MicroGuard 424 OPERATOR'S MANUAL Lattice/Horizontal Display

MG424 OPERATOR MANUAL Page 7 of 14 December 7, 2000

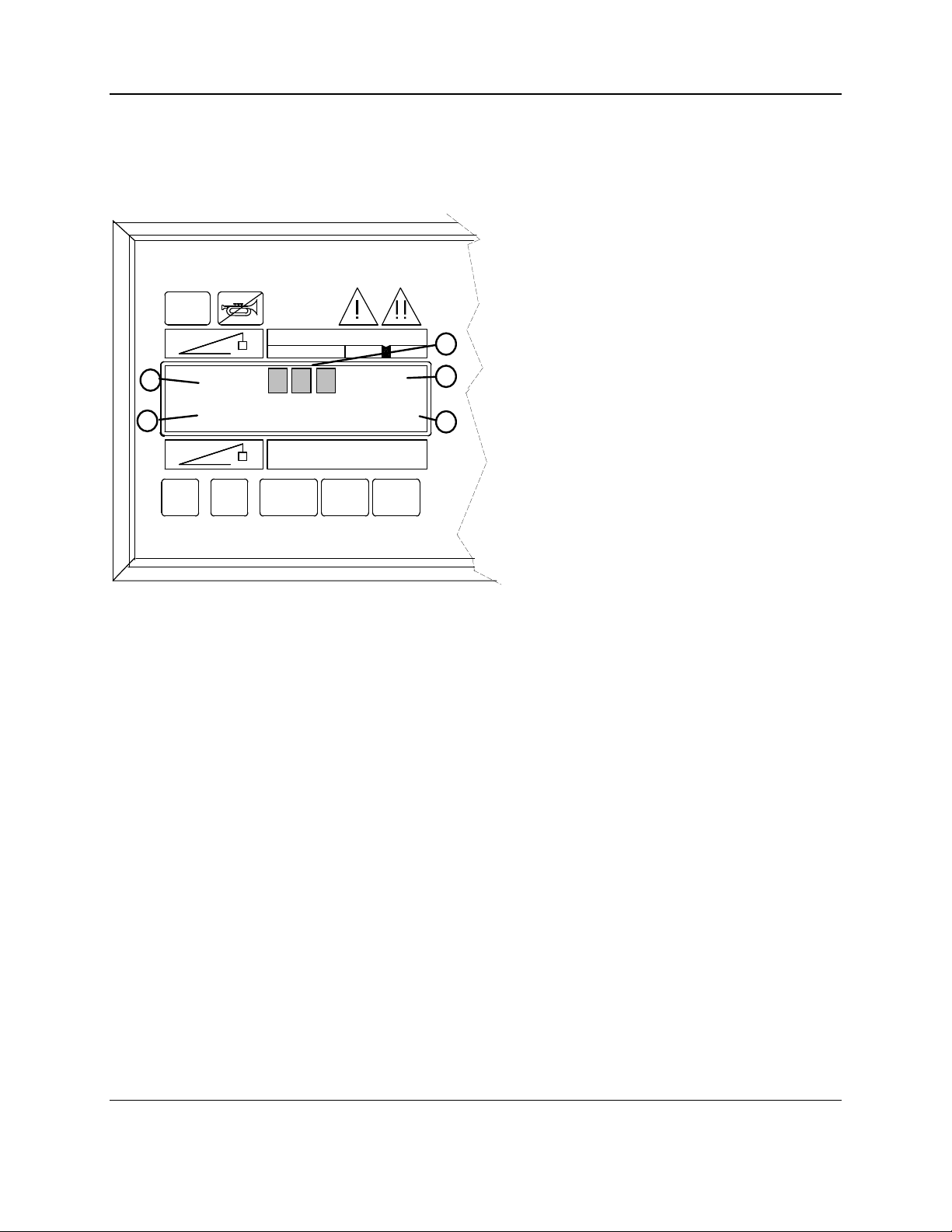

UPPER RIGHT DISPLAY

1 RADIUS/HEIGHT indicates

the area ofthe displaywhich gives

aread-out ofradius and height. It

is also amomentarypush-button

used to select the alternate display

ofheight. Height is displayed only

when the push-button is pressed

and held. When the push-button

is not pressed the displayis

always the radius ofthe load.

2 PARTS-OF-LINE indicates the

area ofthe displaywhich gives a

read-out ofthe parts ofline

currentlyselected. It is also a

push-button used to select the

parts ofline in use on the selected

winch.

3 WINCH SELECT indicates the area ofthe displaywhich gives aread-out ofthe winch currently

selected. It is also the push-button which is used to select the Main or Auxiliarywinch. When switching

between winches the parts ofline previouslyselected for the other winch is remembered and displayed

whenever the alternate winch is selected.

4 ANGLE/LENGTH indicates the area ofthe displaywhich gives aread-out ofangle or length. It is also

amomentarypush-button used to select the alternate displayofLength. Length is displayed onlywhen

the push-button is pressed and held. When the push-button is not pressed the displayis alwaysthe Angle

ofthe main boom.

5 WORKING AREA indicates the part ofthe displaywhich showsthe working area. Messages in this

area will conformto the current dutyselection and the swing position ofthe crane upper for

machines which have swing and multiple working swing areas.

6 TARE is apush-button, which is used to “tare”out the weight ofhookand slings. The actual load

displaywill then displaythe actual weight ofthe load being lifted. The bargraph displaywill continue to

reflect the percentage ofthe total weight belowthe boomhead.

Toset the tare: With the hookand slings lifted, press and hold the TARE button for three seconds.

The displayconsole will beep after three seconds and will “zero”the actual load display.The TARE

lamp (#3 on next page) will then illuminate to indicate that a tare has been set.

Toclear the tare: Press the TARE button momentarily.The displayconsole will immediatelybeep,

the actual load displaywill showthe total weight belowthe boomhead and the TARE lamp (#3 on next

page) will be off.

7 CRANE SETUP indicates the area ofthe displaywhich gives aread-out ofthe selected on or off rail

configuration. It is also apush-button used to start the selection ofthe machine configuration.

CRANE

SET UP WORKING

AREA

TARE

1

2 3 4

5

6

7

UPPER RIGHT DISPLAY