SDI PORTALEVEL MAX User manual

PORTALEVEL® MAX

USER MANUAL

Contents

2

Note: For information on converting Liquid Levels to approximate agent weights,

see the separate guide ‘Liquid Level to Weight Conversion,’also on sdifire.com/support.

1. Introduction and Key Features

1.1 What does the Portalevel®do?

1.2 The Portalevel®Max

2. Operating Instructions

2.1 Introduction

2.2 Preparation

2.21 Function Test

2.22 Dip Test

2.23 Cylinder Preparations

2.24 Temperature

2.3 Calibration Procedure Identification (CPI)

2.31 Test Procedure 1

2.32 Test Procedure 2

2.4 Troubleshooting

2.5 Frequently Asked Questions

3. Accessories

3.1 Extension Rod

3.2 Portatherm®

3.3 Ultrasonic Gel

3.4 Portalevel®Sensors

4. Maintenance

4.1 Sensor Care

4.2 Battery Care

4.21 Battery Replacement

4.3 Storage

5. Training

5.1 The Bench Test

3

3

3

6

7

7

7

8

8

9

10

12

14

19

21

21

23

24

24

25

25

25

26

26

27

27

1. Introduction and key features

What does the Portalevel®do?

The Portalevel®Max is designed to be a portable way to non-invasively locate the

liquid level inside any single skinned cylinder. Portalevel®s are capable of detecting the

presence of any liquid externally; from water and liquid pressurised gases to

firefighting clean agents. Portalevel®s can be used on a huge variety of container types,

composed of different materials and of different shapes and sizes, but are typically

most used on steel compressed gas cylinders.

Many applications exist for our technology, but it is most widely used as a

replacement to both weighing fire suppression cylinders during installation and

servicing, or the fitting of internal and invasive liquid level ‘float’ devices. Once the

liquid height inside a container has been found, the contained weight of liquid can be

determined, after taking into consideration other environmental factors such as the

size of the cylinder and type of liquid.

Portalevel®Max

With an intelligent calibration feature and four separate power settings, the

Portalevel® Max is versatile and our most user friendly unit. It is capable of testing a

wide variety of fire suppressant agents; CO2, FM200™, NOVEC 1230™, old Halon

agents, FE-13™, FE-25™, NAF S III™ and all core Clean Agent Systems.

