3

HIPOT.COM

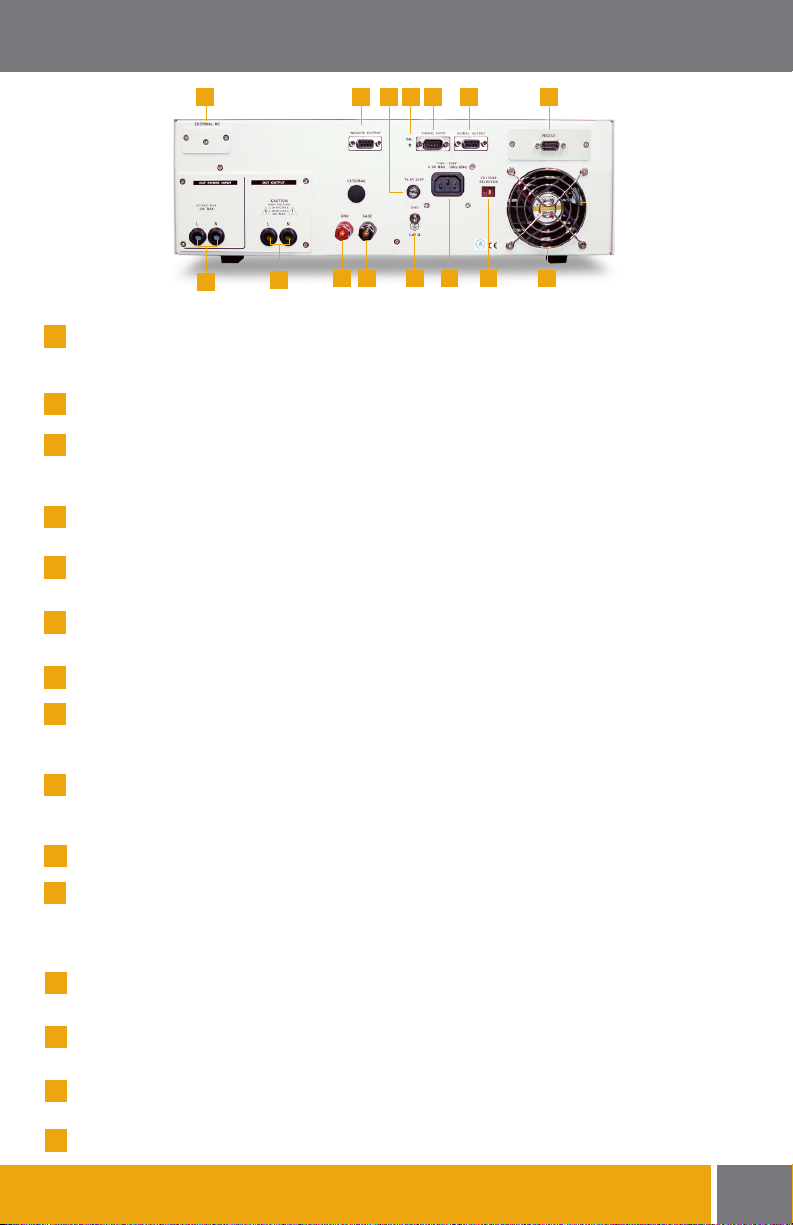

Back Panel Controls

External Measuring Device: Provides an access port for a custom measuring device. The port

may be activated during Line Leakage testing from the instrument’s menu system. The operator

must supply the appropriate measuring device as none is provided.

