SmartMeter

2/4

4OPERATION

The meter features two input channels. Channel readouts are

updated two times per second. Channel 1 readouts are shown in the

largest digits and channel 2 readouts are shown in the smallest digits,

as Figure 07 shows. Channel 02 can be turned-off by operator.

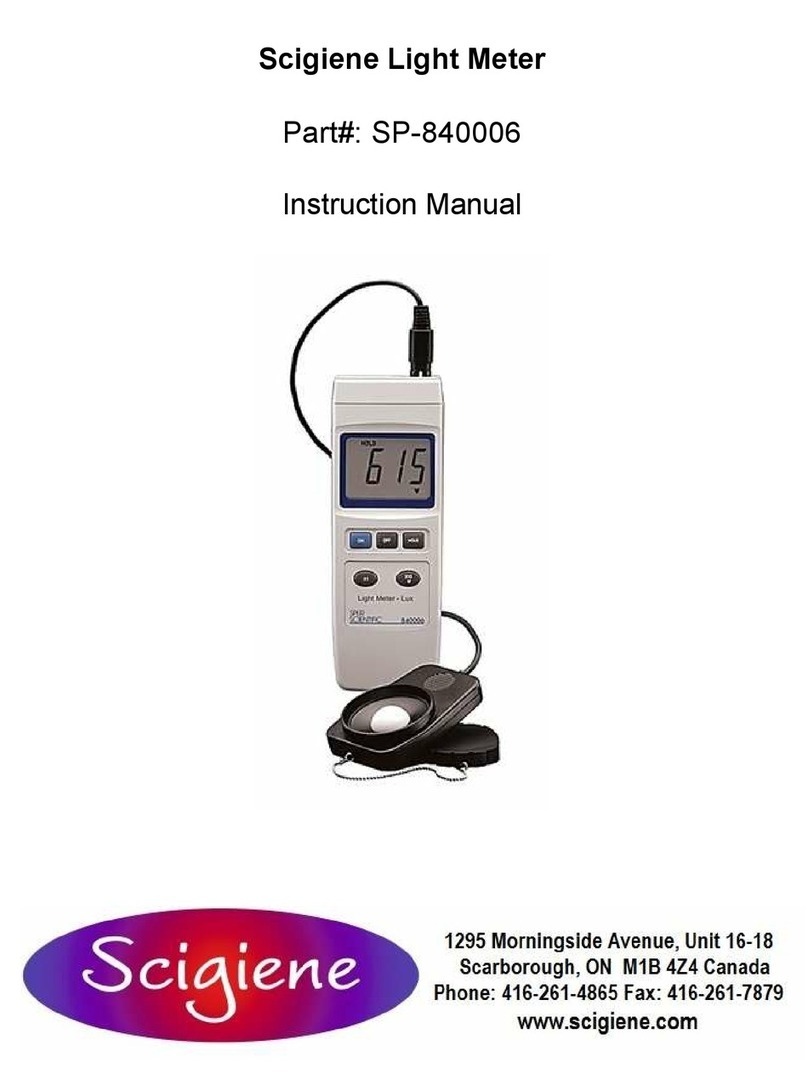

Figure 06 —Meter front panel

Figure 07 —SmartMeter display

4.1 TURNING THE METER ON/OFF

Press

to turn on the meter. To turn off, press for 3 seconds.

The meter basic configuration is factory set, so it can be immediately

used with the sensor provided. Factory configuration is: two enabled

channels, K-type sensor, one decimal space, zero offset, sound

alarm not enabled, auto power off after five minutes, temperature unit

in degrees Celsius, 60 Hz filter and channels 1 and 2 for special

functions.

4.2 FIRST READOUTS

Insert the sensor provided with the meter in the terminals of the

required channel and take the sensor leads to the measurement

location. Check the indication displayed.

Use the keys to find special functions the meter offers. When using

other sensors, check if factory setup is still compliant. If not, access

the configuration cycle and change settings.

4.3 SPECIAL FUNCTIONS

HOLD FUNCTION

It “freezes” the measure reading indication. HOLD is then displayed. It

is activated by pressing key

.To resume the meter operation,

press key

again.

MIN FUNCTION

It allows the user to retrieve the minimum temperature value

measured within an interval. An indicator of such condition is

displayed in the meter. It is activated by pressing key

.To

resume the meter operation, press key

again.

MAX FUNCTION

It allows the user to retrieve the maximum temperature value

measured within an interval. An indicator of such condition is

displayed in the meter. It is activated by pressing key

.To

resume the meter operation, press key

again.

AVG FUNCTION (average)

It displays the average temperature value measured within an

interval. An indicator of such condition is displayed in the meter. It is

activated by pressing key

.To resume the meter operation,

press key

again.

Notes: Functions MIN, MAX and AVG are accessed via key

.

Values displayed are the ones acquired from the start of an interval of

measurements. The interval starts after a RESET action.To reset the

meter, press and hold key

for more than 10 seconds. When

reset button is pressed, MIN, MAX and AVG values are erased and a

new interval starts.

RELAT FUNCTION (relative)

When enabled, it will void the measured values and starts to indicate

variations from such zeroed values. An indicator of such condition is

displayed in the meter. It is activated by pressing key

.To

resume the meter operation, press key

again.

T1 –T2 FUNCTION

When enabled, it displays the highest value corresponding to the

difference between the value measured through channel 1 and the

value measured through channel 2. The indication corresponding to

channel 2 is not changed. An indicator of such condition is displayed

in the meter. It is activated by pressing key

.To resume the

meter operation, press key

again.

Note: This function is only enabled when both channels are enabled

and operating.

ALARMS

The meter has an audible alarm (BEEP) that can inform the operator

about an alarm condition. In each channel there can be two indication

values, when they are reached the audible alarm is triggered. A

visual indicator is also displayed in the meter when the indication is

under an alarm condition.

LOW BATTERY INDICATOR

A low meter indicator is displayed warning that the battery should be

replaced.

SET UP

To set up the meter, the user must access the Alarm and Meter Set

up cycles, where a series of parameters must be defined.

ALARM CYCLE

In the alarm cycle you find the setpoints parameters of the meter

alarms. Press

to access this cycle. The meter displays spk.1,

the first parameter of the cycle. To access the remaining parameters

of this cycle, press

again,until you reach the measures screen.

Keys

and

make possible to change the parameters defined.

The parameters of this cycle are:

spk.1 (Highest setpoint of channel 1)

Determines a temperature value in channel 1 that when exceeded

upwards triggers the meter alarm (BEEP). When the alarm is

triggered, the indication ALARM is displayed in the meter.

sp1.1 (Lowest setpoint of channel 1)

Determines a temperature value in channel 1 that when exceeded

downwards triggers the meter alarm (BEEP). When the alarm is

triggered, the indication ALARM is displayed in the meter.

spk.2 (Highest setpoint of channel 2)

Determines a temperature value in channel 2 that when exceeded

upwards triggers the meter alarm (BEEP). When the alarm is

triggered, the indication ALARM is displayed in the meter.

spk1.2 (Lowest setpoint of channel 2)

Determines a temperature value in channel 2 that when exceeded

downwards triggers the meter alarm (BEEP). When the alarm is

triggered, the indication ALARM is displayed in the meter.