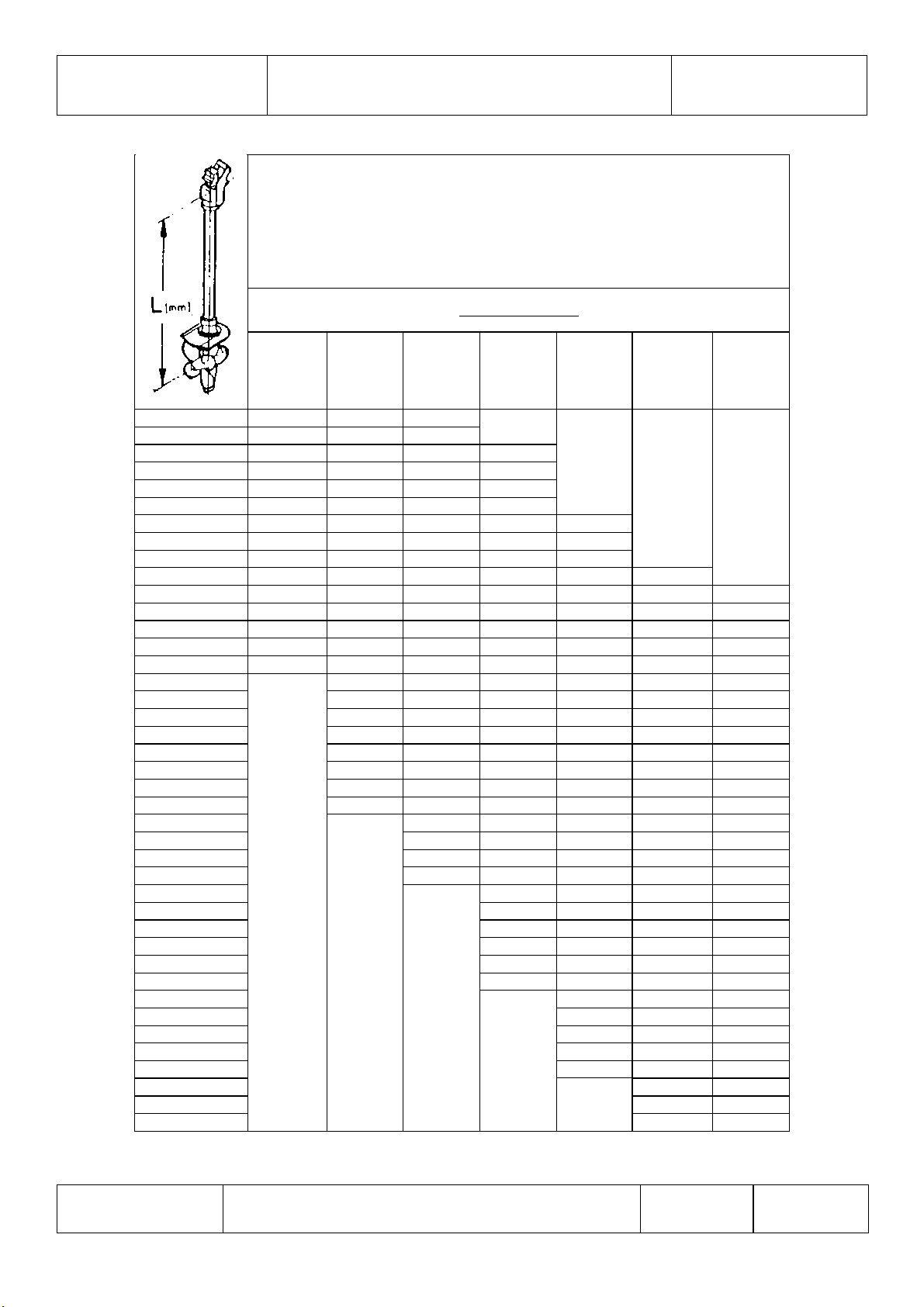

SCHOTTEL

SRP 15 .... SRP 300

No.

BA 103 E

Dat.

1-12-77

TD-NM-in

Seitenz.