3

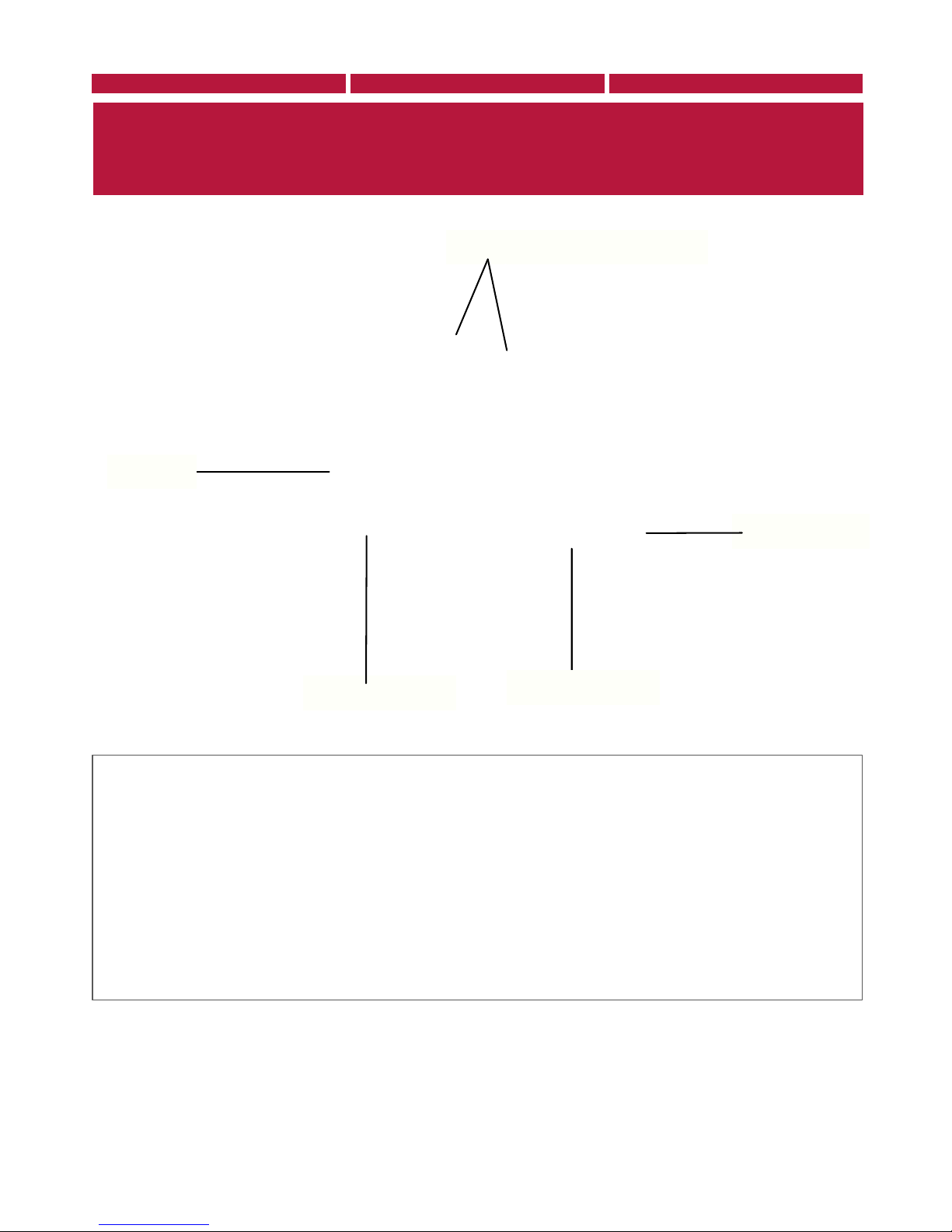

Portalevel®Max

The Portalevel®Max also includes; sensor, and ultrasonic gel (couplant).

Gromit: The gromit at

the top of the unit is

the ultra secure simple

fastening for the sensor

Sealing: Red sealing

ring for watertight

integrity

Display: ‘Go/No-Go’

readings for quick and

easy use

On: Simple power ON

button – powered by 1

x 9V battery providing

approximately 8 hours

battery life

Off: Simple power OFF

button – keep turned

off to save battery life

SPA: The SPA capability

enables an increased

strength of signal output to

achieve better readings for

poor condition cylinders,

more challenging

applications and large

volume uses.

CAL: The CAL button is

the standard procedure

feature enabling self-

calibration prior to testing

on each individual cylinder,

to ensure accurate and

reliable readings.

Battery

Compartment: The

battery compartment is

on the bottom of the unit

and has a double gateway

to be waterproof. It must

be opened by a flat head

tool, e.g. a screwdriver in

order to change the

battery.

V1.02: Version 1.02

Digital display:

Numerical readings for

experienced users to

gauge a better

interpretation of the

ultrasound behaviour

Bar graph display: Easy

to interpret visual reading

CAL: Highlights when

CAL in use

SPA: Checks SPA feature

is working

BAT OK: Checks battery

level

4

5

2. Operating Instructions

POINTS TO CONSIDER BEFORE PROCEEDING:

!Do not proceed before reading section 1.

!Do not proceed before familiarising yourself with the Training section on page 27.

Introduction

There are three basic procedures which must be carried out when using the

Portalevel®Max:

1. Preparation: Function Tests and cylinder preparations.These tests ensure that the

Portalevel®equipment is functioning properly and that the cylinder(s) are prepared in

a way to give the most accurate readings.

2. Calibration Procedure Identification (CPI): This test allows you to determine

which method of testing should be used on the cylinders you wish to measure. Once

you know the appropriate method of testing for that type of cylinder, you do not need

to perform this again for that testing session.

3.Testing: After step two, you can follow the appropriate testing procedure (1 or 2)

for that set of cylinders.

Note: If you move on to testing a different type of cylinder, which is a different size, weight or

filled with a different agent, you must repeat step 2 on the new cylinder type to confirm

which testing procedure is required.

As with all electronics, do to leave the Portalevel® Max in the

sun for long periods of time. Excessive UV exposure can lead

to damage of the LCD screen.

