SAG SAFE-O-TRONIC Installation

Schulte-Schlagbaum AG Page 8of 12 SOT-Manual.DOC

5.2. Configuring the SAFE-O-TRONIC with the "SetupKey"

The SetupKey is used to configure the System-ID, the cabinet number, the operating mode and

the group number in the SAFE-O-TRONIC . Only than can the SAFE-O-TRONIC be used in the

system.

An already configured SAFE-O-TRONIC will no longer accept the SetupKey. To change the con-

figuration of a SAFE-O-TRONIC , the latter must first have been cleared using a valid ResetKey.

CAUTION:

Use only a SetupKey having the correct Group No. and System-ID.

Sequence:

1. Set the parameters on megalock Admin or on the megalock Programmer and program them

into the SetupKey.

Set the following data:

- Next SAFE-O-TRONIC number to be programmed (cabinet number)

- Operating mode (free cabinet select / fixed cabinet assignment / multi-user mode)

- Group No. to which the SAFE-O-TRONIC is to be assigned.

2. Go to the first SAFE-O-TRONIC with the SetupKey, waken up the lock and configure it by pre-

senting the SetupKey.

The SetupKey must be held in front of the rotary knob until the SAFE-O-TRONIC ac-

knowledges this by causing the green LED to flash.

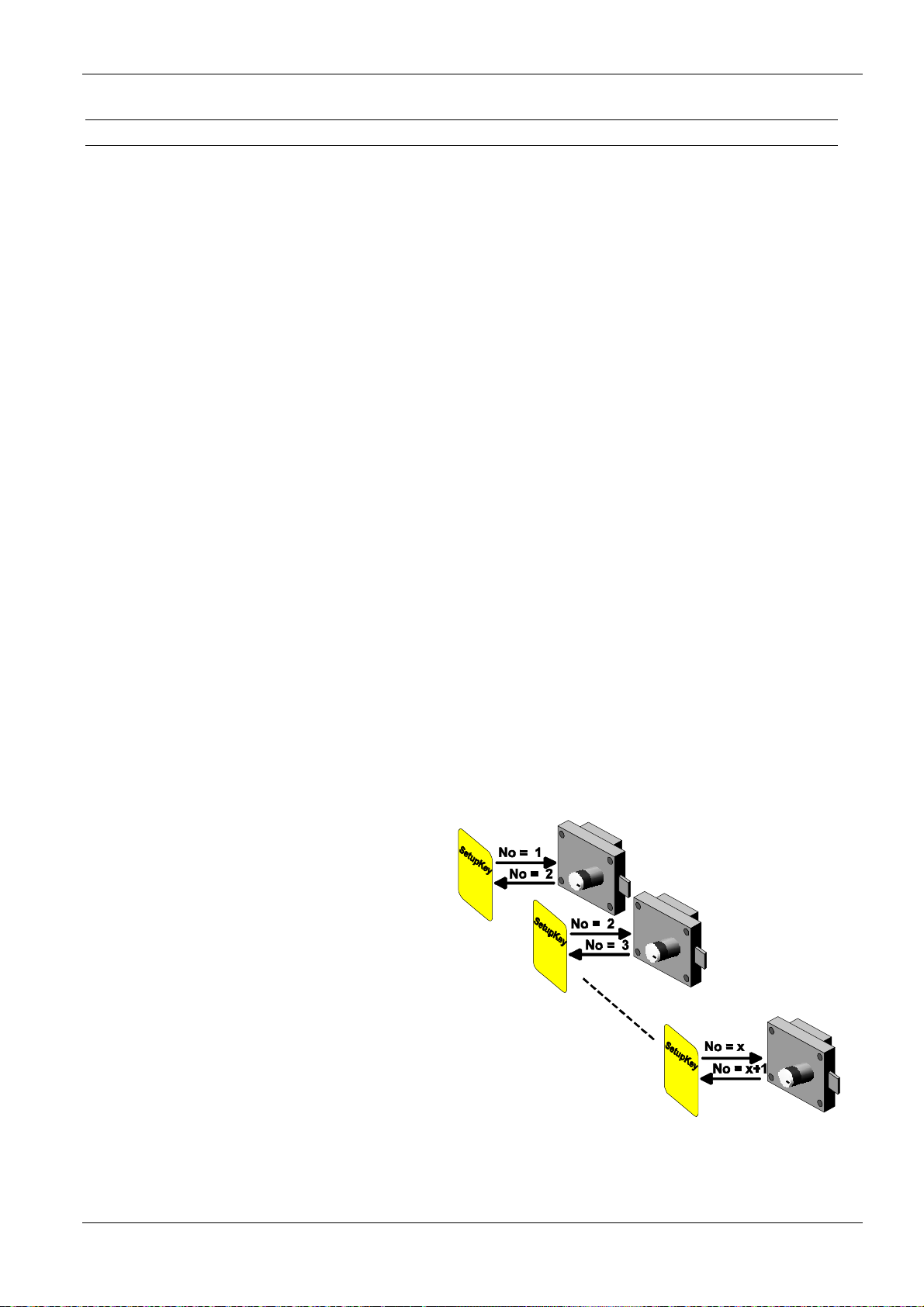

3. Now the next SAFE-O-TRONIC can be configured with a sequential cabinet number.

Assigning the megalock number is done according to the same principle.

Once the SAFE-O-TRONIC has uploaded

the number, it increments the number on the

SetupKey by +1.

Now the number for the next SAFE-O-

TRONIC is stored on the SetupKey, and as

many megalocks as desired can be initialized

with a sequential number without having to

first reprogram the SetupKey.

NOTE:

If a gap in the sequential numbering of the

SAFE-O-TRONIC s is desired, such as at

the end of a row of cabinets, the new

cabinet number will have to be pro-

grammed into the SetupKey.