7www.raytecled.comUK / Europe Tel: +44 (0) 1670 520055

Americas Tel: +1 613 270 9990

3. Maintenance

1. It is essential that all SPARTAN Bulkhead units are maintained in accordance with

the requirements of the EN60079-17standard: (Electrical apparatus for explosive gas

atmospheres – other than mines).

2. IMPORTANT. No modications are permitted to the unit, all spare parts must be

purchased from the manufacturer, unauthorized modications or spare parts will

invalidate certication and make the equipment dangerous.

3. Isolate the SPARTAN Bulkhead from the mains supply and allow to cool before

carrying out any maintenance work.

• For Emergency variants, battery must be isolated/ connected when a hazardous

environment is NOT present prior to carrying out any maintenance work.

4. In the unlikely event of a number of LED’s failing, the light engine assembly must be

replaced. This is achieved by loosening front cover bolts, disconnecting the white

LED cables to power supply, remove four M6 bolts from rear of light engine and pull

the light engine assembly clear. Re tting a light engine is a reversal of the above

procedure.

5. The unit has one independent power supply, in the event that the power supply

needs to be replaced the cables to the LED and mains terminal block will need to

be disconnected, the four M6 bolts released, then the power supply can then be

removed. Fitting a new power supply is a reversal of the above procedure.

6. Disposal of packaging, SPARTAN unit and old LED assemblies should be carried out

in accordance with national regulations.

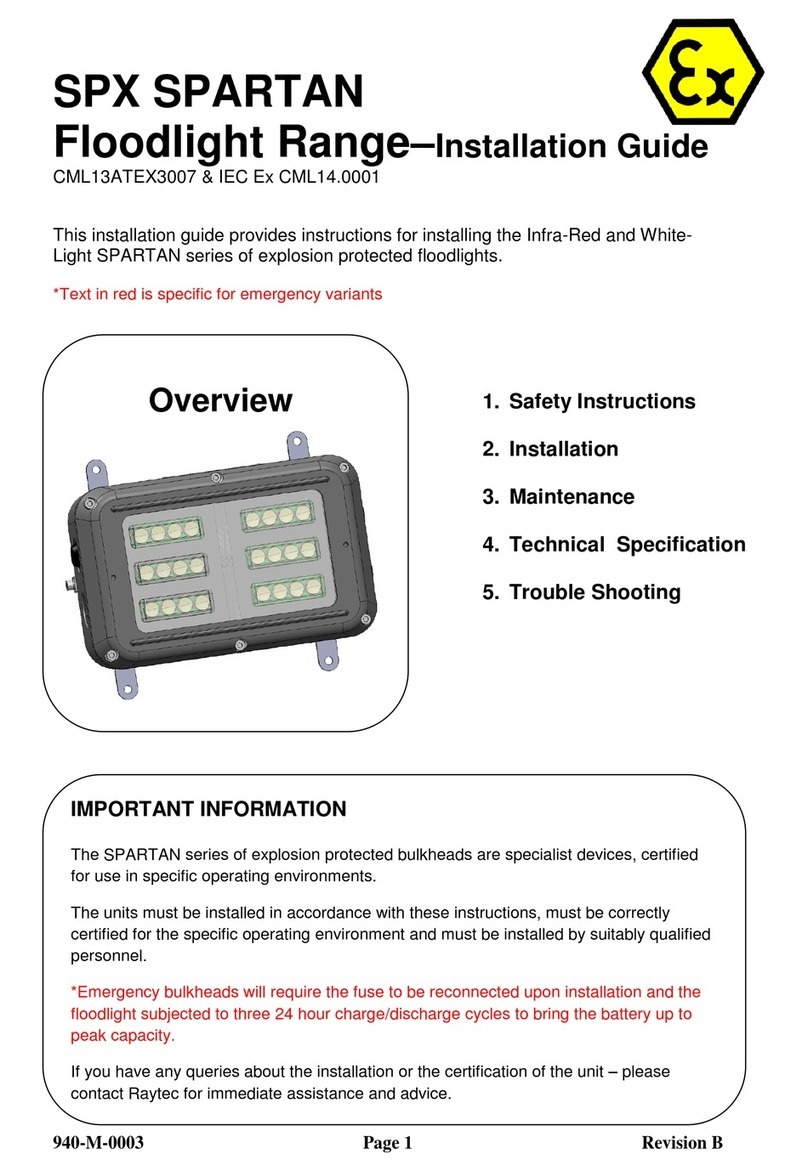

PROTECTION/CERTIFICATION

CML13ATEX3007 or IEC Ex CML14.0001

II 2 GD Ex e mb op is IIC T4 Gb

Ta -52oC to +55oC (standard variants)

II 2 GD Ex e mb op is IIC T4 Gb

Ta -20oC to +46oC (emergency variants)

Ex tb IIIC T98°C Db

IP66 & IP67 Ta = -52°C to +55°C

110V-254V AC/155V-355V DC or 18-48V AC/18-69V DC

CML17ATEX4231 or IEC Ex CML17.0135

II 3 GD Ex ec mc op is IIC T4 Gc

Ta -50oC to +55oC or

Ex tb IIIC T98°C Dc

IP66 & IP67 Ta = -50°C to +55°C

110V-254V AC/155V-355V DC or 18-48V AC/18-69V DC

Emergency variants restricted to -20oC