6

1. Preparation

Preparation for testing is simple, quick and ensures you get the most reliable and

accurate results from your testing.The FUNCTION Test and DIP Test both ensure the

main unit and sensor are working correctly. CYLINDER PREPARATIONS ensure that

you test on the best possible area of the cylinder wall.

FUNCTION Test:

A FUNCTION Test should be performed every time you wish to use the unit.To

perform the test, simply connect the sensor to the main unit and turn on the

Portalevel®.After a couple of seconds, the readout should reset itself to zero.Then

press the CAL button.The CAL symbol should become blacked out like this:

Then disengage CAL by pressing the CAL button again and turn the unit off.This

completes the Function Test.

DIP Test:

The DIP Test checks whether the sensor you are using is working correctly and is

communicating with the Portalevel®main unit.

Step 1: Connect sensor to unit and turn on.

Step 2: Lightly dip the tip of sensor into cup of water vertically.The amount of water in

the cup is not important, as long as there is enough to dip the end of the sensor so the

black central patch on the end of the senor is submerged, without it touching the

bottom of the cup.

Step 3:When dipping the sensor, you should see the readings of the Portalevel®spike

to high values and the bar graph rise also. If you do observe this, then the DIP Test is

complete and you know the sensor is working well.!

7

CYLINDER PREPARATIONS:

It is important to prepare the cylinders well to attain accurate and reliable readings.To

perform CYLINDER PREPARATIONS:

Step 1: Find on the cylinder the side which has the least damage, rust or chipped paint.

For accurate testing you must find a vertical strip down the side of the cylinder which

is as smooth as possible.You will be placing the sensor and testing along this strip.

Step 2:Wipe down the chosen side of cylinder with damp cloth to remove dirt and

debris.This completes the CYLINDER PREPARATIONS.

IF YOUR UNIT FAILS THE FUNCTION OR DIP TEST, PLEASE

CONTACT SUPPORT AT (732)-751-9266 OR

SERVICE@SDIFIRE.COM

Temperature:

The surface temperature of the cylinders stored must be measured before the liquid

levels are checked. This should be measured around half way up the cylinder.

IF THE TEMPERATURE EXCEEDS 86oF (30°C) DO NOT TEST CO2or

FE-13 CYLINDERS.

Further information regarding this issue can be found on page 20 under Frequently

Asked Questions.

8

To perform CPI:

Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose

during CYLINDER PREPARATIONS.

Step 2: Place sensor at top of cylinder (below top wield seam or curve).Take note of

digital reading.

Step 3: Place sensor 5cm below. (Take note of digital reading).

Step 4: Repeat Step 3 down the full vertical length of the cylinder.

Step 5: Analyse the results using the guide below.

2. Calibration Procedure Identification (CPI)

The purpose of this test is to identify whether method 1 or 2 should be used for

the cylinder being tested.The details and differences between methods 1 and 2 are

explained in the next section.

Compare your results to the guide below to decide whether Procedure 1

or Procedure 2 should be used when testing the cylinders you wish to

measure.

INSTANCE 1:“Higher readings were found in the upper portion (gas area) of the

cylinder compared with the lower portion (liquid area).” – Carry out Procedure 1.

INSTANCE 2:“Higher readings were found in the lower portion (liquid area) of the

cylinder compared with the upper portion (gas area).” – Carry out Procedure 2.

INSTANCE 3:“There was no difference in readings between the upper portion and

lower portion of the cylinder” – Carry out Procedure 2.

Both Procedure 1 and 2 are fully explained in the next section.

9

3.Testing

PROCEDURE 1:TO BE USED WHERE HIGHER READINGS ARE FOUND

IN THE GAS PHASE COMPARED TO THE LIQUID PHASE.

Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose

during CYLINDER PREPARATIONS.

Step 2: Place the sensor on the area covered with gel or water and on the UPPER

portion of the cylinder, where you are certain the sensor will be above the liquid level.

DO NOT place the sensor close to the upper weld or start of the dome, as

anomalous readings will be found.

Note: The sensor must always be positioned with the ‘TOP’ marking positioned pointing

exactly upwards. On some sensors the ‘TOP’ is marked by a simple dot. If the sensor is not

accurately placed the right way up, then anomalous readings will be found.

