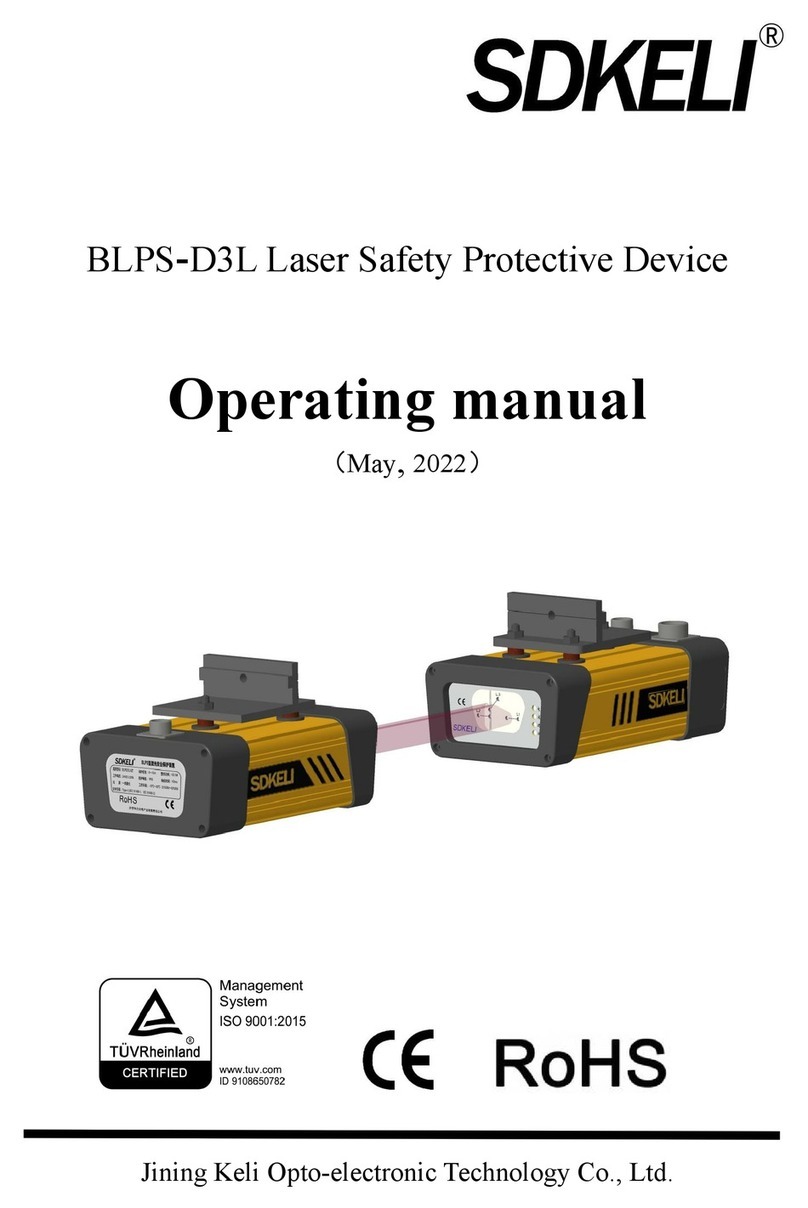

SDKELI BLPS-C3L User manual

BLPS-C3L Laser Safety Protective Device

Operating manual

(May,2022)

Jining Keli Opto-electronic Technology Co., Ltd.

I

CONTENTS

Ⅰ.Legislation and standards ................................................................................................................ - 3 -

Ⅱ.User instructions .............................................................................................................................- 3 -

Ⅲ. Precautions on safety ...................................................................................................................... - 4 -

Ⅳ.Precautions for safe use ...................................................................................................................- 4 -

Section1 Product description ........................................................................................................................ - 6 -

1.1. Applications .................................................................................................................................. - 6 -

1.2. System components ...................................................................................................................... - 6 -

1.2.1 Sensor used alone ............................................................................................................... - 6 -

1.2.2 Sensor and controller used together ................................................................................... - 7 -

1.3. Specification ................................................................................................................................. - 7 -

1.3.1 System specification ...........................................................................................................- 7 -

1.3.2 Emitter / receiver specification ...........................................................................................- 7 -

1.3.3 Controller specification ...................................................................................................... - 8 -

1.3.4 Cable specification ............................................................................................................. - 8 -

1.4. Sensor ............................................................................................................................................- 8 -

1.4.1 Appearance ......................................................................................................................... - 8 -

1.4.2 Dimensions ......................................................................................................................... - 9 -

1.5. Controller .................................................................................................................................... - 10 -

