SDI PORTAGAUGE 4 User manual

PORTAGAUGE® 4

USER MANUAL

Contents

2

1. Introduction and Key Features

1.1 What does the Portagauge®do?

1.2 The Portagauge® 4

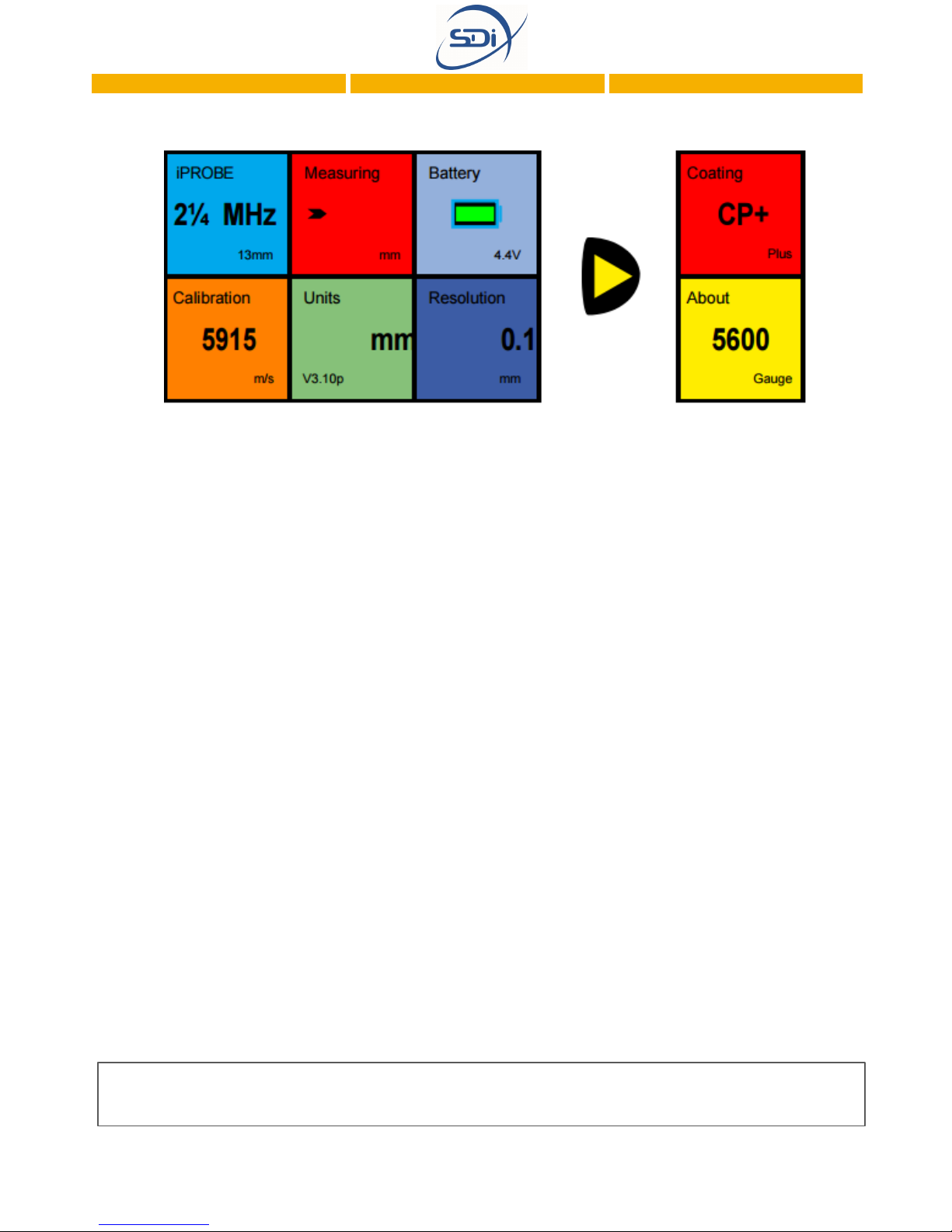

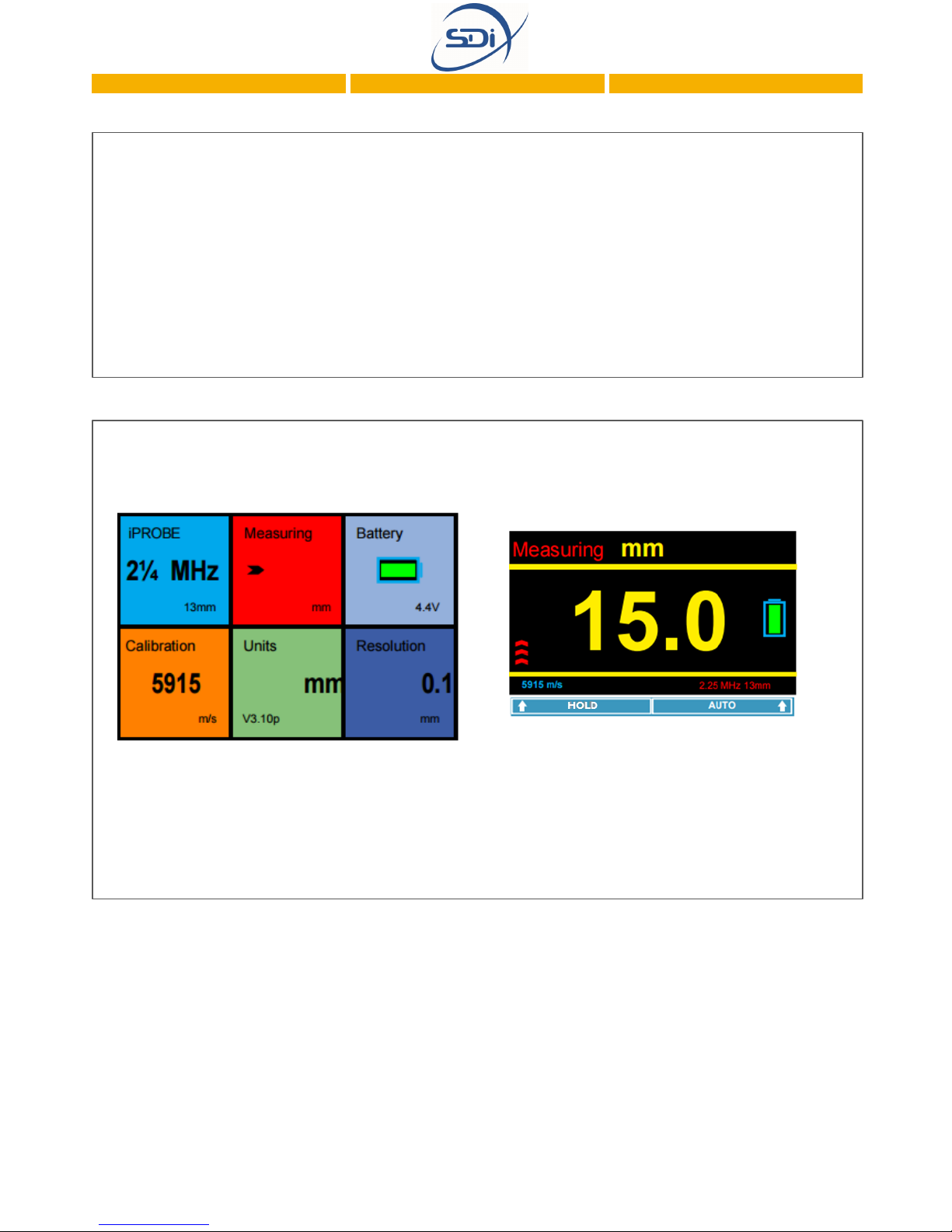

1.21 The Portagauge® 4– Unit and Measuring Screen

1.22 The Portagauge® 4– Definition of Menu Items

1.3 How does a Portagauge® 4work?

2. Operating Instructions

2.1 Introduction

2.2 Preparation

2.21 Assembly

2.22 Probes

2.23 Probe Membranes

2.24 Calibration

2.25 Speed Table

2.3 Test Procedure

3. Maintenance

3.1 Probe Care

3.2 Battery Care

3.21 Battery Replacement

3

3

3

4

5

6

7

7

8

8

8

9

10

11

12

14

14

15

16

1. Introduction and key features

What does the Portagauge® do?

The Portagauge® 4is a portable, robust device used to accurately measure the

thickness of a material using multiple echo, ultrasonic technology.The Portagauge® 4is

capable of working across a large number of different applications and environments,

whether this be different surface conditions, the presence of rust, small curvature

surfaces or for any other maintenance and inspection requirement.The unit operates

on a wide range of metal materials (Steel/ Stainless Steel, Cast Iron, Aluminium,

Copper, Brass, Zinc, Grey Cast Iron).