Step 3: Once location has been found, press CAL. A full bar graph will appear on the

Portalevel®screen, example below:

Above liquid level

Calibration must be carried out for each individual cylinder tested.

Step 4: Move sensor 5cm down, observing the bar graph.

Note:When moving the sensor, it is important NOT to slide it, as this will damage the sensor

pad, rendering the sensor inefficient and inaccurate. Remove the sensor fully and replace in

steps each time you move the sensor.

Step 5: Repeat Step 4 until the bar graph reduces and disappears (example below). In

some areas the bar graph may ‘bounce’ up and down for a few seconds. If this occurs,

simply wait for the bar graph to settle.

10

Below liquid level

Note: Some cylinders are prone to giving ‘false levels’;that is the bar graph may disappear

after moving the sensor even though the Liquid Level has not been passed. If you think you

may have found a false Liquid Level, simply move the sensor slightly to the left or right to

check if the bar graph returns, as false levels can usually be caused by irregularities in a

specific part of the steel wall.

Step 6: Move sensor back up the cylinder in smaller steps until the bar graph rises

again.The position of the sensor on the wall of the cylinder at this point is the Liquid

Level position inside the cylinder. You have found the Liquid Level.

Note: For increased accuracy, it is possible to move the sensor in very small steps further up

or down to find the position where the bar graph settles in the middle of its range (neither

full or empty).At this point, the Liquid Level can be identified at the position of the exact

middle of the sensor with an uncertainty of ±1.5mm.

IF YOU ENCOUNTERED DIFFICULTY USING PROCEDURES 1 OR 2

PLEASE MOVE ONTO TROUBLE SHOOTING ON PAGE 14.

11

PROCEDURE 2: TO BE USED WHERE HIGHER READINGS ARE

FOUND IN THE LIQUID PHASE COMPARED TO THE GAS PHASE.

Step 1: Place a strip of gel or water down the vertical strip on the cylinder you chose

during CYLINDER PREPARATIONS.

Step 2: Place the sensor on the area covered with gel or water and on the LOWER

portion of the cylinder, where you are certain the sensor will be below the Liquid

Level. DO NOT place the sensor close to the weld or very close to the bottom of

the cylinder, as anomalous readings will be found.

Note: The sensor must always be positioned with the ‘TOP’ marking positioned pointing

exactly upwards. On some sensors the ‘TOP’ is marked by a simple dot. If the sensor is not

accurately placed the right way up, then anomalous readings will be found.

Step 3: Once location has been found, press CAL. A full bar graph will appear on the

Portalevel®screen, example below:

Below liquid level

Calibration must be carried out for each individual cylinder tested.

Step 4: Move sensor 5cm up, observing the bar graph.

Note:When moving the sensor, it is important NOT to slide it, as this will damage the sensor

pad, rendering the sensor inefficient and inaccurate. Remove the sensor fully and replace in

steps each time you move the sensor.

Step 5: Repeat Step 4 until the bar graph reduces and disappears (example below). In

some areas the bar graph may ‘bounce’ up and down for a few seconds. If this occurs,

simply wait for the bar graph to settle.

12

Above liquid level

Note: Some cylinders are prone to giving ‘false levels’, that is the bar graph may disappear

after moving the sensor even though the Liquid Level has not been passed. If you think you

may have found a false Liquid Level, simply move the sensor slightly to the left or right to

check if the bar graph returns, as false levels can usually be caused by irregularities in a

specific part of the steel wall.

Step 6: Move sensor back down the cylinder in smaller steps until the bar graph rises

again.The position of the sensor on the wall of the cylinder at this point is the Liquid

Level position inside the cylinder. You have found the Liquid Level.

Note: For increased accuracy, it is possible to move the sensor in very small steps further up

or down to find the position where the bar graph settles in the middle of its range (neither

full or empty).At this point, the Liquid Level can be identified at the position of the exact

middle of the sensor with an uncertainty of ±1.5mm.

IF YOU ENCOUNTERED DIFFICULTY USING PROCEDURES 1 OR 2

PLEASE MOVE ONTO TROUBLE SHOOTING ON PAGE 13

13

Troubleshooting

ISSUE 1:“The readings on the main unit did not change when the sensor

was placed anywhere on the cylinder”

SOLUTION: Firstly, ensure you are using an adequate quantity of water or gel to

couple the sensor to the cylinder and also ensure that the rubber pad of the sensor is

clean and undamaged.