19

Seite

4

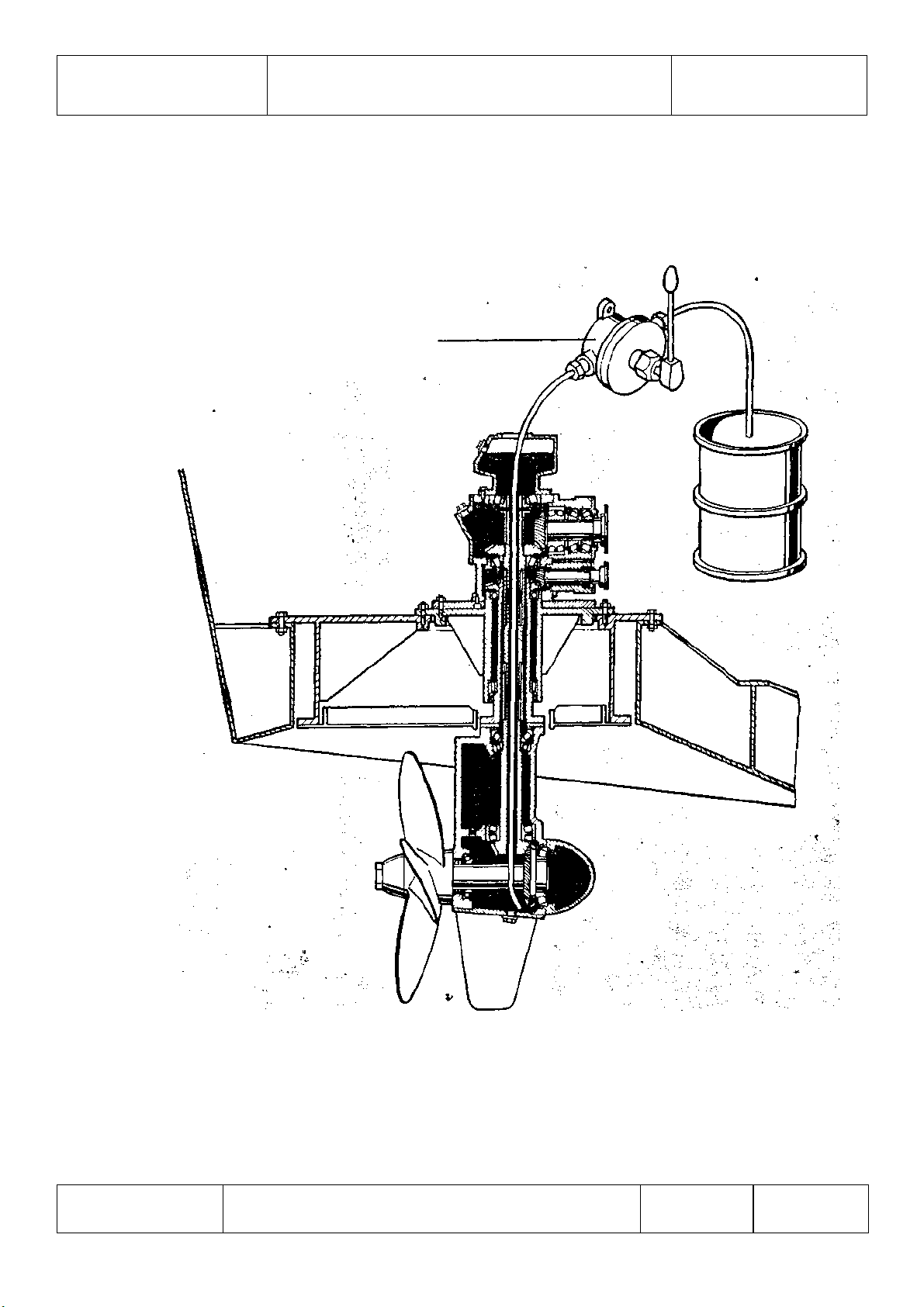

To avoid air from entering the propeller, a cover plate

(Figures 4/2 or 6/2) can be provided. In addition, a nozzle

can be provided for increasing the thrust.