Due to its use of ultrasonic methods, the Portagauge® 4only needs access to one side

of a surface to measure the thickness of the material.This enables the device to non-

invasively measure the wall thickness of metal pipes, tanks, beams and other such

structures without any risk of damage.

The Portagauge® 4

The Portagauge® 4is the most advanced and accurate model of the Portagauge®

range. Its use of multiple echo ultrasonic technology allows it to account for coatings

of up to 20 mm, ensuring that they are not included in the measurement of the

thickness of the material. Its design and function has been built on earlier models to

achieve this accuracy as well as its durability and consistency. The enclosure is rated to

IP 65 providing a high level of protection in even hard industrial environments.

3

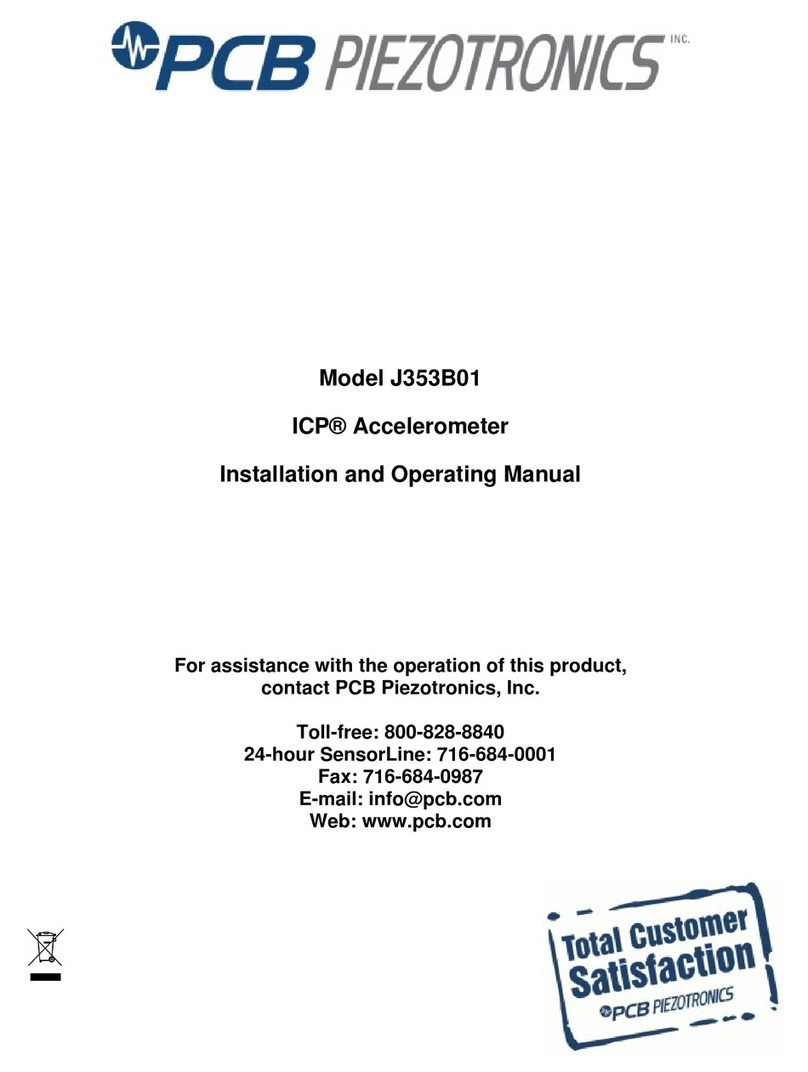

HOLD

4

Battery

Compartment: The

battery compartment is at

the back of the unit. It

must be opened by a flat

head tool

Lemo Connector:

Allows for secure

fastening of the cable for

the sensor probe.

Units of Measurements:

The units of the

measurements can be

changed (inch/mm) by

navigating to the “Units”

section of the menu

Digital Display:

Numerical readings allow

users to determine the

thickness of the material

Echo Strength: The

greater the number of bars

the greater the strength of

the returning signal

BAT OK: Checks battery

level

Sealing: Black rubber

sealing for watertight

integrity IP 65

Directional Pad: The

directional pad allows

the items on the menu

and sub-menus to be

navigated using the left,

right, up and down keys

and selected using the

Enter/OK key at the

centre

Menu Button:

Accesses the menu for

the unit (see page 5 for

more information on

menu items).

