ii

Contents

5 Operating the Vibrometer 5-1

5.1 Switching On and Off...........................................................................................................5-1

5.2 Beam Shutter and Emission Indicator..................................................................................5-1

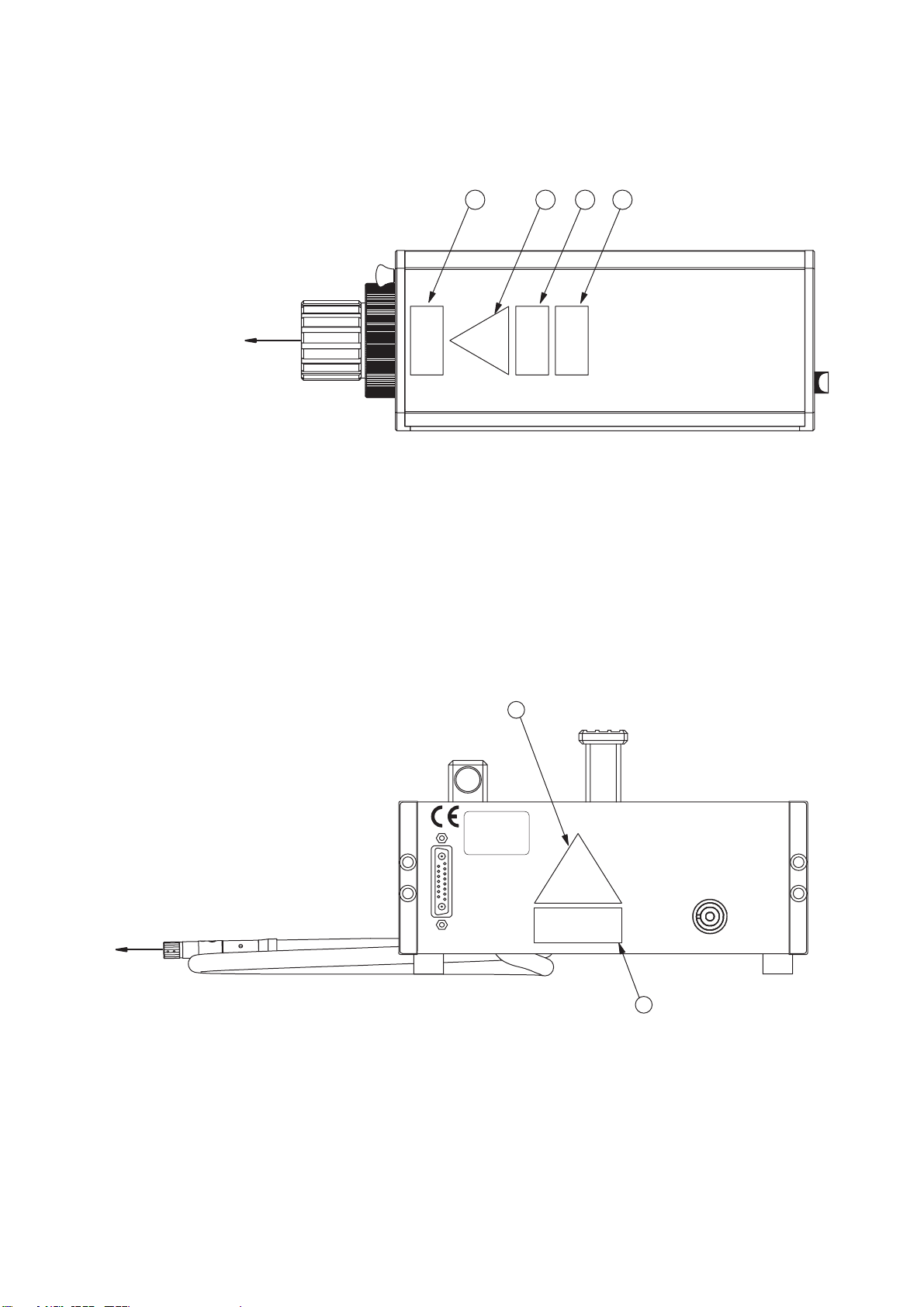

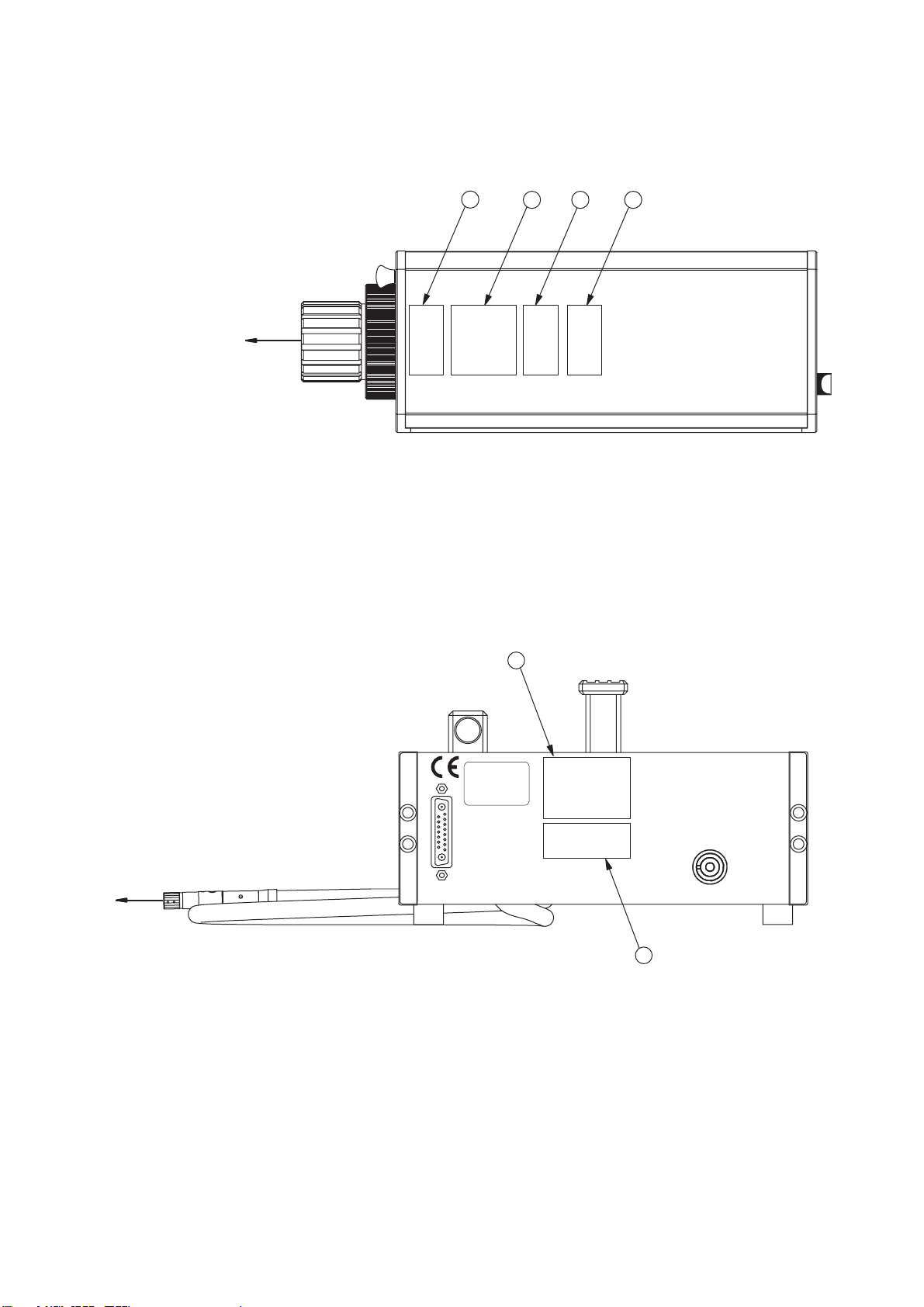

5.3 Signal Level Display ............................................................................................................5-2

5.4 Focusing the Laser Beam....................................................................................................5-2

5.5 Exchanging the Front Lens..................................................................................................5-4

5.6 Making Single Point Measurements with the Sensor Head OFV-512 ...................................5-5

5.7 Fixing the Focus (only OFV-353) .........................................................................................5-5

5.8 Transport Safety Mechanism (only OFV-511/-512)...............................................................5-6

5.9 Operating the Vibrometer via the Display of the Controller...................................................5-7

5.9.1 Operating Philosophy.................................................................................................5-7

5.9.2 Organization of the Menus.........................................................................................5-8

5.9.3 The Individual Menus.................................................................................................5-9

5.10 Setting Measurement Ranges and Filters ........................................................................5-11

5.11 Displaying the Configuration of the Controller ..................................................................5-11

5.12 Configuring the Interfaces................................................................................................5-11

6 Fault Diagnosis 6-1

6.1 General Tests ......................................................................................................................6-1

6.2 No Laser Beam....................................................................................................................6-2