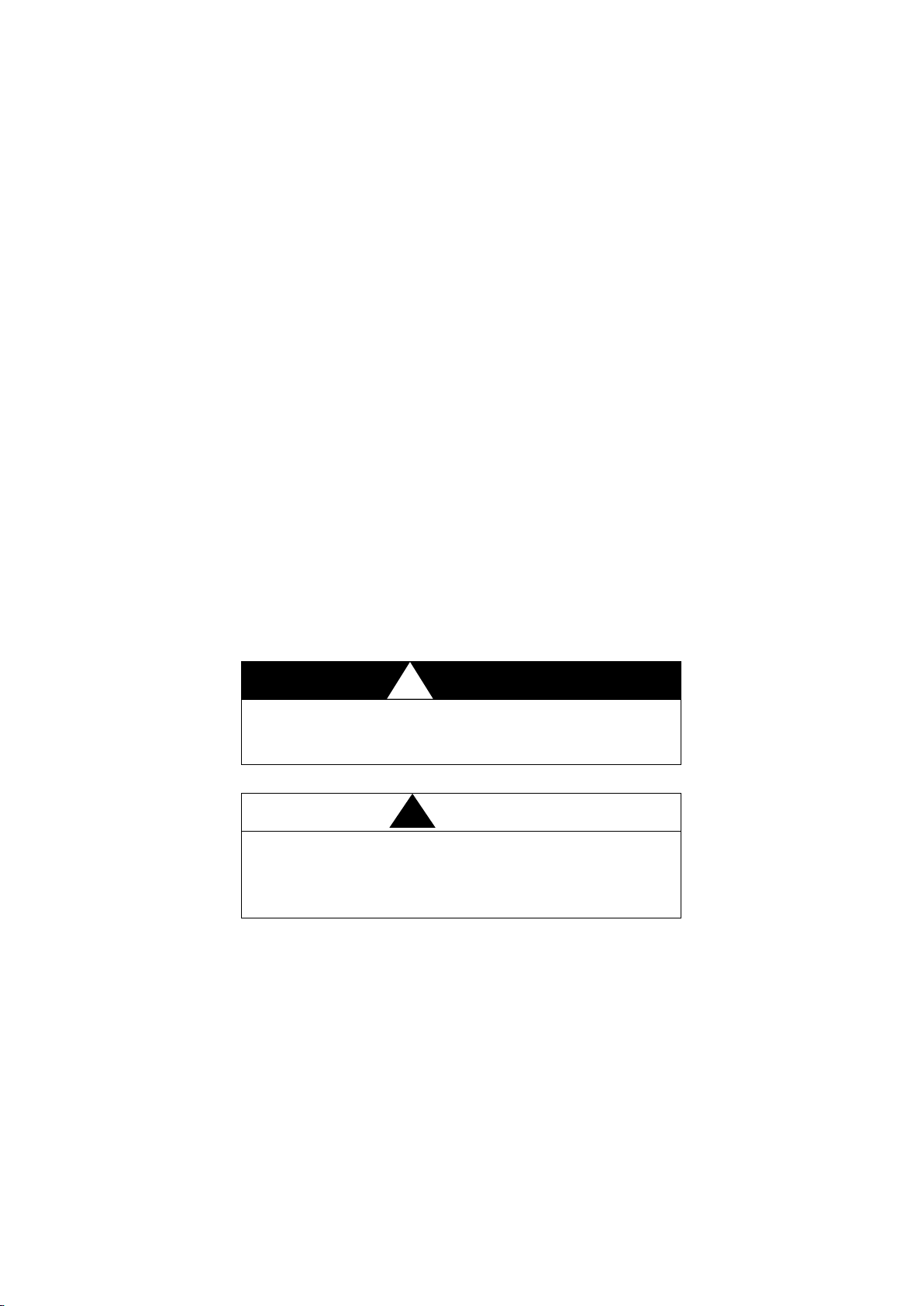

1.5.1 Appearance ....................................................................................................................... - 10 -

1.5.2 Dimensions ....................................................................................................................... - 12 -

1.6. Cables ..........................................................................................................................................- 13 -

1.6.1 Power cable .......................................................................................................................- 13 -

1.6.2 Signal cable .......................................................................................................................- 13 -

1.6.3 Transmission cable ........................................................................................................... - 14 -

1.7. Mounting brackets ...................................................................................................................... - 15 -

1.8. Technical parameters .................................................................................................................. - 16 -

Section2 Function introduction .................................................................................................................. - 18 -

2.1 Input/Output interface circuit ....................................................................................................... - 18 -

2.1.1 Interface circuit of sensor .................................................................................................. - 18 -

2.1.2 Interface circuit of controller ............................................................................................- 19 -

2.2 Function declaration ..................................................................................................................... - 21 -

2.2.1 Self-test function ............................................................................................................ - 21 -

2.2.2 Monitoring function ...........................................................................................................- 22 -

2.2.3 Safety output ......................................................................................................................- 22 -

2.3 Operating mode ............................................................................................................................ - 23 -

2.3.1 Sensor used alone .............................................................................................................. - 23 -

2.3.2 Sensor and SR controller used together ............................................................................ - 23 -

2.3.3 Sensor and SP controller used together .............................................................................- 24 -

2.3.4 Sensor and ST controller used together .............................................................................- 27 -

Section3 Installation and wiring .................................................................................................................- 29 -

3.1 Installation suggestion .................................................................................................................. - 29 -

3.1.1 Interference prevention measures ......................................................................................- 29 -

3.1.2 Muting point setting .......................................................................................................... - 30 -

3.1.3 Safety distance ...................................................................................................................- 30 -

3.2 Installation of sensor .....................................................................................................................- 31 -

3.2.1 Installation site ...................................................................................................................- 31 -

3.2.2 Mounting brackets ............................................................................................................. - 33 -

3.2.3 Installation steps ................................................................................................................ - 35 -

3.2.4 Light debugging ..............................................................................................................- 36 -

3.3 Installation of controller ............................................................................................................... - 38 -

3.3.1 Installation of SR/SP controller .........................................................................................- 38 -

3.3.2 Installation of ST controller ...............................................................................................- 39 -