Right Option Key:

Selects the option at

the bottom right of the

LCD screen

The Portagauge® 4

Display: Color LCD

display for access to the

Measuring screen and Menu

screen.

Left Option Key:

Selects the option at the

bottom left of the LCD

screen

ON/OFF Button Simple

power ON/OFF button –

powered by 3 x 1.5V AA

batteries providing

approximately 20 hours of

battery life. Keep turned

off when not in use to

save battery life

Measuring Screen

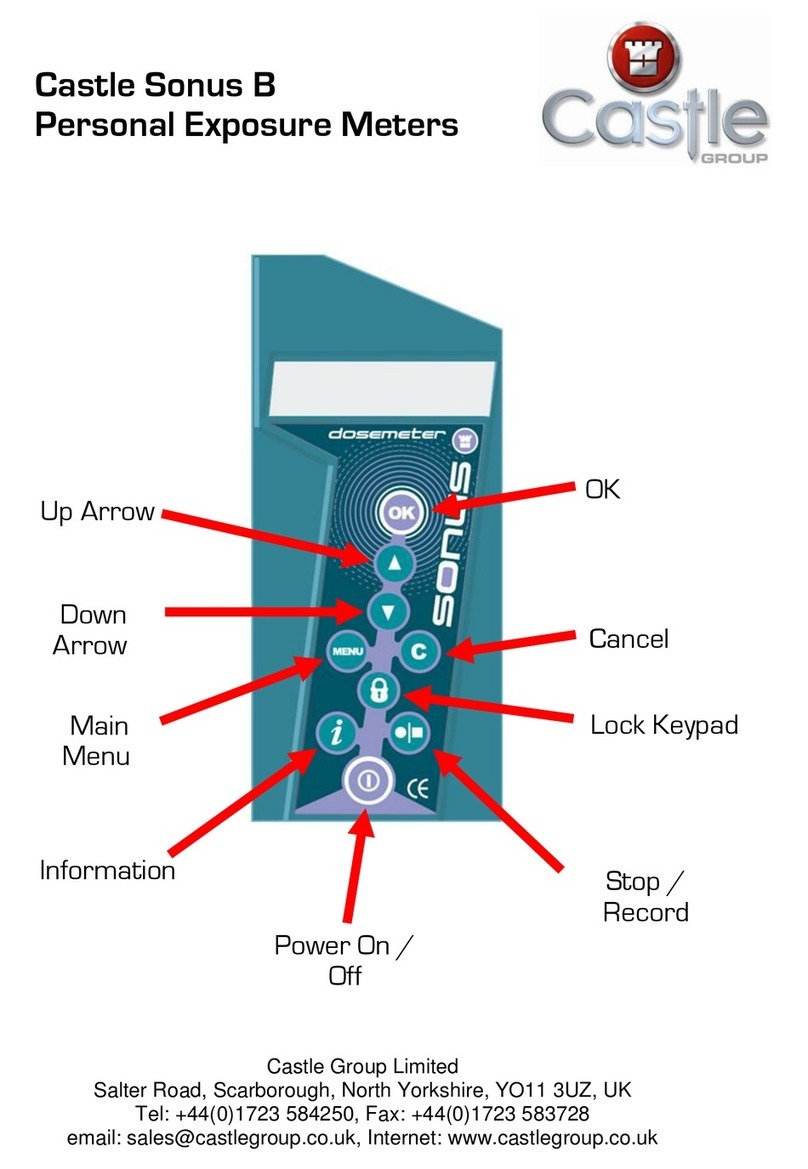

iProbe indicator:

Indicates the type of probe

connected

Velocity of Ultrasound:

Indicates the velocity of

the ultrasound travelling

through the material Hold Measurement: Fixes the

last thickness reading on the

screen when the Left Option

Key is pressed

—Shows that an iProbe has been connected. The probes are

automatically recognised by the gauge and all the relevant

probe data is transferred to the gauge to perfectly match the

probe to the gauge for optimum performance.

—All materials have varying velocity of sound properties and

this section allows the gauge to be calibrated for the different

materials that the gauge can measure.

