9

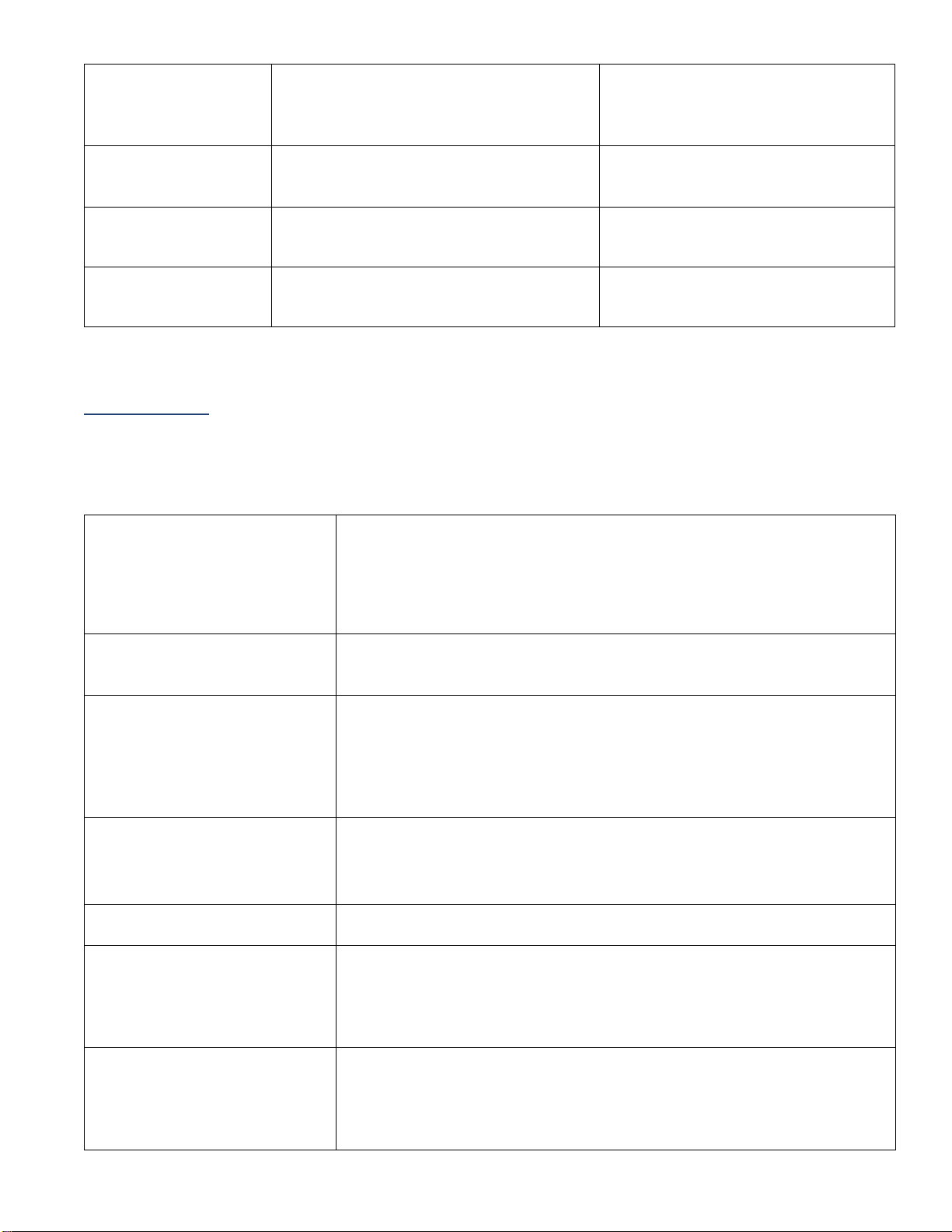

Situation - Standard Automation, AutoUP Action(s)

Plow doesn’t raise automatically.

Selector Switch is in the manual position.