3.4 Installation of optional accessories ...............................................................................................- 39 -

3.4.1 Limit switch .......................................................................................................................- 40 -

3.4.2 Approach switch ................................................................................................................ - 40 -

3.5 Wiring ........................................................................................................................................... - 40 -

II

3.5.1 Wiring considerations ........................................................................................................ - 40 -

3.5.2 Power supply ..................................................................................................................... - 41 -

3.5.3 Wiring procedures ..............................................................................................................- 41 -

Section4 Check and debugging .................................................................................................................. - 45 -

4.1 Installation condition check ..........................................................................................................- 45 -

4.2 Wiring check before switching on power supply ......................................................................... - 45 -

4.3 Operation check while the bender is stopped ...............................................................................- 45 -

4.4 Operation check while the bender operates ..................................................................................- 46 -

Section5 Maintenance .................................................................................................................................- 47 -

5.1 Inspection at startup and when changing operators ..................................................................... - 47 -

5.2 Inspection for the guarded machine ............................................................................................. - 47 -

5.3 Items to inspect every 6 months or when machine settings are changed .....................................- 47 -

Section6 Troubleshooting ........................................................................................................................... - 49 -

6.1 Fault analysis ................................................................................................................................ - 49 -

6.2 Braking system fault of the bender ...............................................................................................- 50 -

- 3 -

Ⅰ.Legislation and standards

BLPS-C3L Laser Safety Protective Device(Hereinafter referred to as“BLPS”)complies with

the following standards:

EU legislations

Machinery Directive 2006/42/EC

EMC Directive 2014/108/EU

European Standards

EN 61496-1 (Type 4)

EN 61496-2 (Type 4 )

EN 60825-1 (class 1 laser product)

EN 13849-1 (PL e)

International Standards

IEC 61496-1 (Type 4 )

IEC 61496-2 (Type 4 )

ISO 13849-1 (PL e)

National Standards

GB/T 19436.1

GB/T 19436.2

GB 28243

GB 7247.1

GB 4208(IP65)

Ⅱ.User instructions

Read this manual thoroughly and confirm the product from the appearance before installing,

operating and maintaining BLPS. Please contact us if you have any questions or comments.

(1) Limitations of Liability

The quality guarantee period of BLPS is 12 months.

KELI makes no warranty or representation, express or implied, regarding non-infringement,

merchantability, or fitness for particular purpose of the products. Any buyer or user

acknowledges that the buyer or user alone has determined that the products will suitably meet

the requirements of their intended use. KELI disclaims all other warranty, express or implied.

(2) Limitations of Liability

KELI shall not be responsible for special, indirect, or consequential damages, loss of profits

or commercial loss in any way connected with the products, whether such claim is based on

contract, warranty, negligence, or strict liability.

In no event shall responsibility of KELI for any act exceed the individual price of the product

on which liability is asserted.

In no event shall KELI be responsible for warranty, repair, or other claims regarding the

products unless KELI’s analysis confirms that the products were properly handled, stored,

installed, and maintained and not subject to contamination, abuse, misuse, or inappropriate

modification or repair.

(3) Performance

Performance data given in this document is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of KELI’s test

- 4 -

conditions, and the users must correlate it to actual application requirements.

(4) Change in Specifications

Product specifications and accessories may be changed at any time based on improvements

and other reasons.

When the product's rating, performance, or structure changes, the product's specifications will

change accordingly. For the change of product specifications, our company will not notify, if

in doubt, please contact us.

(5) Errors and Omissions

The contents of the manual have been made as accurate and complete as possible, but there is

no guarantee that there are no errors or omissions in this manual.The Company shall not be

responsible for any errors or omissions that may have occurred in this specification.

(6) Copyright and Copy Permission

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with

BLPS. Please notify us before copying or reproducing this document in any manner, for any

other purpose. If copying or transmitting this document to another, please copy or transmit it

in its entirety.

Ⅲ. Precautions on safety

The following special information may appear at any place in the manual or on BLPS, as a

warning of potential risk or promotion of special attention to information about clarifying or

simplifying certain procedures.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!

WARNING

WARNNING indicates an actual or potential risk or

health hazard. They are designed to help you to prevent

accidents. Read carefully and follow the warnings!

!

CAUTION

CAUTION indicates the key information which, if not

avoided, can result in expected legal dispute, or

equipment damage.

Read carefully and follow the cautions!

Ⅳ.Precautions for safe use

Make sure to observe the following precautions that are necessary for ensuring safe use of the

product.

(1) Thoroughly read this manual and understand the installation procedures, operation check

procedures, and maintenance procedures before using the product.

(2) BLPS should only be installed, checked, and maintained by a qualified person. A

qualified person is defined as a person or persons who, by possession of a recognized

degree or certificate of professional training, or who, by extensive knowledge, training

and experience, has successfully demonstrated the ability to solve problems relating to

the subject matter and work.

(3) The OSSDs of the sensor should not be short-circuited with the anode or cathode of the

- 5 -

power supply.

(4) The OSSDs of the system should not be used with a current that is higher than the rating.

(5) Do not drop the product.

(6) Dispose of the product in accordance with the relevant rules and regulations of the

country or area where the product is used.

(7) Users should establish the rules and regulations used for safe operation and implement

them effectively.

(8) BLPS provides protection only in fast down stroke, it is less likely to put the finger across

the upper die under the gearshift point, but that does not mean injury will not occur.