—Displays the measurements being taken by the gauge.

—The measurements can be displayed in metric or imperial.

—Displays the remaining battery life. The green changes to

yellow when the battery is getting low and then changes to

red when the batteries are critically low.

—The measurements can be displayed to a resolution of

0.05mm or 0.1mm.

—Allows measurements to be taken through extremely thick

coatings up to 20mm, depending on the type of coating. In

normal mode the gauge can still ignore up to 6mm of coating.

—Displays the software and firmware versions and includes a

facility to reset the gauge to factory settings.

5

iProbe

Calibration

Measuring

Units

Battery

Resolution

Coating

Plus+

About 5600

Definition of Menu Items

Note: The “Coating Plus” and “About 5600” menus items may be found by pressing the right

key on the directional pad.

How does a Portagauge® 4 work?

All sound is physical vibrations which move through a material, and in the case of the

sound we are used to, the vibrations move through air. Ultrasound is the same as the

sound we experience, but its frequency is beyond that which humans are capable of

hearing. Whilst the highest frequency a human can hear is around 20,000 Hz,

Portagauge® 4 units use sound at a frequency of 2.5 MHz, 3.5 MHz or 5 MHz

depending on the specific probe being used.

All Portagauge® devices use ultrasound to measure the thickness of a material. The

unit sends a strong electrical signal to the probe, causing it to emit a high energy pulse

of ultrasound. The transmitted ultrasound pulse travels though both the coating and

the metal and reflects from the back wall. The returned echo then reverberates within

the metal, with only a small portion of the echo travelling back through the coating

each time (Figure 1). The timing between the small echoes gives the timing of the

echoes within the metal, which relate to the metal thickness. The returned echoes

need not be consecutive as the gauge will interpret them automatically and calculate

the thickness. A minimum of three echoes are checked for each pulse that is sent into

the metal.

6

Timing 1

Figure 1

7

2. Operating Instructions

DO NOT PROCEED BEFORE READING SECTION 1.

There are two basic procedures which must be carried out when using

the Portagauge® 4:

1. Preparation: Calibration ensures that the Portagauge®equipment functions

properly for the specific metal being tested.

2.Testing: After step one, you can follow the appropriate testing procedure.

8

1. PREPARATION

Preparation for testing is simple, quick and ensures you get the most reliable and

accurate results from your testing. It ensures the equipment is assembled correctly

and that the appropriate probe is selected. Calibration ensures that the unit and

probe work correctly for the specific metal being tested.

Assembly

To assemble the gauge for use:

STEP 1: Attach the probe to the probe cable by pushing the cable Lemo

plug into the socket on the probe.

STEP 2: Connect the other end to the gauge Lemo socket (see page 4).

To remove the connectors, simply pull back on the connector collars to release the

plug from the socket. Do not force or twist under any circumstances.

Probes

The probes used with the Portagauge® 4thickness gauges are single

crystal soft faced probes.The table below identifies the different probe

options and which probe is the most suitable for different applications.All

probes are color coded to help identify their frequency.

Frequency

2.25 MHz

3.5 MHz

5 MHz

Measuring

Range

3 –250 mm

(0.120” to 10”)

2 –150 mm

(0.080” to 6”)

1 –50 mm

(0.040” to 2”)

Color Yellow Green Blue

Diameters

Available

13 mm (0.5”) & 19

mm (0.75”)

13 mm (0.5”)

6 mm (0.25”) & 13

mm (0.5”)

Suitable For

Most thickness

gauging

applications.

Works particularly

well on heavy

corrosion,

especially the 19

mm probe.

Will measure

relatively thin

metal which is

corroded.

Normally used

only if measuring

down to 2 mm is

of importance.

Ideal for

measuring thin

metal in relatively

good condition.

Not advisable to

use as main probe.

Note:The details of the probe connected are recognized and displayed on the

Measuring Screen, as seen on page 4, or under the iProbe item on the Menu, as seen

on page 5.

9

Probe Membranes

All probes are fitted with protective membranes to help prolong the life of the

probe.The membranes also provide a flexible interface which acts as an aid

when working on rough surfaces. Membrane wear should be monitored and

checked at regular intervals.

NormalTemperature Membranes

Standard membranes allow measurements to be taken on hot surfaces up to a

maximum of 158°F(70°C).