If this does not solve the problem, carry out the DIP Test and the FUNCTION Test

found in section 2.2, page 7. If the sensor fails the DIP Test or the main unit fails the

FUNCTION Test then contact service@sdfire.comas the equipment is likely

malfunctioning.

ISSUE 2:“The readings fluctuate greatly even with the sensor repeatedly

placed on the same side of the Liquid Level.” / “Readings on the main unit

increase the longer the sensor is left on the cylinder.”

Some fluctuation in the reading is normal when working with this and any other

ultrasonic equipment. If the variation is extreme, ensure the end of the sensor and the

area of the cylinder you are testing are clean and free of debris and chipped paint.

You can expect the readings to rise once you have placed the sensor on cylinder,

especially when using the gel couplant.This rising of the reading values is caused by a

few separate factors, but does not prevent accurate Liquid Level detection.To reduce

the impact of this effect, try to keep the sensor on the cylinder for roughly the same

amount of time for every step up or down the cylinder you take with the sensor.

If the readings fluctuate more than ±100% when the sensor is left in one location

then please contact service@sdifire.com

14

ISSUE 3:“Readings are rarely/never greater than 1000 on the side of the

level where the highest readings are found.”

SOLUTION:The Portalevel®Max should, in most scenarios, be able to attain readings

of more than 1000 on a cylinder. Achieving readings less than 1000 DOES NOT

always prevent measurement, but in some cases may cause problems. If you are having

problems making a measurement:

Step 1: Clean surface of cylinder with damp cloth to remove dirt, debris, flaking paint

and rust. Choose a vertical strip on the cylinder which has the most consistently

smooth surface, top to bottom. Use this strip to place the sensor on for testing.

Step 2: Ensure you are using either gel or water to couple the sensor to the cylinder.

Be aware that especially in hot environments, water quickly evaporates from the

surface of a cylinder, so in this case use gel. Also check the end of the sensor for

damage to the rubber sensor pad, and clean lightly with a damp cloth if necessary.

If the above steps still do not fix the problem, try some of the additional solutions

below.

Step 3: Replace the batteries on the main unit (see page 26). Low power can often

significantly reduce the measurement readings seen on the unit.

Step 4: Engage SPA by pressing the SPA button.This will boost power to the sensor

and is useful for dealing with dirty, rusty or damaged cylinders. SPA will not correct

the problem however if the battery power is already low.There are four SPA settings,

each of greater power than the last. Use the lowest SPA setting which gives you values

of at least 1000, and then continue with testing.

SPA 1 Engaged

15

ISSUE 4:“The bar graph does not fill up, even with CAL engaged”

SOLUTION:The bar graph will only fill up if very high readings are found without

CAL engaged, or once CAL is engaged and the current reading is significantly larger

than the value displayed when CAL was pressed. If you cannot get the bar graph to fill

up:

Step 1: Use the DIP Test (Section 2.2, page 7) to check the sensor and main unit is

working correctly. During the DIP Test the bar graph should light up entirely.

Step 2: Replace the battery on the main unit (see page 26). Low power can often

significantly reduce the measurement readings seen on the unit.

Step 3: If neither of the above steps solves the problem, contact

service@sdifire.com as it is likely a technical fault.!

16

ISSUE 5:“Debris/gel in sensor housing has caused the sensor mechanism

to stick making it hard to use.”

SOLUTION:The sensor can be removed from its housing and cleaned following the

below steps.

Step 1: Hold sensor in left hand with dot/top facing up.With right hand, unscrew rear

cap completely by twisting anticlockwise.

Step 2: Once the rear cap is unscrewed, gently pull out the sensor and spring by

pulling on the cable.

Step 3:With a damp cloth, clean the various parts, taking extra care on the sensor

itself, the spring, and the inside of the housing/around the magnet. Ensure all

components are dried before continuing, as rusting can occur.

Step 4:To reassemble, slide sensor back into the applicator housing whilst twisting

gently so the sensor seats itself into the guide rail inside the housing.This rail ensures

the sensor remains the right way up inside the housing. Then push in the sensor until

it stops and screw the rear cap back on.