- 6 -

Section1 Product description

BLPS is designed to protect the safety of the fingers and arms of the operator in close to the

region of upper mold die tip. Under the premise of installing the device correctly and

complying with the safety instructions, Operators can be allowed to keep close contact with

workpiece and be provided effective protection under high-speed clamping.

1.1. Applications

Objects protected by BLPS must meet following requirements:

1)BLPS only protects the objects which can block light beam completely, cannot detect

transparent and/or translucent objects;

2)The detecting beam must be adjusted to the correct detecting position;

3)The safe distance is determined by the response time of BLPS and the bender, it must

be greater than the braking distance of the bender;

4)The bender must be able to stop any where in its cycle;

5)The bender must not present a hazard from flying parts;

6)The bender should be in good operating state and stop in the prescribed braking time;

7)All applicable governmental and local rules, codes, and regulations must be satisfied.

This is the user’s and employer’s responsibility;

8)All safety-related machine control elements must be designed so that an alarm in the

control logic or failure of the control circuit does not lead to failure to danger;

9)Do not use radio transmitting and receiving equipments near BLPS such as

transceivers.

Do not use BLPS in the following environments:

1)Areas with heavy smoke, particulate matter, and corrosives;

2)Areas exposed to intense interference light, such as direct sunlight;

3)Areas with high humidity where condensation is likely to occur;

4)Areas exposed to vibration or shock levels higher than in the specification provisions;

5)Areas where the product may come into contact with water;

6)Areas where the product may get wet with oil that can solve adhesive;

7)Environments where flammable or explosive gases are present.

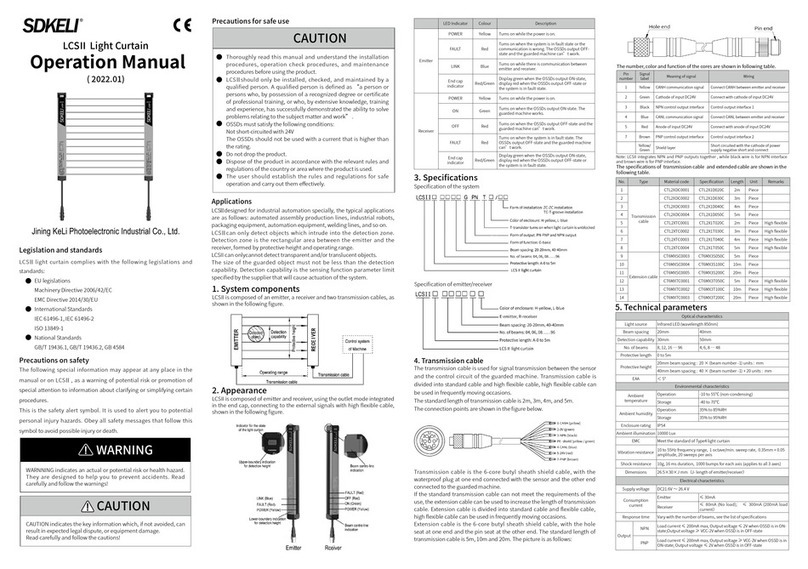

1.2. System components

BLPS consists of detection sensor (a emitter and a receiver), controller and cables.

1.2.1 Sensor used alone

Sensor can be used for CNC bender with PLC programming functionality separately.

Fig.1.1 Operation schematic diagram

- 7 -

1.2.2 Sensor and controller used together

Sensor together with controller can be used for ordinary bender and CNC bender.

Fig.1.2 Operation schematic diagram

1.3. Specification

1.3.1 System specification

1.3.2 Emitter / receiver specification

- 8 -

1.3.3 Controller specification

1.3.4 Cable specification

Power&signal cable specification:

Note:SR type controller and ST type controller power line common, No:CPSRX1X□□□□。

Receiver-Controller Transmission cable specification:

1.4. Sensor

1.4.1 Appearance

Fig.1.3 Appearance of sensor

- 9 -

Beam E1 forms the front protection area, beam E2 and beam E3 form the central protection

area.

The horizontal distance between E1 and E2 is 20mm, and the vertical distance between E2

and E3 is 7mm.

Fig.1.4 Panel of sensor

Sensor

LED

indicators

Color

Description

Emitter

Power

Orange

Turns on when the power is on.

Link

Green

Turns on when there is communication between emitter and receiver.

Fault

Red

Turns on when the system is in fault state or the communication is wrong.

Receiver

Power

Orange

Turns on when the power is on.

On

Green

Turns on when all the detecting beams are received matched successfully.

E1 Off

Red

Turns on when beam E1 is blocked.

E2 Off

Red

Turns on when beam E2 is blocked.

E3 Off

Red

Turns on when beam E3 is blocked.

1.4.2 Dimensions

Fig.1.5 Dimensions of sensor

- 10 -

1.5. Controller

1.5.1 Appearance

Fig.1.6 Appearance of SR/SP controller

Name

Description

Indicator

Power

Yellow indicator light, when the power is turned on, the light is on,.

Fault

Red indicator light, when the system detects a fault, the light is on.

OSSD ON

Green indicator light, when the system output relay contact is on, the light

is on.

OSSD OFF

Red indicator light, when the system output relay contact is disconnected,

the light is on.

Normal mode

Green indicator light, when the controller is working in normal mode, the

light is on.

Box mode

Yellow indicator light, when the controller is working in box folding mode,

the light is on.