HighTemperature Membranes

Teflon™ membranes are available for measurements on hotter surfaces. In this

case measurements can be taken on surfaces up to 302°F(150°C). Care

should be taken that the probe does not overheat.The probe should be

allowed to cool down in between each measurement.A high temperature

ultrasonic gel is advised for this application.

Note: All probes should be treated with care. When taking measurements, they should not

be scraped or dragged along the surface. Although the membranes will protect the probe

against everyday wear and tear, they will not protect against rough treatment and misuse.

10

Calibration

The gauge should be calibrated to the type of material that is being measured.This is

because ultrasound travels at different speeds in different materials.

There are two methods of changing the calibration. Either adjust the velocity of sound

setting according to the metal being measured, or adjust the gauge to a known

thickness of metal.

Gauges are supplied with the calibration set to mild steel at approximately 5900 m/s.

This may vary according to the properties of the supplied 15 mm test block material.

Calibrating to the Velocity of the Ultrasound

STEP 1: Navigate to ‘Calibration’ on the ‘Menu’ screen using the keys on the

directional pad (see page 4). Use the Definition of Menu Items on page 5 as a guide.

STEP 2: Press the ‘OK’ button at the centre of the directional pad.

STEP 3: Use the left and right buttons on the directional pad to adjust the velocity of

sound to the required new velocity that the ultrasound travels at in the material being

tested.Approximate values for these may be found on page 11.

STEP 4: Press the ‘Right Option Key’, the gauge will save the new calibration and

return to the ‘Menu’ screen.

Calibrating to a KnownThickness

STEP 1: Navigate to ‘Calibration’ on the ‘Menu’ screen using the keys on the

directional pad. Use the Definition of Menu Items on page 5 as a guide.

STEP 2: Press the ‘OK’ button at the centre of the directional pad.

STEP 3: Place the probe on a piece of material of known thickness such as the 15mm

test block supplied with the kit.

STEP 4:Adjust the measurement displayed to the known thickness using the left and

right buttons on the directional pad.

STEP 5: Press the ‘Right Option Key’, the gauge will save the new calibration and

return to the ‘Menu’ screen.

Note:The calibration does not need to be reset each time the gauge is used.The last setting

will be remembered.