1.3 LUBRICATION

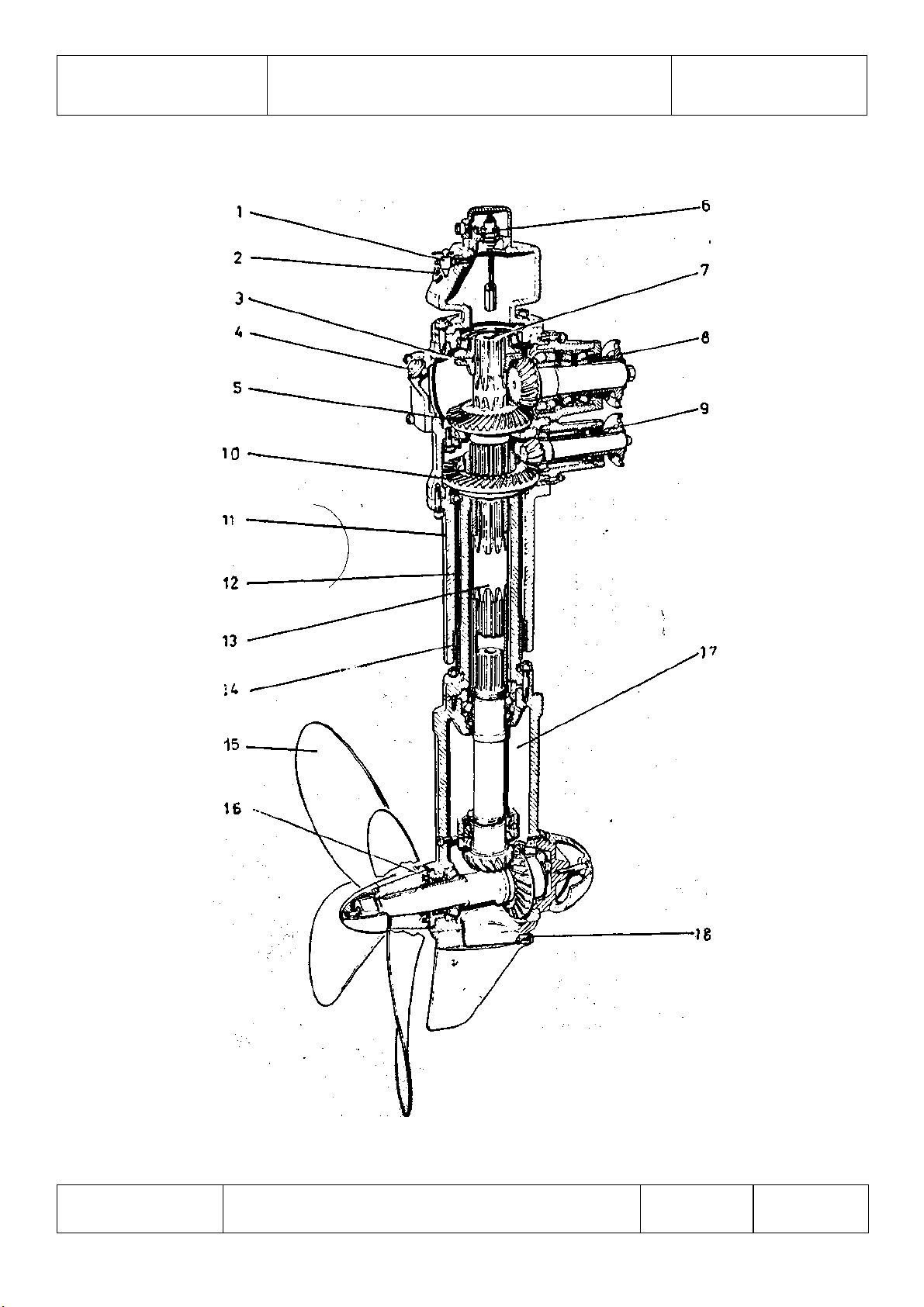

The SRP features oil bath lubrication, i.e. it is filled with

oil. An oil tank, either directly mounted on the SRP or

separately mounted, is used as expansion and compensating tank.

The oil in the SRP is circulated during operation and cooled in

the lower section. The circulation is accomplished by an oil

slinger (Figure 1/3) for sizes up to SRP 100, and by a worm gear

(Figure 7) for sizes SRP 150-300. This oil worm gear is located

on the power transmission shaft and forces the oil down. A

sight-glass (Figure 1/2) on the oil tank and an electric warning

switch (Figure 1/6) are provided for checking the oil level; the

warning switch closes a contact as soon as the specified oil

quantity is fallen below. The attached steering worm gear

(Figure 2) are sealed from the upper gearing and are equipped

with a separate oil fill hole.

1.4 COMPENSATING FIN

The torque of the vertical power transmission shaft (Figure 1/13)

is transmitted through the bevel gear pair of the lower gearing

of the SRP to its housing. The torque must be fully absorbed by

the steering gear, unless it is compensated.