Muting mode

Yellow indicator light, when the controller is working in inhibit mode, the

light is on.

Switch

Power switch

System power control switch.

Mode switch

Rotate the key according to the indicated direction, and switch in turn in

normal mode-box folding mode-suppression mode-normal mode.

- 11 -

Fig.1.7 Appearance of ST controller

Number

Name

Description

1

Process

10 yellow indicator lights indicate the current program number. There are 10

processes in total. When the controller status is in a certain process, the

yellow indicator light of this process is on, and the other process lights are

off.

2

Shield

10 red indicator lights, indicating the shielding status of the corresponding

process.The red light is on, indicating that the corresponding process is in

the shielding state;The red light is off, indicating that the corresponding

process is in the normal protection state.

3

Shield 1~10

10 two-position key switches are used to select the shielding/normal

function of the corresponding process.

4

Sensor status

Green indicator light;

The green light is on, the sensor is normal;

The green light is off, and the sensor is shading.

5

Variable

speed signal

Red indicator light;

The red light is on, the variable speed signal is in the high-level active state,

and the bending machine is in the work advance (slow speed) state at this

time;

The red light is off, and the variable speed signal is in a low level state.

6

Output state

Green indicator light;

The green light is on, and the controller relay contact output is in the closed

state;

The green light is off, and the controller relay contact output is in the

disconnected state.

7

Reset

The self-reset button, when pressed, forces the controller to return to the

process 1 state.

8

Switch

System power control switch

- 12 -

1.5.2 Dimensions

Fig.1.8 Dimensions of SR/SP controller

Fig.1.9 Dimensions of ST controller

- 13 -

1.6. Cables

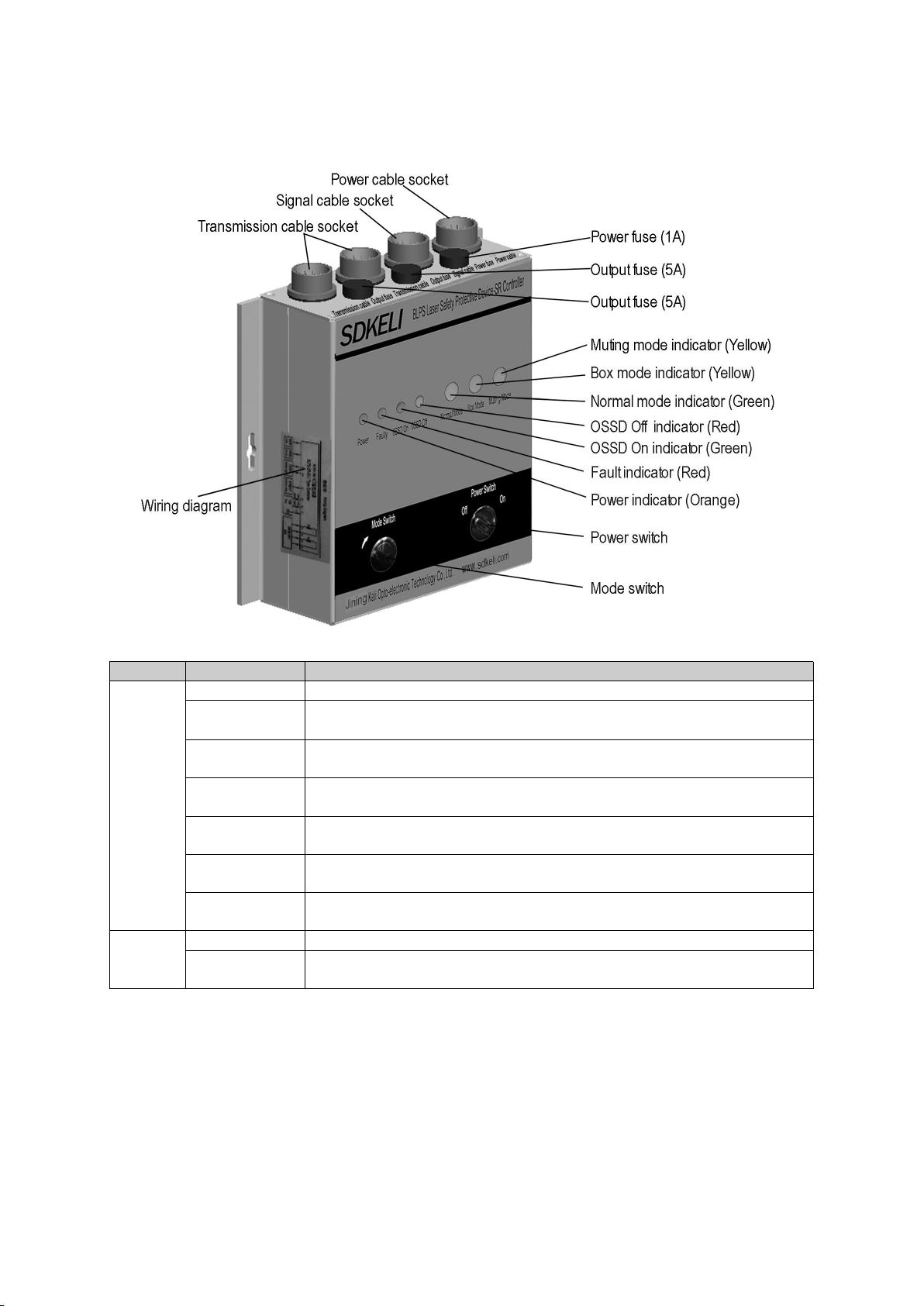

1.6.1 Power cable

Power cable is the 7-core butyl sheath shield cable with a 7-core hole-plug end connected to

the controller and each core at the other end of the cable is crimped with binding terminal to

connect to the bending machine. The number, color and function of the cores are shown as

follows:

Fig.1.10 Power cable

1.6.2 Signal cable

Equipped with signal cable for SR/SP controller

The signal line with SR / SP controller adopts 9-core butyl sheath shield cable, one end is

9-core hole-plug, which is connected with the controller, and the other end is connected with

each wire core crimping terminal, which is connected with the bending machine. The serial

number, color and function of each core are shown in the figure below:

Fig.1.11 Signal cable for SR/SP controller

Equipped with signal cable for ST controller

The signal line for ST controller is a 6-core shielded cable, one end is a 7-core aviation plug,

which is connected with the controller, and the other end is connected to the bending machine

by crimping terminals. The serial number, color and function of each core are shown in the

figure below:

Fig.1.12 Signal cable for ST controller

- 14 -

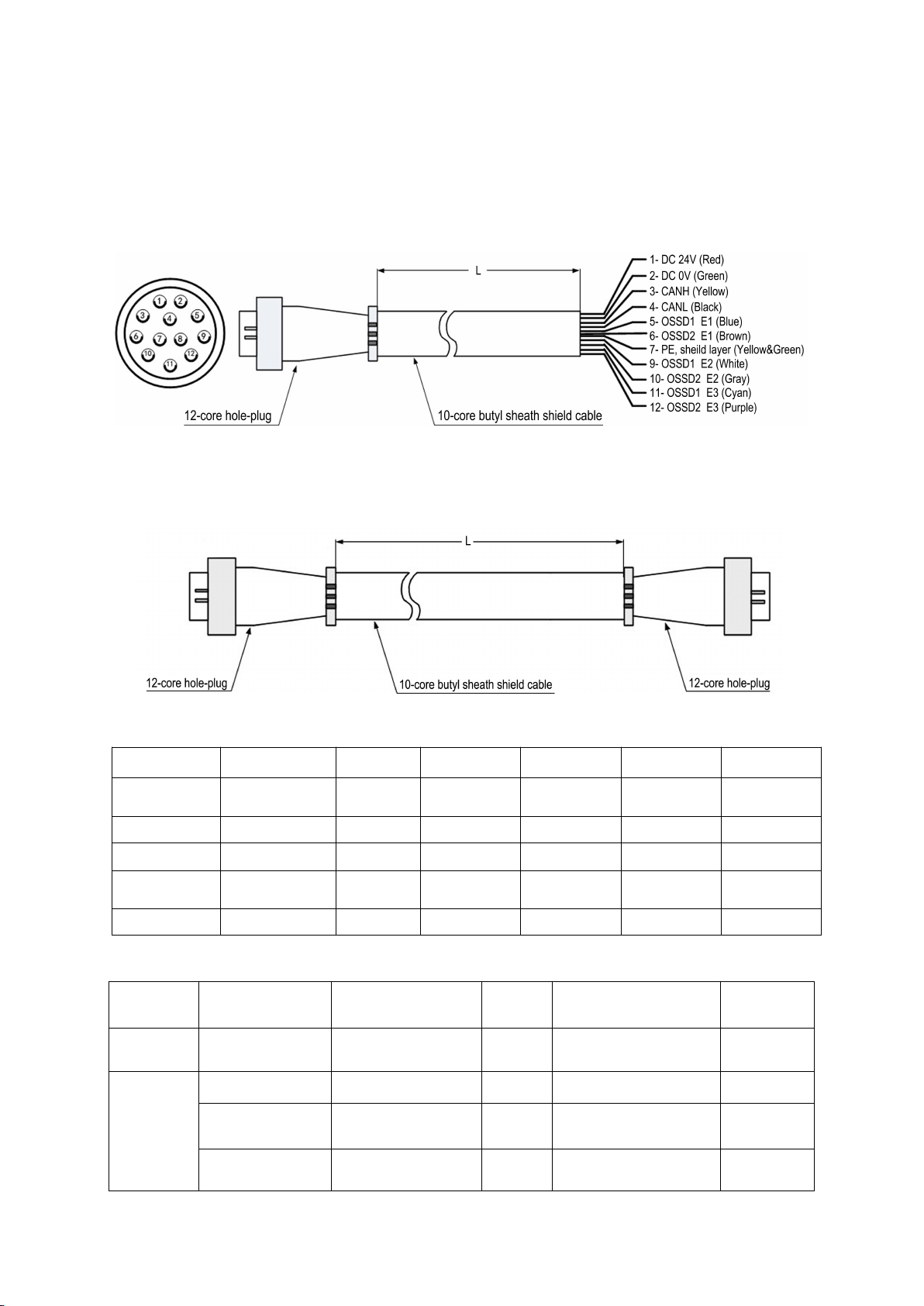

1.6.3 Transmission cable

Single-end cable

The single-ended transmission line uses a 10-core butyl sheath shield cable, one end is a

12-core hole-plug, which is connected to the sensor, and the other end is crimped to the

terminal with each core and connected to the bending machine. The serial number, color and

function of each core are as shown in the figure below:

Fig.1.13 Single-end cable

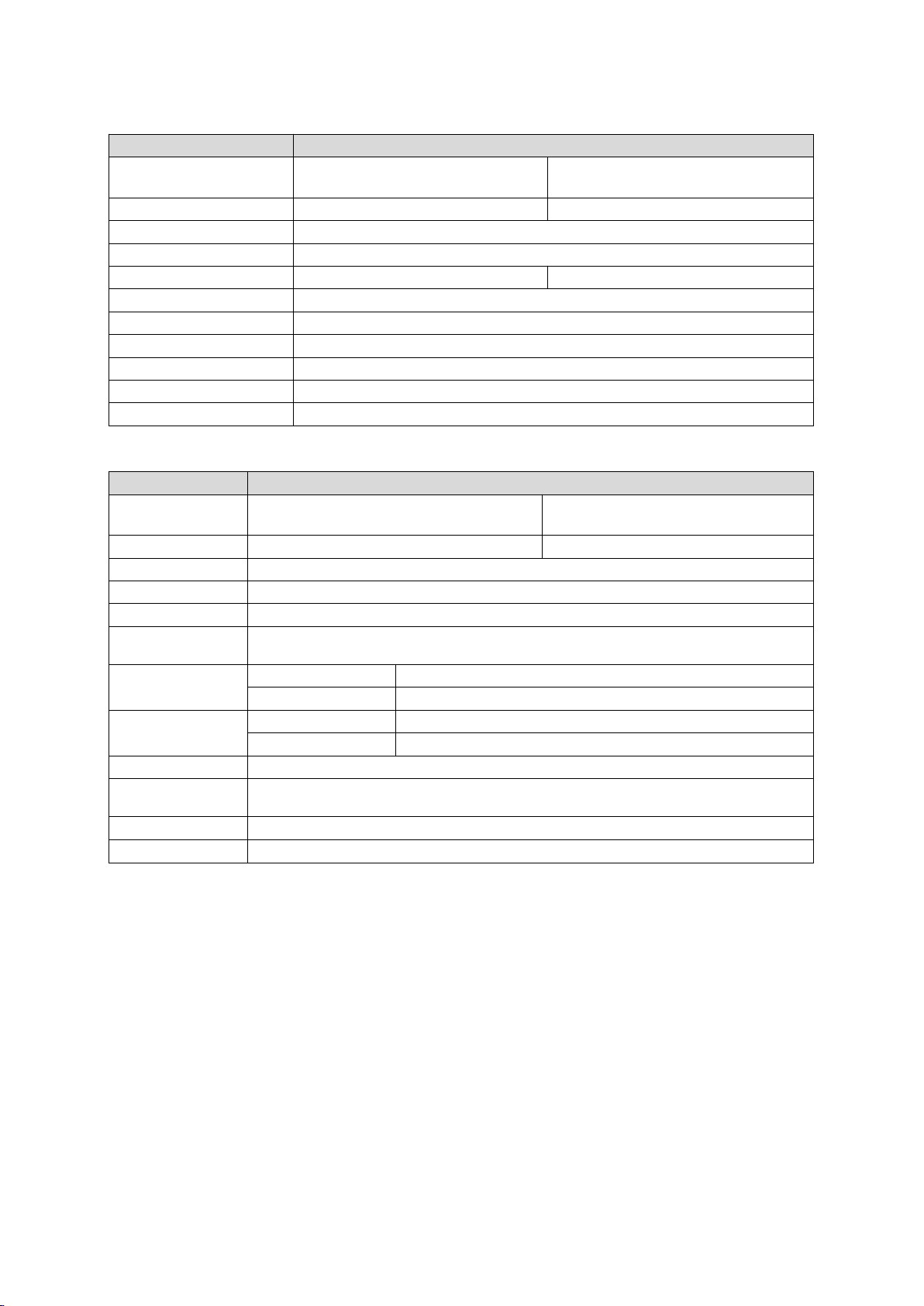

Double-end cable

Double-end cable is the 10-core butyl sheath shield cable with two 12-core hole-plugs at each

connected to the sensor. The number, color and function of the cores are shown as follows:

Fig.1.14 Double-end cable

Socket pin

1

2

3

4

5

6

Signal

definition

VCC

GND

CANH

CANL

OSSD1 (E1)

OSSD2(E1)

Wire color

Red

Green

Yellow

Black

Blue

Brown

Socket pin

7

8

9

10

11

12

Signal

definition

PE

-

OSSD1 (E2)

OSSD2(E2)

OSSD1 (E3)

OSSD2(E3)

Wire color

Yellow&Green

-

White

Gray

Cyan

Purple

Cable specifications list:

Usage

Name

Specifications

Number

Connecting devices

Standard

line length

Sensor

used alone

Single-end cable

CTBLX1D

2

Sensor to Bending

machine

5m&9m

Sensor

used with

SR / SP

controller

Double-end cable

CTBLX1S

2

Sensor to Controller

5m&9m

Power cable

CPSRX1X

1

Controller to Bending

machine

5m

Signal cable

CPSRX2X

1

Controller to Bending

machine

5m

- 15 -

Sensor

used with

ST

controller

Double-end cable

CTBLX1D

2

Sensor to Controller

5m&9m

Power cable

CPSRX1X

1

Controller to Bending

machine

5m

Signal cable

CPSTX2X

1

Controller to Bending

machine

5m

Note 1: the total length of two transmission lines of each set of products is not more than 40m, and the

cable length can be customized according to the actual demand.

