1

1. FOREWORDS ...............................................................................................................................................2

1.1. HISTORY........................................................................................................................................................... 2

1.2. LEEB HARDNESS TEST (DEFINITION)....................................................................................................................... 2

1.3. NOTATION OF LEEB’S HARDNESS ........................................................................................................................... 2

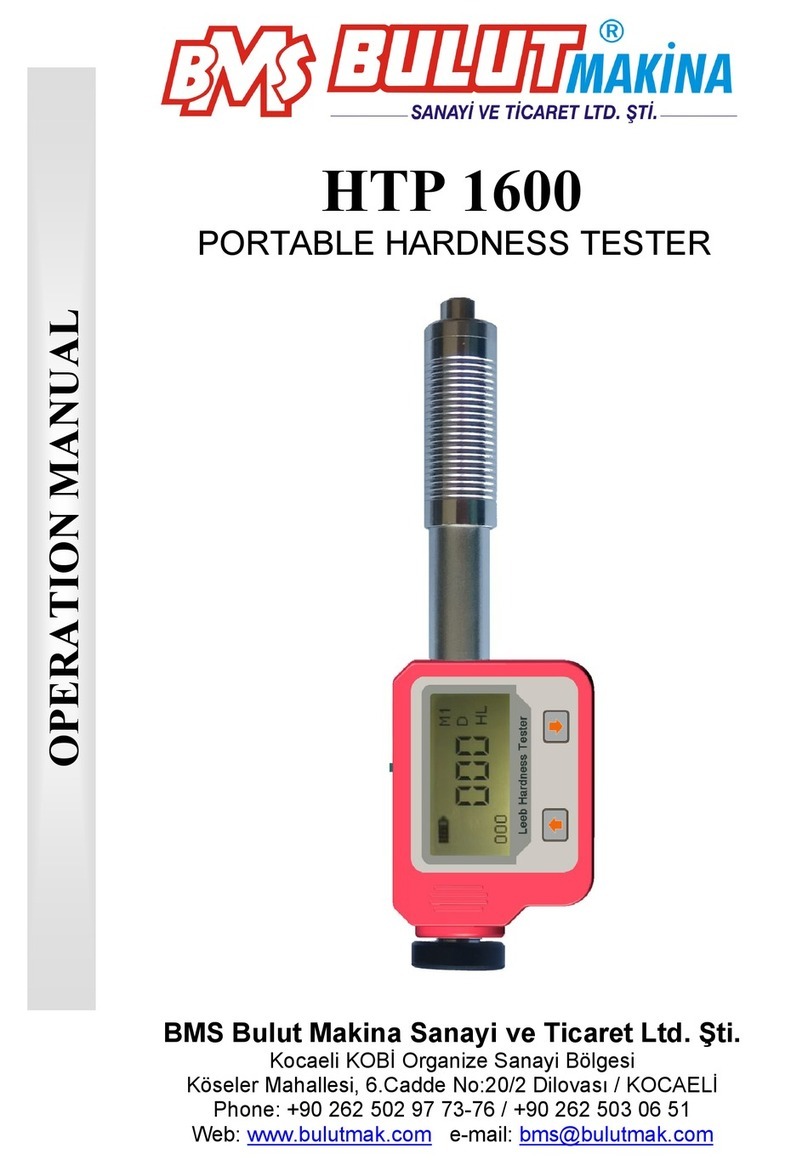

2. FEATURES AND APPLICATIONS.....................................................................................................................3

2.1. INTRODUCTION.................................................................................................................................................. 3

2.2. SPECIFICATIONS ................................................................................................................................................. 3

2.3. APPLICATIONS ................................................................................................................................................... 3

3. SYMBOLS AND ILLUSTRATIONS....................................................................................................................4

3.1. SYMBOLS AND ILLUSTRATIONS .............................................................................................................................. 4

3.2. MEASUREMENT AND CONVERSION TABLE............................................................................................................... 4

4. PREPARATION BEFORE MEASURING ............................................................................................................4

4.1. REQUIREMENTS FOR THE SAMPLE .......................................................................................................................... 4

4.2. REQUIREMENTS FOR THE WEIGHT OF THE SAMPLE..................................................................................................... 4

4.3. REQUIREMENT FOR THE SURFACE HARDENED LAYER OF THE SAMPLE ............................................................................. 5

4.4. SAMPLES WITH CURVED SURFACES ........................................................................................................................ 5

5. OPERATION .................................................................................................................................................6

5.1. LAYOUT OF INSTRUMENT ..................................................................................................................................... 6

5.2. BUTTON DESCRIPTION......................................................................................................................................... 6

5.3. STRUCTURE OF MENUS ....................................................................................................................................... 7

5.4. ICONS DESCRIPTION ........................................................................................................................................... 8

5.5. MEASUREMENT SCREEN...................................................................................................................................... 8

5.6. LANGUAGE MENU............................................................................................................................................ 11

5.7. CONFIGURATION MENU .................................................................................................................................... 11

5.8. MENU ........................................................................................................................................................... 18

5.9. SHORTCUTS .................................................................................................................................................... 25

6. OPERATION ...............................................................................................................................................25

6.1. START/SHUTDOWN .......................................................................................................................................... 26

6.2. OPERATION OF PROBE ...................................................................................................................................... 26

6.3. RE-READ, SAVE, DELETE AND PRINT MEASUREMENTS ............................................................................................. 27

6.4. UPLOAD MEASUREMENT TO COMPUTER .............................................................................................................. 29

6.4.1. DRIVER INSTALLATION ....................................................................................................................................... 29

6.4.2. SOFTWARE INSTALLATION .................................................................................................................................. 29

6.4.3. START PC SOFTWARE ........................................................................................................................................ 29

7. MAINTENANCE OF PROBE .........................................................................................................................30

8. ACCESSORIES.............................................................................................................................................30

8.1. THERMAL PRINTER ........................................................................................................................................... 30

8.2. SHAPED SUPPORT RING .................................................................................................................................... 32

9. CALIBRATION OF INSTRUMENT .................................................................................................................33

9.1. CALIBRATION APPLICATIONS ............................................................................................................................... 33

9.2. SETTING OF CALIBRATION .................................................................................................................................. 33

10. Q&A ..........................................................................................................................................................33

10.1. ABOUT CONFIGURATION MENU.......................................................................................................................... 33

10.2. ABOUT MENU................................................................................................................................................. 33

10.3. ABOUT WIRELESS APPLICATIONS......................................................................................................................... 34

10.4. ABOUT USB COMMUNICATION .......................................................................................................................... 34

10.5. ABOUT MEASUREMENTS ................................................................................................................................... 34

10.6. WIRELESS MICRO PRINTER................................................................................................................................. 35