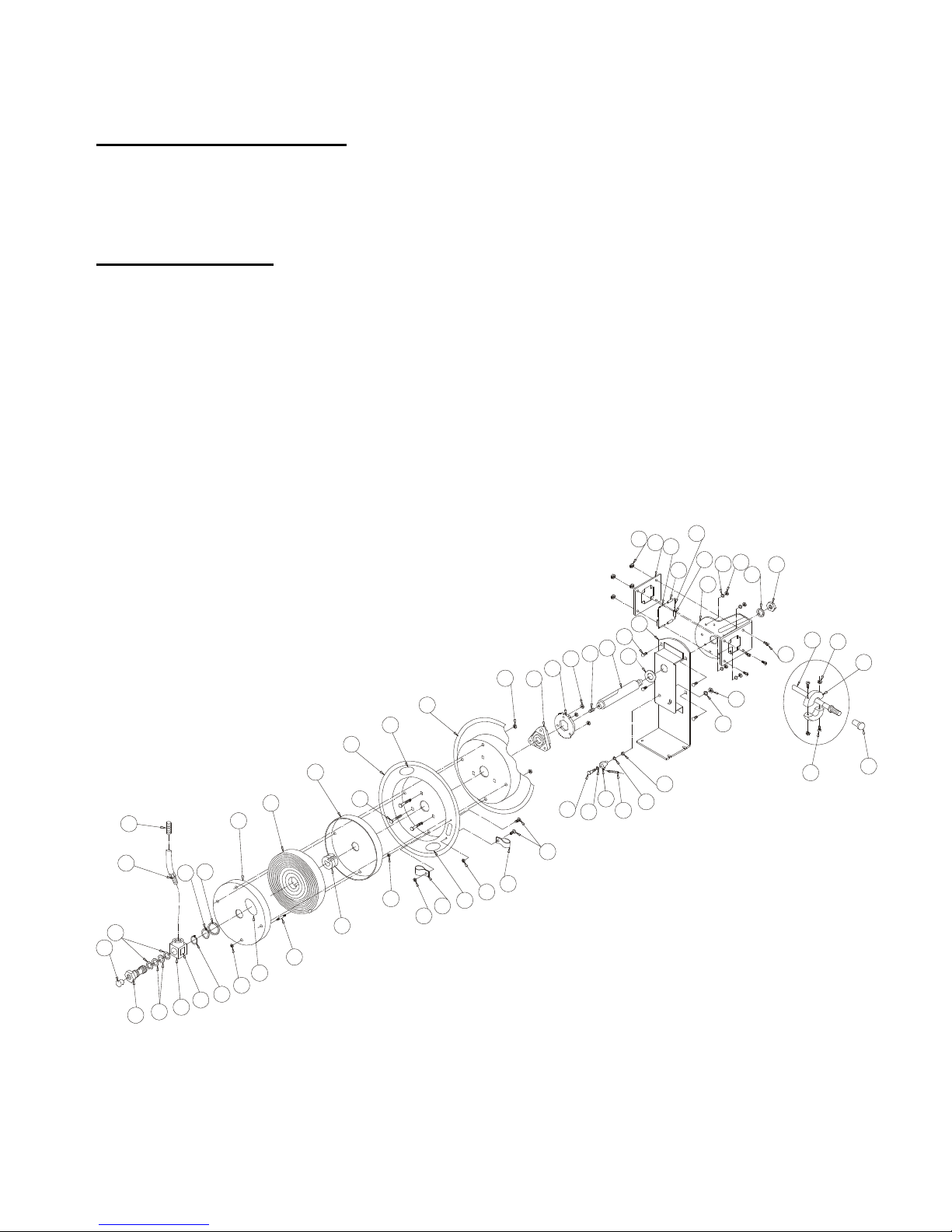

Operation

1 Check reel for correct operation by slowly pulling out the hose. A “clicking” noise

will be heard every half revolution of the drum.

2 To latch the reel, pull out the hose and allow it to retract after hearing the first

second or third “ click”.

3. To unlatch, slowly pull out the hose until the “clicking” noise stops, then let the

hose

retract until the hose stop rests against the hose guide. Note: To avoid damage

to the reel, always hold on to the hose while it is rewinding.

3 Periodically check the hose condition for wear or damage, and check the swivel

fitting for leakage. Replace any worn, damaged, or leaking parts.

Adjustment of Spring Tension

1 Pull out approximately 6ft or 2m of hose and allow the drum to latch.

2 Remove hose stopper from hose, and feed hose back through guide.

3 Wrap the pulled hose one time around the drum to increase tension or un-wrap

hose one time from drum to decrease tension.

4 Re-insert hose through guide, and install stopper onto hose end.

5 Unlatch the Drum and check tension. Pull hose from reel, and adjust stopper

position if necessary.

Replacement of Swivel Seal

1 Turn off and disconnect supply line from swivel inlet.

2 Remove swivel assembly from reel axle.

3 Remove circlip from swivel, and take apart. Note: You may want to remove

swivel from reel hose end, but this in not necessary unless a new swivel is being

installed.

4 Replace the seals and reassemble swivel.

5 Use Teflon type or thread sealant on swivel thread fitting, reconnect the swivel

thread fitting with axle.

6 Re-connect inlet supply line.

Replacement of Hose

1 Turn off supply to reel.

2 Pull out all the old hose and lock the reel in this position. Caution: Make sure reel

drum is securely locked and cannot rotate back.

3 Remove two hose clamps from hose.

4 Carefully disconnect hose from swivel joint on side of reel, or male fitting in axle

center and remove old hose.

5 Feed new hose through guide and opening in drum, and connect to swivel.

Re-install two hose clamps, on inside and outside of drum flange. Install stopper on

other end of hose in the same position as before.

6 Carefully release the drum latch, and slowly allow the hose to wind onto the reel.

Note: Final spring adjustment is accomplished by adding or removing wraps of hose

around the drum. (Details see spring tension adjustment).