11

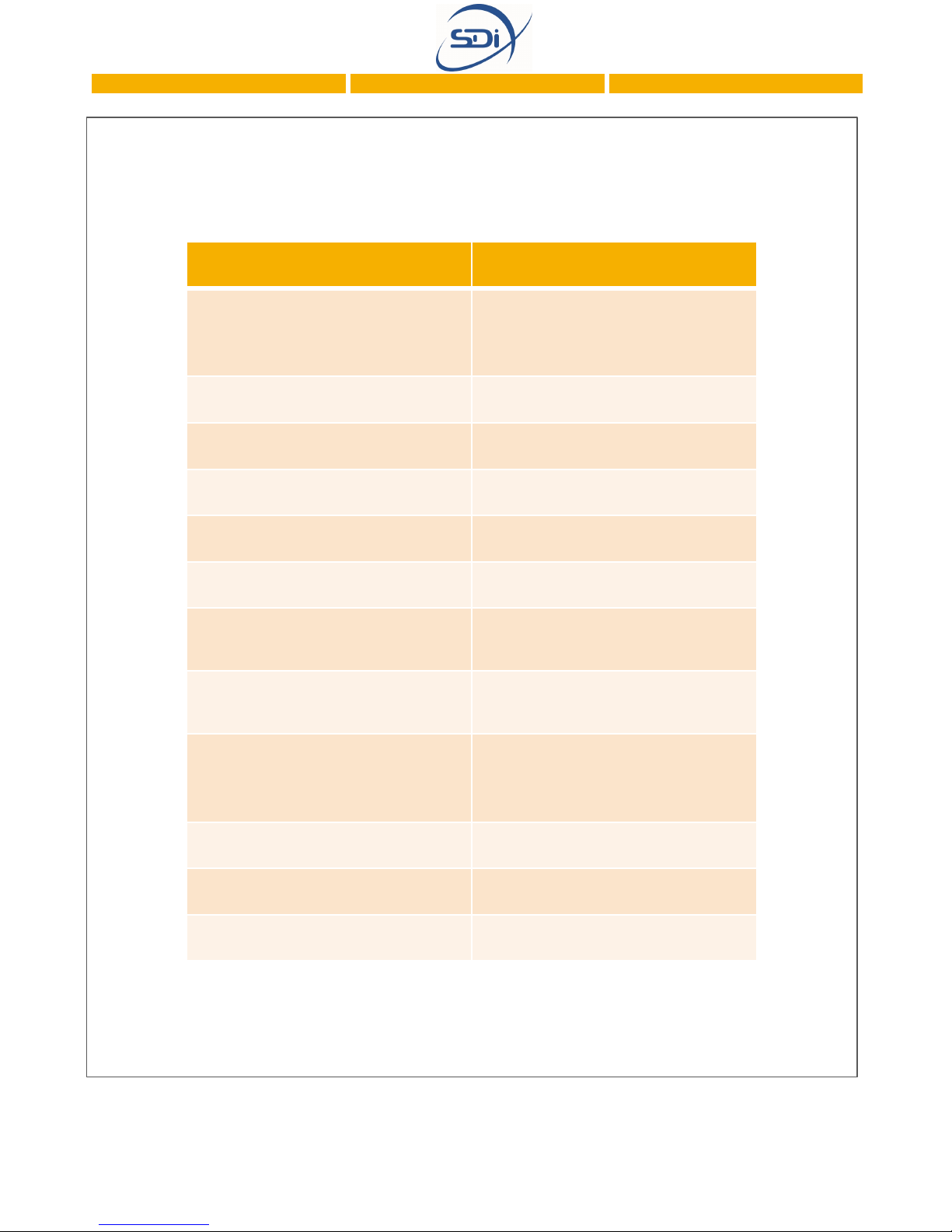

Speed Table

The given values are in certain cases strongly dependent on the alloy, heat treatment,

manufacturing and processing and are therefore only approximate standard values.

They are given here as a guide only.

Reference: Mathies, Klaus (1998), Thickness Measurement with Ultrasound, Berlin: German Society of

Nondestructive Testing.

Material

Speed

–m/s

Aluminium

Rolled

Duraluminium

6200 –6360

6420

6320

Bronze (5%P)

3531

Copper

3666 –4760

Glass, Plate

5766

Inconel, Forged

7820

Lead

2050 –2400

Steel, Mild

SuppliedTest Block

5890 –5960

5900 approx.

Steel, Stainless

10 Cr Ni 18 8, ann

5530 –5790

5530

Steel

,Tool

C105 Annealed

C105 Hardened

5490 –5960

5854

Tin

3210 –3320

Titanium

5823 –6260

Zinc

3890 -4210

2. TESTING with the Portagauge® 4

PRECAUTIONS:

Check that the material has parallel front and back walls. If the front and

back walls are not parallel, the ultrasound hitting the back wall will be deflected away

from the face of the probe.The probe will therefore not receive any echoes back.

The surface being measured should be free from dirt or debris. It may be

necessary to clean or brush the surface prior to taking measurements.

Ensure the coating is not layered or does not contain foreign objects in its

construction. Layered coatings cause reflections at the layer interface.This seriously

weakens the strength of the ultrasound and may prevent it from travelling all the way

through.The same applies to foreign objects which can deflect the ultrasound path or

prevent the ultrasound from passing.

Ensure the coating is solidly adhered to the surface. Triple echo will ignore

coatings as long as they are solidly adhered to the surface. If the coating has become

loose or delaminated then air pockets will exist which interfere with the Ultrasound.

PROCEDURE:

STEP 1: Unscrew the probe knurled ring and apply a few drops of membrane oil to

the face of the probe. Do not apply too much membrane oil underneath the

membrane. Once fitted, the membrane should be flat with no air bubbles trapped

behind.

STEP 2: Re-screw the knurled ring, ensuring there are no air pockets.

STEP 3: Connect the probe, cable and gauge together (see page 8).

STEP 4:Turn on the gauge using the ON/OFF button (see page 4).

STEP 5:The normal measurement mode will ignore coatings of up to approximately 6

mm. If a coating between 6 mm to 20 mm exists then the Coating Plus+ mode,

accessed by navigating to the right of the Menu screen (see page 5) using the arrow

keys on the directional pad and selecting the feature using the ‘OK’ button, can be

turned on to measure the metal thickness in such cases.

Note: If a compatible probe other than an SDi probe is attached to the unit, the gauge will

automatically detect this and display the message “Unrecognised Probe”. If this occurs

press the “OK” button and then select the correct parameters (frequency and diameter) for

the probe being used.