Step 5: If these steps do not rectify the issue then please contact

service@sdifire.com

17

ISSUE 6:“There is not a significant difference between above and below

level readings”

Step 1: Carry out a ‘Calibration Procedure Identification’ (CPI) explained in Section

2.3, page 9.

Step 2: Upon completing Step 1 press CAL on the exact location where the highest

readings are found.

Step 3: Continue to test as normal.

Step 4: If this still does not rectify the problem, engage SPA 1 and retest. If the Liquid

Level still cannot be found, proceed to SP A 2 and SPA 3 and retest.

Step 5: If this does not rectify the problem, please contact service@sdifire.com

18

Frequently Asked Questions

Why do I have to use water or gel with the sensor?

The use of water or ultrasonic couplant gel is essential to the operation of a

Portalevel®unit.When the sensor both emits a high energy pulse and listens for the

retuning echoes, excellent mechanical contact must be maintained between the senor

and the container in order for the ultrasonic signals to pass into and out of the

container efficiently and without interference.This is done by placing a thin layer of gel

or water between the sensor and container wall, which omits all air from the contact

area, ensuring good operating conditions. If no water or gel is used then the ultrasonic

signal can be broken up or even destroyed when traveling between the container and

the sensor, making taking measurements impossible.

What does SPA stand for and what does it do?

Under some conditions, even if you are using gel or water between the sensor and

the container wall, some of the ultrasonic signal can still be lost.This may be because

the internal or external walls are heavily rusted or corroded or maybe some part of

the cylinder or liquid inside is especially good at absorbing ultrasound.To overcome

this Signal Power Amplification (S.P.A.) can be engaged which boosts the output

power of the Portalevel®allowing stronger ultrasonic pulses to be emitted and

stronger pulses to be received allowing a measurement to be made.

What does the digital reading mean?

The digital display on the Portalevel®units represents the strength of the returning

echoes and once the Portalevel®is calibrated to an area of the cylinder where high

readings are found, the sensor can be moved up and down the container in order to

find the exact location where the transition from liquid to gas contents is found.The

exact operating procedure to be used is explained in detail in Chapter 2.

19

Why can’t I test CO2and FE-13 in high temperatures?

When testing some liquids, it is vital that testing is done under atmospheric

temperatures lower than their critical temperature.At the critical temperature of a

liquid, it transforms into a vapourous state in which a liquid level no longer exists

inside the container to be measured. NOVEC 1230 has a critical temperature of 168.7

ᵒC and as such testing is never practically limited by this, but some commonly tested

liquids have low critical temperatures. CO2, carbon dioxide, has a critical temperature

of 31 ᵒC and FE-13 has a critical temperature of 26 ᵒC.Whilst this can prove

problematic in especially hot climates, there are several methods in which this can be

overcome:

! Running fresh water lines across cylinders to act as a heat exchanger

! Use of portable AC units

! Use of bagged ice around cylinders to cool them

! Testing both early and late in the day.

Testing these gases at the coolest temperature achievable will allow for the most

accurate and efficient results.

It is also important to note that agitating cylinders of FE-13 can also cause a change in

the liquid level due to the physical properties of FE-13. It is possible that agitating

cylinders can cause more FE-13 to be in the vapour phase than expected at a given

temperature, this results in a lower liquid level reading than is the case. It is

recommended that FE-13 cylinders are left at rest for a few hours before testing to

avoid inaccurate liquid level measurement.

20

3. Accessories

Portalevel®Max in carry case with accessories

Extension rod (Extra)

The Portalevel®extension rods are primarily developed for use in the marine industry

and as such come as standard with the Portalevel® Max Marine (not with the

Portalevel®Max). However practically, they can be used in any environment with

multiple banked rows of cylinders to allow easy liquid level detection two or even

three rows back.

We manufacture and supply two models of extension rod, but both are assembled and

used in the same way (see overleaf).

