10/2022•L-01424-4-14 3

2. Operating Advice

Any application of the light fitting that is incorrect or even forbidden will lead to the fact that the

manufacturer's warranty is lost.

LED are sensitive electronic components. Please ensure that the LED are protected against

mechanical and electrostatic attacks whenever the light fitting is open. For this reason the LED

must not be touched either.

Due to harmful gases and other corrosive substances (e.g. ammoniac, sulphur- or chlorine

compounds) it may come to damages of the LEDs. Depending on the substance, the concentration,

the temperature and the dwell time, damages up to total black-out are possible. This may occur

also to fittings with high degree of protection. The suitability of the light fitting for the respective

application can only be checked by running a test at site.

Please note, that fittings of series nD8700 runs with LED modules of risk group 2. The luminaires

should be positioned so that prolonged staring into the luminaire at a distance closer than 1.08 m is

not expected.

Precautions must be taken to protect the light fitting against potential overvoltage caused by

lightning strikes.

The light fitting has an additional Ex cable gland, which is locked by a closing plug and which is

designed as a test port to run the test for restricted breathing (see section 5.3, Testing the

restricted breathing).

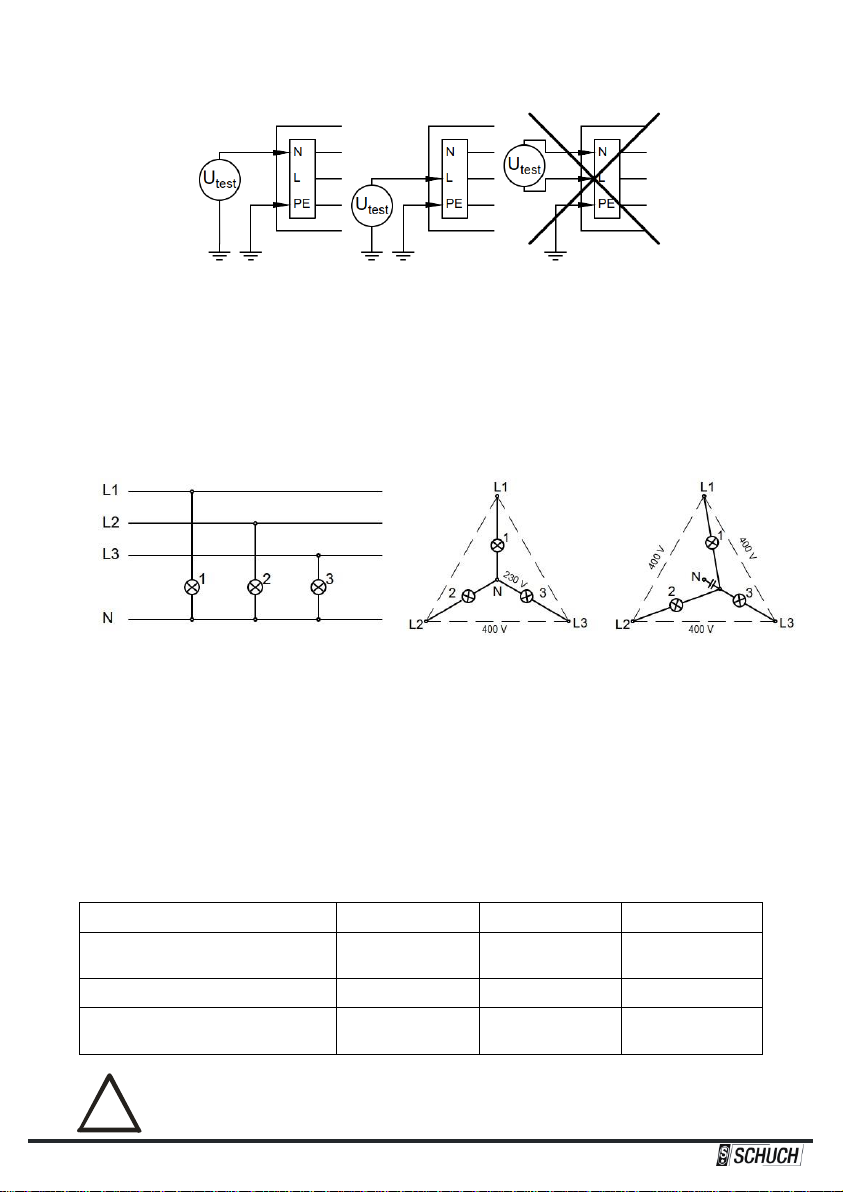

The Ex cable gland with closing plug, which is designed as a test port, must not

be used for cable entry!

The operation of this light fitting is only allowed if the Ex cable gland, which is

designed as a test port, is installed and locked with the provided closing plug!

Due to a high inrush current when switching on the light fitting, the number of light fittings which can

be connected to a single fused circuit is limited (Possible number of light fittings per circuit breaker

see section 3, Technical Data).

All DALI dimmable light fittings have two additional terminals marked „DA“. Lines to the control

terminals must be mains voltage proof.

Light fitting versions with the option of power reduction (nD8700 ... LR) are designed with an

additional connection terminal (Marking: LSt) for connecting the control phase.

In the standard setting, the light fitting delivers 100% luminous flux when the control phase is

pending (LSt = 230V). Without a control phase (LSt = 0V), the light fitting is dimmed to 50%. The

control phase does not have to be in phase with the supply (L).

In case of versions for connection to group or central battery systems (ZB), the type of operation

(Stand-by operation = 0; Maintained operation = 1) must be permanently marked on the type plate

of the light fitting (see illustration).

Delivery status Stand-by operation Maintained operation