12

13

The Coating Plus+ feature is automatically switched off when the unit is turned off. If

this feature is required permanently, press the ‘Right Option Key’ labelled “SAVE” to

keep this as a permanent setting.The CP+ icon will be displayed on the right of the

Measuring screen if the feature is selected.

STEP 6: Navigate using the arrow keys on the directional pad to the ‘Measuring’ item

on the Menu screen. Press the ‘OK’ button to access the Measuring screen.

STEP 7: Apply a small amount of gel to the surface being measured to eliminate the

possibility of air pockets between the surface and the probe.

STEP 8: Apply the probe firmly to the surface, ensuring good contact, and take the

measurement. It may sometimes be necessary to rock the probe slightly and gently in

order to obtain measurements (only do so if you are having trouble obtaining

measurements).

STEP 9: If you wish to hold a measurement, press the ‘Left Option Key’ whilst

readings are being taken. The display will hold the measurement and flash ‘Holding’ in

the top right corner of the LCD screen. Measuring may be resumed by pressing the

‘Left Option Key’ again which is now labelled “Resume”.

STEP 10: Remove debris from the probe face between measurements.

Note: If the message “No Probe connected” appears, either connect a suitable probe or

simply press the “OK” button to enable the navigation of the menus without a probe fitted.

No measurements can be taken if a probe is not detected.

Note: The Coating Plus+ mode should not be left on for all measurements.The gauge will

achieve a better performance on standard coatings with this function turned off.

Note: The units and resolution of measurements can be changed using the respective

options on the Menu screen (see page 5).

14

3. Maintenance

This section contains instructions on how to maintain the equipment to extend its

lifetime as long as possible. Maintenance of the equipment is simple and only requires

the cleaning of the probe and battery care. For any major works or re-calibrations

the unit can may need to be sent to the manufacturer for repair.

Probe Care

The ultrasonic probe is the most delicate part of a Portagauge®, and care must be

taken when using it. After using a Portagauge®, it is essential to ensure that the probe

is dried off and free from dirt.The probe is robust, but damage may occur if it is

dropped, or if the probe is dragged across the surface rather than being removed and

replaced. Never try to repair a probe or try to remove scratches from the face of

the probe.This may result in further damage.Always return it to SDi for investigation

and possible repair.

The membrane requires changing from time to time to ensure the protection of the

probe and the prolonging of its lifetime. See below for instructions on how to change

this membrane.

STEP 1: Unscrew the knurled ring (1) from the probe (4).

STEP 2: Using the membrane key (5), remove the retaining ring (3) from

inside the knurled ring (1).

STEP 3: Push the old membrane (2) out from the front.

STEP 4: Fit a new membrane (2) from the back and push it down until it

locates in the groove on the inside front edge.

15

Battery Care

The Portagauger® 4has a battery indicator on the right of the ‘Measuring’ screen and

on the top right of the ‘Menu’ screen.

When the battery is indicated to be low on power, the battery must be replaced

before it is used further, or the unit may provide anomalous results.

When a Portagauge®unit is going to be stored, or not used for a long period of time,

remove the battery from the main unit to prevent corrosion damage to the unit.

STEP 5: Refit the retaining ring (3) and secure it in place using the

membrane key (5).

STEP 6: Place a few drops of membrane oil (6) onto the face of the probe

(4). Do not use too much.

STEP 7: Screw the knurled ring (1) back onto the probe (4) whilst applying

pressure on the membrane (2) with the thumb to expel any air

from behind the membrane.

Battery Replacement

You will need a small flathead screwdriver and three 1.5V AA batteries.

STEP 1: Ensure the unit is off and turn the unit so that the front fascia faces

downwards.

STEP 2: Take a small, flat head screwdriver and unscrew the two screws holding down

the hatch of the battery compartment.

STEP 3: Lever the screwdriver gently to remove the hatch.

STEP 4: Remove the old batteries and replace with the new, taking care to connect +

and –correctly.

STEP 6: Close battery cover, ensuring that the wires are not trapped.

STEP 7: Press battery hatch and use the screwdriver to replace the screws so that

the hatch of the battery compartment is closed once again..

16

Battery Compartment

Positive

Terminals (+)

Table of contents

Other SDI Measuring Instrument manuals