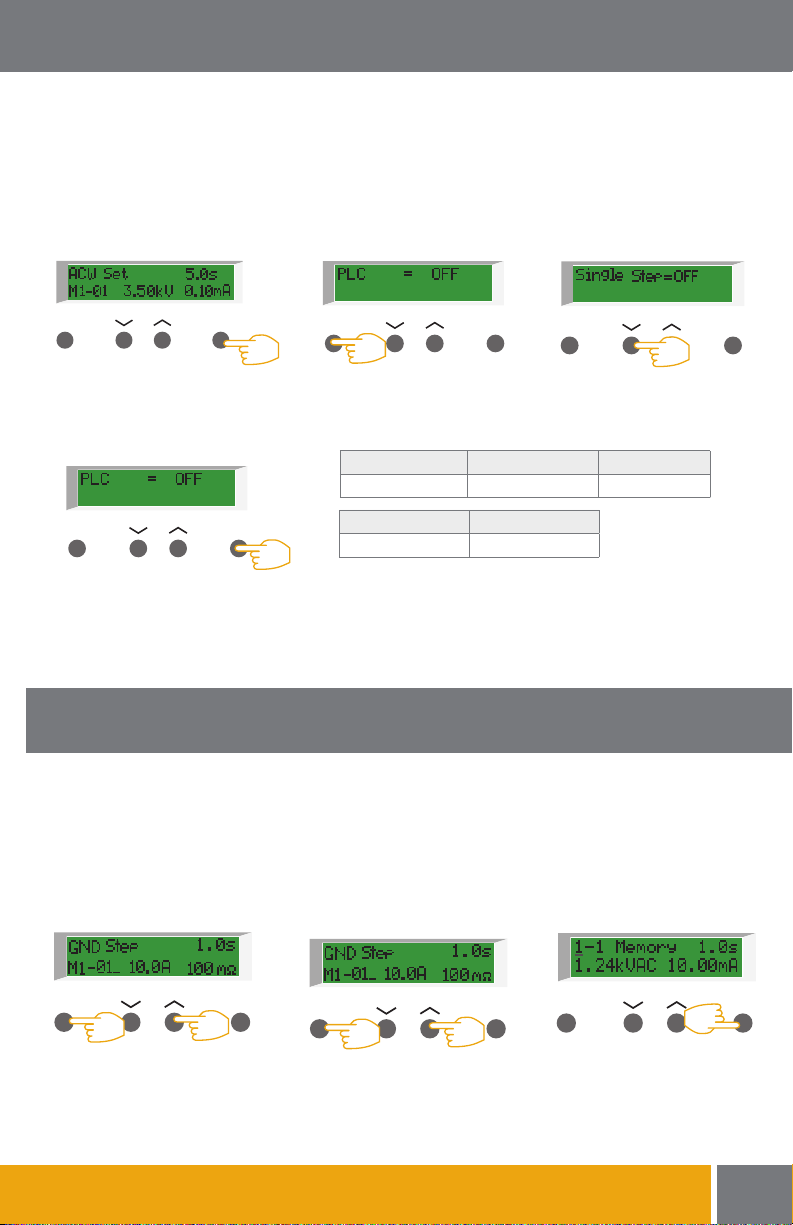

Power Control

Fuse Receptacle: To change the fuse, unplug the power (mains) cord and turn the fuse

receptacle counterclockwise. The fuse compartment will be exposed. Please replace the fuse with

one of the proper rating.

Calibration Button: To put the instrument into the calibration mode push this button and turn on

the power switch simultaneously.