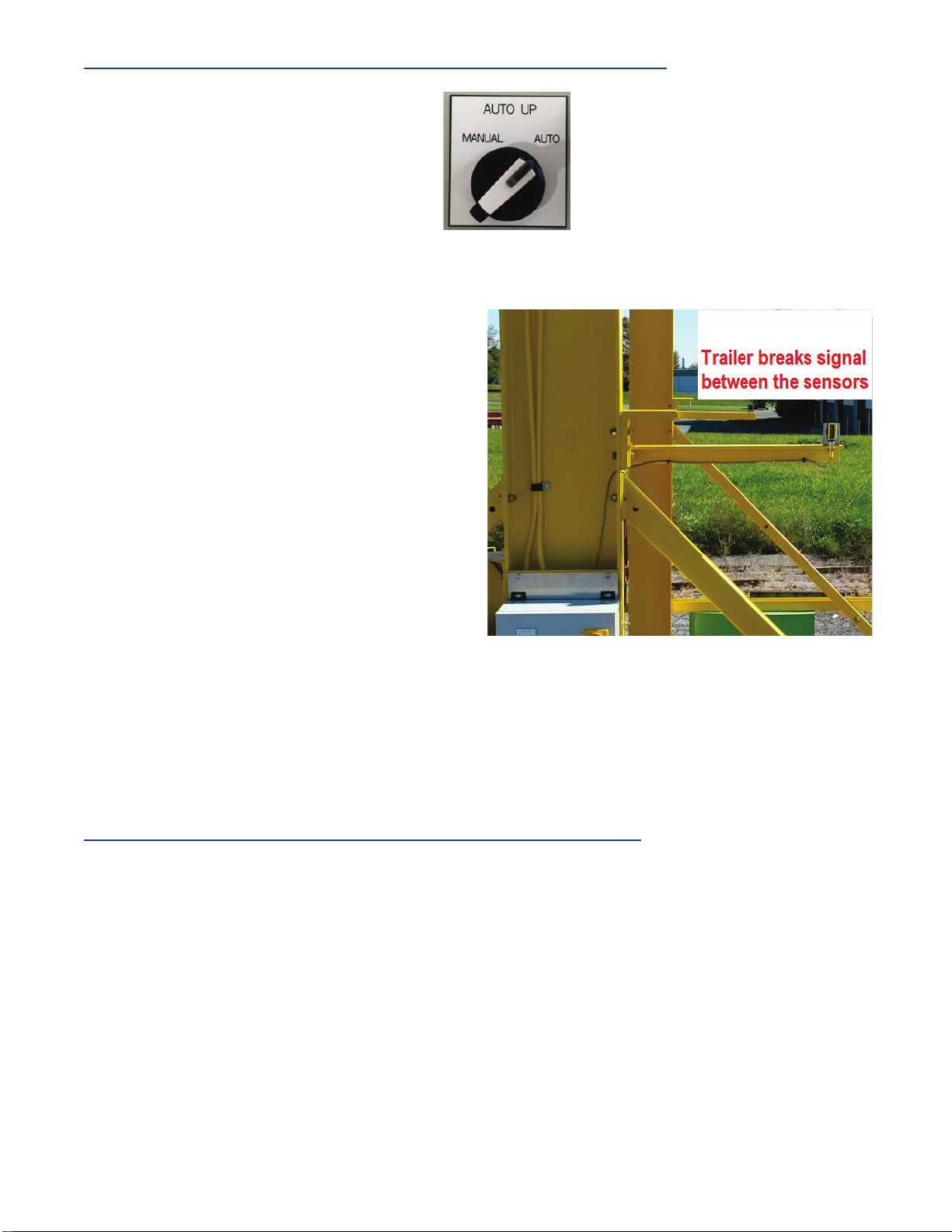

Emitter and Receiver sensors not lined up.

(

LED on top of Receiver should be off when lined up correctly.)

Emitter and Receiver sensors are installed on the wrong sides.

Plow Full Up sensor cable switched with Emitter cable on junction box.

Plow doesn’t stay down in Auto mode.

Emitter and Receiver sensors are installed on the wrong sides.

Cables for the Emitter and Plow Full Up sensor are switched at junction box.

Plow doesn’t stop at full up sensor while

raising.

Cable not tightened properly on back of sensor or junction box.

Plow Full Up and Emitter cables switched at junction box.

Plow Full Up Sensor and/or cable broken.

Plow does not clear snow towards back of

the trailer. Plow not in contact with roof’s

entire length.

The front of the trailer is higher than the back. Level trailer to reduce slope.

Ensure drive-thru is clear of built-up mounds of snow.

If slope of the exiting path is excessively inclined, manually increasing the amount of slack with

another link may resolve this. Or relocate the FleetPlow to a more level location.

Plow drops hard off back of trailer.

Level trailer to reduce slope, back higher than front.

Ensure drive-thru is clear of built up mounds of snow.

Slope of the exiting path is excessively declined. Manually decreasing the amount of slack by

another link may resolve this.

Or relocate the FleetPlow to a level location.

Excessive solid snow or ice build-up on the roof can create a ramp effect at the back of the trailer.

Situation - OneTAP Full Automation Action(s)

Check breakers and power cords.

Check power to OneTAP button, which should be lit green. Check button contacts.

Check for operation with 2 button manual pendant.

Hoist continues to pay out chain once plow lands on trailer

top.

(After approximately 1 ½ links of slack, the hoist is programmed to

Plow Full Up and Load Spring Piston Assembly

(P/N 92690 see figure 2, pg. 12)

proximity sensor cables switched at junction box.

* Load Spring Piston Assembly proximity sensor not adjusted properly per

Plow doesn’t automatically raise.

Proximity sensor in Load Spring Piston Assembly malfunctioned, broken, not in

range.

Check “up” operation with manual pendant.

Plow doesn’t go up in auto or using manual buttons, but

lowers in both modes.

(Full up sensor is indicating the plow is already up.)

Plow Full Up cable switched with proximity cable at junction box.

Ice buildup on sensor.

Plow Full Up sensor cable not tight.

Plow doesn’t return to full up position.

Model prior to November 2017 Reset by turning disconnect off and back on.

Model after November 2017. Tap the OneTAP button to reset.

Plow does not clear snow towards back of the trailer. Plow

not in contact with roof’s entire length.

Level trailer to reduce slope, front higher than back.

Ensure drive-thru is clear of built up mounds of snow, particularly where the back

wheels of the tractor will come to rest when properly locating the plow over the

trailer.

** If slope of the exiting path is too steep (up) due to the installation site, your

dealer may be able to increase the amount of slack to solve this.

Plow seems to drop hard off back of trailer.

Level trailer to reduce slope, back higher than front.

Ensure drive-thru is clear of built up mounds of snow.

Ensure the vehicle is exiting at the required speed of 8-10 MPH.

Excessive snow or ice has frozen solid, creating a ramp effect at the back of the

trailer.

** If slope of the exiting path is too steep (down) due to the installation site, your

dealer may be able to decrease the amount of slack to solve this.