Note 2: the power supply wire and signal wire used by SP controller are the same as SR type controller.

1.7. Mounting brackets

Fig.1.16 Dimensions of linear bracket

Fig.1.16 Dimensions of guide bracket

- 16 -

1.8. Technical parameters

Sensor technical parameters:

Security category

Safety type

Type 4(IEC 61496)PL e(ISO 13849)

Executive

standard

2006/42/EC (Machinery Directive) 2014/108/EU (EMC Directive)

IEC 61496-1 IEC 61496-2 ISO 13849-1

CCF

100

DCavg

99%

MTTF(Year)

95

MTTFD

(Year)

761

PFHD(1/h)

3.25 E-09

Optical characteristics

Light source

Class 1 laser product, 635nm wavelength

Detecting range

0~20m

Effective aperture angle

≤1.5mrad

Environmental characteristics

Ambient

temperature

Operation:-10℃~55℃(without frost and fog)

Storage:-30℃~70℃

Ambient

humidity

Operation:35%RH~85%RH

Storage: 35%RH~95%RH

Protection

level

IP65

Environmental

illuminance

Incandescent lamp:3000

Lux

Fluorescent lamp:3000

Lux

Sunlight: 10000 Lux

Homologous

light

interference

Interference light from the same design transmitter will not cause the BLPs to fail

Anti-vibration

ability

The frequency is 10-55hz, the amplitude is 0.35 ± 0.05mm, 20 times in X, y and Z

directions respectively

Impact

resistance

Acceleration 10g, pulse duration 16ms, 1000 times in X, y and Z directions

Electrical characteristics

Supply voltage

24V DC±20%

power consumption

≤3.5W

Current

consumption

Emitter

≤20 mA

Receiver

≤100 mA(Without load)

Response time

≤20ms(Complete machine, including controller)

Safety output(OSSD)

PNP output, each beam of detection light output two control signals

In on state, IOUT ≤ 100mA (6-way total ≤ 600mA), Vout ≥ vcc-2v

In off state, IOUT ≤ 1mA, Vout ≤ 2V

Function to prevent

mutual interference

Light interference avoidance algorithm

- 17 -

SR/SP controller technical parameters:

Project

Parameter

Ambient temperature

Operation:-10℃~55℃(without

frost and fog)

Storage:-40℃~70℃

Ambient humidity

Operation:35%RH~85%RH

Storage:35%RH~95%RH

Protection level

IP54

Dimensions

190×150×58mm

Supply voltage

AC100V~230V±10%,50/60Hz

DC24V±20%

Total power consumption

≤8.5W

Output form

Relay contact output

Output contact capacity

Contact capacity 5A, 250VAC/5A, DC24V

Start Time

<3s

Detection function

Real-time self-check

Protection circuit

The protection of overvoltage and overcurrent Output short circuit protection

ST controller technical parameters:

Project

Parameter

Ambient

temperature

Operation:-10℃~55℃(without frost and

fog)

Storage:-40℃~70℃

Ambient humidity

Operation:35%RH~85%RH

Storage:35%RH~95%RH

Protection level

IP54

Dimensions

195×180×82mm

Supply voltage

DC24V±20%

Total power

consumption

≤15W

Output form

OSSD1/OSSD2

Two-way relay normally open contact (main control output)

ALARM

PNP alarm output

Output contact

capacity

OSSD1/OSSD2

Contacts5A,250VAC/5A,DC24V

ALARM

Load current≤200mA

Response time

≤20ms

Insulation

resistance

>100MΩ

Dielectric strength

AC1500V,60S No breakdown or flashover

Relay life

≥100 million times

- 29 -

- 18 -

Section2 Function introduction

2.1 Input/Output interface circuit

2.1.1 Interface circuit of sensor

Fig.2.1 Interface circuit of sensor

Signal and wiring introduction:

Signal label

Meaning of signal

Wiring

DC24V

Anode of power supply

Connect with anode of power supply

DC0V

Cathode of power supply

Connect with cathode of power supply

PE

GND

Connecting to the ground

CANH/CANL

The communication interface between

emitter and receiver

Link CANH and CANL respectively

between emitter and receiver

OSSD1 E1

OSSD2 E1

Control output interface of E1, PNP

output, output high level voltage when

the sensor is on light-passing state

Two safety outputs

OSSD1 E2

OSSD2 E2

Control output interface of E2, PNP

output, output high level voltage when

the sensor is on light-passing state

Two safety outputs

OSSD1 E3

OSSD2 E3

Control output interface of E3, PNP

output, output high level voltage when

the sensor is on light-passing state

Two safety outputs

- 29 -

- 19 -

2.1.2 Interface circuit of controller

SR controller

Fig.2.2 Interface circuit of SR

Signal and wiring introduction:

Signal label

Meaning of signal

Wiring

A1/A2/PE

Power input

Connect to the right power supply

according to the rated voltage

CG

Reference high- level signal output of

the controller

Provide high-level voltage for external

relay contacts

BS1/BS2

Gearshift signal of the bender

Connect to the NO contacts of the relay

which controls the slow down stroke of

the bender

OSSDs

Output signal of the sensor

Connect to the controller

13/14,23/24

OSSD in the form of relay output

signal

Connect to the circuit which controls the

fast down stroke of the bender

Table of contents

Other SDKELI Safety Equipment manuals