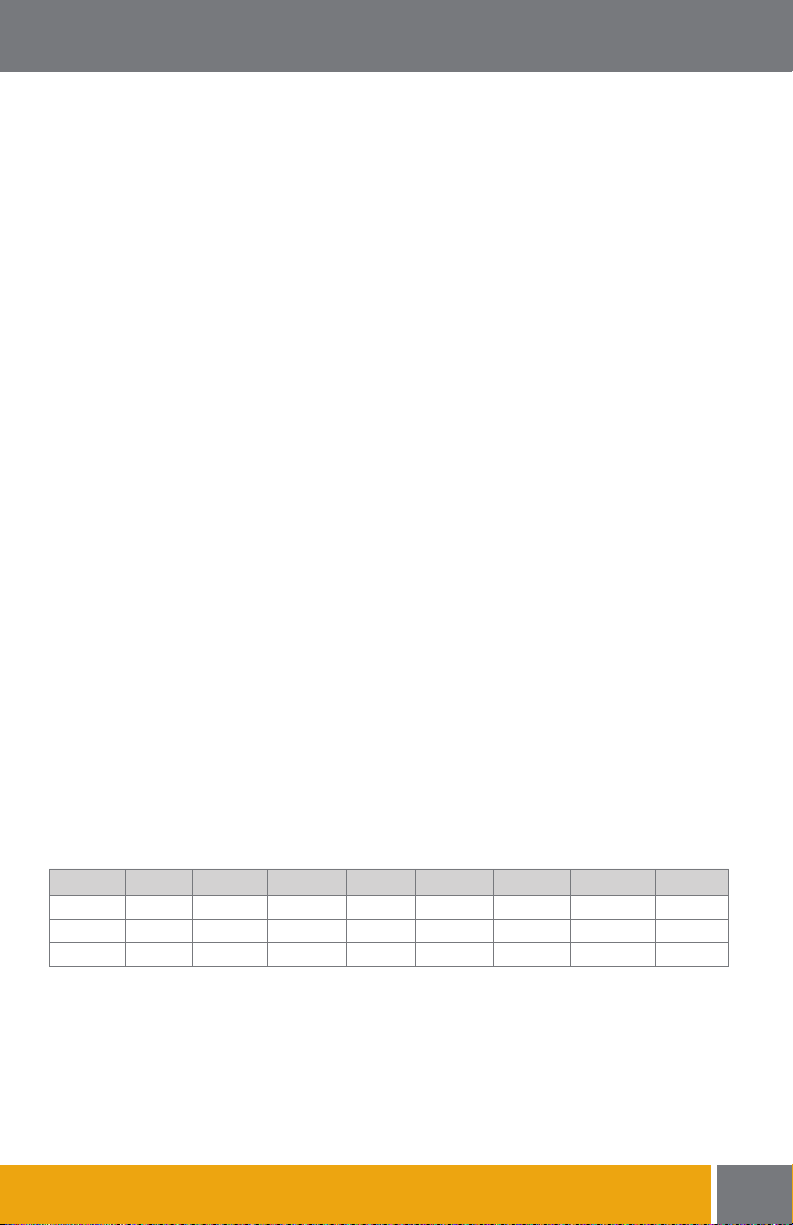

Signal Input: 9-pin D-type subminiature male connector for remote control of TEST, RESET, AND

INTERLOCK functions as well as remote memory tests recall.

Signal Output: 9-pin D-type subminiature female connector for monitoring PASS, FAIL, and PRO-

CESSING output relay signals.

Bus Interface: Optional connector for interconnection to RS-232 bus interface.

DUT Power Input: Provides the line and neutral connections for an input power source to be

used during Functional Run and Line Leakage testing. Only a U.S. style single phase unbalanced

power source may be used.

DUT POWER OUTPUT: Provides the line and neutral connections from the 6330 to the DUT

duringFunctional Run and Line Leakage testing. Provides the high voltage connections to the

DUT during ACW, DCW and IR testing if the DUT OUTPUT and DUT-HV parameters are turned ON.

GROUND CONNECTION: Connector used to attach the adapter box ground to the instrument.

CASE CONNECTION: Provides the return connection during ACW, DCW or IR testing. This terminal

is wired in parallel with the return terminal during a Ground Bond test and may be used in place

of the front panel connection. During a Line Leakage test this connection provides a connection

to one side of the measuring device (MD).

CHASSIS GROUND (EARTH) TERMINAL: This safety terminal should be connected to a good

earth ground before operation.