Extension Rod (Marine Model)

Ultrasonic Gel

Portalevel® Max

Portatherm®

Sensor®

Table of contents

Other SDI Test Equipment manuals

Popular Test Equipment manuals by other brands

Tektronix

Tektronix 3 Series Service manual

ACE INSTRUMENTS

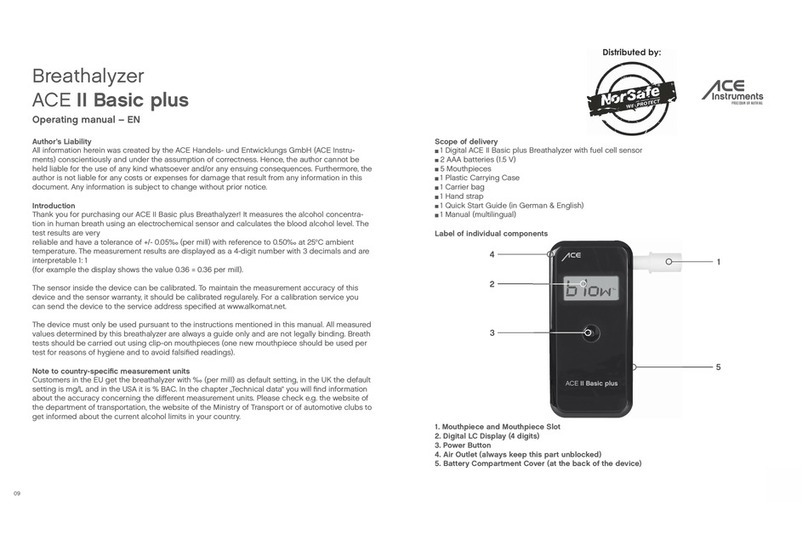

ACE INSTRUMENTS ACE II Basic plus operating manual