6.3 No Measurement Signal ......................................................................................................6-3

6.4 Checklist for Fault Diagnosis ...............................................................................................6-5

6.4.1 Controller OFV-3001 with the Sensor Head OFV-303/-353 ........................................6-5

6.4.2 Controller OFV-3001 with the Sensor Head OFV-511/-512.........................................6-6

7 Technical Specifications 7-1

7.1 Controller OFV-3001............................................................................................................7-1

7.1.1 General Data .............................................................................................................7-1

7.1.2 Interfaces...................................................................................................................7-1

7.1.3 Low Pass Filter..........................................................................................................7-2

7.1.4 Signal Voltage Output VELOCITY OUTPUT...............................................................7-2

7.1.5 Signal Voltage Output DISPLACEMENT OUTPUT (optional) .....................................7-5

7.2 Sensor Head OFV-303/-353 ................................................................................................7-6

7.2.1 General Data .............................................................................................................7-6

7.2.2 Optics........................................................................................................................7-6

7.3 Sensor Head OFV-511/-512.................................................................................................7-8

7.3.1 General Data .............................................................................................................7-8

7.3.2 Optics........................................................................................................................7-8

Appendix A: Optional Accessories for the Sensor Head OFV-303/-353

Appendix B: Optional Accessories for the Sensor Head OFV-511/-512

Appendix C: Basics of the Measurement Procedure

Appendix D: Functional Description of the Controller

Appendix E: Interface Operation RS-232 and IEEE-488/GPIB