL’ SOLENOID

(TYPICALLY LOCATED INSIDE CONSOLE NEAR THE SHOCK)

LOW PRESSURE PUSH TO CONNECT HOSE

PRESSURE RELIEF VALVE

AIR/WATER SEPERATOR

AIR COMPRESSOR

MAIN DRAIN SOLENOID

LOW PRESSURE PUSH TO CONNECT HOSES

TANK GAUGE TANK

MAIN FILL SOLENOID

HIGH PRESSURE

JIC (FLARE) HOSE

MEGAFLOAT SHOCK

HIGH PRESSURE JIC (FLARE) HOSE

4-SHOCK SYSTEM

8-SHOCK SYSTEM

20

WARRANTY

SHOCKWAVE Seats expressly warrants that all mechanical seat components in its MARINE AND OTHER and SUSPENSION

SEATS shall be free from defects in material and workmanship for one year from the date-of-sale provided such seats

are subject to normal use and receive proper maintenance. SHOCKWAVE Seats expressly warrants that the cushions and

seat covers shall be free from defectively sewn seams for a period of 90 days or 750 hours of use, whichever comes first,

excluding normal wear and tear. Rips, tears, abrasions and installation damages are not covered by warranty.

Your sole and exclusive remedy against SHOCKWAVE Seats arising from the purchase or use of MARINE AND OTHER

and SUSPENSION SEATS is limited to repair or replacement of defective materials or defective workmanship, after

verification by SHOCKWAVE Seats. Defective product or materials may be requested for return by SHOCKWAVE Seats

for inspection prior to issuing any replacements. Freight charges for returns are to be covered by the user.

All warranty claims shall have prior approval from SHOCKWAVE Seats warranty department and must be accompanied

by the information requested on the following Claim Form. Products will be repaired or replaced at the sole discretion of

SHOCKWAVE Seats.

THESE WARRANTIES WILL BECOME NULL AND VOID IF:

• The ICE is abused or altered

• The ICE is involved in an accident

• The ICE is improperly installed

• The ICE is used for other than its intended use, contrary to any of the instructions in the manual provided.

• There is damage to the ICE caused during installation or unpacking.

• There is damage to the cushions and covers caused by cuts, burns, or abuse

The above expressed warranties shall be the exclusive warranties, and SHOCKWAVE seats

makes no other warranties, expressed or implied. SHOCKWAVE seats expressly disclaims any

implied warranties or merchantability and implied warranties of fitness for a particular purpose.

It is agreed that SHOCKWAVE seats shall not be liable for incidental or consequential damages,

including, but not limited to, loss of income, loss of use, lost profits, damage to other property, the cost of removing

and reinstalling the INDUSTRIAL SEATING or SUSPENSION SEATS, attorney’s fees, and any liability you may have with

respect to any other person.

It is agreed that you have one year from the accrual of a claim to commence any legal action arising from the purchase or

use of the MARINE AND OTHER or SUSPENSION SEATS, or be barred forever.

Failure to give prompt written notice within ten (10) days of the discovery of any defect in material or workmanship that

occurs within the warranty period will void the warranty. Send notification and completed warranty claim form to:

SHOCKWAVE SEATS WARRANTY DEPARTMENT

2074 Henry Avenue West, Sidney BC Canada V8L 5Y1

WARRANTY CLAIM FORM MUST BE SUBMITTED

Download your Warranty Claim Form at shockwaveseats.com/warranty

To the extent any provision of this Limited Warranty contravenes the law of any jurisdiction, such provision shall be

inapplicable in such jurisdiction, and the remainder of this Limited Warranty shall not be affected thereby.

WARRANTY

Table of contents

Other Shockwave Marine Equipment manuals

Popular Marine Equipment manuals by other brands

JRC

JRC JFV-130HP Series installation manual

EMBRON

EMBRON Hatteland Technology HD 15T22 MMD F Series user manual

Nexus

Nexus Autopilot R-1600 Installation and operation manual

Abus

Abus FUSG50110 quick guide

Abus

Abus AZSG10020 Installation instructions and user manual

Edgetech

Edgetech STARMUX IV USER HARDWARE MANUAL

Dura-Max

Dura-Max Box Cooler installation manual

Speedtech

Speedtech EE-1 user manual

vesper marine

vesper marine WatchMate 850 install guide

Simrad

Simrad GN70 Operator and installation manual

Sailmon

Sailmon E4 installation manual

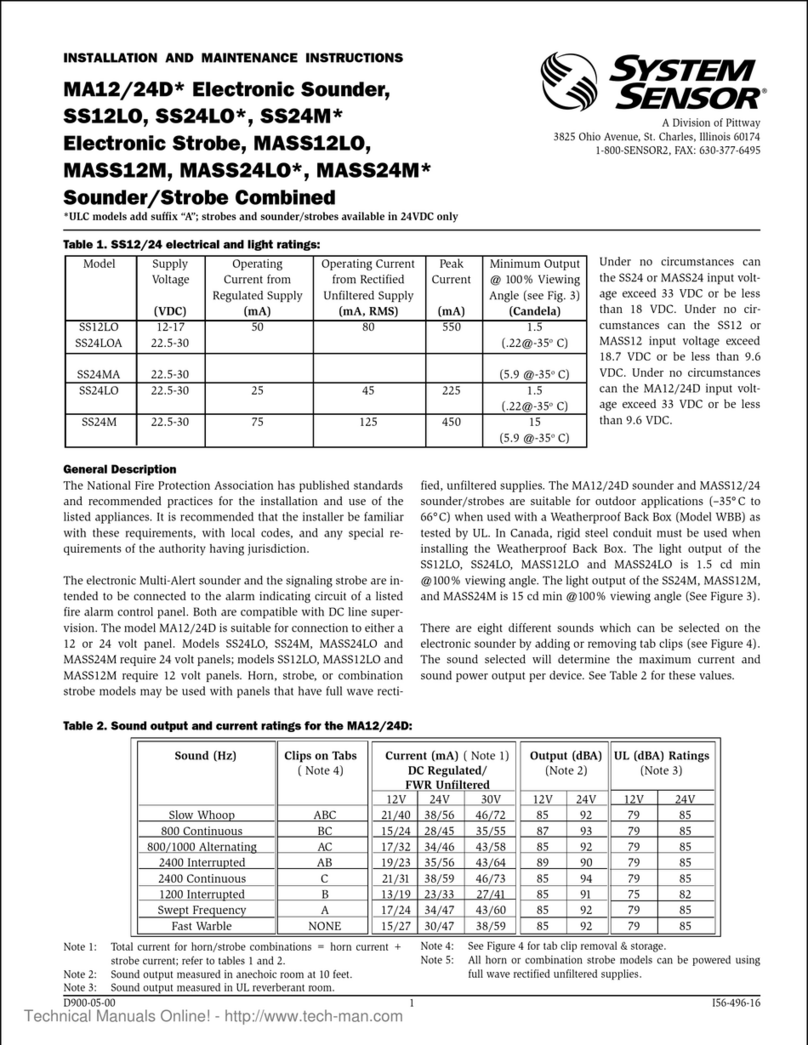

System Sensor

System Sensor MASS12LO Installation and maintenance instructions