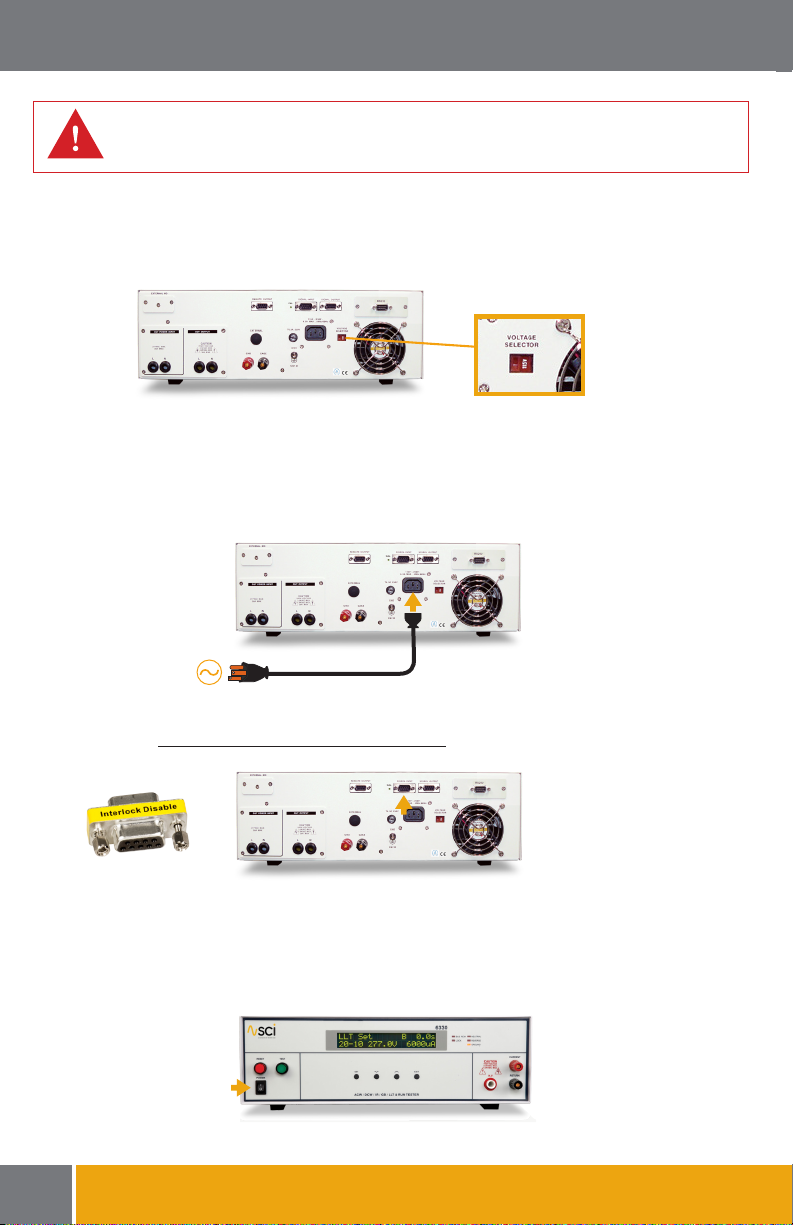

INPUT POWER RECEPTACLE: Standard IEC 320 connector for connection to a standard NEMA

style line power (mains) cord.

VOLTAGE SELECT SWITCH: Sets the line voltage conguration of the instrument. In the left

position it is set for 115 volt operation, in the right position it is set for 230 volt operation.

THERMAL FAN: Used to cool the instrument.

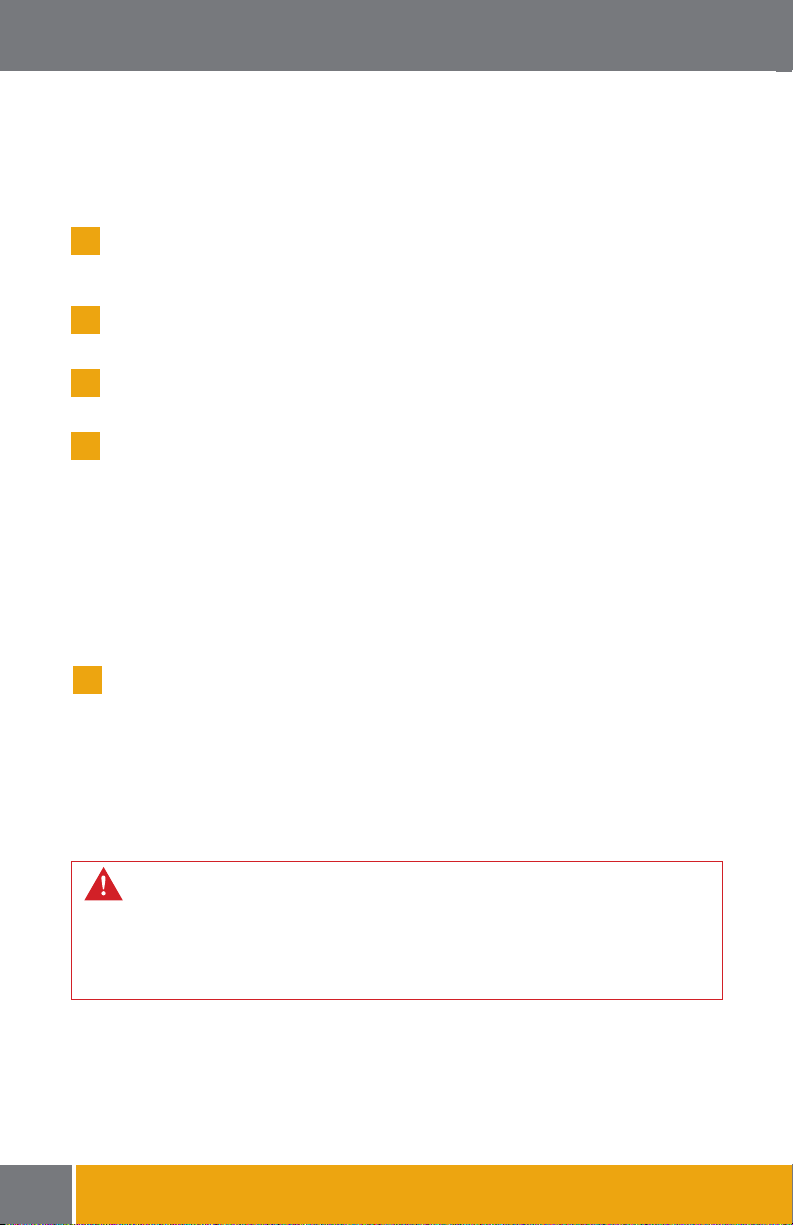

1

2

3

4

5

6

7

8

9

10

11

12

14

13

12 345

811

7

15

6

910 12 13 14 15