PPM

PPM Sentinel 3 System & Accessory Handbook

Elenco Electronics

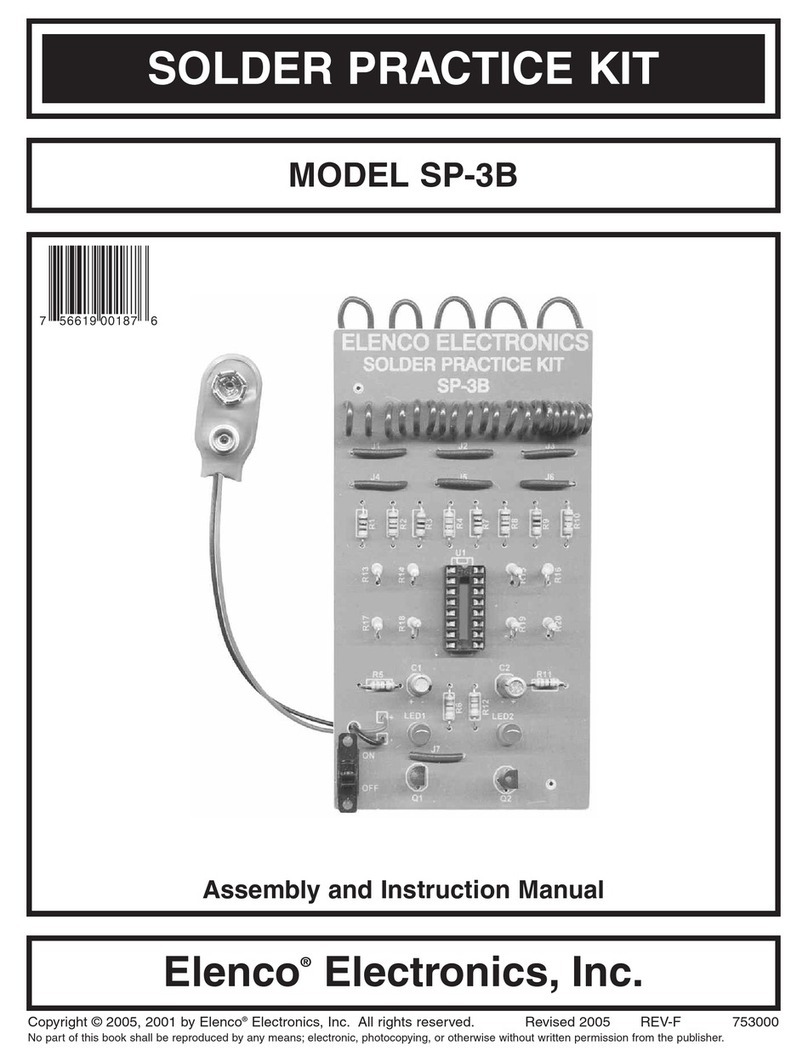

Elenco Electronics SP-3B Assembly and instruction manual

Viavi

Viavi P5000i Getting started guide

Fluke

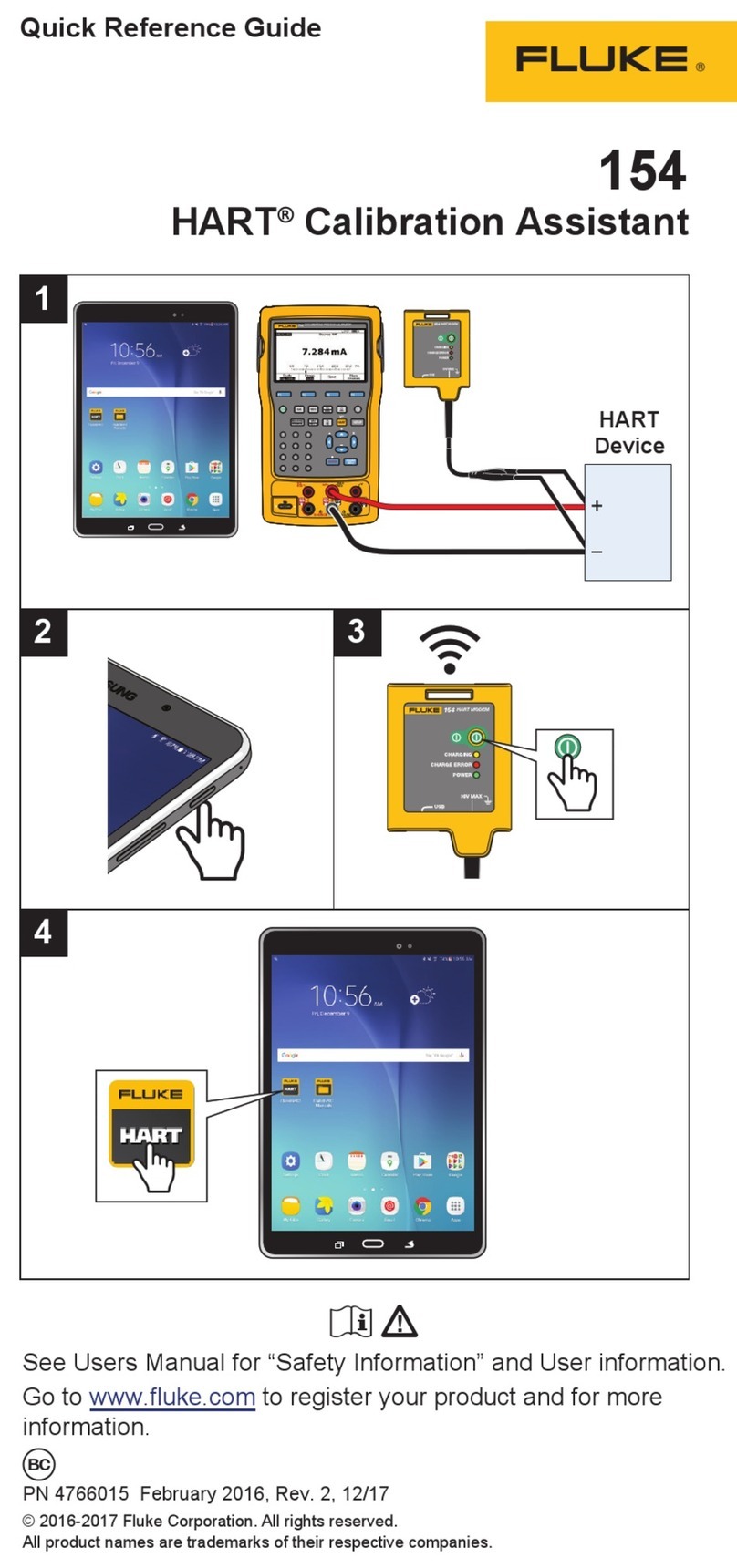

Fluke 154 HART Quick reference guide