For this reason, the manually controlled SRP's (steering systems

S 100, S 200 and S 300) are equipped with compensating fins

(Figures 4/4, 5/1 or 6/4).

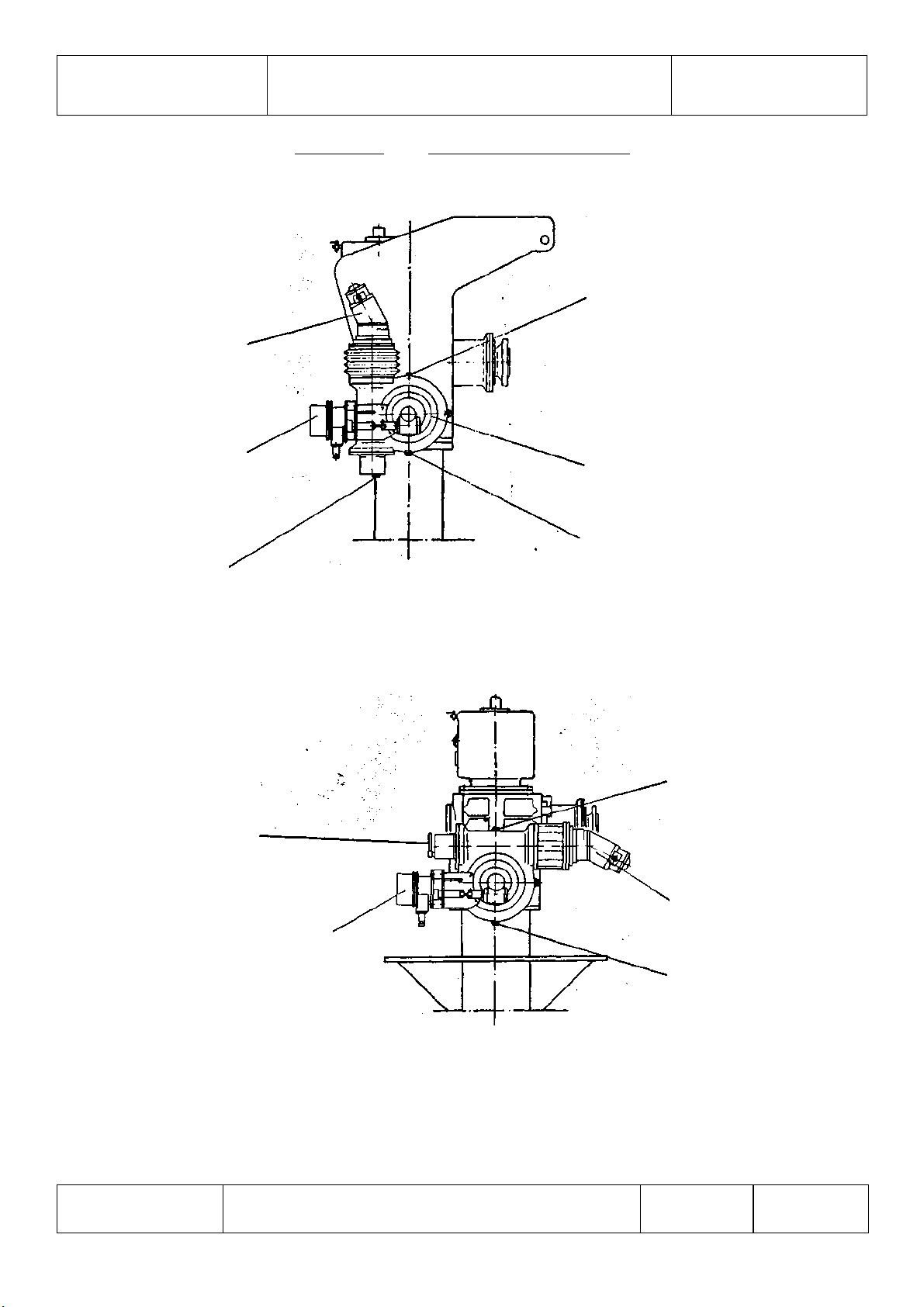

1.5 STEERING WORM GEARS (See Figure 2)

One, or, in case of higher outputs, two (DST) worm gears can be

mounted at the side of the upper gearing. The steering drive is

accomplished by a hydraulic motor attached to each worm gear.